High/low-temperature durable double-door testing machine for measuring automotive water cut long-term compressive load

A compressive load, high and low temperature technology, used in measuring devices, vehicle testing, machine/structural component testing, etc., can solve problems such as affecting the replacement of samples, crashing sensors, and inaccurate compression load data, etc., to improve the test. Efficiency, stable and reliable mechanism, easy to move and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

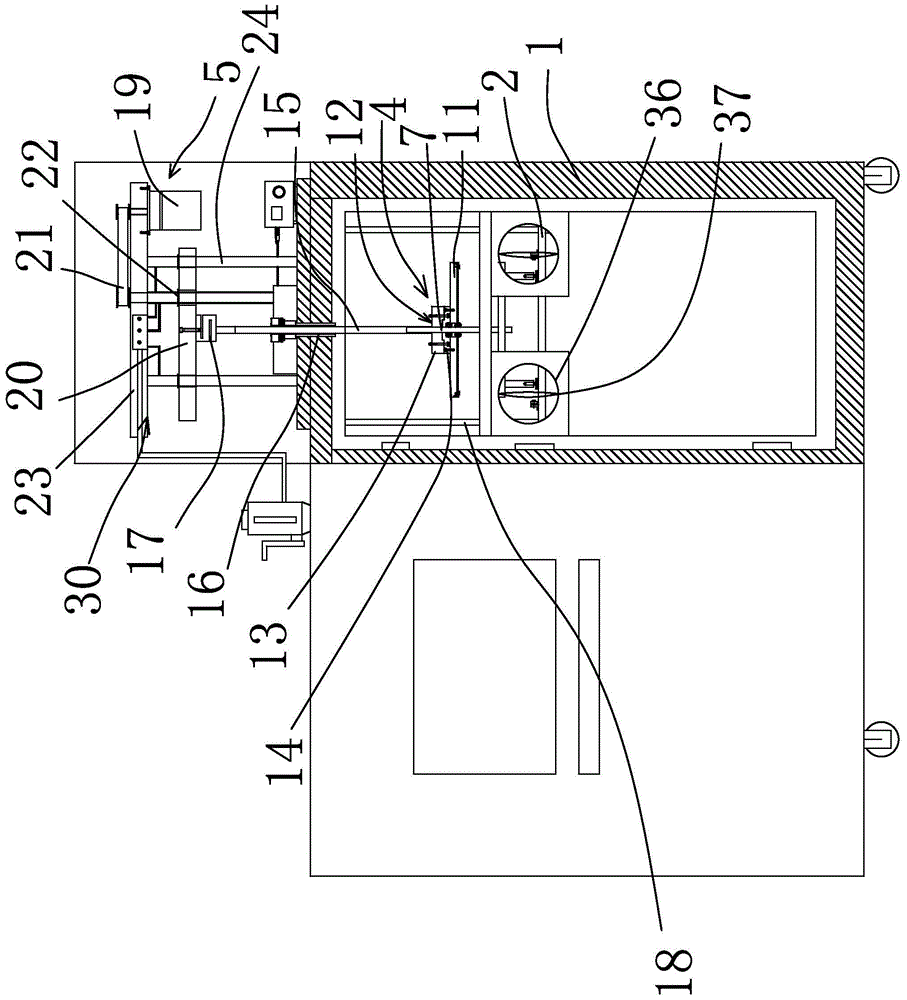

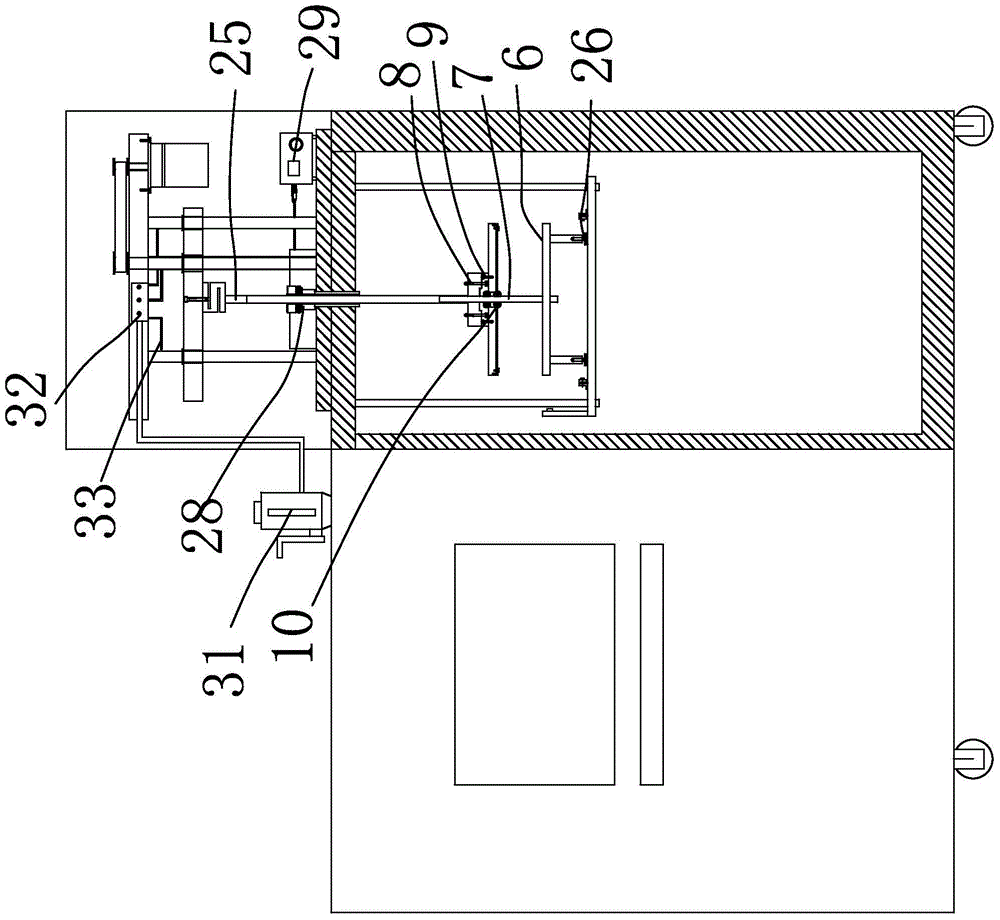

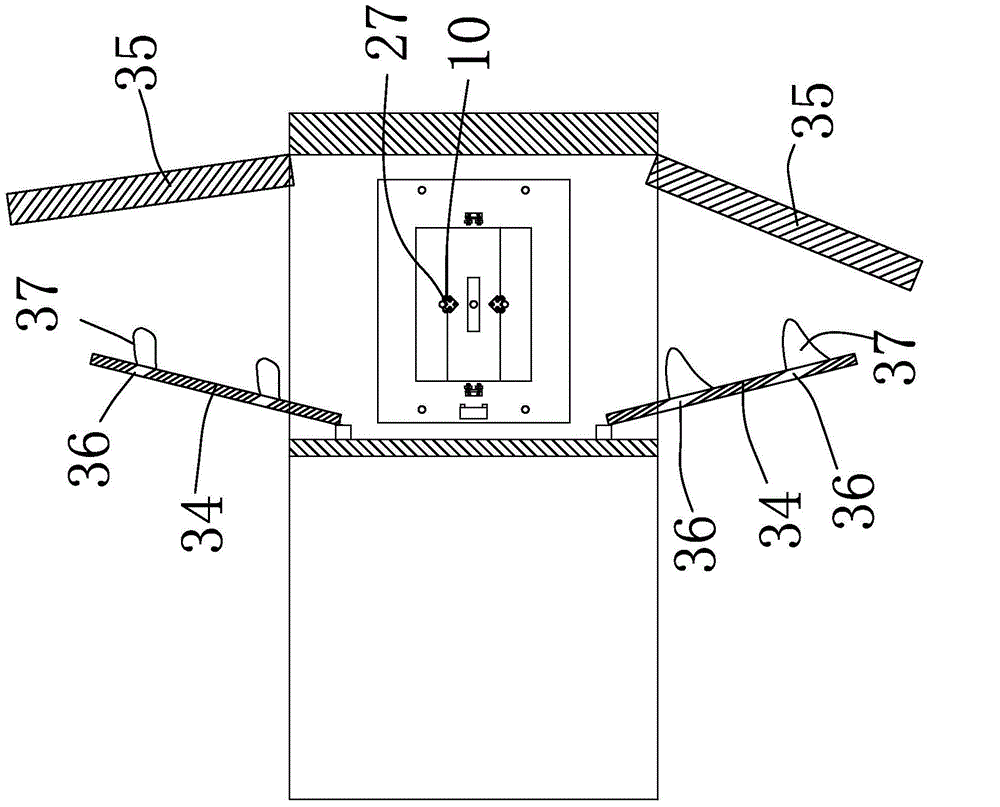

[0027] In the figure, box body 1; test worktable 2; water cutting 3; upper platform moving mechanism 4; driving mechanism 5; lower platform jig fixing mechanism 6; guide post 7; upper screw 8; lower screw 9; roller bearing 10; Compression upper platform 11; compression platform fixing device 12; concave block 13; bump 14; pull rod 15; pull rod hole 16; force sensor 17; fixed rod 18; motor 19; lifting plate 20; pulley pair 21; screw nut pair 22 ; Fixed plate 23; Guide light rod 24; Connecting rod 25; Parallel adjustment screw device 26; Roller 27; Constant temperature device 28; Conduit 33; inner sealing door 34; outer sealing door 35; operating hole 36; sealing membrane 37.

[0028] Such as figure 1 and figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com