Patents

Literature

38results about How to "No hard impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

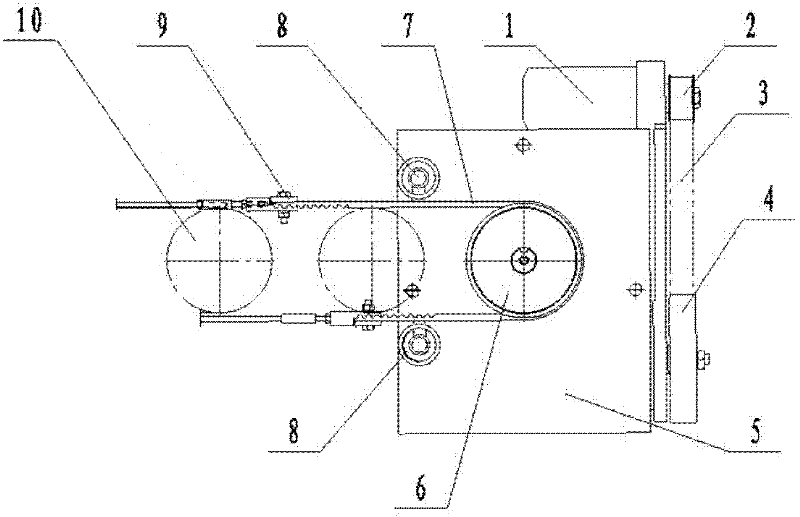

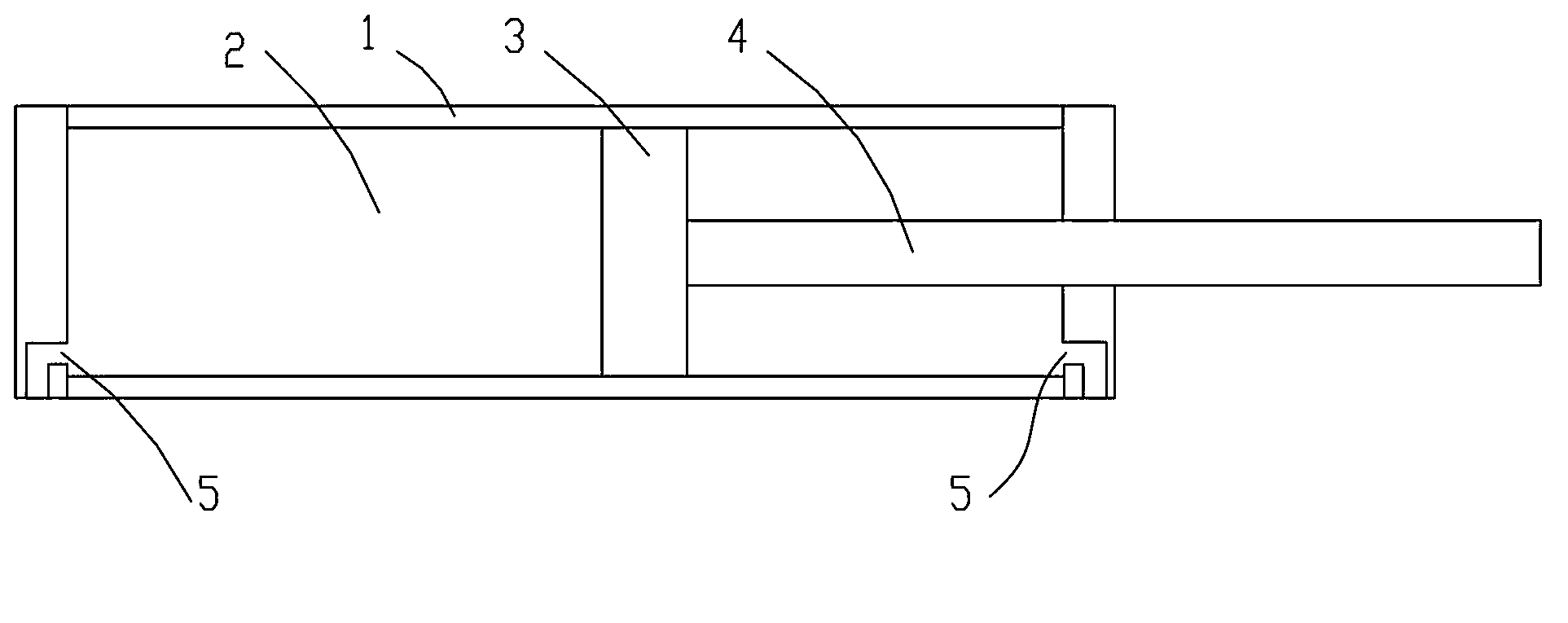

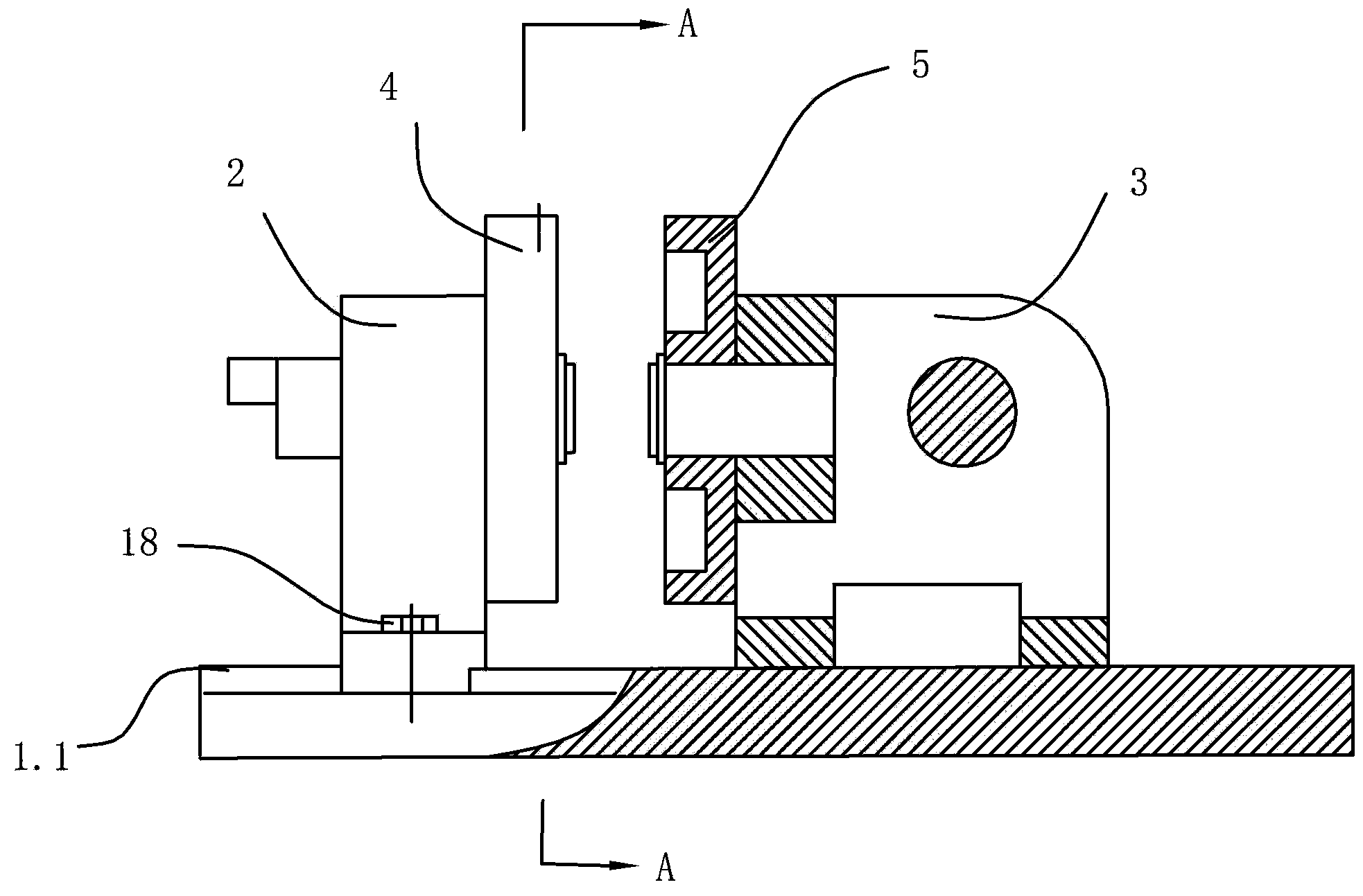

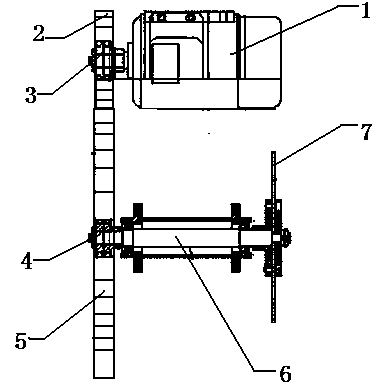

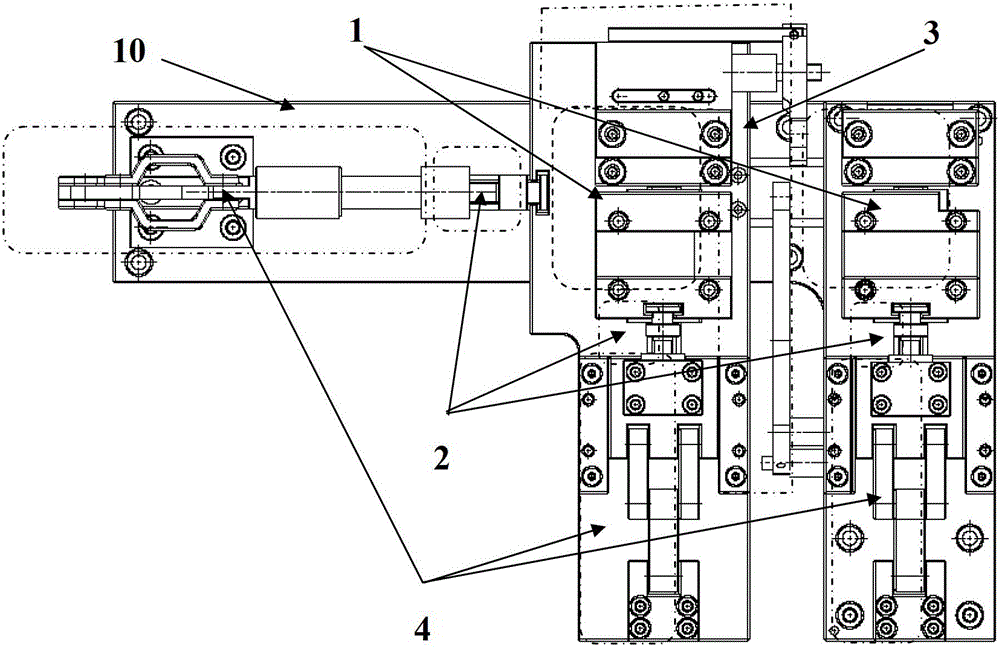

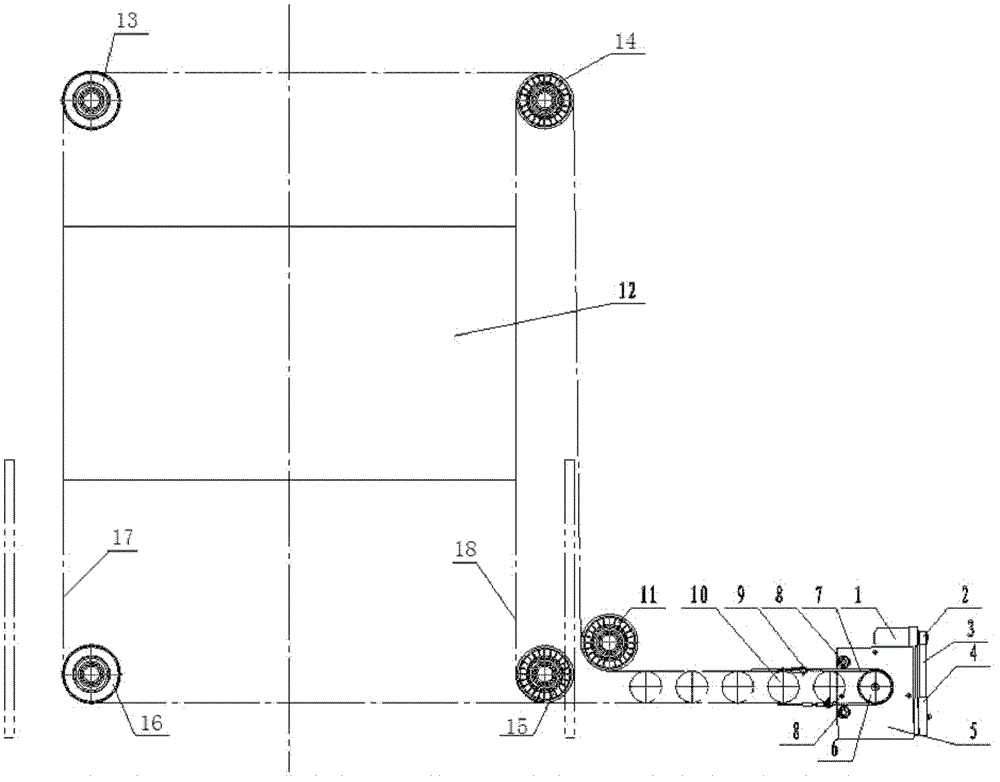

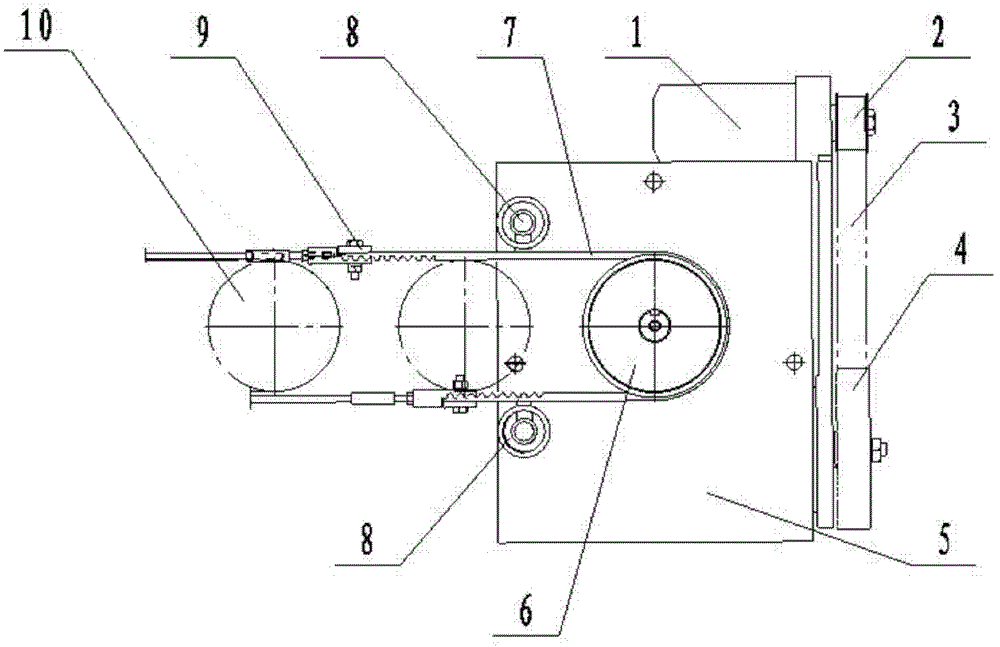

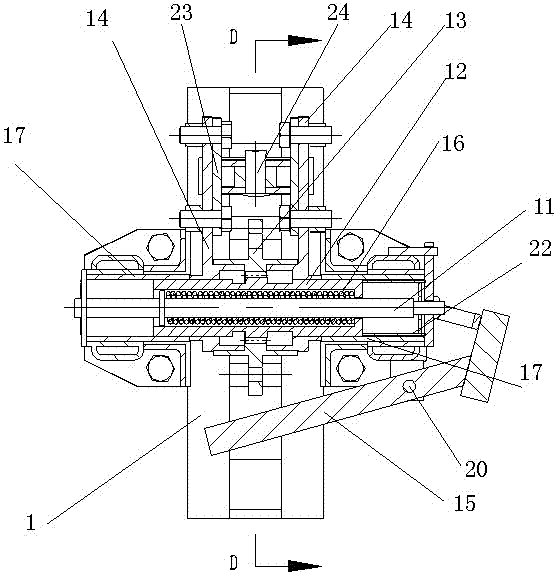

Peeling device and coated pipe peeling machine

ActiveCN103056897AReduce labor intensityEven strengthMetal working apparatusReciprocating motionEngineering

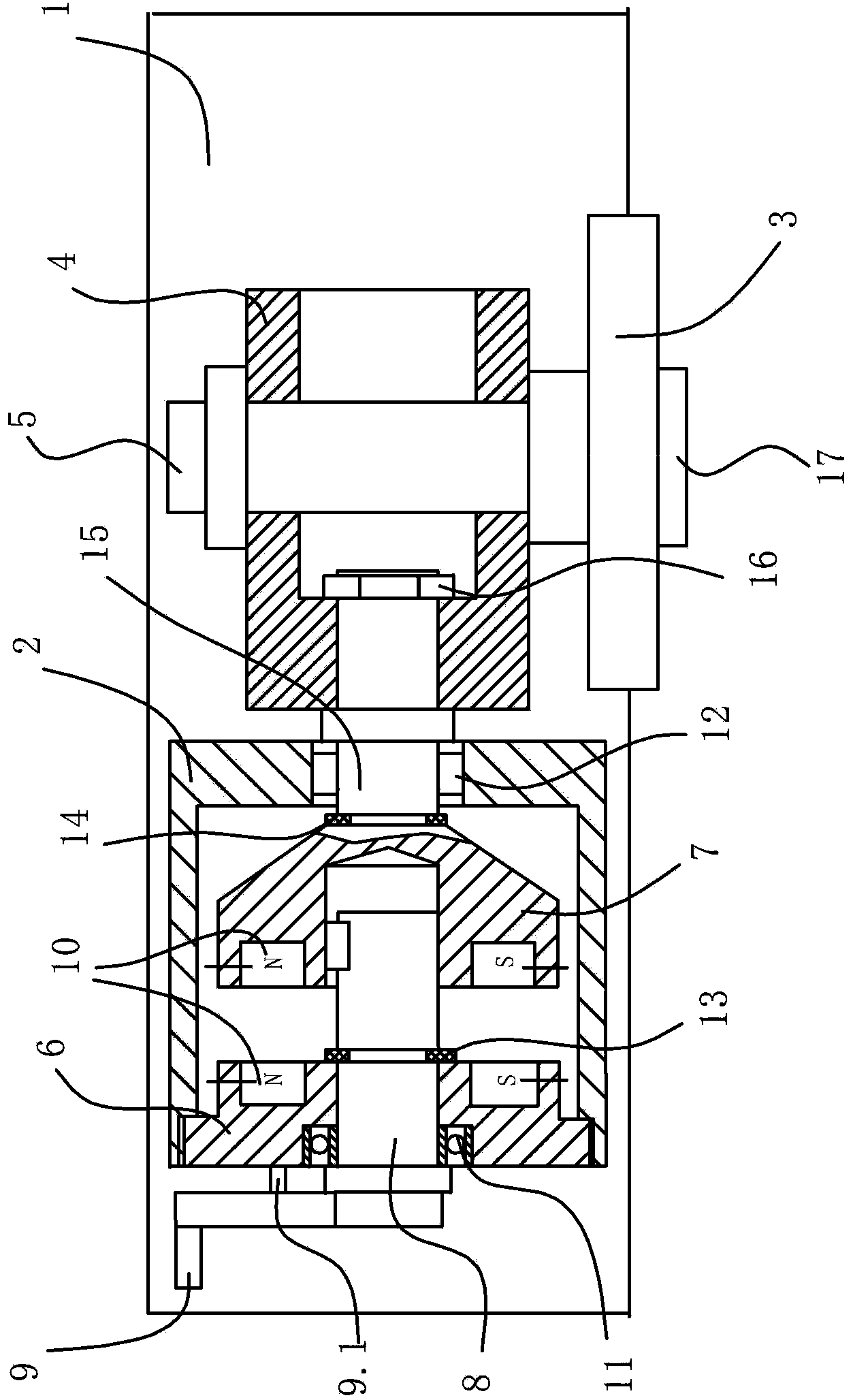

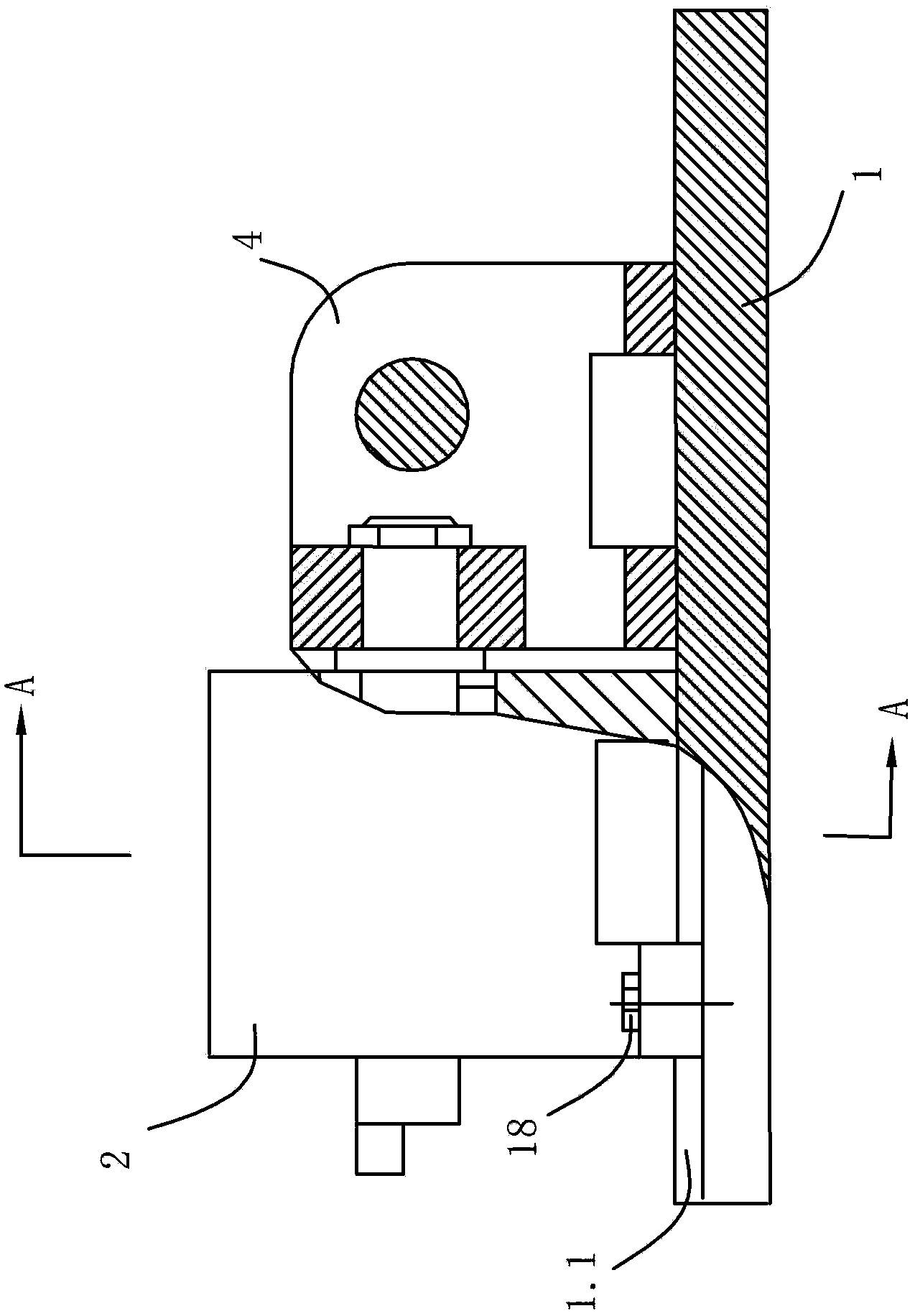

The invention discloses a peeling device and a coated pipe peeling machine, and relates to the technical field of automobiles. Technical problems of poor consistency and low production efficiency of products in the prior art are solved. The peeling device comprises a cutting mechanism, a connecting seat and a peeling mechanism; the cutting mechanism is arranged on the connecting seat and comprises a cutter and a cutter driving mechanism, and the cutter driving mechanism can drive the cutter to at least cut a required-to-be-peeled skin coated on the peripheral surface of a pipe or a rod along the radial direction of the pipe or the rod; and the peeling mechanism is connected with the connecting seat and can drive the cutting mechanism via the connecting seat, so that the cutting mechanism can reciprocate along the axial direction of the pipe or the rod. The coated pipe peeling machine comprises the peeling device, the pipe is a coated pipe, and a chuck driving mechanism can drive a chuck to clamp or release the coated pipe. The peeling device and the coated pipe peeling machine are used for improving the consistency and the production efficiency of products.

Owner:HEBEI CHINAUST AUTOMOTIVE PLASTICS CORP LTD

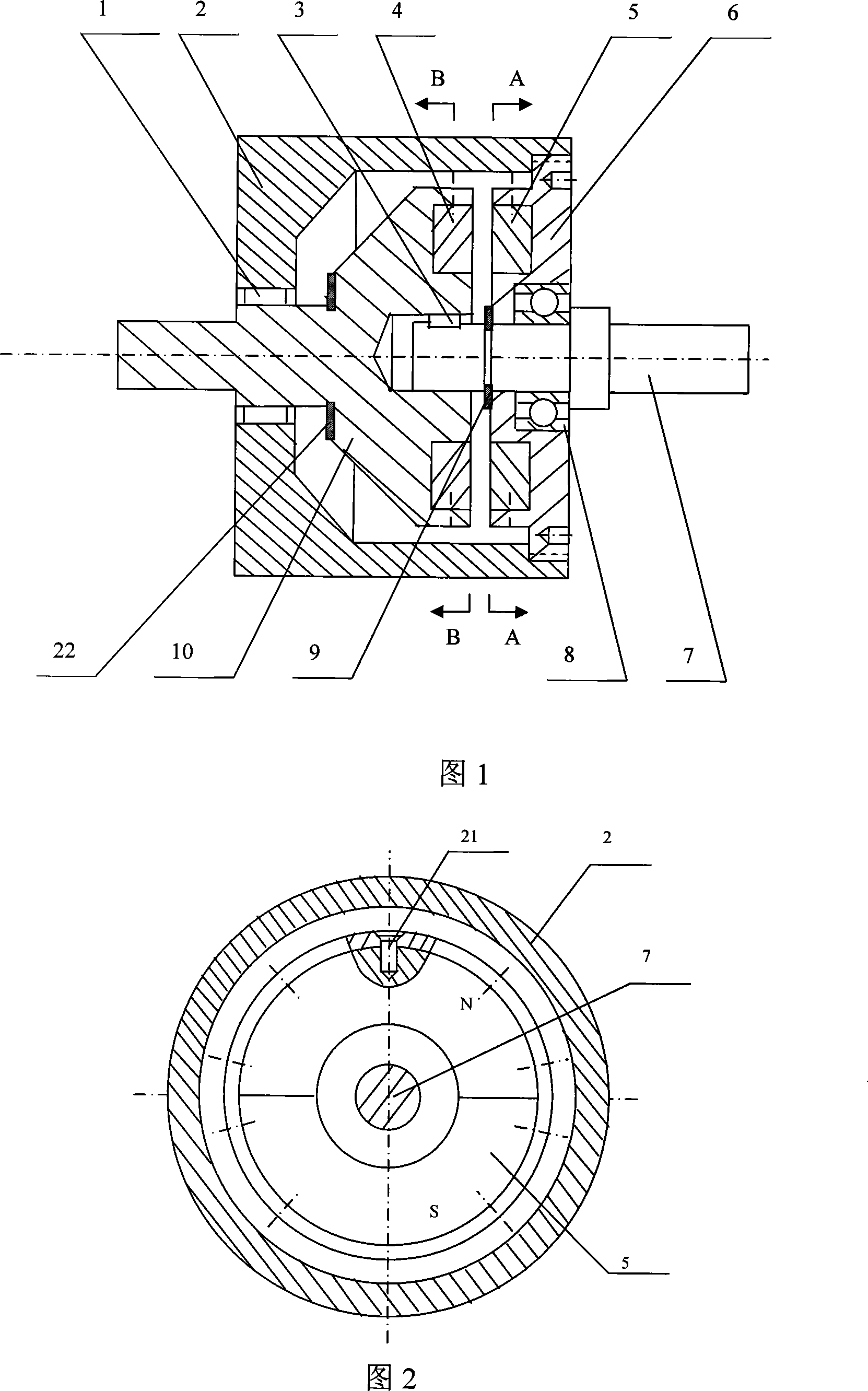

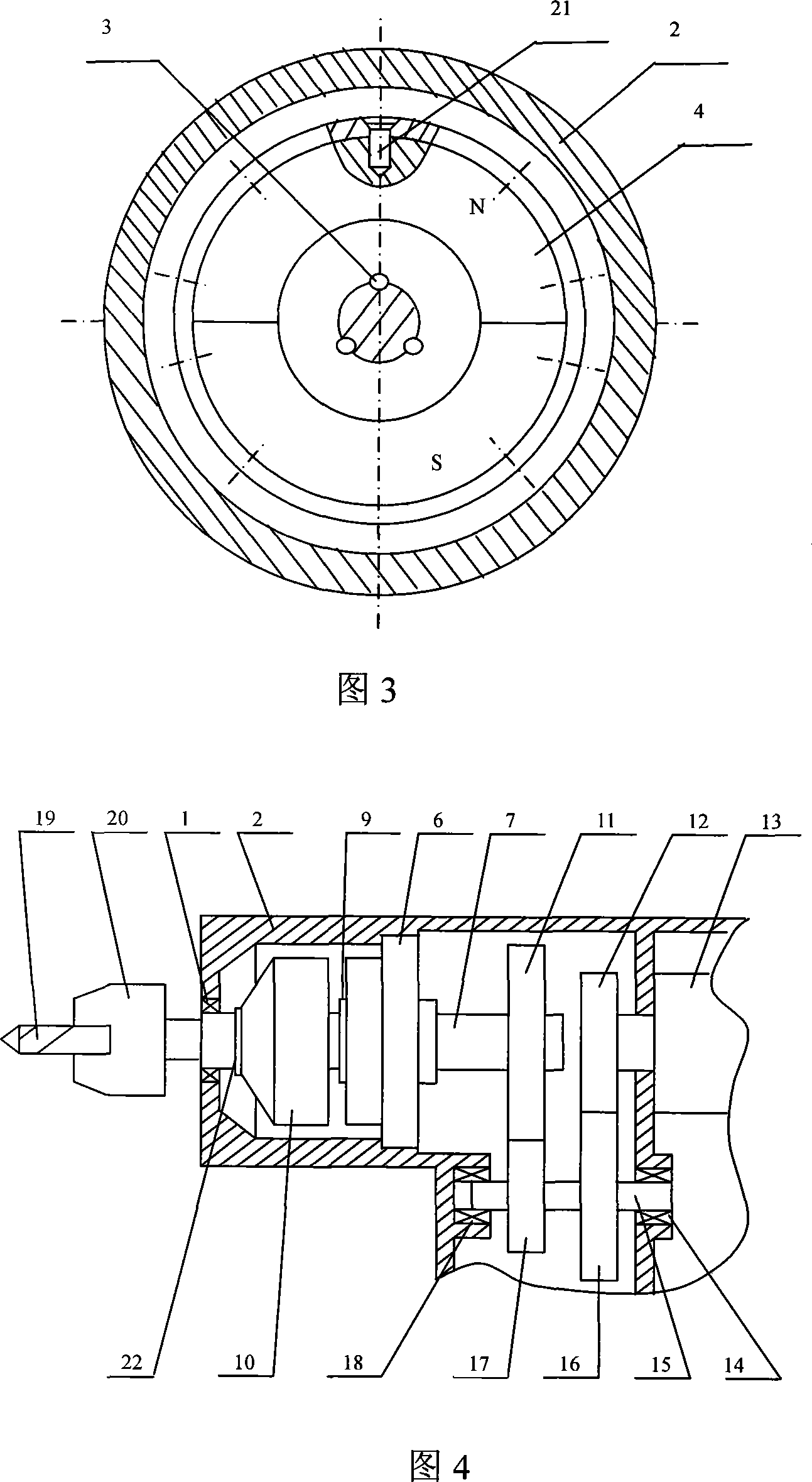

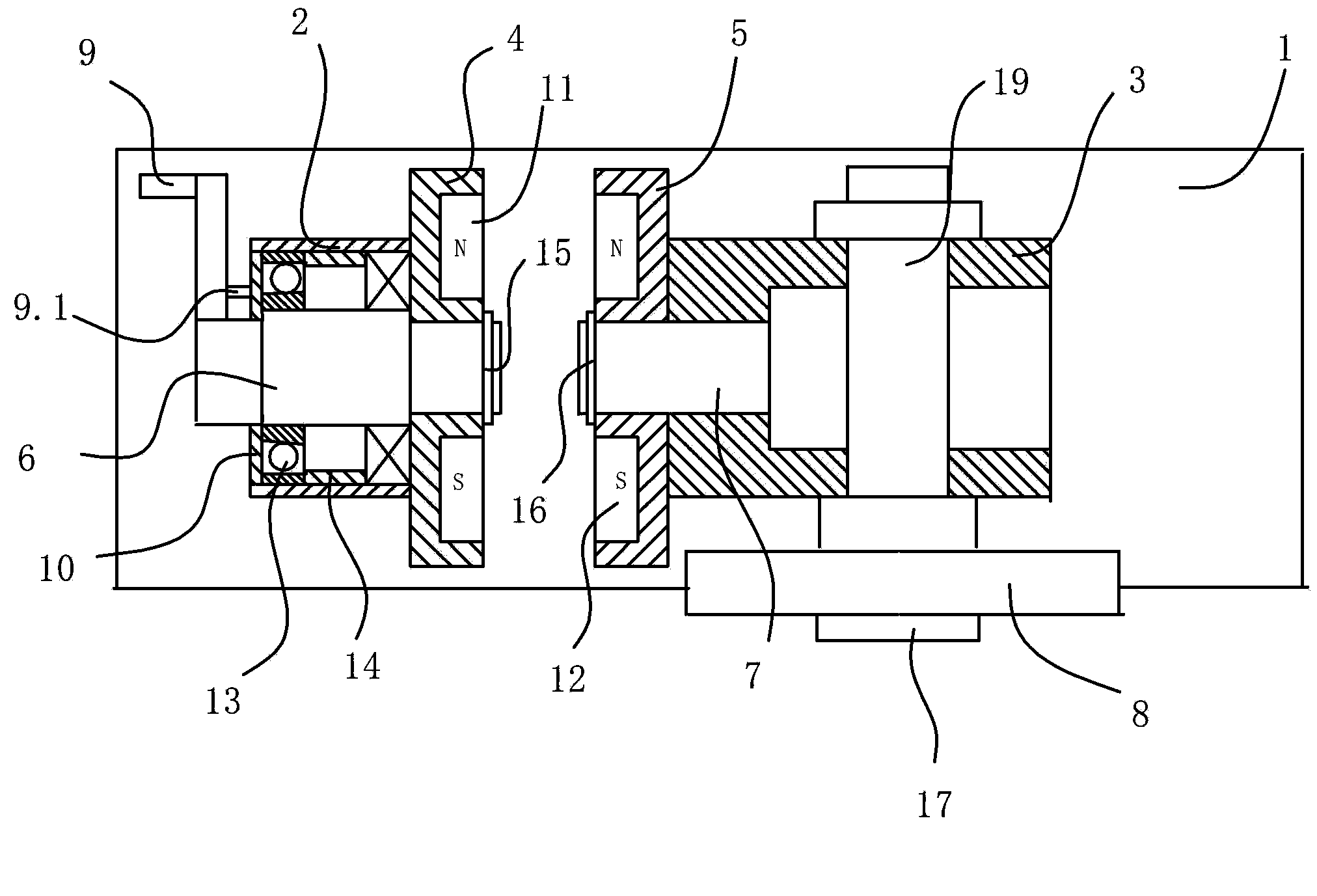

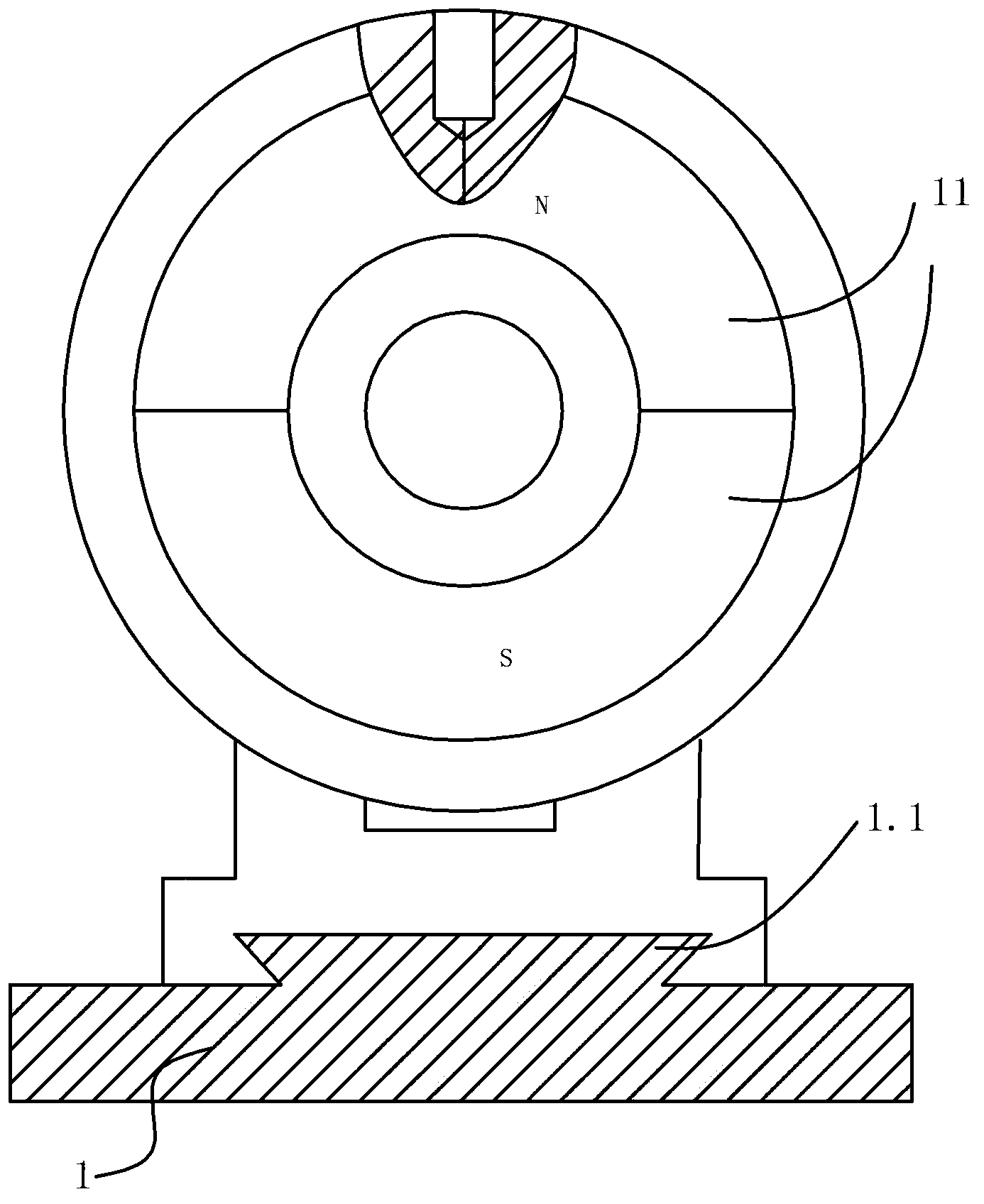

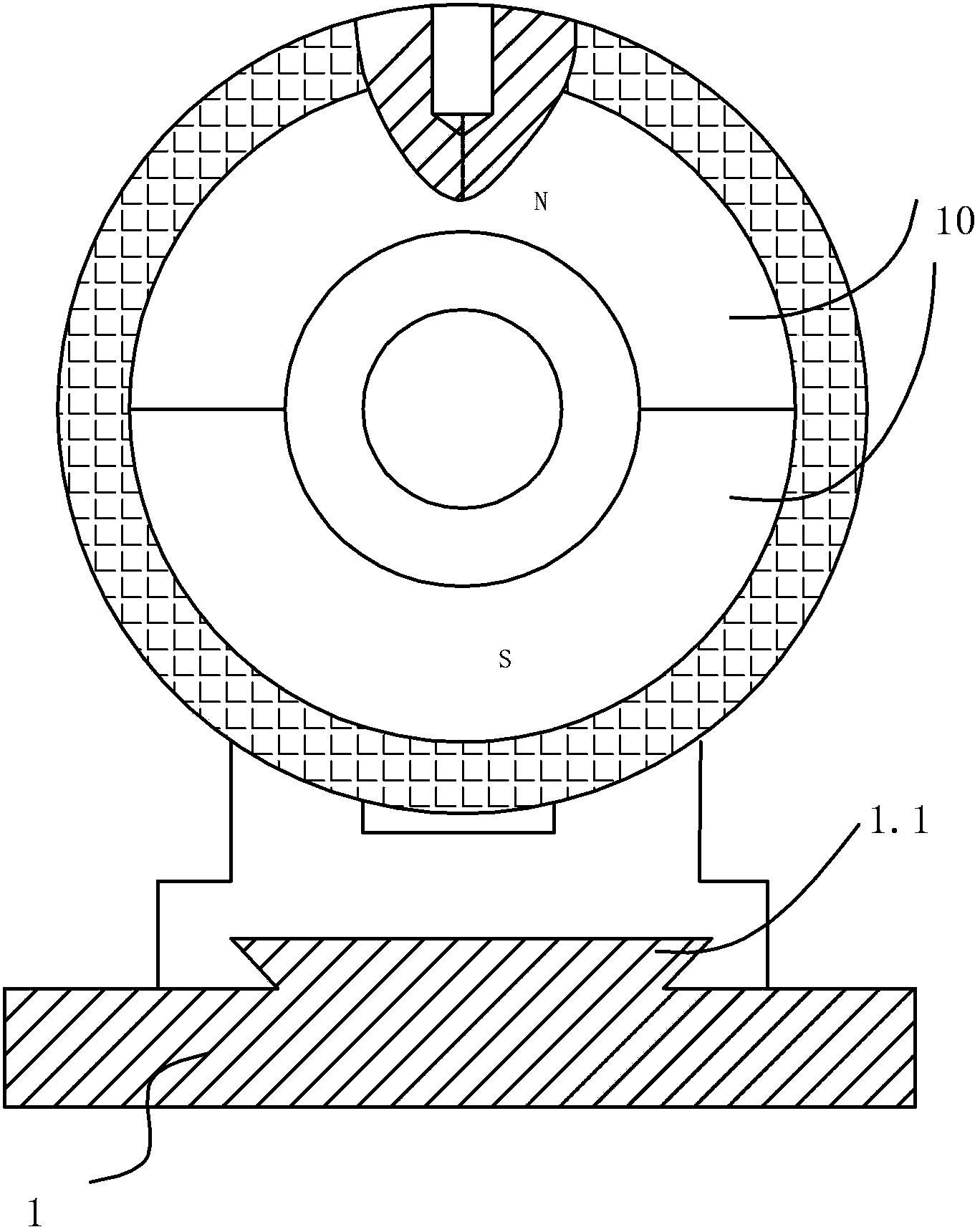

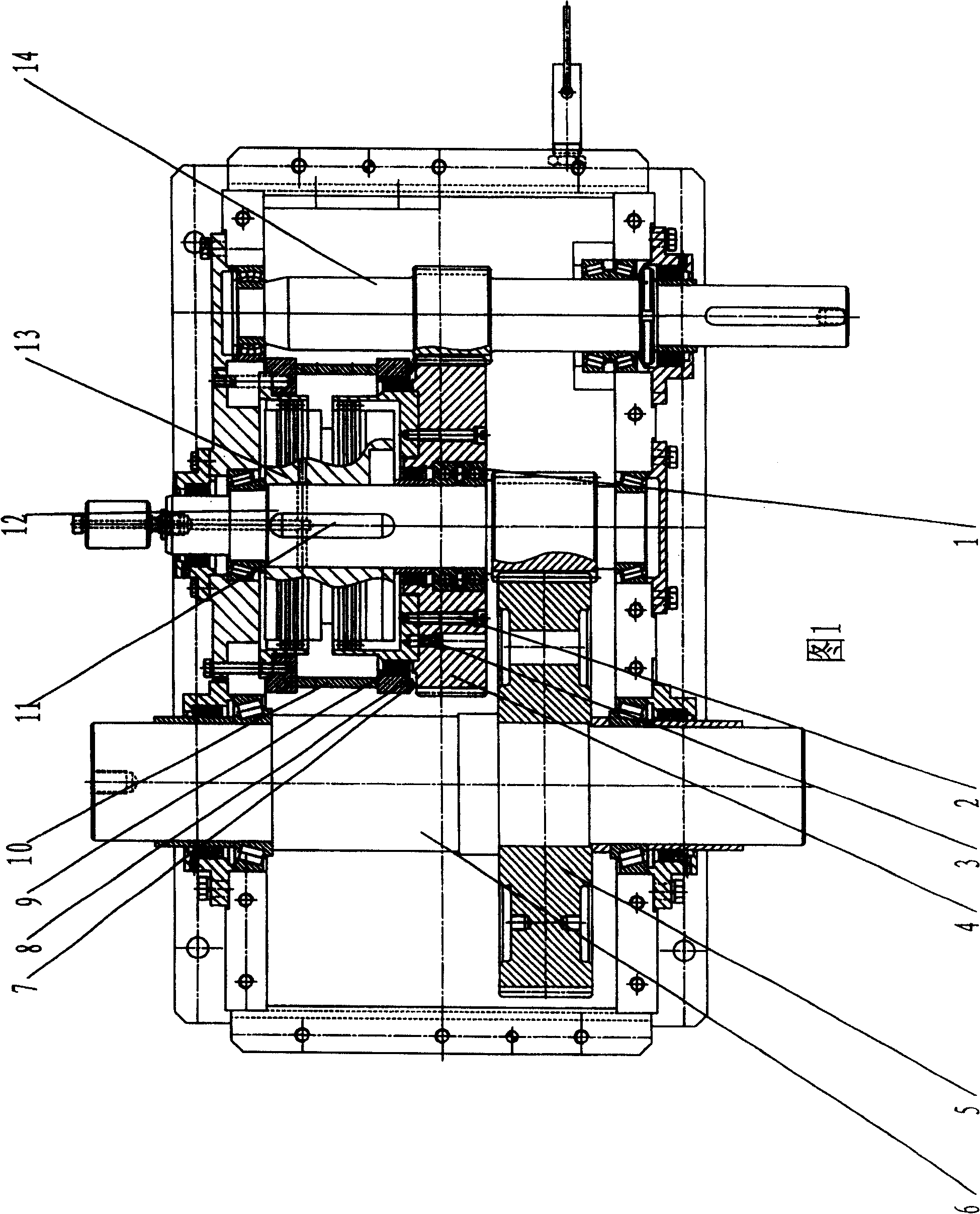

A percussion drill possessing magnetometric percussion arrangement

The invention discloses a cable drilling tool with magnetic force percussion mechanism. It includes case, moving delivering structure, magnetic impact structure, and drill chuck. The small end surface axis using bearing supports at the front of case and extrudes out to install drill chuck. The large end surface has circle slot, where has circle permanent magnet. The driving axis is set in supporting base through bear. One end of driving shaft connects to center hole of driving disc through bond. A circle slot is set on the surface of supporting base where permanent magnet is installed. The permanent magnets would cause repulsive force and attractive force while rotating to make the driving disc move back and forth relative to driving shaft. The other end of driving shaft is connected to driving gear of driving structure. There are no energy consumption and no rigid impact in the invention. The useful life would be prolonged, and the lubricant will be saved. It also has no dust and noise during moving process.

Owner:ZHEJIANG UNIV

Special vertical crushing device

InactiveCN107377154AReasonable structural designSimple structural designDrying chambers/containersDrying solid materialsControl theoryEnergy loss

A special vertical crushing device, characterized in that: the special vertical crushing device includes a driving machine, a connecting fixed plate, a rotating shaft, an inner rotating crushing and drying cylinder, a discharge port, a shaft seat, an inner cylinder crushing tooth, an outer Rotary crushing and drying cylinder, outer cylinder crushing teeth; wherein: the device is composed of a driving machine and a drying and crushing system, the driving machine is a hydraulic driving machine or a motor, the power output end of the driving machine is fixedly connected to the rotating shaft, and the other end of the rotating shaft is connected The shaft seat and the rotating shaft are fixedly installed with the inner rotary crushing and drying cylinder by connecting the fixed plate. The inner cylinder crushing teeth are uniformly arranged on the outer edge of the inner rotary crushing and drying cylinder, and the inner cylinder crushing teeth are evenly arranged on the inner side of the outer rotary crushing and drying cylinder. The outer cylinder crushing teeth on the top, and the outer rotary crushing and drying cylinder are fixedly set on the inner rotating crushing and drying cylinder. The advantages of the present invention: the special vertical crushing device described in the present invention has reasonable and simple structural design, convenient installation and disassembly, convenient maintenance, time-saving and labor-saving, high transmission efficiency, no energy loss caused by friction, and no friction between parts. Hard impact, long service life of parts, good crushing and drying effect.

Owner:丛晓庆

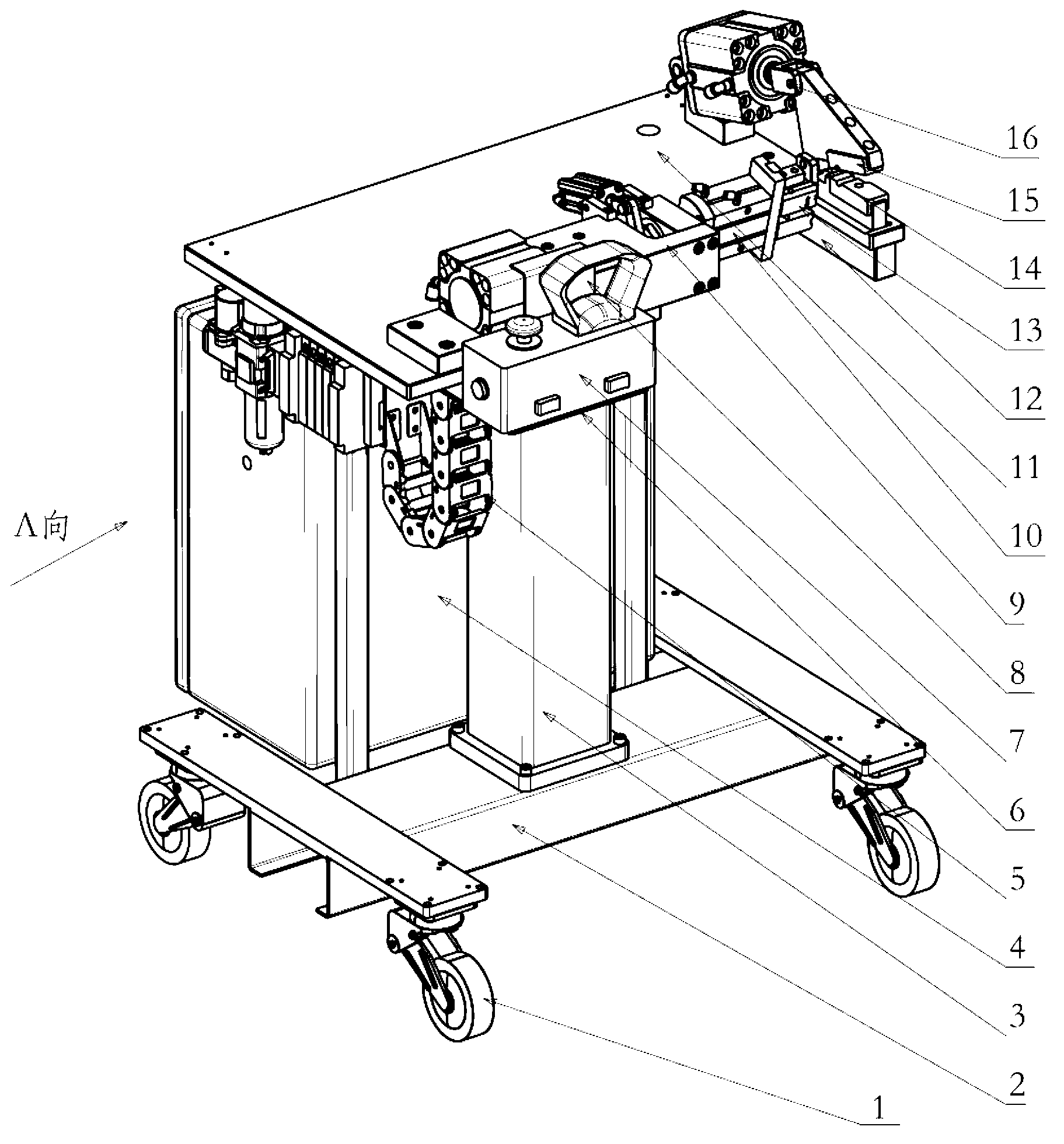

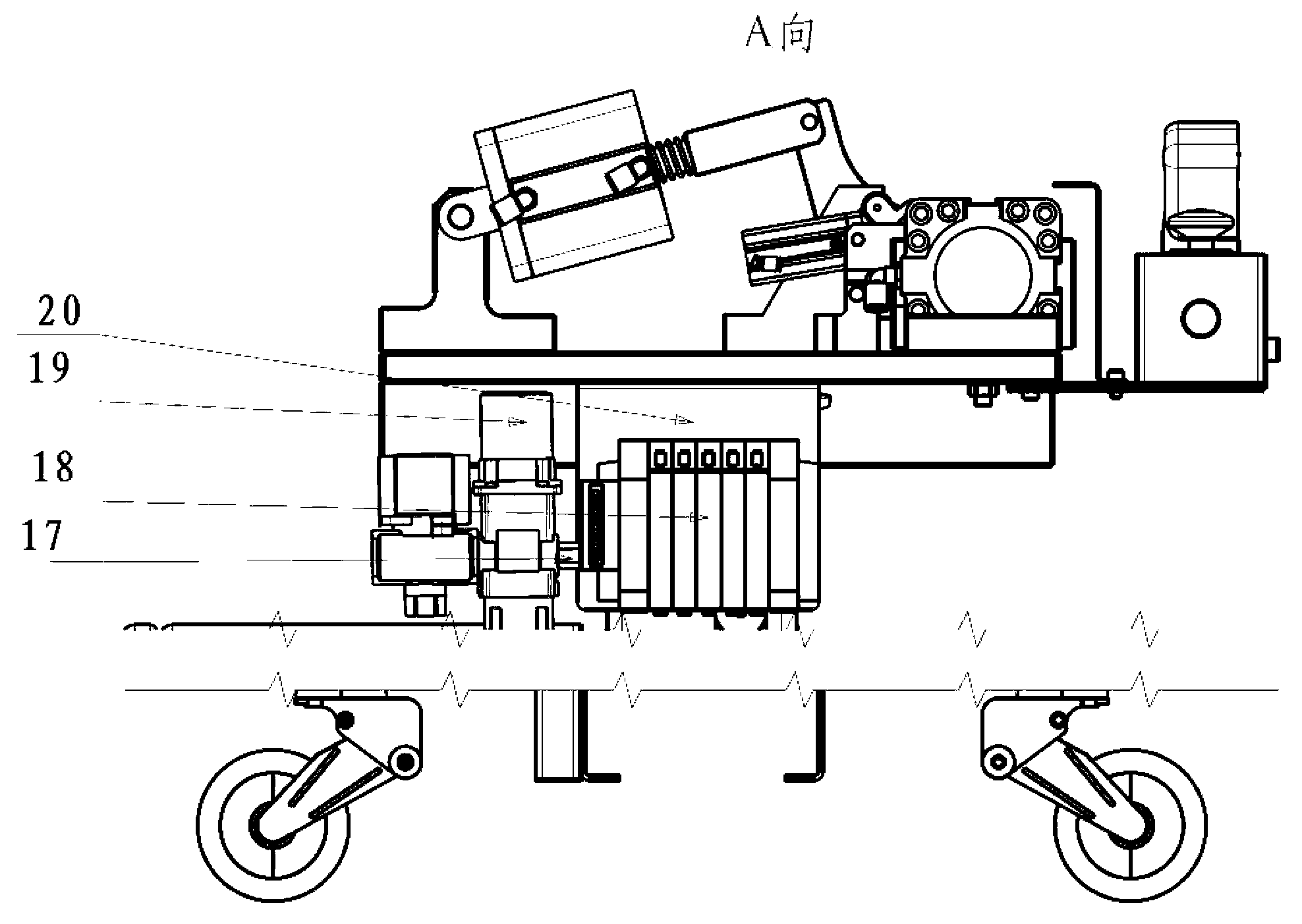

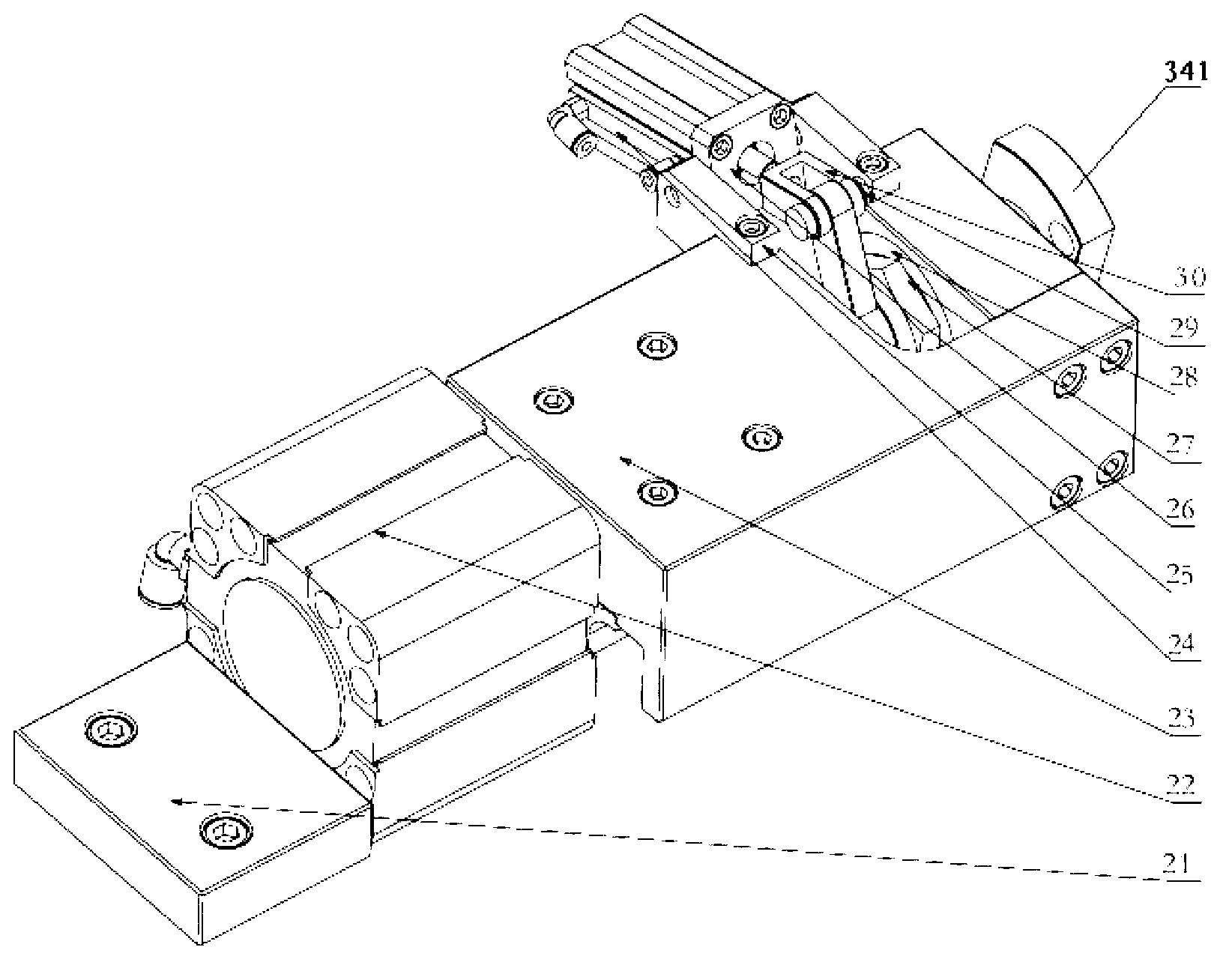

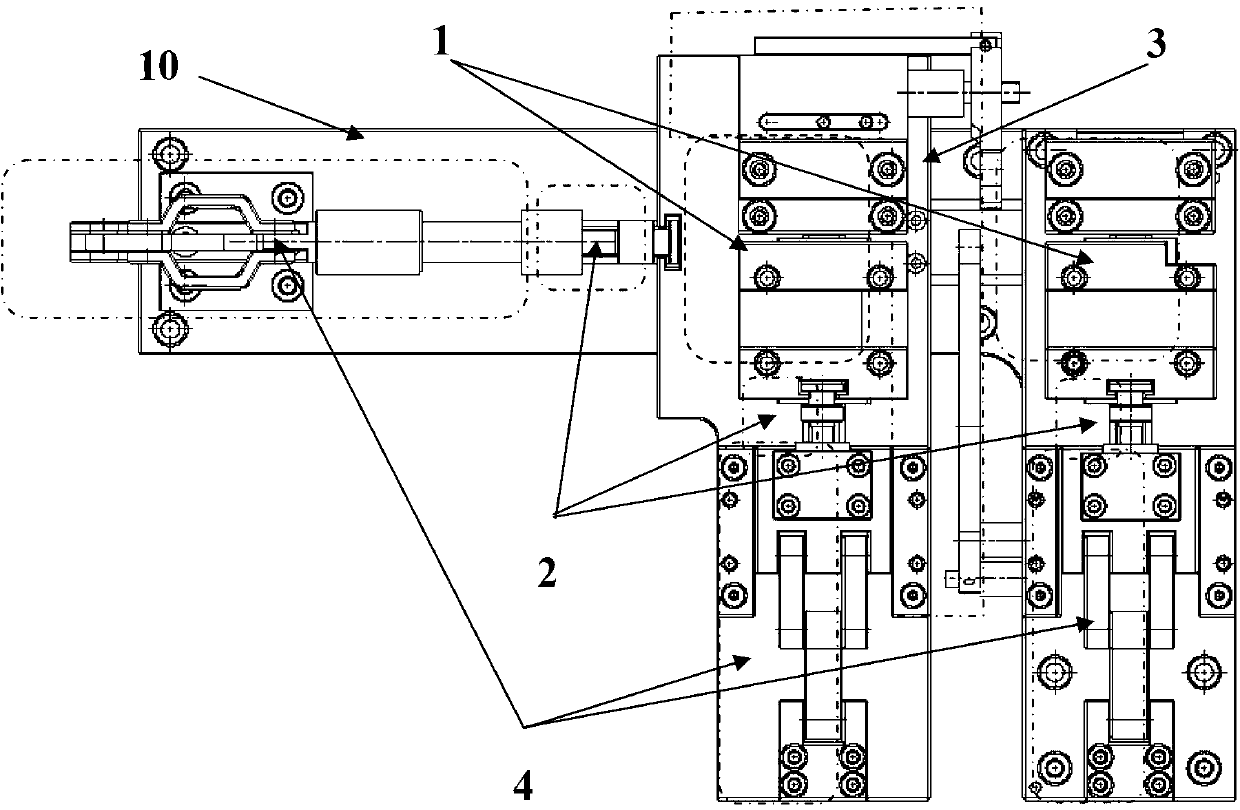

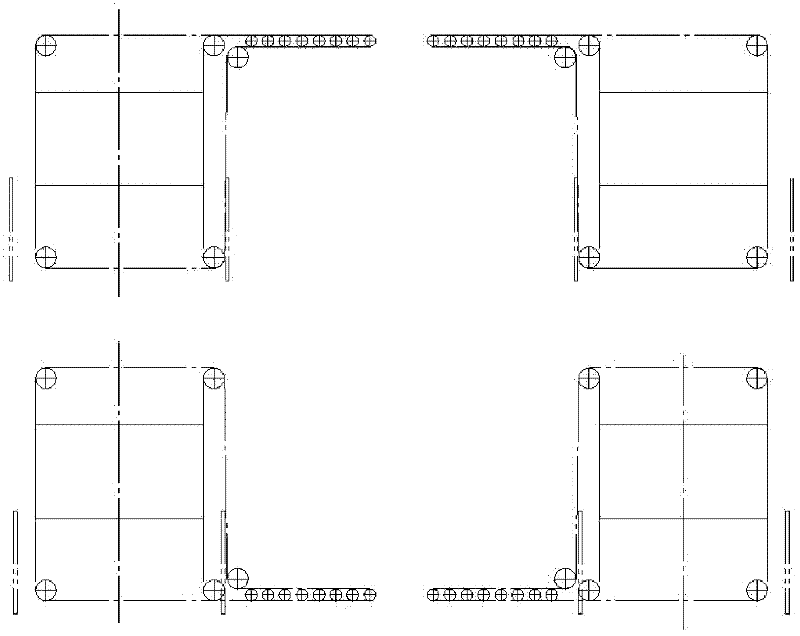

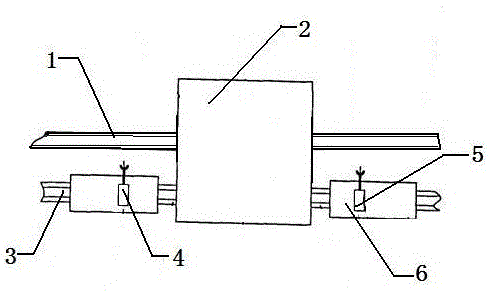

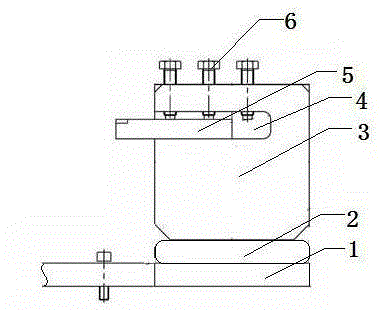

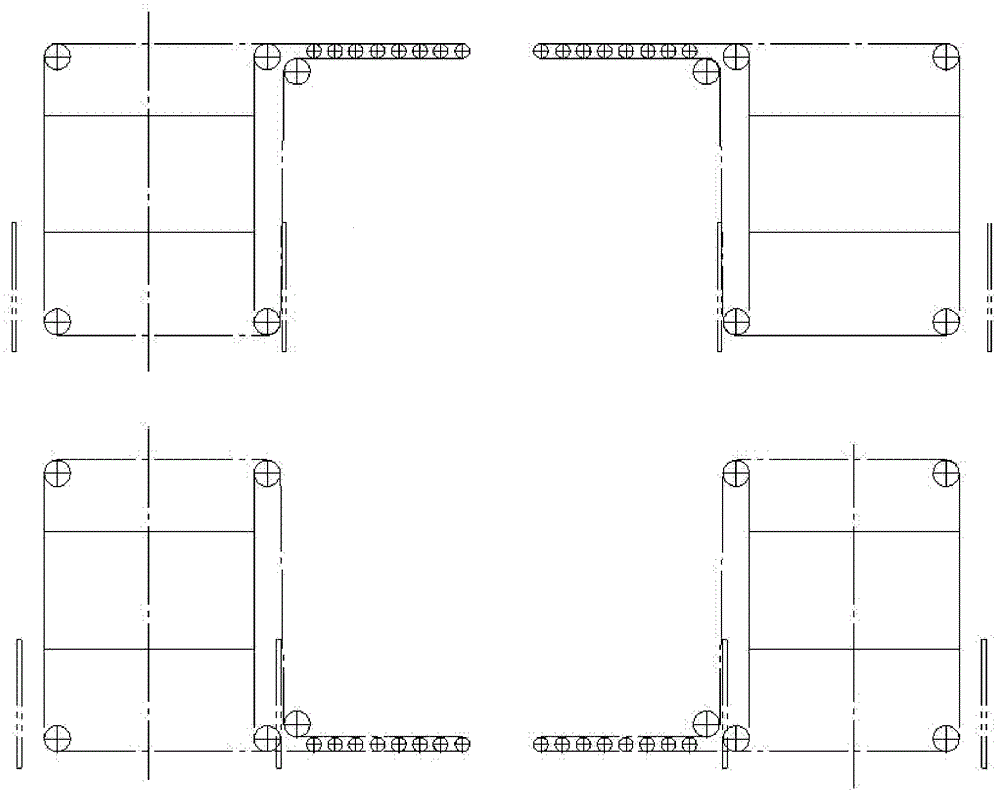

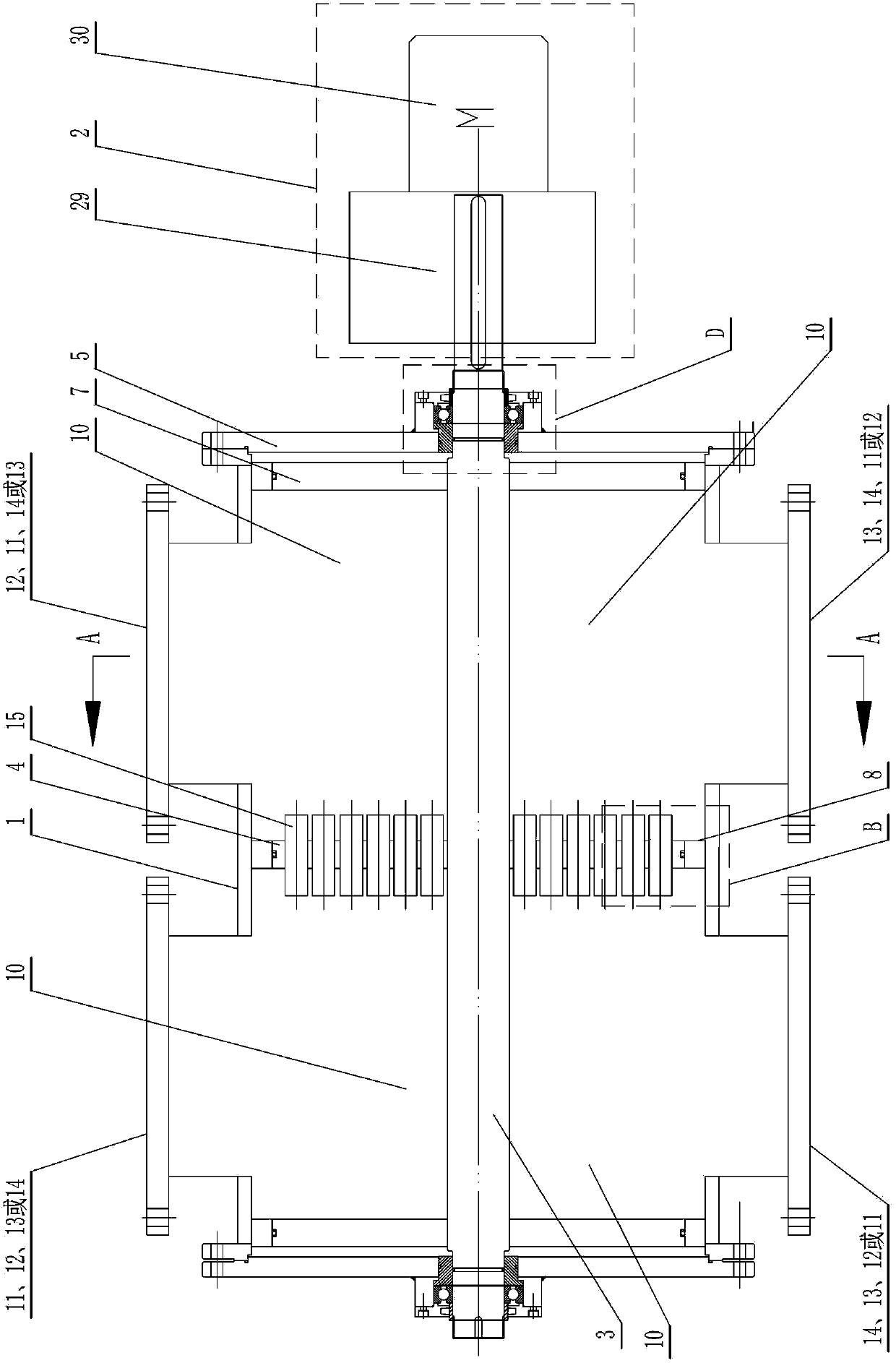

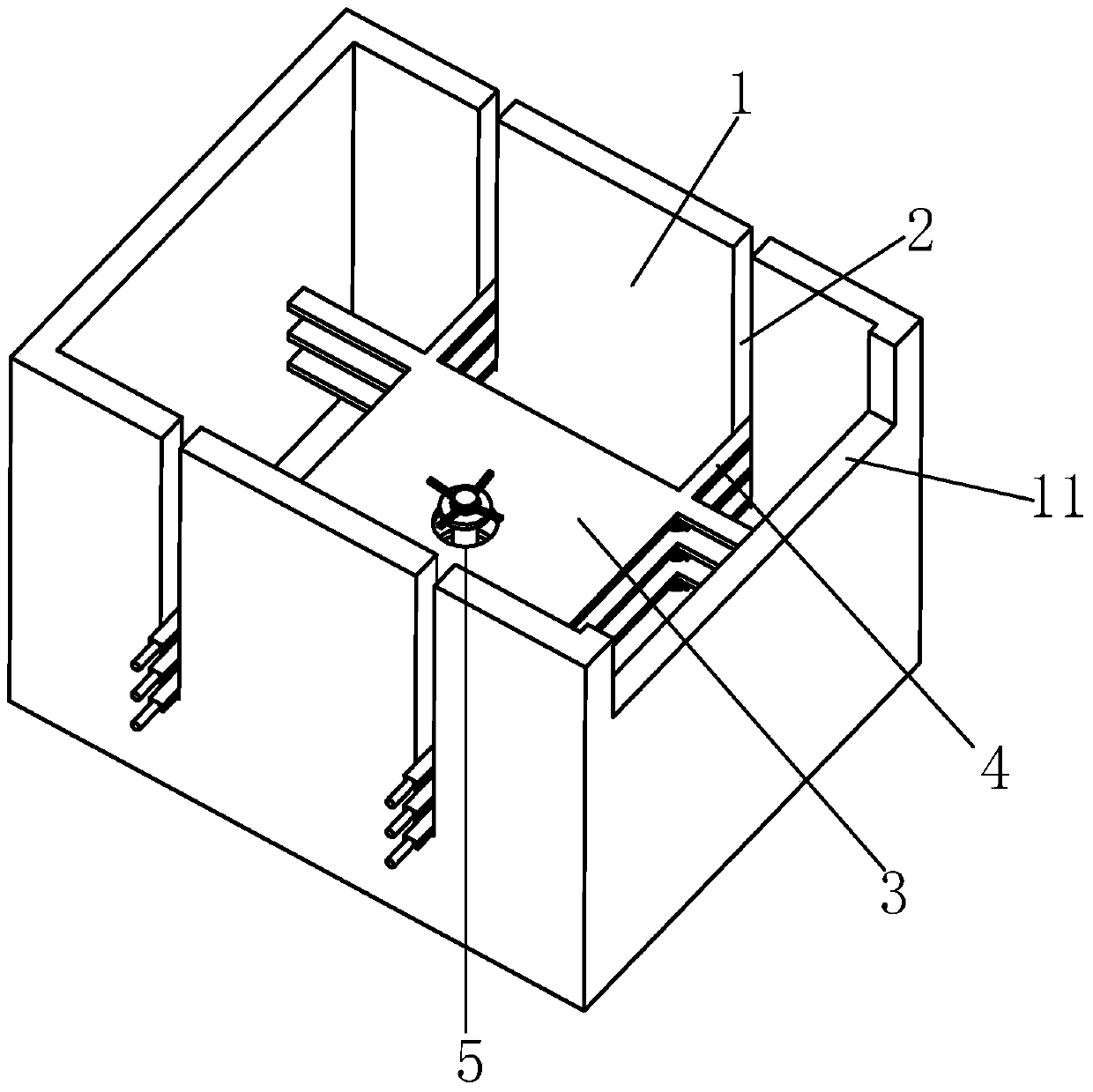

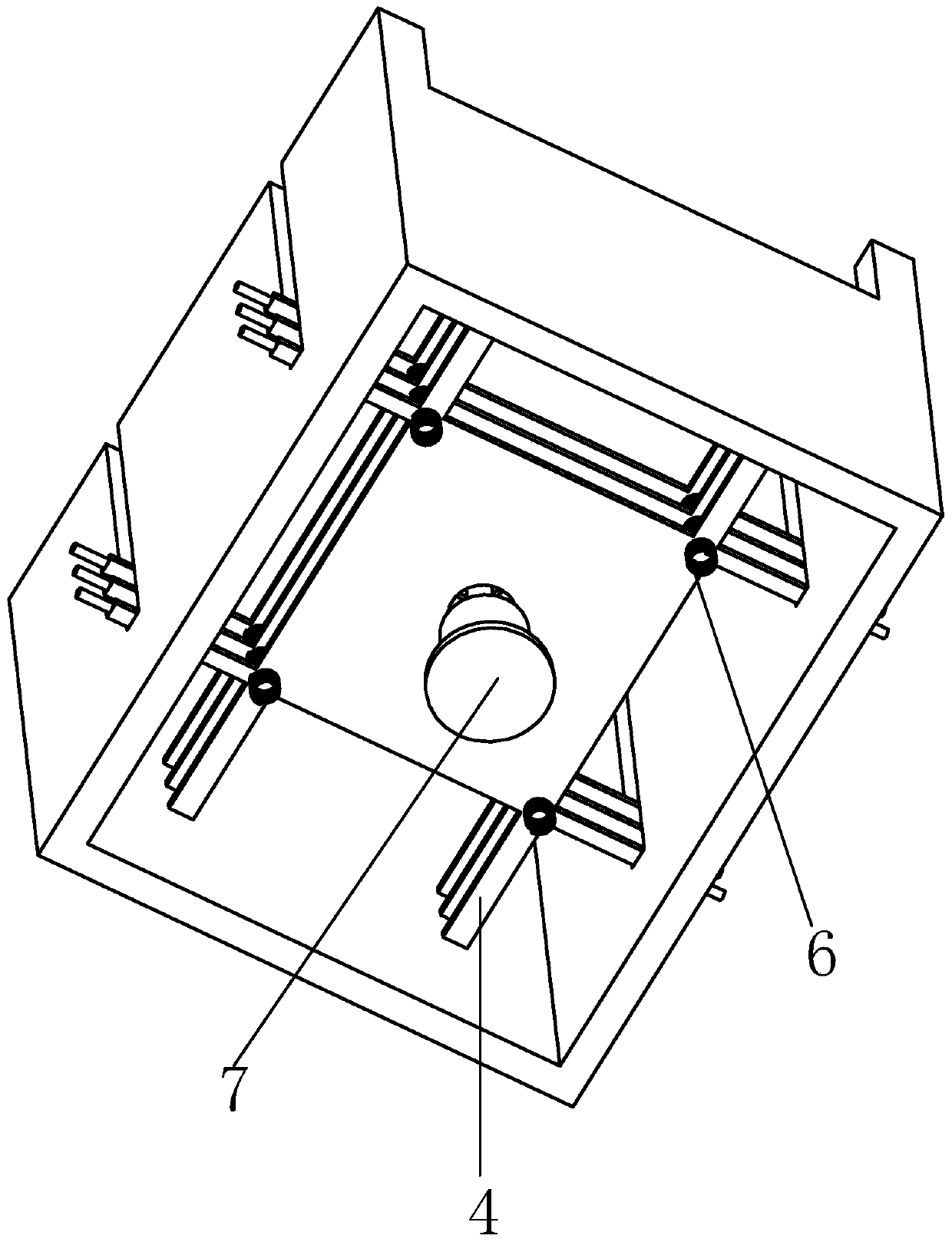

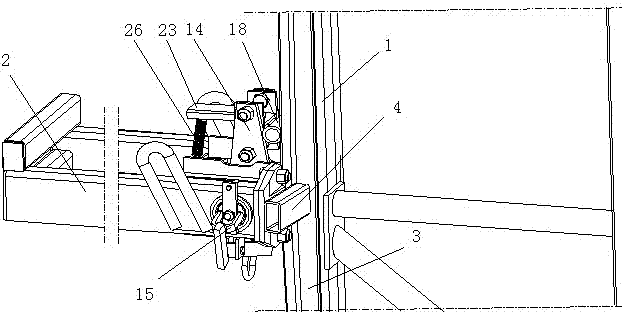

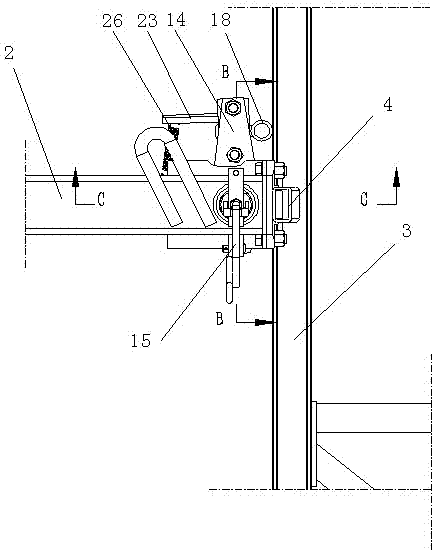

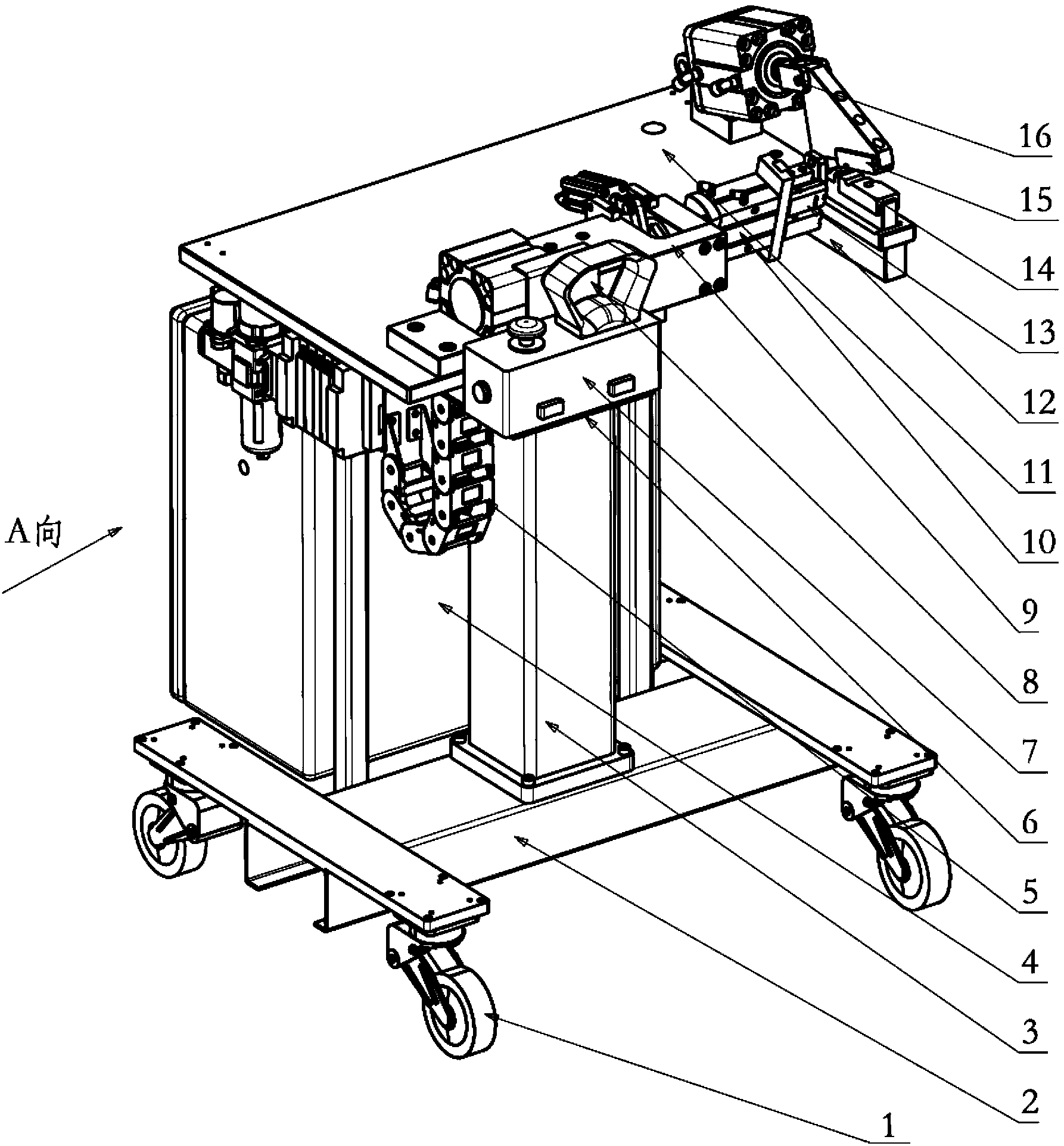

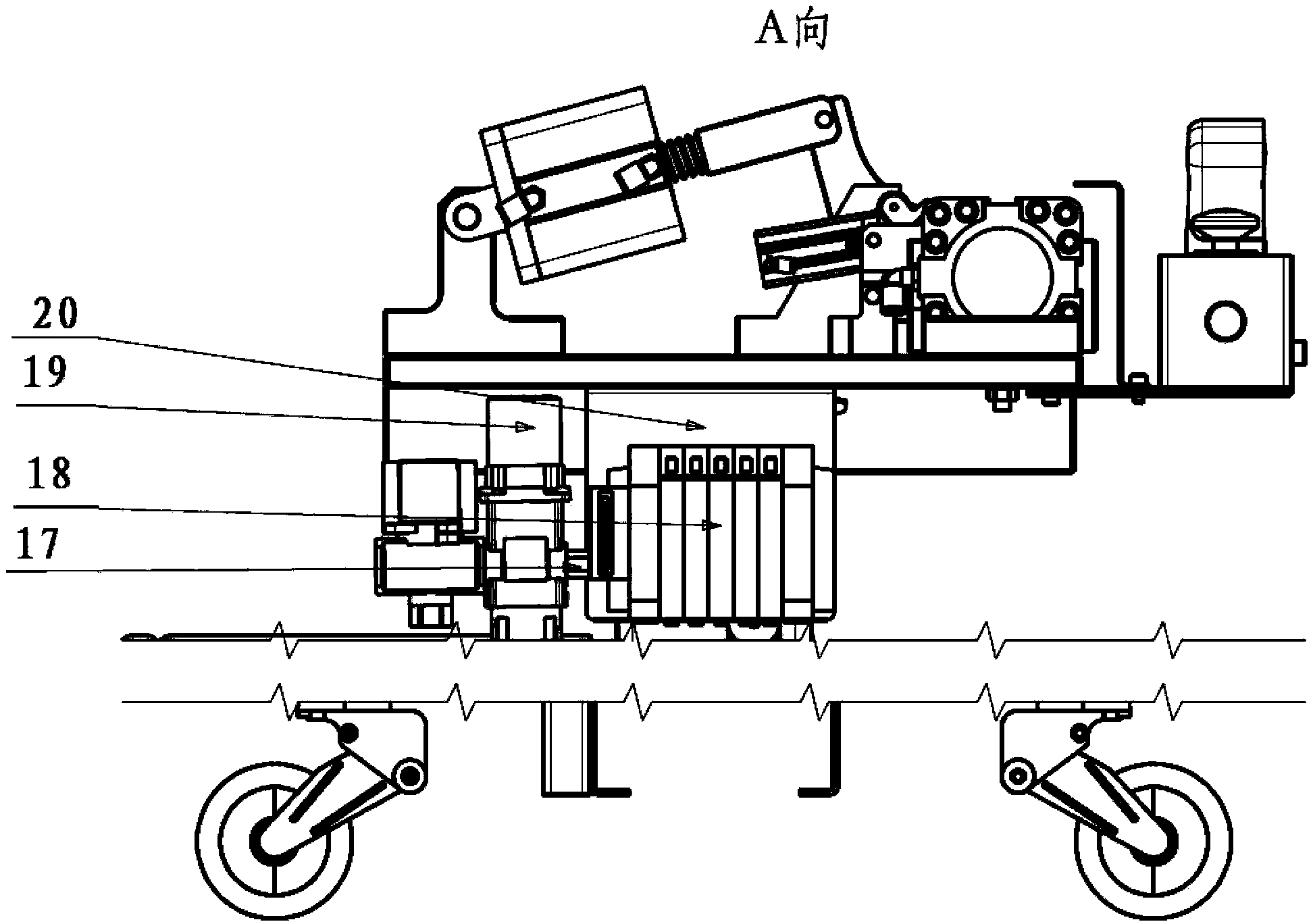

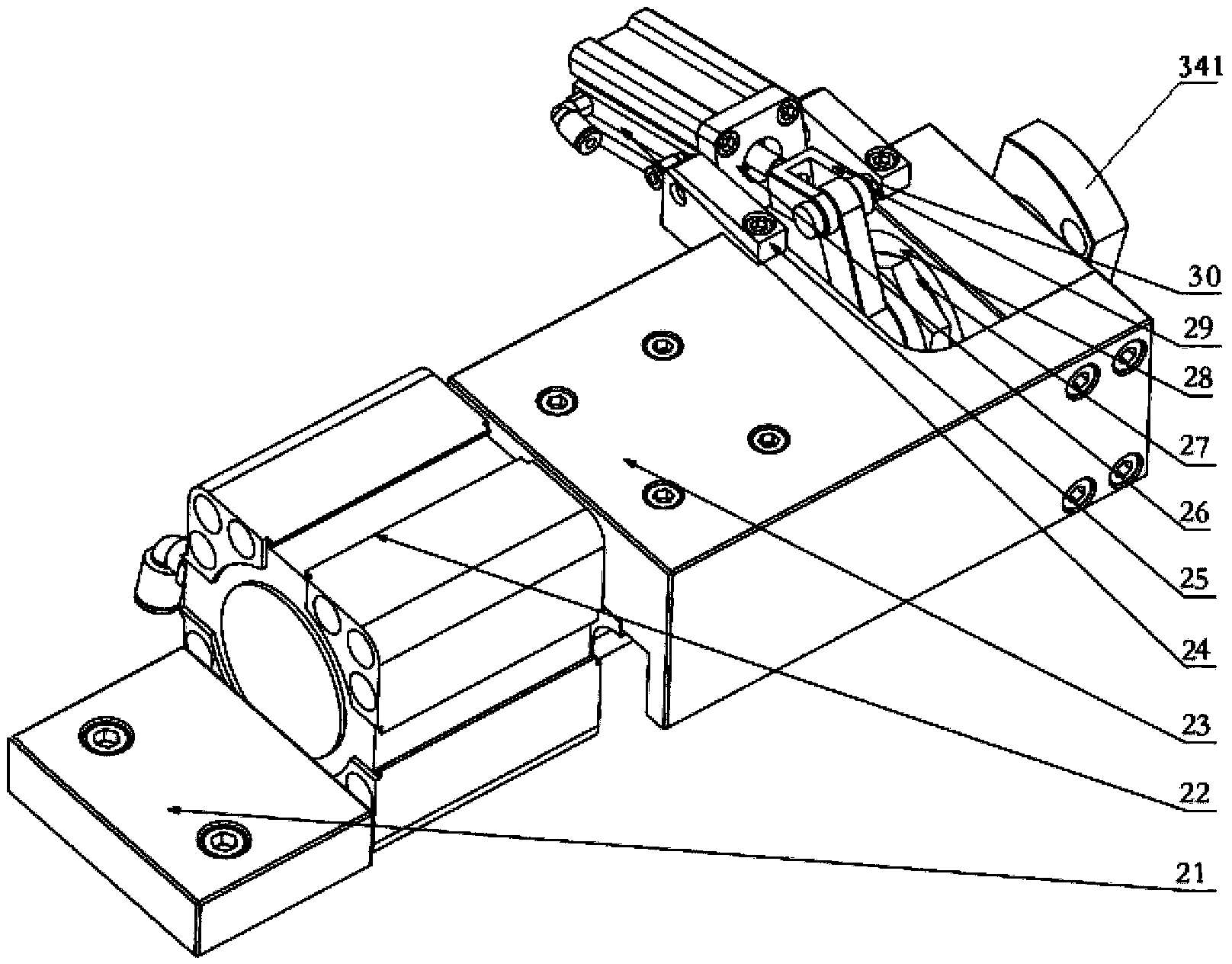

Manual assembly machine of plastic pipeline assembly

The invention relates to a manual assembly machine of a plastic pipeline assembly. The manual assembly machine of the plastic pipeline assembly comprises an assembly machine body. A plurality of groups of clamp bodies and a plurality of regulating components are arranged on the assembly machine body, wherein the clamp bodies are used for clamping objects to be assembled and the regulating components are matched with the clamp bodies. The regulating components are used for regulating the clamp force and assembling travel distance of the clamp bodies. A pipe groove and a positioning and flaring component are further arranged on the assembly machine body, wherein the pipe groove is used for containing a flexible pipe and the positioning and flaring component is used for fixing a protruding length of the flexible pipe and achieving flaring. The positioning and flaring component is arranged on the lateral sides of the clamp bodies. When the manual assembly machine of the plastic pipeline assembly is used, a clamping block of a connector and a clamping block of the flexible pipe are fixed through a three-coordinate detector after a relative angle between the clamping block of the connector and the clamping block of the flexible pipe is well adjusted, and assembling is accurately achieved by enabling the clamping blocks to be clamped on the clamp bodies on the assembly machine when the assembling is carried out. In addition, the manual assembly machine of the plastic pipeline assembly has the advantages of being small in size, capable of being pushed away freely due to the fact that trundles are arranged on the bottom of the assembly machine, and free of noise in an operation process due to the fact that the whole assembly machine is designed to be free of rigid impact.

Owner:HEBEI CHINAUST AUTOMOTIVE PLASTICS CORP LTD

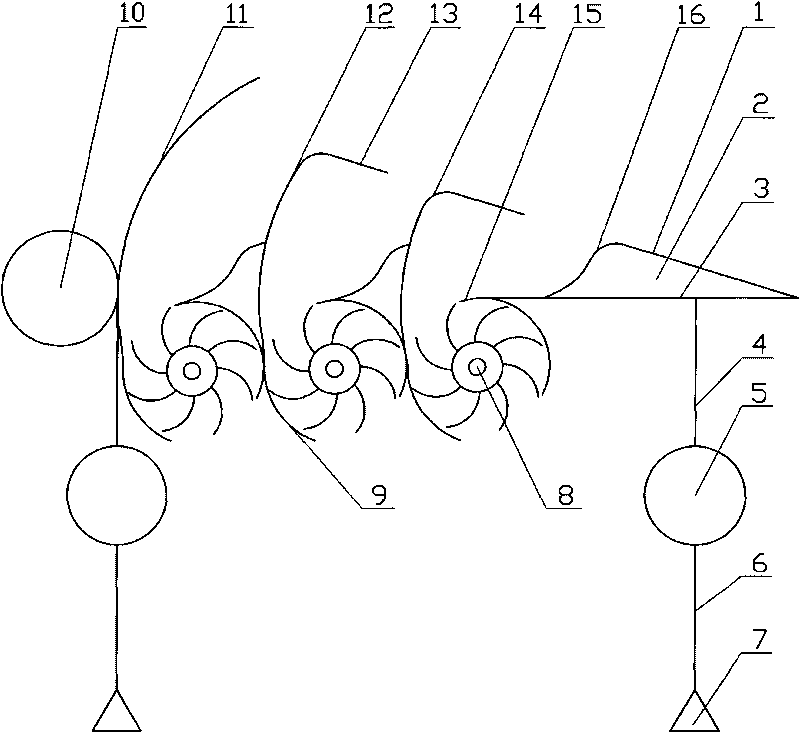

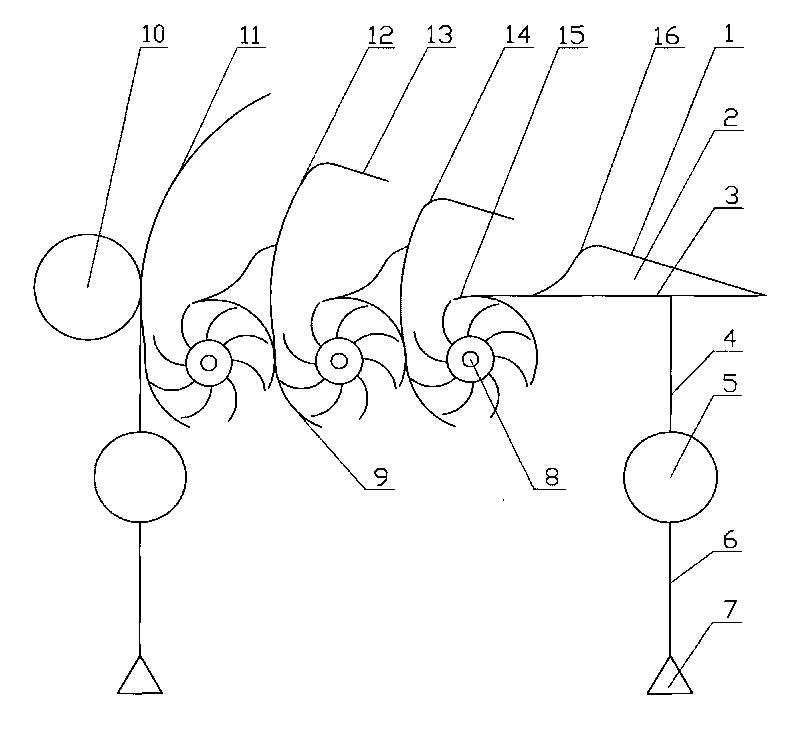

Impeller-type sea wave power generation device

InactiveCN101705903AReduce lossNo hard impactMachines/enginesSafety/regulatory devicesImpellerHigh energy

The invention relates to an impeller-type sea wave power generation device which comprises energy collecting units and a platform, wherein each energy collecting unit comprises an impeller taken as an energy collecting component and a transmission mechanism connected with the impeller and power generating equipment; the platform is used for providing an offshore platform for the energy collecting units, the front part of the platform is provided with an inclined surface, the tail end of which is provided with a deflector, and the tail end of the deflector is provided with one or a group of energy collecting units with the same impeller axial line; the deflector extends right above the impeller; and the platform is also provided with a baffle positioned at the rear side of the impeller, thus forming flow guide along the tangential direction of the impeller for the inrush sea wave. The impeller-type sea wave power generation device based on the scheme has high energy collecting efficiency.

Owner:张正泉

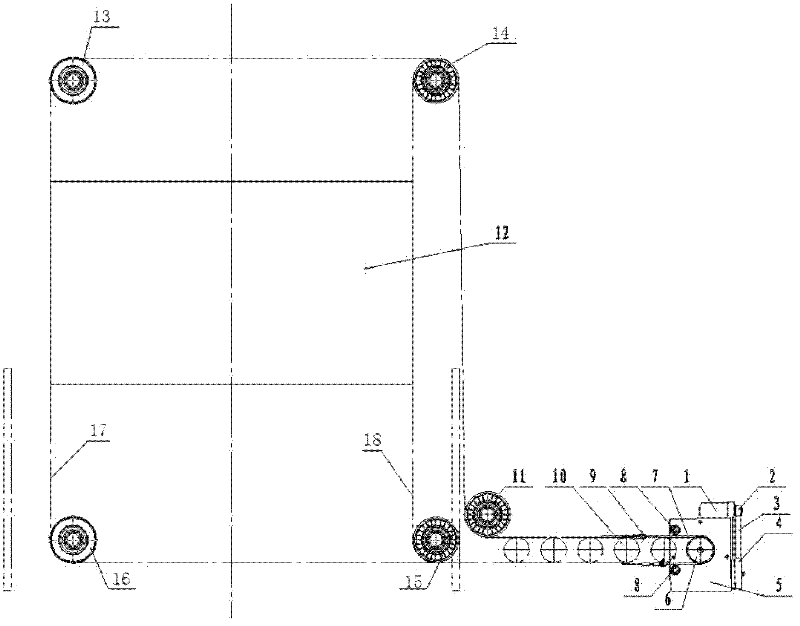

Electronic opening device with any opening in multiple positions

InactiveCN102286822ANo hard impactReduce vibrationOther shedding mechanismRest positionControl system

The invention provides an electronic opening device capable of casually opening at multiple positions, which can make a large amount of openings and casually set an opening motion and rest position. The electronic opening device comprises a heald frame, a driving system, a control system, a transmission system, two steel wire ropes, guide wheels, and orienting guide wheels, wherein the control system is used for controlling the driving system; the transmission system is connected with the driving system; Four guide wheels are respectively fixed above and below the heald frame; one orienting guide wheel is further arranged adjacent to the inside of guide wheels of the transmission system; one end of one of the steel wire ropes is fixed on the transmission system, rounds the outside of the four upper and lower guide wheels of the heald frame, then rounds the orienting guide wheel; at last, the other end is also fixed on the transmission system; one end of the other steel wire rope is fixed on the transmission system, rounds the two guide wheels adjacent to one side of the transmission system, then rounds the orienting guide wheel; at last, the other end is also fixed on the transmission system; and the heald frame is fixed on two steel wire ropes inside the four guide wheels.

Owner:JINGWEI TEXTILE MASCH CO LTD

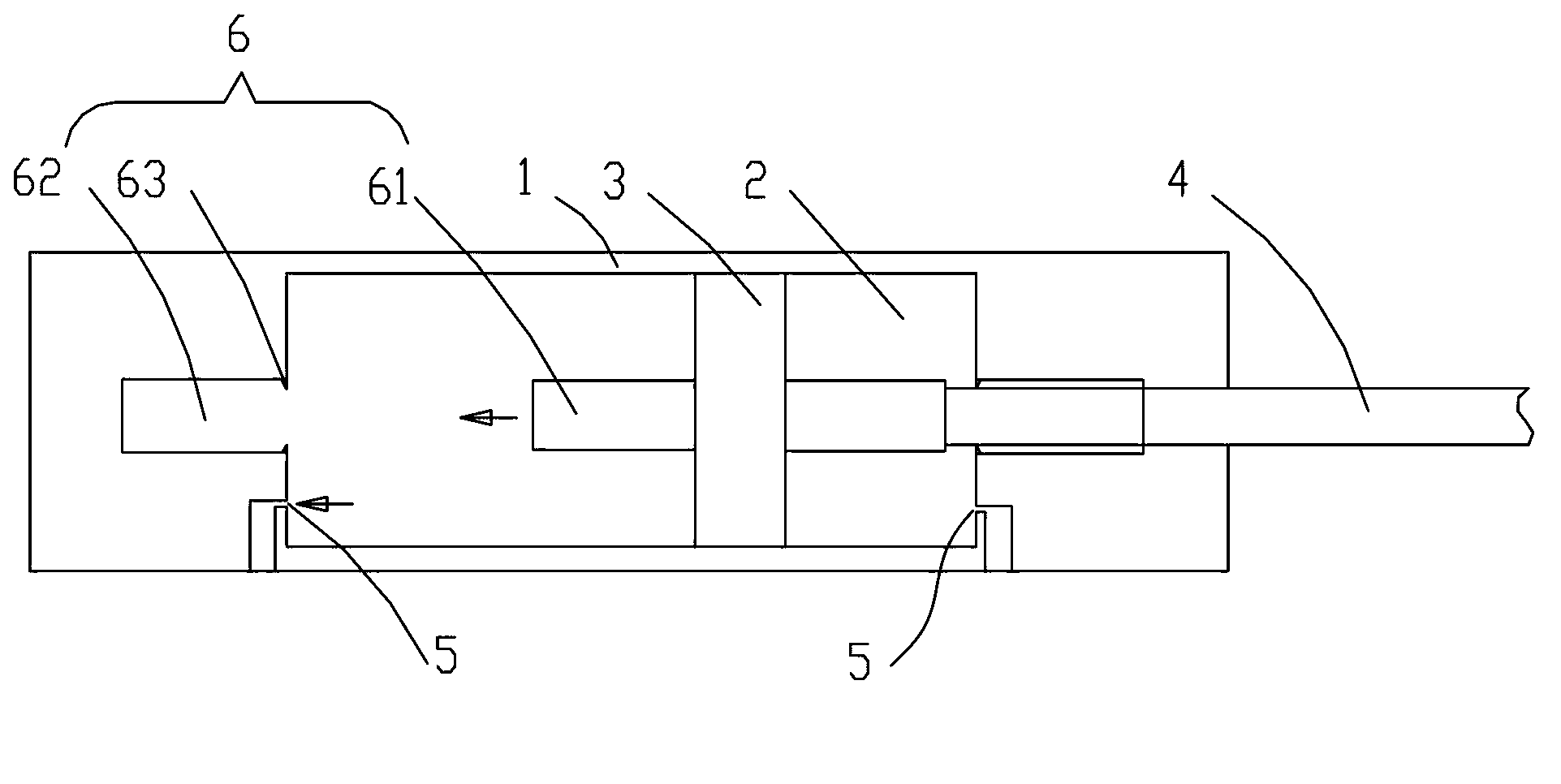

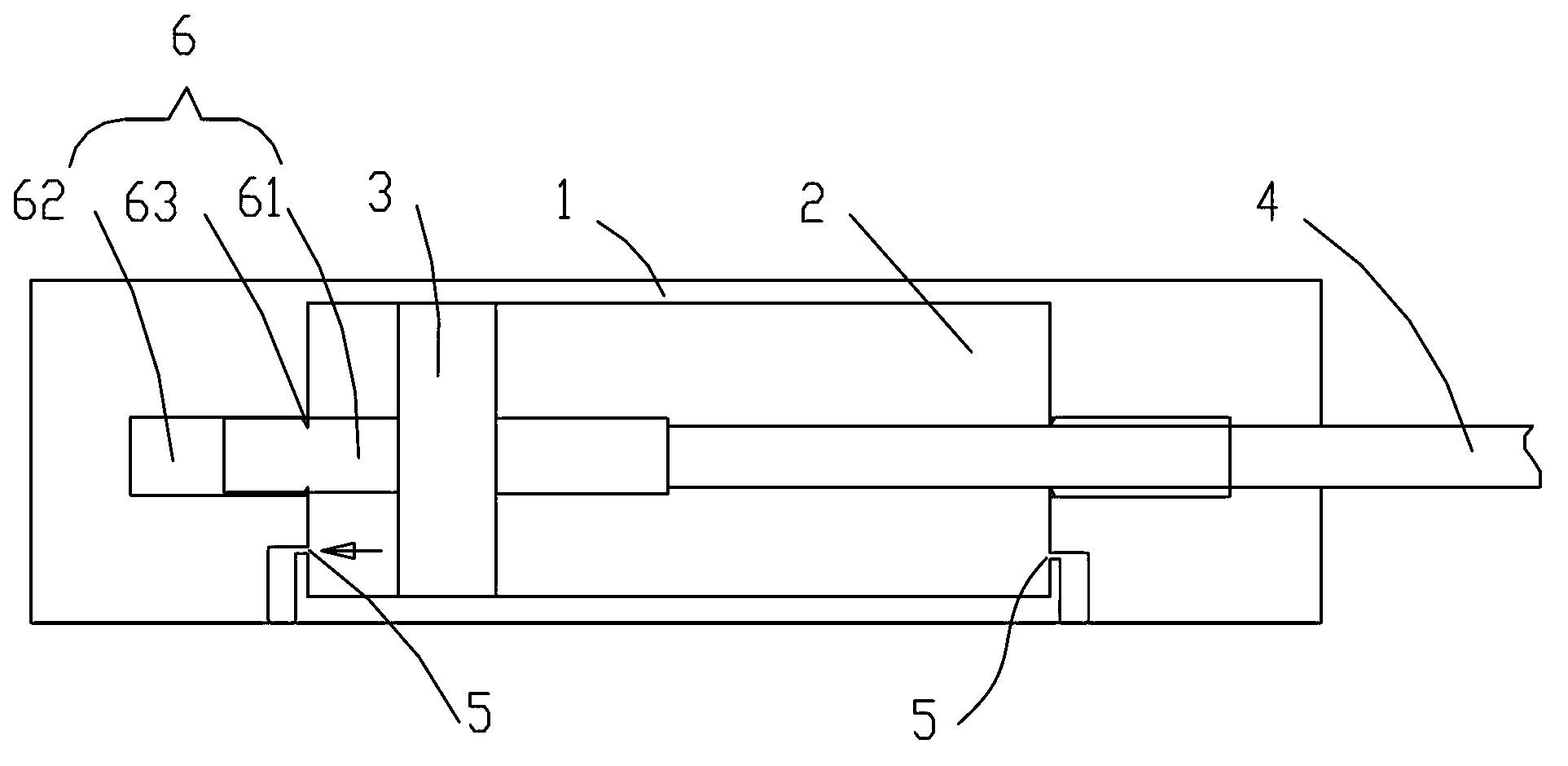

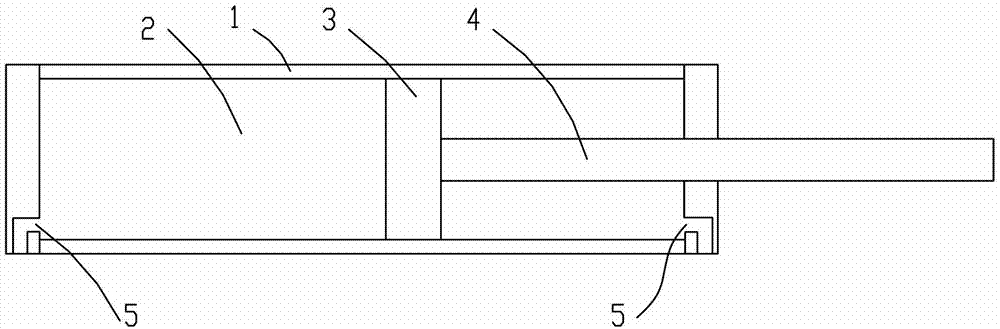

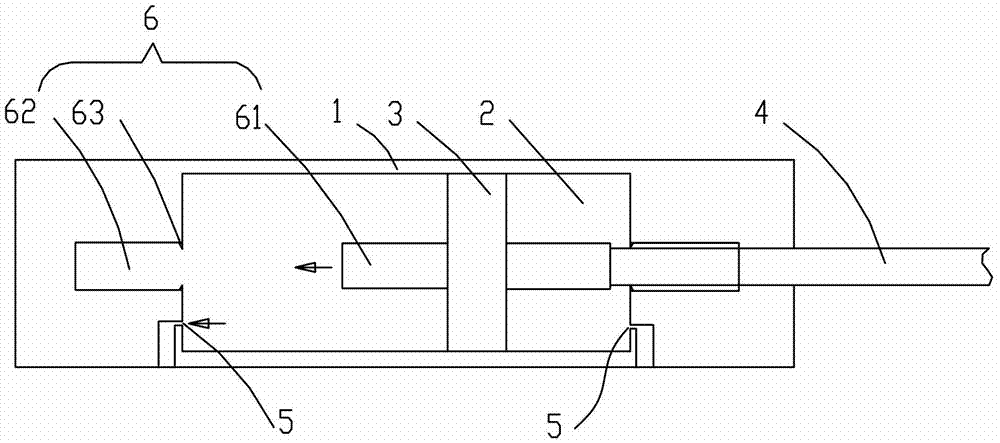

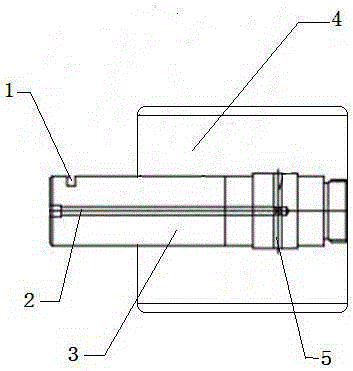

Air cylinder

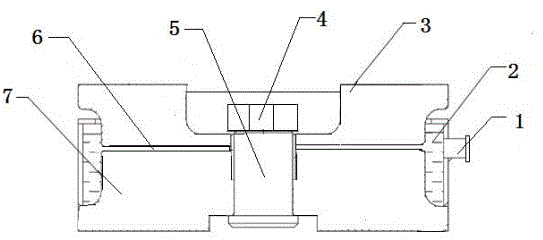

ActiveCN102852895AReduce vibrationImprove stabilityFluid-pressure actuatorsEngineeringAtmospheric pressure

The invention belongs to the field of air pressure driving and particularly relates to an air cylinder. The air cylinder comprises a cylinder body, a main cavity, a piston and a piston rod, wherein air inlets and air outlets are respectively formed in two ends of the cylinder body; an anti-collision structure is arranged on the air cylinder and comprises a buffer rod; the buffer rod is arranged on the piston; an accommodation hole corresponding to the buffer rod is formed in the cylinder body; and a first sealing ring for sealing a clearance between the buffer rod and the accommodation hole is arranged at the accommodation hole. The anti-collision structure disclosed by the invention has a flexible buffer function without generating hard impact, so that the air cylinder is small in vibration and high in stability; the air cylinder can be used for conveying vibration-sensitive articles; the application range is widened; and in addition, the mechanical damage to the air cylinder is reduced and the wear and the deformation are reduced, and thus the service life of the air cylinder is prolonged.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

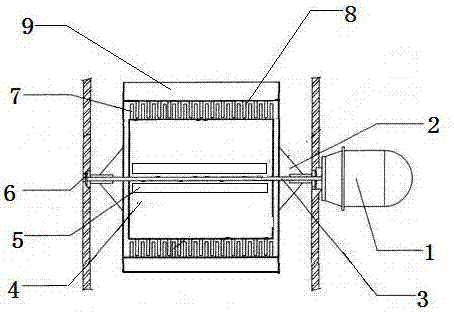

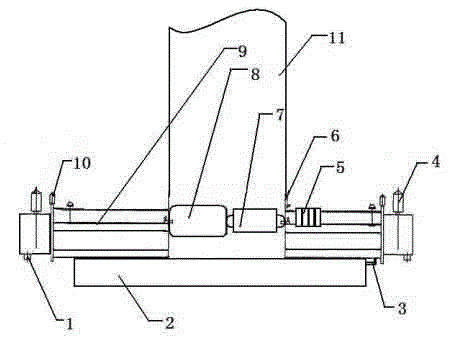

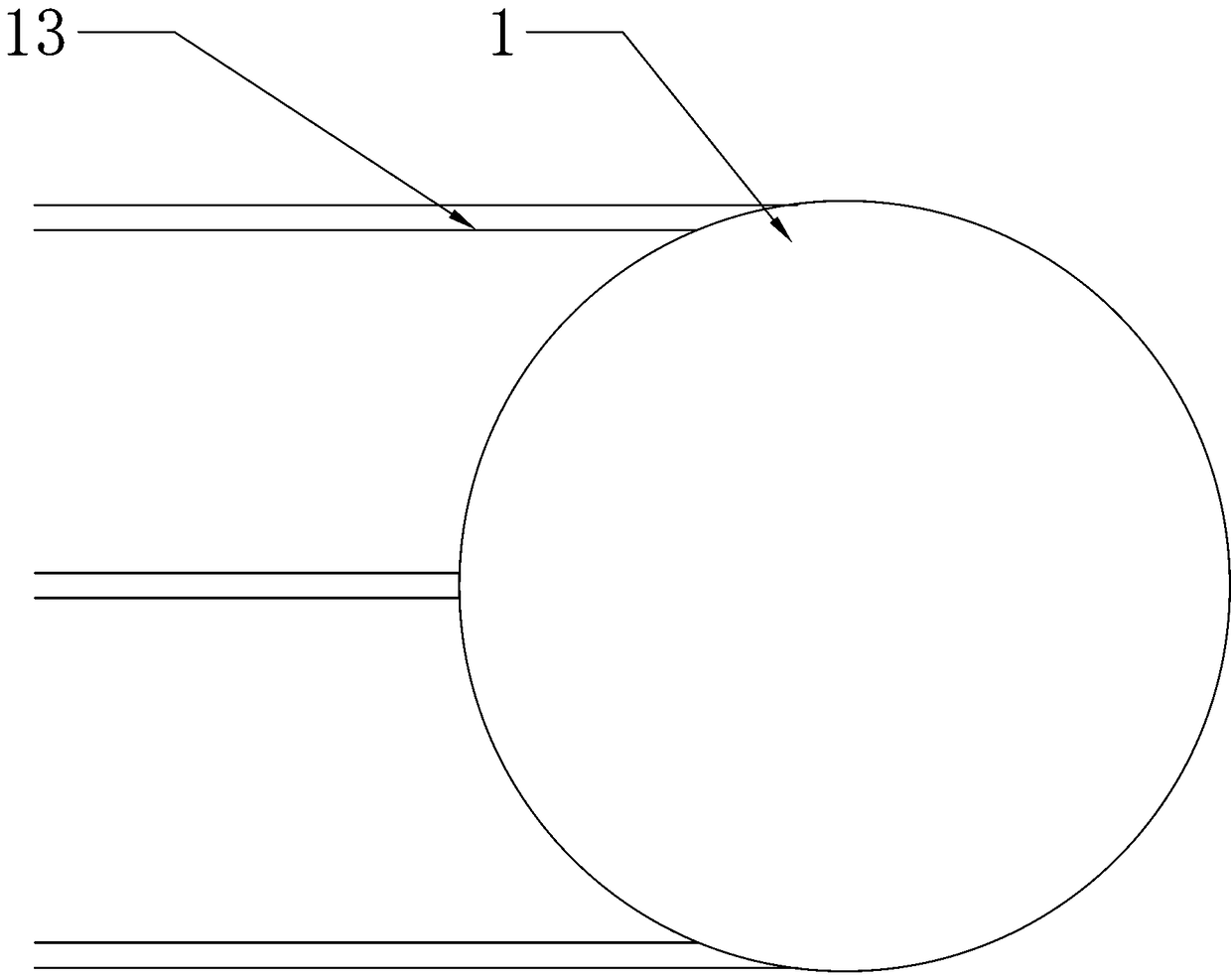

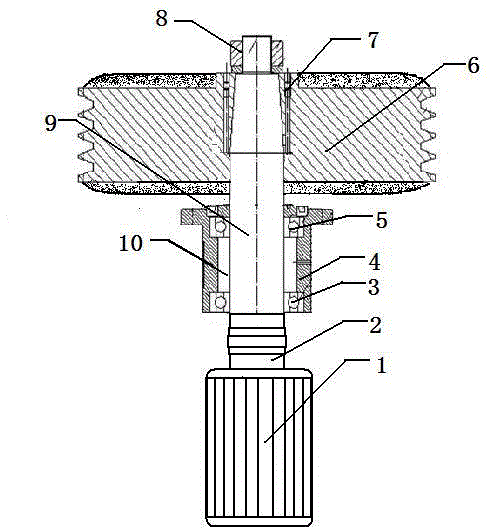

Tensioning device of underwater diamond wire saw

InactiveCN103692016ANo wearNo hard impactMetal sawing devicesStone-like material working toolsDiamond wire sawEnergy loss

The invention discloses a tensioning device of an underwater diamond wire saw. The tensioning device comprises a support and a tensioning wheel. The tension device is characterized in that a tensioning mechanism comprises a left support and a right support, wherein the left support is fixed on the support, the right support is arranged on the support and slides relative to a left seat body, a drive disk is arranged on the end face of the left support, and a first magnet is arranged on the end face of the drive disk; a fixed disk, which corresponds to the drive disk, is arranged on one end of the right support, a corresponding second magnet is arranged on the end face of the fixed disk, a tensioning wheel shaft and the tensioning wheel are arranged on the other end of the right support, when the drive disk rotates, the first magnet rotates, the first magnet and the second magnet generate repulsive force and suction, so that the fixed disk and the tensioning wheel can move back and forth relative to the drive disk, thus the tensioning wheel is horizontally moved to realize tensioning adjustment of a beading strand. By adopting the magnetic tensioning mechanism, in comparison with the conventional mechanical tensioning mechanism, the tensioning device has no energy loss generated by the friction, the vibration and the noise are greatly reduced, and the tensioning device has the advantages of long service life of parts, capability of saving lubricant oil and quick adjustment.

Owner:ZHEJIANG OCEAN UNIV

Air cylinder

ActiveCN102852895BReduce vibrationImprove stabilityFluid-pressure actuatorsEngineeringAtmospheric pressure

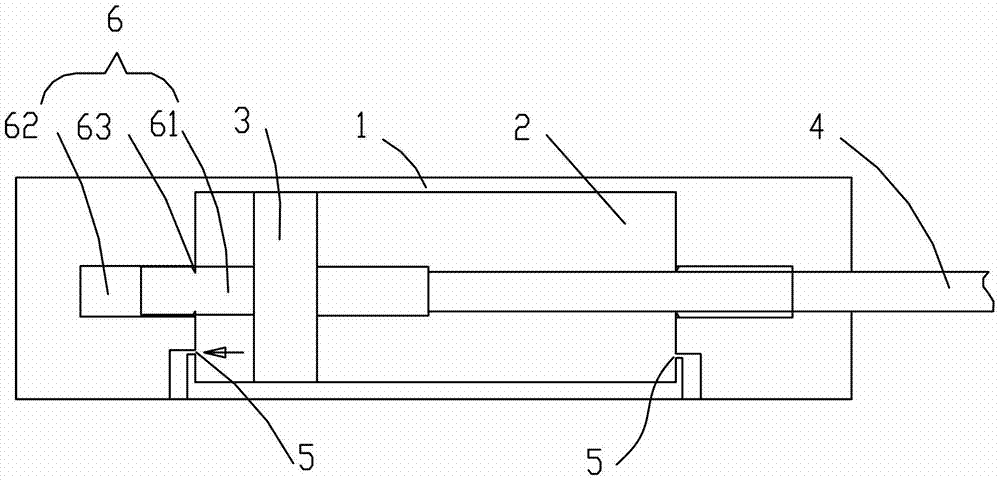

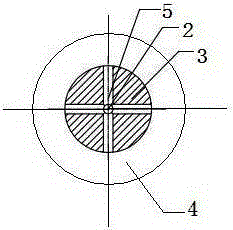

An air cylinder, the air cylinder comprising a cylinder body (1), a main cavity (2), a piston (3) and a piston rod (4), wherein air inlets and air outlets (5) are respectively formed in two ends of the cylinder body (1), an anti-collision structure (6) is arranged on the air cylinder and comprises a buffer rod (61), the buffer rod (61) is arranged on the piston (3), an accommodation hole corresponding to the buffer rod (61) is formed in the cylinder body (1), and a first sealing ring (63) for sealing a clearance between the buffer rod (61) and the accommodation hole (62) is arranged at the accommodation hole (62). The anti-collision structure has a flexible buffer function without generating hard impact, so that the air cylinder is small in vibration and high in stability.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Agricultural land leveler scraping device

ActiveCN112449769APlay a role of buffer protectionNo hard impactSoil-working equipmentsAgricultural landAgricultural engineering

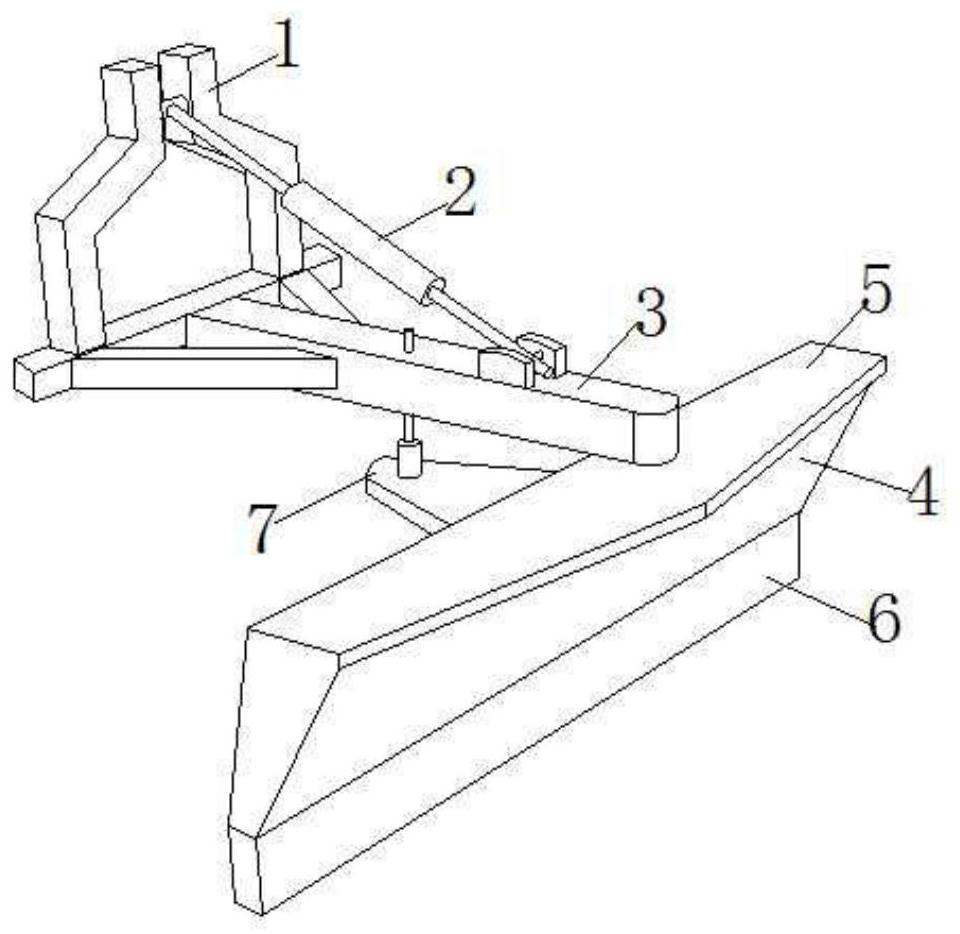

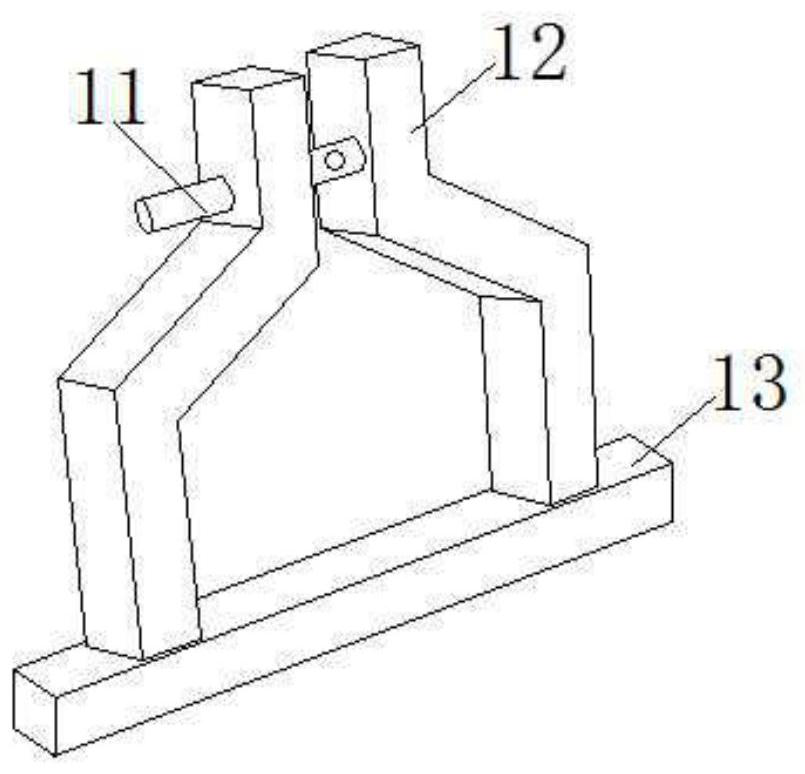

The invention discloses an agricultural land leveler scraping device. The device comprises a transmission frame and a mounting frame arranged on the upper side of one end of the transmission frame. One end of an adjusting frame is hinged to the mounting frame. A lifting adjusting frame is arranged on the lower side of one end of the transmission frame. A top plate is arranged at one end deviatingfrom the mounting frame. A pushing frame is arranged below the top plate. A scraper is arranged on the lower side of the pushing frame in the length direction. The pushing frame comprises a top plateand a side plate, and the adjusting frame is arranged on the side wall of the side plate. The scraper comprises a third shell, and a mounting plate is cuboid-shaped. A rolling part is arranged at thelower portion of the third shell. A strickling piece is fixed on one side of the third shell. The top plate comprises a second frame, and a spring plate is arranged in a second mounting groove. A locking piece is screwed on the upper side of the second frame. The lifting adjusting frame comprises a bottom plate and a mounting pipe. A lifting rod is screwed in the mounting pipe along the axial direction of the mounting pipe. A cross beam is fixed on the side wall of the bottom plate. An auxiliary fixing block is arranged on the lower side of the bottom plate. The agricultural land leveler scraping device is capable of buffering.

Owner:义乌市龙川农业开发有限公司

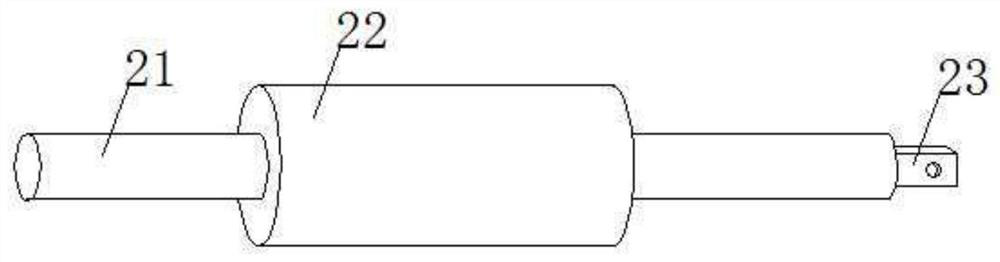

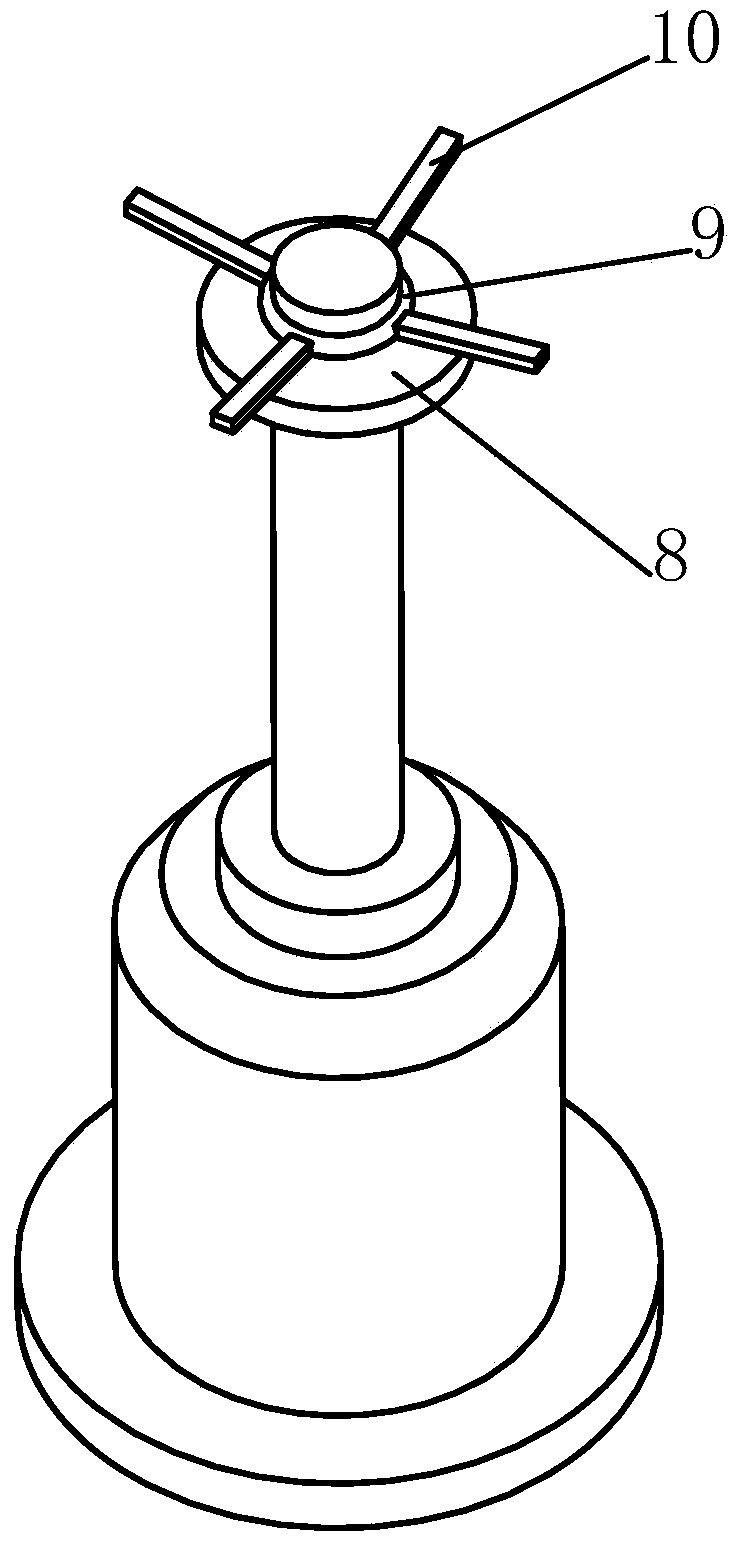

Tensioning device of underwater diamond wire sawing machine

InactiveCN103692017ANo wearNo hard impactMetal sawing devicesStone-like material working toolsDiamond wire sawDrive shaft

The invention relates to a tensioning device of an underwater diamond wire sawing machine. The tensioning device comprises a bracket, a tension pulley and a tensioning mechanism which is mounted on the bracket, and is characterized in that the tensioning mechanism comprises a support seat, a fixing disc and a driving disc are coaxially arranged in the internal cavity of the bracket, the fixing disc is fixedly connected with the bracket, a driving shaft penetrates through the center hole of the fixing disc and is connected with one end of the driving disc, the other end of the driving disc penetrates through the support seat and is connected with a tension pulley seat, two permanent magnets are respectively arranged on opposite end faces of the fixing disc and the driving disc, when the driving disc rotates under the drive of the driving shaft, the two magnets generate a repulsion force and an attraction force, the driving disc moves forwards and backwards relative to the fixing disc, and the tension pulley seat is driven to move forwards and backwards, so that the tension pulley moves leftwards and rightwards, and the tension regulation on a beaded rope is realized. According to the tensioning device, due to the adoption of the magnetic tensioning mechanism, the energy loss resulting from friction does not exist, and the vibration and noise can be reduced greatly, so that the tensioning device has the advantages of long part service life, lubricating oil saving and rapidity in regulation.

Owner:ZHEJIANG OCEAN UNIV

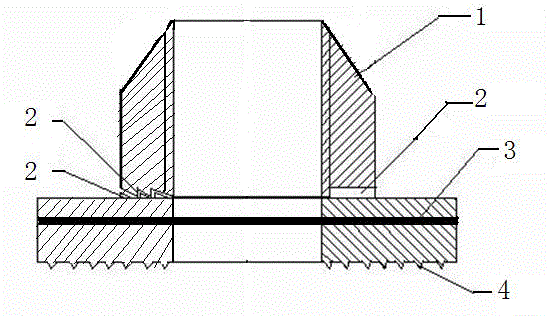

Core disc structure for connecting locomotive and steering frame

InactiveCN105270426AImprove transmission efficiencyNo hard impactBogie-underframe connectionsBogieEngineering

A core disc structure for connecting a locomotive and a steering frame is characterized by comprising oil openings, lubricant grooves, an upper core disc body, a nut, a stud shaft, lubricating gaps and a lower disc body, wherein the core disc structure is provided with the upper core disc body and the lower core disc body, the nut is arranged in the center of the upper core disc body, and the lubricating gaps are formed in the upper core disc body and the lower core disc body; the contact planes of the core disc bodies are planes so that wear can be lowered; the vertical stud shaft is arranged between the upper core disc body and the lower core disc body to connect the upper core disc body and the lower core disc body in series; the lower end of a bolt is welded to the lower core disc body in a sealed manner, and the upper end of the bolt is connected with the upper core disc body through the nut; stators of the stud shaft are fixedly welded to the core disc bodies, a rotor of the stud shaft is in transmission connection with the nut in the upper core disc body, and the lubricant grooves are formed in the two sides of the core disc structure and provided with the oil openings. The core disc structure for connecting the locomotive and the steering frame has the beneficial effects that transmission efficiency is high, no energy loss generated by friction exists, no hard impact among parts exists, the service life of the parts is long, lubricating oil is saved, no dust or noise is generated in the movement process, and bearing capacity is high.

Owner:杨海龙

Anti-loose mechanical device

An anti-loose mechanical device is characterized by comprising a nut, sawteeth, a flange gasket and triangular teeth. The outer portion of the nut is hexagonal, and threads are arranged inside the nut; the sawteeth are arranged at the bottom of the nut, and the sawteeth arranged at the bottom of the nut are correspondingly connected with the sawteeth on the flange gasket; the flange gasket is in a disc shape, and a round hole is formed in the center of the flange gasket; the sawteeth are arranged on the upper portion, corresponding to the sawteeth at the bottom of the nut, of the flange gasket; and the triangular teeth are arranged at the bottom of the flange gasket. The helical tooth face of the nut and the helical tooth face of the flange gasket can only rotate in the forward direction, and when the helical tooth face of the nut and the helical tooth face of the flange gasket rotate inversely, the helical tooth face of the nut and the helical tooth face of the flange gasket are locked mutually. The anti-loose mechanical device has the advantages of being good in anti-loose antitheft effect, simple in design, easy to manufacture and low in cost.

Owner:周家欣

Automatic feeding and discharging device

InactiveCN106475511ASimple structureImprove transmission efficiencyMetal chainsElectric machineryEngineering

The invention discloses an automatic feeding and discharging device. The automatic feeding and discharging device is characterized by comprising a screw rod, a numerically-controlled drive device, a feeding device, a manipulator A, a manipulator B and a discharging device, wherein the screw rod penetrates through the numerically-controlled drive device, a numerically-controlled motor or a servo motor can be installed inside the numerically-controlled drive device, the feeding device is arranged below the screw rod and on the left side of the numerically-controlled drive device, the discharging device is arranged on the right side, the manipulator A is arranged at a feeding port of the feeding device, and the manipulator B is arranged at a discharging port of the discharging device. The automatic feeding and discharging device has the advantages that the structure is simple and reasonable, the transmission efficiency is high, the friction energy loss is small, rigid impact is prevented from being generated between parts, the service life of the parts is long, the operating environment is good, the occupied space is reduced, the machining cost is lowered, mechanized and automatic operation is realized, and the labor intensity is lowered.

Owner:陈洪厚

Large-size rotatable machine tool equipment used for machining special workpieces

The invention discloses large-size rotatable machine tool equipment used for machining special workpieces. The large-size rotatable machine tool equipment used for machining the special workpieces is characterized by comprising a cutter head, a base plate, a horizontal limit switch, horizontal cutter head motors, a balancing weight, a vertical limit switch, a speed limiter, a motor, a cross beam, vertical cutter head motors and a vertical beam, wherein the cross beam penetrates the vertical beam; the base plate is arranged at the lower end of the vertical beam; machining devices are arranged at the two ends of the cross beam; the machining devices are composed of the horizontal cutter head motors, the vertical cutter head motors and the cutter head; an electric appliance box is arranged on the vertical beam and internally provided with the motor and the speed limiter connected with the motor; the cross beam is sleeved with the balancing weight; the horizontal limit switch is arranged on the base plate; and the vertical limit switch is arranged on the vertical beam. The large-size rotatable machine tool equipment for machining the special workpieces has the beneficial effects that transmission efficiency is high, energy loss generated due to friction is avoided, rigid impact among parts cannot be generated, the parts are long in service life, no dust or noise is generated in the moving process, the structure is reasonable, the machined workpieces are high in quality, and work efficiency is high.

Owner:田玥

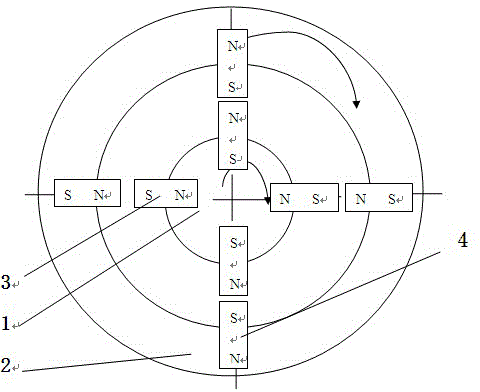

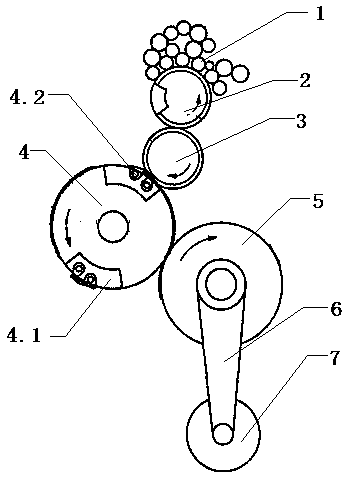

Device of using electromagnetism to sense rotation motion of starting machines

InactiveCN104421399AHigh transmission efficiencyNo energy lossDynamo-electric brakes/clutchesGearingEnergy lossElectromagnetic induction

The invention discloses a device for using electromagnetism to sense rotation motion of starting machines. The device for using the electromagnetism to sense the rotation motion of the starting machines is characterized by comprising a drive wheel and a driven wheel, wherein a plurality of drive wheel magnets are evenly arranged on the circumference of the drive wheel, a plurality of driven wheel magnets are evenly arranged on the circumference of the driven wheel, the drive wheel drives the driven wheel to rotate, at least one drive wheel magnet on the drive wheel is corresponding to the driven wheel magnets on the driven wheel, and the at least one drive wheel magnet and the corresponding driven wheel magnets are opposite in polarity. The device for using the electromagnetism to sense the rotation motion of the starting machines has the advantages that transmission efficiency is high, no energy loss is caused by friction, no rigid impact can be generated among the parts, the parts are long in use life, lubricating oil is saved, and no dust and no noise can be generated during the moving process.

Owner:李晓巍

Cutting component

InactiveCN105500427AImprove transmission efficiencyNo hard impactMetal working apparatusDrive shaftCoupling

The invention discloses a cutting component. The cutting component is characterized by comprising a cutting motor, a first coupling, a first roller, a second coupling, a second roller, a transmission shaft and a disc cutting saw, wherein the cutting motor is arranged at the upper end of the device; a power output end of the cutting motor is connected with the first coupling; the first coupling coats the center of the first roller; the first roller is engaged with the second roller in an exterior contact manner; the second coupling is arranged in the center of the second roller; an output end of the second coupling is connected with the transmission shaft at the lower end; and the disc cutting saw is mounted at the other end of the transmission shaft. The cutting component has the advantages of high transmission efficiency, no energy loss caused by friction, no hard collision among parts, long service life of the parts, saving of lubricating oil, no dust and noise in the movement process and improvement of productivity.

Owner:贾雪松

Sac dispersing device

InactiveCN109393531AReduce breakage rateIncrease water pressureFood treatmentWater flowPulp and paper industry

The invention relates to a sac dispersing device. The sac dispersing device comprises a tank body, wherein the inner part of the tank body is divided into a working area and a stirring area through anarc-shaped filtering partition board; water inlets are formed in two sides of a side wall at one side of the working area along tangential directions and formed in the middle part of the side wall atthe same side of the working area, and are connected with a first pipeline, a pump body and a hot water tank through branch pipes; the lower end of the stirring area is connected with a precipitatingtank through a second pipeline; the precipitating tank is connected with the hot water tank; a third pipeline is arranged on a branch path of the first pipeline; an air compressor is mounted on the third pipeline; and a rotating auger is arranged in the stirring area, and the rotating auger is driven by a driving device to rotate. According to the sac dispersing device provided by the invention,up-and-down water current circulation impact is carried out to disperse materials, so that the dispersing integration rate of sacs is increased.

Owner:ZIGUI COUNTY QUGU FOOD

Novel multi-oil-passage lubrication gear

InactiveCN106594232AImprove transmission efficiencyNo energy lossGear lubrication/coolingPortable liftingEngineeringLubrication

The invention provides a novel multi-oil-passage lubrication gear. The novel multi-oil-passage lubrication gear is characterized in that the novel multi-oil-passage lubrication gear comprises a mounting clamping groove, a transverse oil passage, a gear shaft, a gear body and a plurality of longitudinal oil passages, wherein the mounting clamping groove is formed in the power output end of the gear shaft; the gear shaft and the gear body are mounted in a transmission mode; an oil cavity is formed in the mounting joint and communicates with the oil passages in the gear shaft which is provided with the transverse oil passage and the longitudinal passages; the transverse oil passage is formed in the center axis of the gear shaft; and the longitudinal oil passages are formed in the positions perpendicular to the transverse oil passage and communicate with the transverse oil passage. The novel multi-oil-passage lubrication gear has the advantages that the novel multi-oil-passage lubrication gear is high in transmission efficiency, free of energy loss generated by friction or hard impact generated between parts, and long in part service life, good in lubrication effect and long in service life, and saves lubricating oil.

Owner:严云成

Dynamic intermittent running speed reducer

InactiveCN100458216CCompact structureGuaranteed uptimeToothed gearingsAutomatic controlReduction drive

Owner:NINGBO DONLY CO LTD

Lathe tool carrier structure for special machine tool

A lathe tool carrier structure for a special machine tool is characterized by comprising a lathe tool assembly mounting board, a rotary disc, a tool apron, a lathe tool clamping groove, a lathe tool and lock plungers. The lathe tool carrier structure comprises the lathe tool assembly mounting board, as well as the tool apron and the lathe tool which are mounted on the lathe tool assembly mounting board, wherein the tool apron is mounted on the rotary disc which rotates in the circumferential direction; the rotary disc is externally connected to a power device; the lathe tool is fixed in the tool apron through the lock plungers; and the lathe tool clamping groove allowing the lathe tool to be mounted therein is formed in the tool apron. The lathe tool carrier structure has the following advantages: the structure is simple, the design is reasonable, the locking effect is good, parts have low probability of looseness, are prevented from rigid impact and are long in service life and a lubricant is saved.

Owner:乐建军

A manual assembly machine for plastic pipe assembly

The invention relates to a manual assembly machine of a plastic pipeline assembly. The manual assembly machine of the plastic pipeline assembly comprises an assembly machine body. A plurality of groups of clamp bodies and a plurality of regulating components are arranged on the assembly machine body, wherein the clamp bodies are used for clamping objects to be assembled and the regulating components are matched with the clamp bodies. The regulating components are used for regulating the clamp force and assembling travel distance of the clamp bodies. A pipe groove and a positioning and flaring component are further arranged on the assembly machine body, wherein the pipe groove is used for containing a flexible pipe and the positioning and flaring component is used for fixing a protruding length of the flexible pipe and achieving flaring. The positioning and flaring component is arranged on the lateral sides of the clamp bodies. When the manual assembly machine of the plastic pipeline assembly is used, a clamping block of a connector and a clamping block of the flexible pipe are fixed through a three-coordinate detector after a relative angle between the clamping block of the connector and the clamping block of the flexible pipe is well adjusted, and assembling is accurately achieved by enabling the clamping blocks to be clamped on the clamp bodies on the assembly machine when the assembling is carried out. In addition, the manual assembly machine of the plastic pipeline assembly has the advantages of being small in size, capable of being pushed away freely due to the fact that trundles are arranged on the bottom of the assembly machine, and free of noise in an operation process due to the fact that the whole assembly machine is designed to be free of rigid impact.

Owner:HEBEI CHINAUST AUTOMOTIVE PLASTICS CORP LTD

Electronic opening device capable of casually opening at multiple positions

InactiveCN102286822BNo hard impactReduce vibrationOther shedding mechanismRest positionControl system

The invention provides an electronic opening device capable of casually opening at multiple positions, which can make a large amount of openings and casually set an opening motion and rest position. The electronic opening device comprises a heald frame, a driving system, a control system, a transmission system, two steel wire ropes, guide wheels, and orienting guide wheels, wherein the control system is used for controlling the driving system; the transmission system is connected with the driving system; Four guide wheels are respectively fixed above and below the heald frame; one orienting guide wheel is further arranged adjacent to the inside of guide wheels of the transmission system; one end of one of the steel wire ropes is fixed on the transmission system, rounds the outside of the four upper and lower guide wheels of the heald frame, then rounds the orienting guide wheel; at last, the other end is also fixed on the transmission system; one end of the other steel wire rope is fixed on the transmission system, rounds the two guide wheels adjacent to one side of the transmission system, then rounds the orienting guide wheel; at last, the other end is also fixed on the transmission system; and the heald frame is fixed on two steel wire ropes inside the four guide wheels.

Owner:JINGWEI TEXTILE MASCH CO LTD

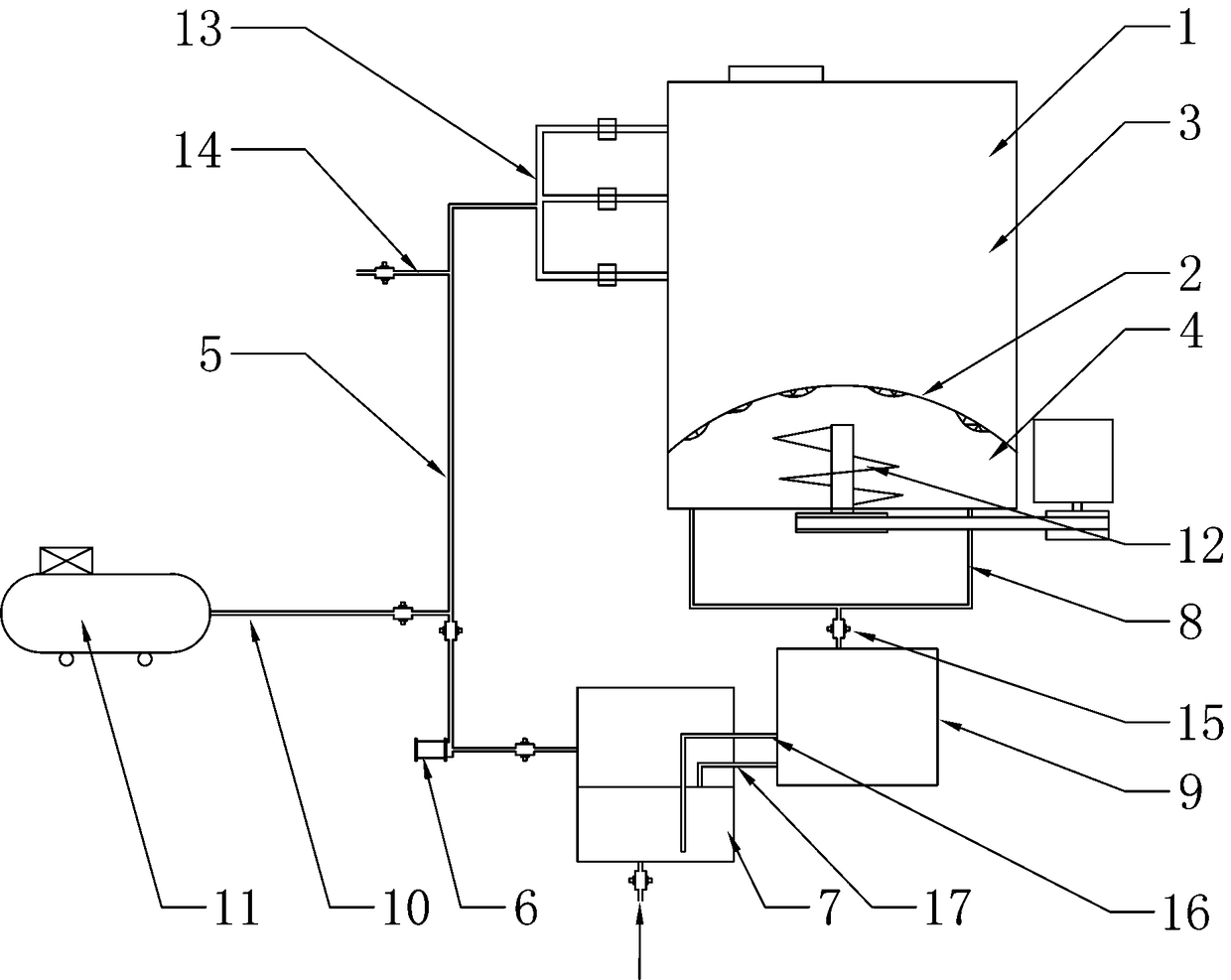

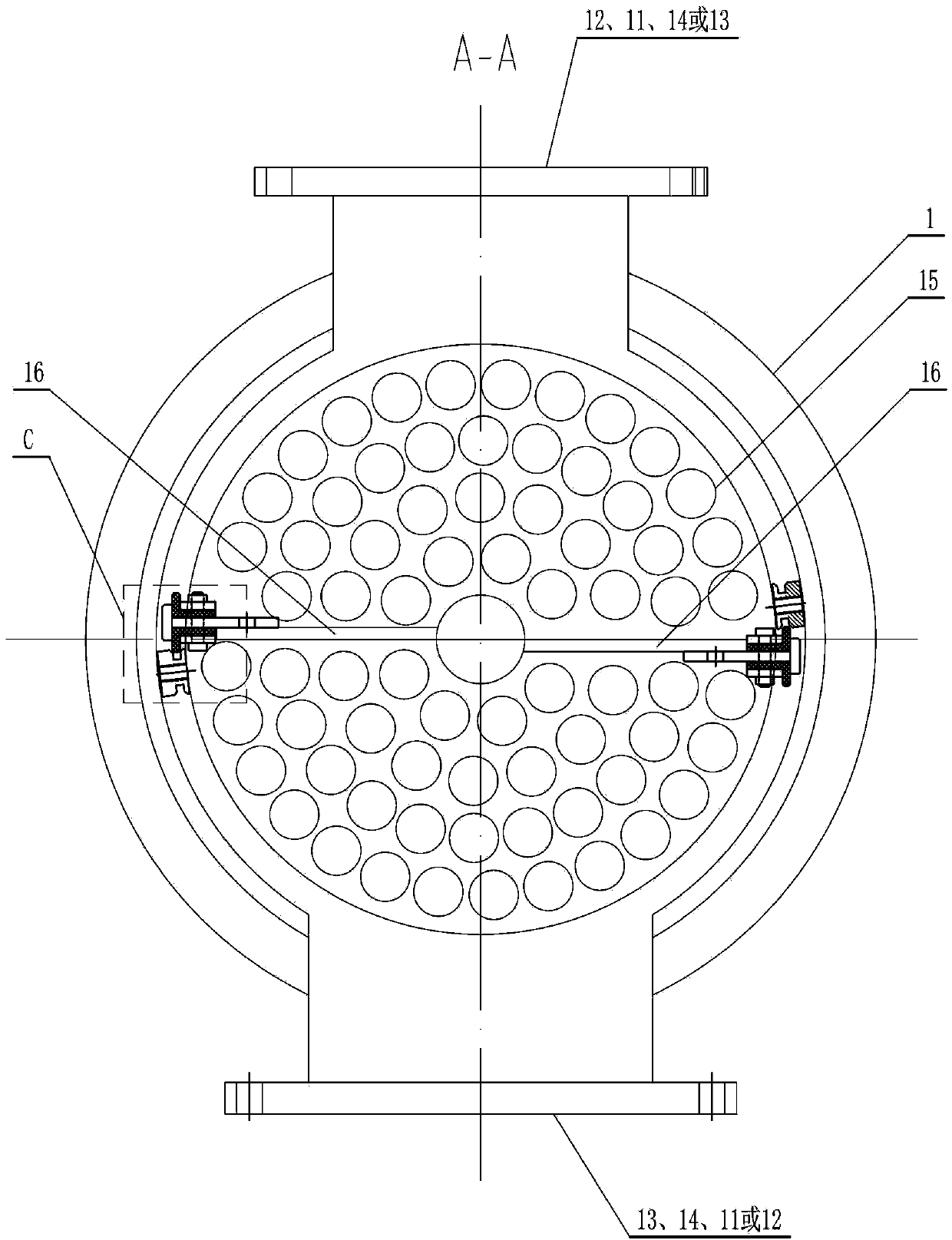

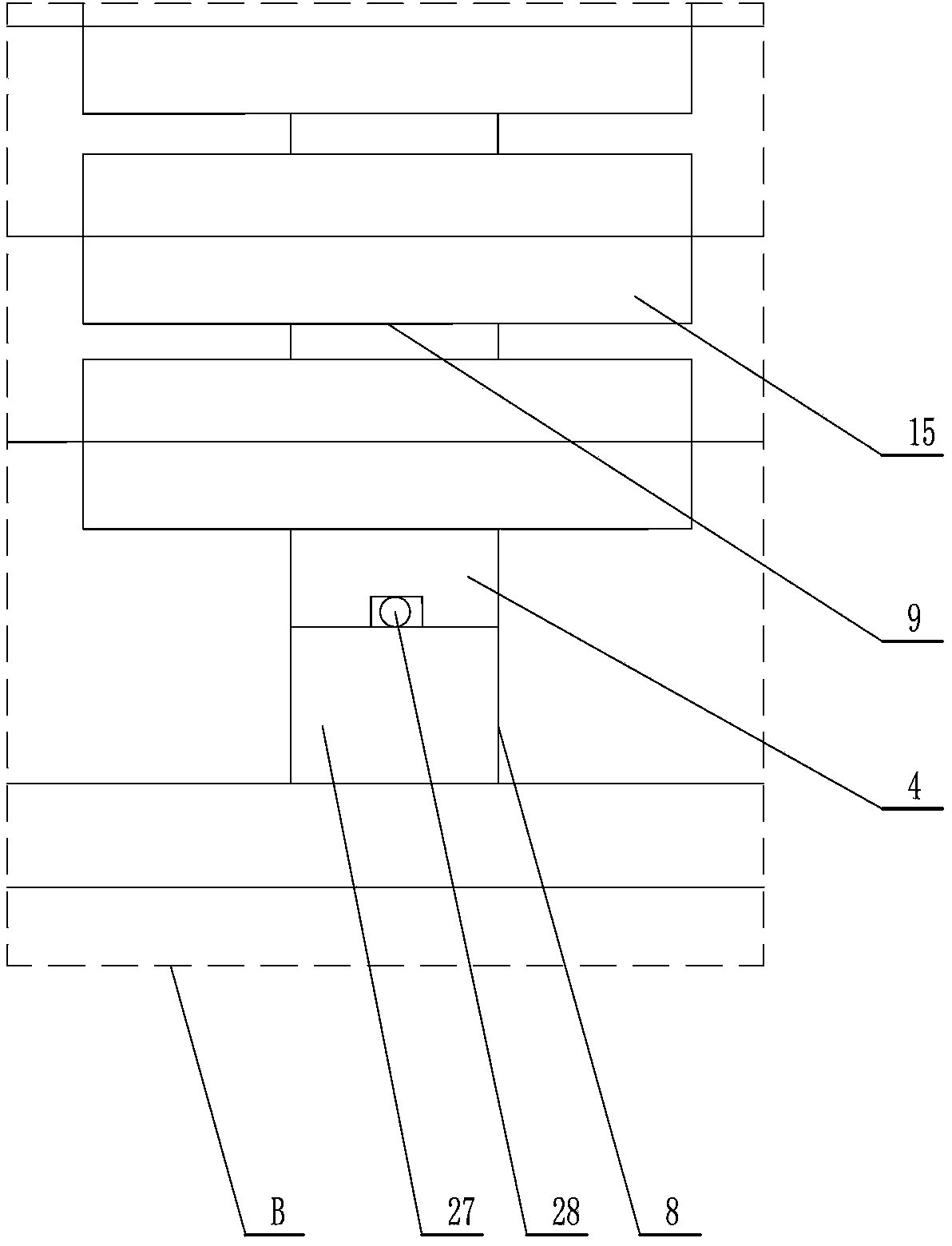

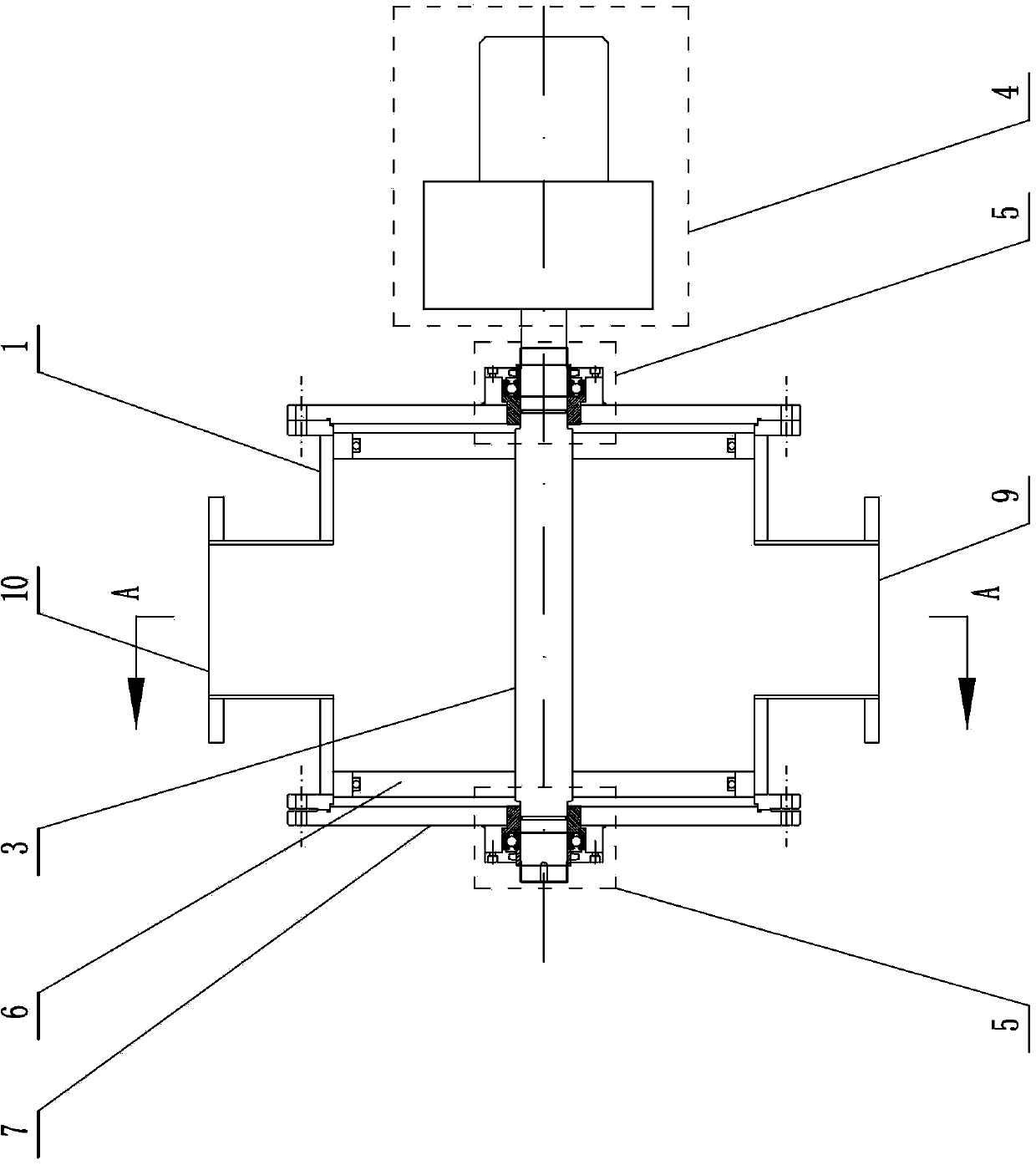

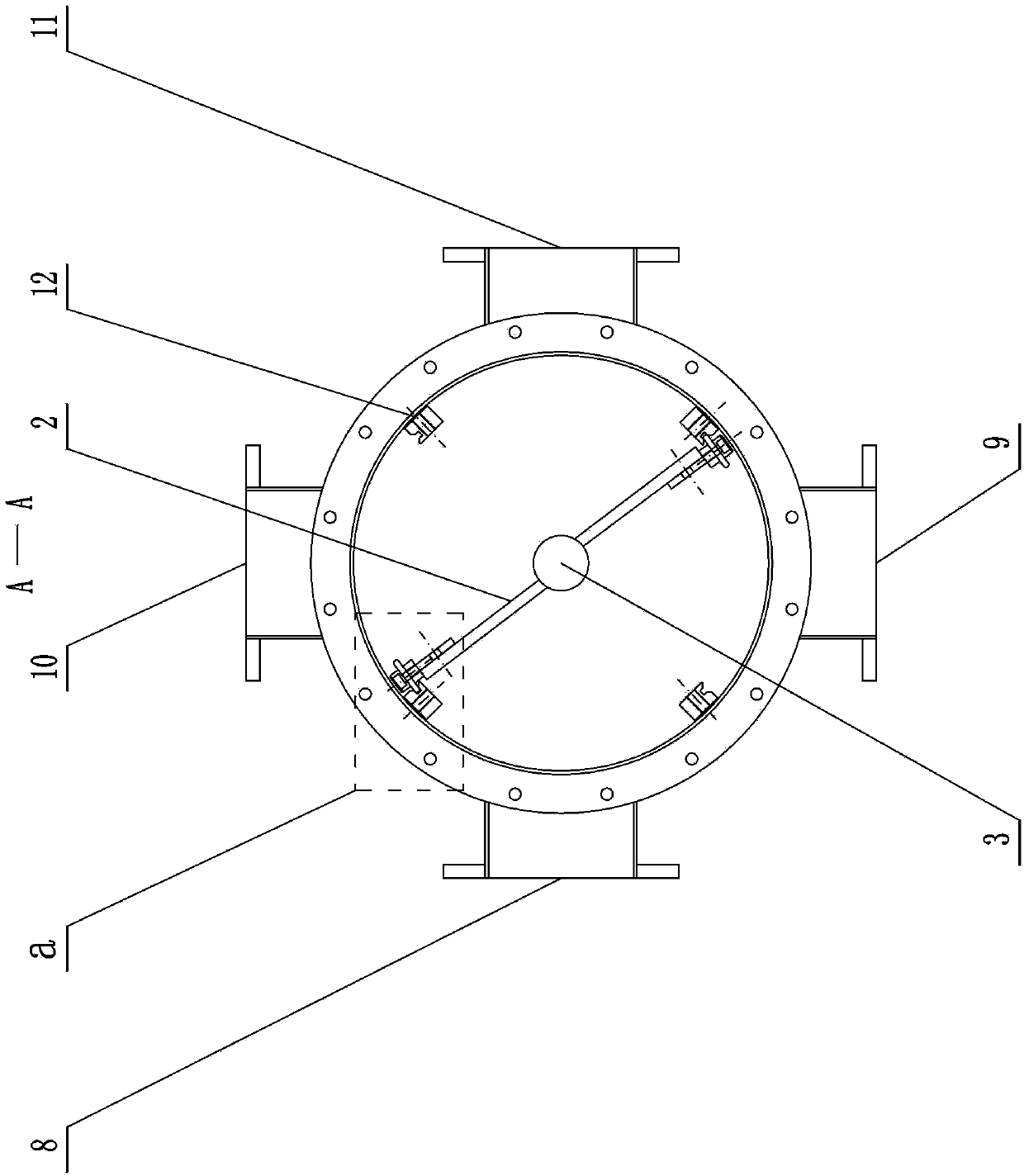

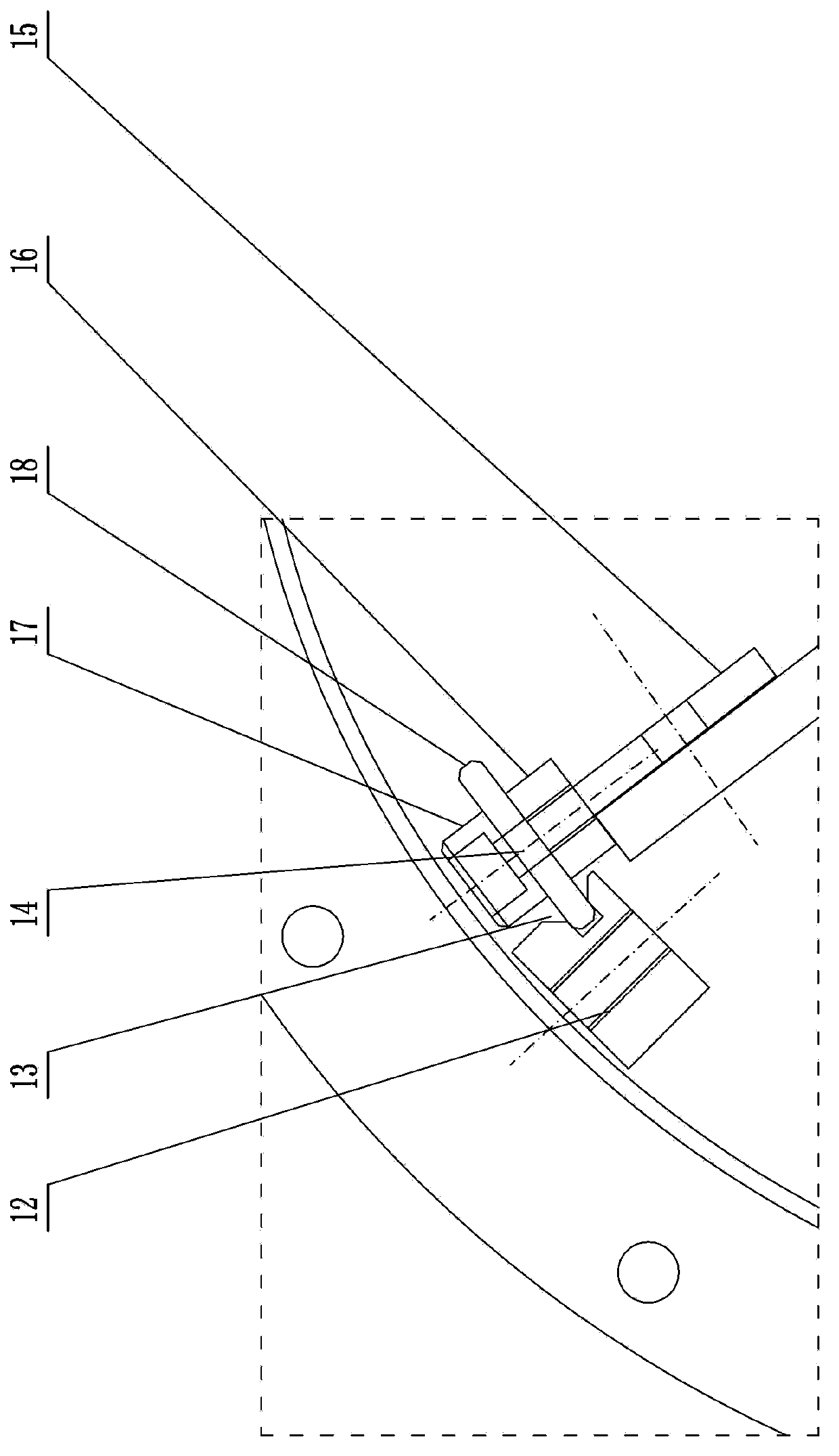

Rotating wheel type block prevention device for sewage or surface water source heat pump system

ActiveCN103028288BThe overall structure is simple and reliableRegular maintenance and replacementHeat pumpsPipe elementsWater sourceEngineering

The invention discloses a rotating wheel type block prevention device for a sewage or surface water source heat pump system, and belongs to the technical field of energy sources. The rotating wheel type block prevention device solves the problems that heat-exchange equipment and a pipeline of the sewage or surface water source heat pump system are blocked, backflushing return water is mixed with inflow water, suspended matters are wound at a filter opening, and the sealing difficulty and the working accuracy difficulty are high in the existing block prevention device. The rotating wheel type block prevention device comprises a housing, a speed reduction driving mechanism, a rotating shaft, a rotating wheel filter disc and division plates, wherein the interior of the housing is divided into two chambers by the rotating wheel filter disk; the two chambers are communicated through a plurality of filter through holes; each chamber is divided into two non-communicated sewage or surface water chamber units in a direction parallel to an axis by each division plate; and four water openings are communicated with the four chamber units respectively. The rotating wheel type block prevention device is used for block prevention of sewage or surface water, and is simple and reliable in structure.

Owner:青岛科创蓝新能源股份有限公司

Storage box for receiving disk parts

The invention relates to a plate part receiving and storing box. The plate part receiving and storing box comprises a box body. The left and right sides of the front surface and the left and right sides of the rear surface of the box body are each provided with a vertical strip-shaped groove. A plurality of horizontal supporting plates are arranged in the box body. Clamping strips are evenly distributed on the periphery of the supporting plates and located in the corresponding strip-shaped grooves in the front surface and the rear surface of the box body. Through holes are formed in the centers of the supporting plates. A plurality of supporting pressing springs are evenly distributed on the lower end surface of each supporting plate. A vertical air cylinder is fixedly arranged at the bottom of the box body, and a shaft of the air cylinder penetrates through the through holes and is sleeved with a limiting ring. According to the plate part receiving and storing box, the supporting plates are isolated through the supporting pressing springs, claw-shaped carrying strips can be unfolded among the supporting plates, independent supporting of each layer of supporting plate is realized, it is guaranteed that hard impact does not occur among the supporting plates, and the supporting plates and the claw-shaped carrying strips are protected.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

Installation tool special for belt pulley in vertical lathe

InactiveCN105563412AHigh transmission efficiencyNo energy lossMetal-working hand toolsEnergy lossLeather belt

The invention relates to an installation tool special for a belt pulley in a vertical lathe. The installation tool special for the belt pulley in the vertical latheis characterized by comprising a motor, a reducer, a first bearing assembly, a bearing sleeve, a second bearing assembly, the belt pulley, a clamping device, a fastening device, a main shaft and an adjusting block; a driving device of the installation tool is the servo motor, a power output shaft of the motor is connected with the reducer and then connected with the main shaft, the main shaft is provided with the first bearing assembly and the second bearing assembly, and the bearing sleeve is arranged outside the bearing assemblies; and the adjusting block is arranged between the first bearing assembly and the second bearing assembly, a center shaft of the belt pulley is installed at the most front end of the main shaft, and the fastening device and the clamping device for clamping the belt pulley are arranged at the upper end of the main shaft. The installation tool special for the belt pulley in the vertical lathe has the beneficial effects that the transmission efficiency is high, energy losses generated by friction are avoided, hard impact cannot be generated between parts, the service life of the parts is long, dust and noise cannot be generated in the motion process, the structure is simple, design is reasonable, and rapid installation is achieved.

Owner:杜桐

Large-scale rotary press

The invention discloses a large-scale rotary press. The large-scale rotary press is characterized by comprising an ink feeding device, a plate cylinder, a transfer cylinder, an impression cylinder, channels, grabbing devices, a paper feeding roller, a chain wheel and a main driving wheel, wherein a roller of the ink feeding device is configured to the plate cylinder, the plate cylinder is meshed with the transfer cylinder in an external tangency mode, the transfer cylinder is meshed with the impression cylinder in an external tangency mode, the impression cylinder is meshed with the paper feeding roller in an external tangency mode, the paper feeding roller is in transmission connection with the main driving wheel through the chain wheel, the two channels for installing the grabbing devices are arranged on the impression cylinder, and the grabbing devices sink into the corresponding channels. The large-scale rotary press has the advantages that structure is simple, design is reasonable, transmission efficiency is high, no hard impact can be generated among parts, the service life of the parts is long, noise is low, and the transfer effect is good.

Owner:刘晓玉

Reversing device and reversing system for waste water heat exchange

ActiveCN103062441BImprove sealingNo leakageCorrosion preventionMultiple way valvesWater flowSuspended matter

The invention relates to a reversing device and a reversing system for waste water heat exchange, belongs to the technical field of energy resource and solves the problem about fouling generation in heat exchange equipment and blockage and twisting of suspended matters during heat exchange of waste water and the problems that a reversing device and a reversing system of the prior art are high in processing difficulty, high in accuracy requirements and poor in reliability, and a big valve cannot achieve the application purpose and the like. The reversing device comprises a casing, a valve plate, four limit slots, notches and a rubber head. Soft sealing is realized by the aid of the limit slots and the rubber head. The reversing system comprises the reversing device, heat exchange equipment, a first water return pipe and a second water return pipe. A speed reduction driving mechanism acts to drive a valve plate to act so as to change water flow direction in the heat exchange equipment for reverse flushing. The reversing device and the reversing system are used for water flow direction changing in waste water heat exchange and reverse flushing of the heat exchange equipment and have the advantages of simple structure and reliability.

Owner:西安水务集团新能源有限公司

Integral lifting scaffold force feedback anti-drop locking mechanism

InactiveCN103628665BDoes not prevent up and down movementSimple structural designBuilding support scaffoldsShortest distanceLocking mechanism

The invention discloses an overall hoisting scaffold force feedback type anti-dropping locking mechanism. A main shaft is sleeved outside a central rod; a spring is arranged between the central rod and the main shaft; a locking rotating wheel is sleeved on outer shaft sleeves of left and right swinging arms; outer teeth are arranged on the outer circumference of the main shaft; the outer teeth are meshed with inner teeth arranged on the inner cavity wall of the locking rotating wheel; the left and right swinging arms are connected with the main shaft; the left and right swinging arms can be driven to rotate when the main shaft rotates; transverse locking press blocks are arranged at the upper ends of the swinging arms; the locking press blocks are capable of pressing left and right guide channel steel; the locking rotating wheel is matched and connected with the main frame so as to limit the ascending and descending of the vertical main frame; the meshing state between the main shaft and the locking rotating wheel is cancelled through an unlocking device. The locking mechanism can automatically locks up when accidents happen no matter in static operation or hoisting operation, and the locking mechanism can immediately locks up within a very short time, so that a whole scaffold body can be immediately prevented from falling and can be stopped after sliding downwards for a very short distance, the security property is improved, and security accidents are prevented.

Owner:刘应杰

Coated pipe peeling machine

ActiveCN103056897BReduce labor intensityEven strengthMetal working apparatusReciprocating motionEngineering

The invention discloses a peeling device and a coated pipe peeling machine, and relates to the technical field of automobiles. Technical problems of poor consistency and low production efficiency of products in the prior art are solved. The peeling device comprises a cutting mechanism, a connecting seat and a peeling mechanism; the cutting mechanism is arranged on the connecting seat and comprises a cutter and a cutter driving mechanism, and the cutter driving mechanism can drive the cutter to at least cut a required-to-be-peeled skin coated on the peripheral surface of a pipe or a rod along the radial direction of the pipe or the rod; and the peeling mechanism is connected with the connecting seat and can drive the cutting mechanism via the connecting seat, so that the cutting mechanism can reciprocate along the axial direction of the pipe or the rod. The coated pipe peeling machine comprises the peeling device, the pipe is a coated pipe, and a chuck driving mechanism can drive a chuck to clamp or release the coated pipe. The peeling device and the coated pipe peeling machine are used for improving the consistency and the production efficiency of products.

Owner:HEBEI CHINAUST AUTOMOTIVE PLASTICS CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com