Synchronous track device

A synchronous, orbital technology, used in bearings, linear motion bearings, shafts and bearings, etc., can solve the problems of cage overtravel, uncoordinated, serious accidents, etc., achieve long service life of parts, reduce energy loss, The effect of saving lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

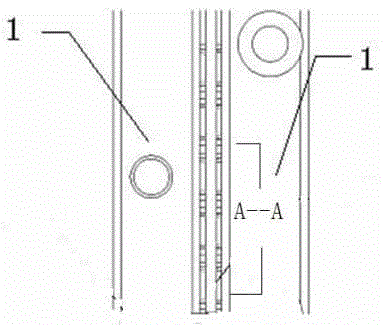

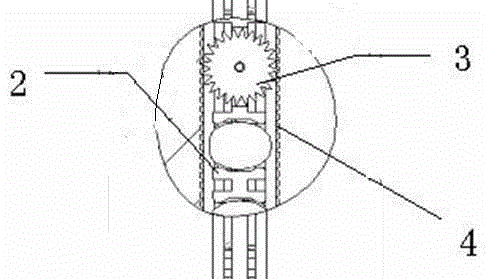

[0013] This embodiment provides a synchronous track device, which is characterized in that: the synchronous track device includes a track 1, a synchronous wheel 2, a sawtooth 3, and a gear 4;

[0014] Wherein: the track 1 is provided with a sawtooth 3 at the contact surface with the synchronous wheel 2, and the synchronous wheel 2 is provided with a gear 4 meshing with the sawtooth 3.

[0015] Described gear 4 is one, is arranged on the middle part of synchronous wheel 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com