A covered wire machine

A technology for covering wire machines and racks, which is applied in the direction of textiles and papermaking, yarn, gear lubrication/cooling, etc. It can solve the problems of falling, low efficiency, troubles, etc., to save lubricating oil, ensure lubricating quality, and ensure cleanliness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

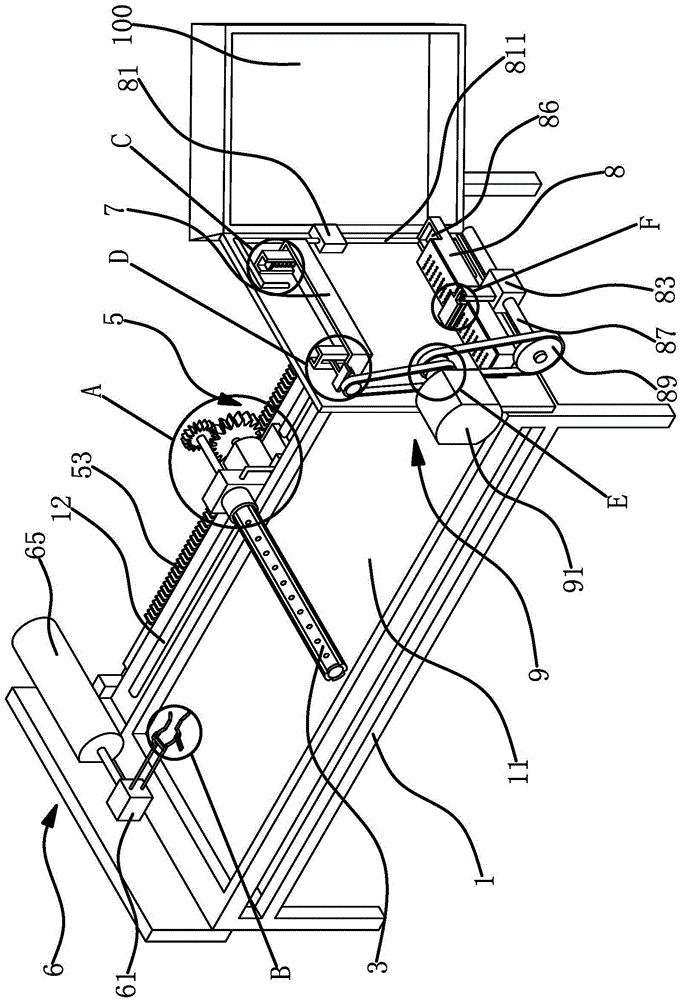

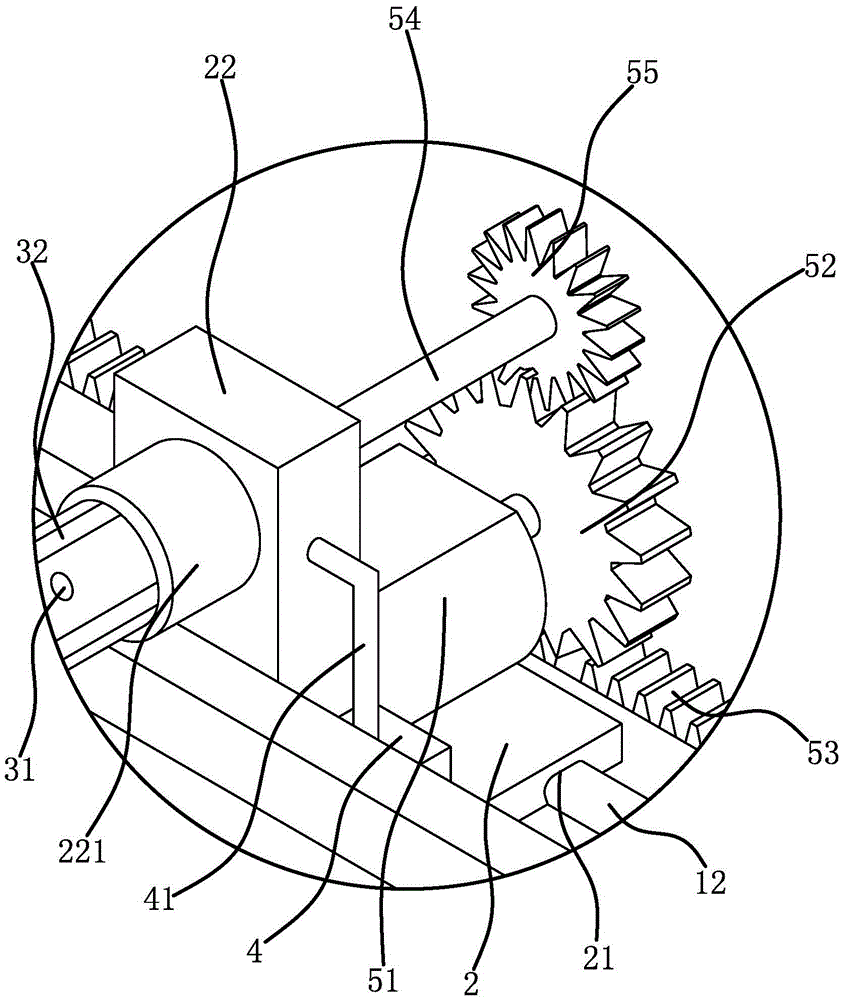

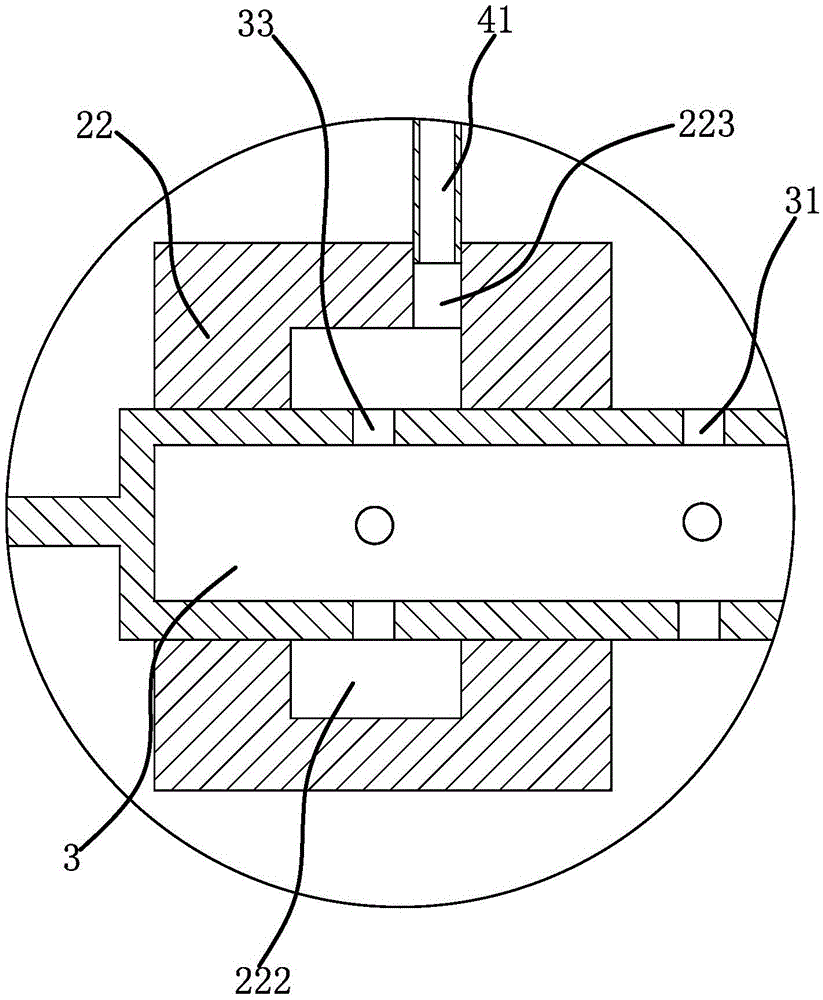

[0032] Such as figure 1 , figure 2 , image 3 As shown, a wire covering machine includes a frame 1, a rectangular waste wire tray 11 is fixed horizontally below the frame 1, and a moving seat 2 is slidably connected to the frame 1 along the length direction of the waste silk tray 11. There is a recovery pipe 3 connected to the upper rotation, the recovery pipe 3 is located above the waste silk tray 11, and is arranged along the width direction of the waste silk tray 11, and a number of suction holes 31 are provided on the outer wall of the recovery pipe 3, and the recovery pipe 3 is connected to the waste silk tray 11. An air pump 4 capable of degassing the inner cavity of the recovery pipe 3 is connected, and the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com