Automatic and high-efficient lubrication equipment for copper alloy wires

A technology of lubricating equipment and copper alloys, applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve problems such as rod blank scratches, mold damage, rough and non-smooth surface, etc., to improve lubrication efficiency, simple structure, and easy operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

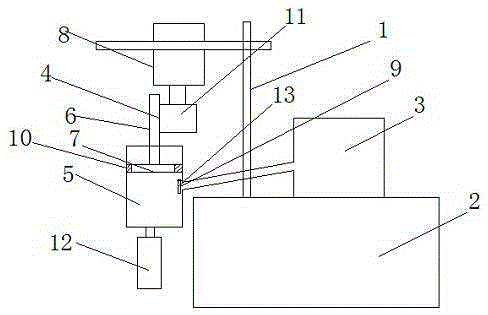

[0036] An automatic and efficient lubrication equipment for copper alloy wires, comprising a bracket 1, a mold box 2, a grease container 3 and a lubricating device 4, the bracket 1 is installed above the mold box 2, and the lubricating device is installed under the bracket 1 4. The grease container 3 is fixed above the mold box 2 by bolts;

[0037] When in use, grease is provided through the grease container 3, and the rod blank is lubricated through the lubricating device 4;

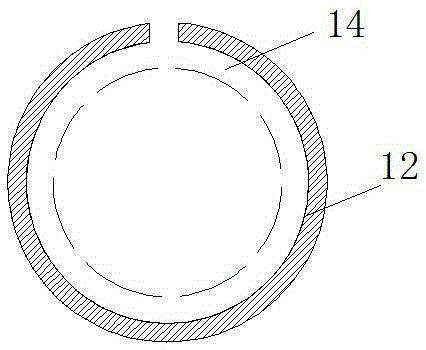

[0038] Described lubricating device 4 comprises cylinder 5, screw rod 6, pressing plate 7, lubricating ring 12 and motor 8, and described motor 8 is installed on the support 1, and motor 8 is a stepper motor, can provide power stably like this;

[0039] The inner side of the cylinder 5 is provided with an oil inlet 9, and the oil inlet 9 communicates with the grease container 3;

[0040] In use, grease can enter the cylinder 5 from the grease container 3;

[0041] The pressing plate 7 is arranged insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com