Oil-accumulating lubrication gear

A gear and oil storage technology, applied in the field of mechanical parts, can solve the problems of not being able to add lubricating oil to gears, waste, and difficulty in lubricating gear teeth, and achieve the effect of omitting manual lubrication and saving lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

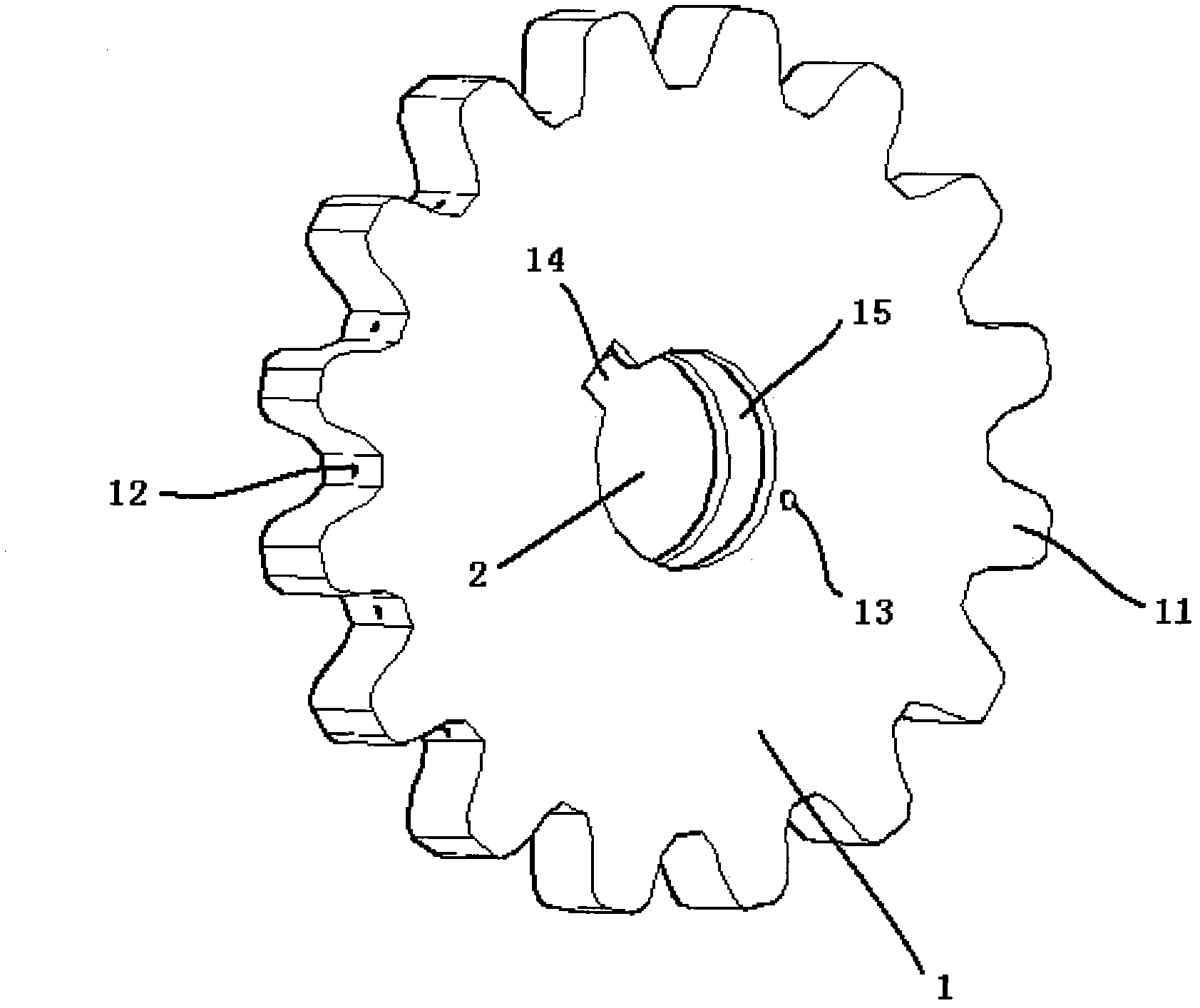

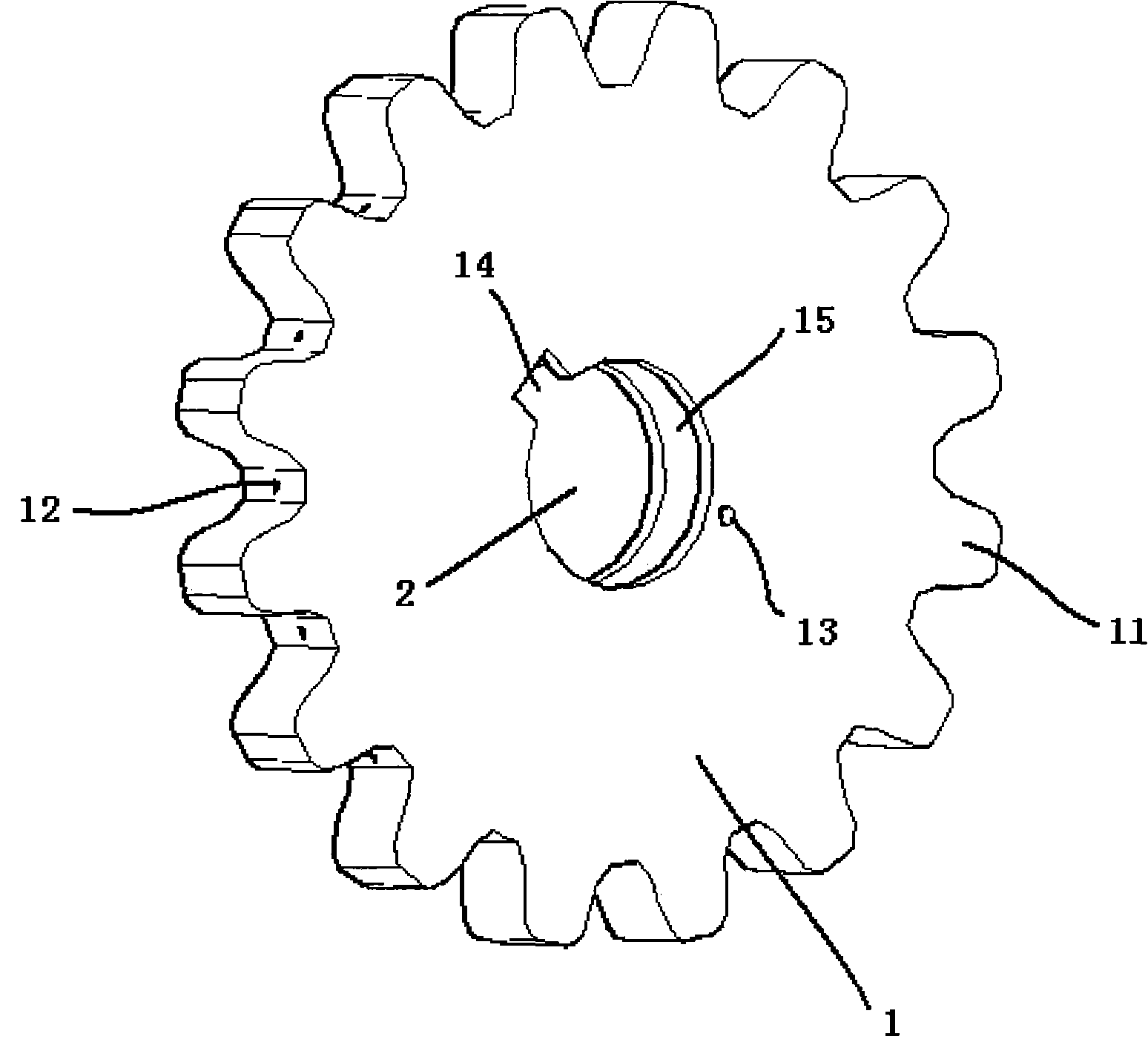

[0011] exist figure 1 In the shown embodiment, the oil storage lubrication gear includes a gear body 1, gear teeth 11, a shaft hole 2 matching with the shaft body in the center of the gear body 1, a keyway 14 is opened on the shaft hole 2, and the shaft An annular inner groove 15 is also provided on the annular surface of the hole 2, and the annular inner groove 15 leads to the surface of the gear body 1 through a liquid injection hole 13, and the annular inner groove 15 is connected with each of the gear teeth 11. Lubricating passages 12 are opened between the tooth roots, and permeate (not shown) is arranged in the lubricating passages 12 .

[0012] For the above-mentioned oil storage lubrication gear, the diameter of the annular inner groove 15 is 1 / 5-1 / 6 of the diameter of the dedendum circle.

[0013] In the aforementioned oil storage lubricating gear, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com