Integral lifting scaffold force feedback anti-drop locking mechanism

An integral lifting and locking mechanism technology, which is applied to the scaffolding supported by the building structure, building structure, building structure support, etc., can solve the problems of long anti-falling distance, mechanical jamming, hard impact, etc., and is beneficial to structural design , Locking and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

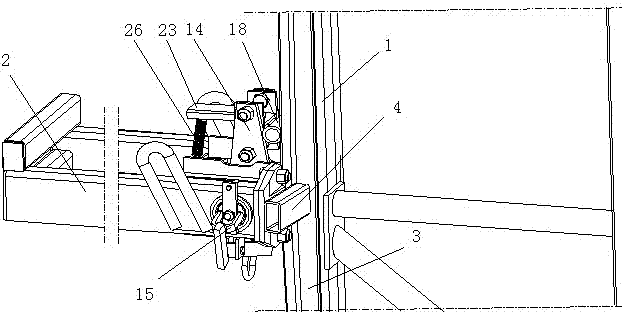

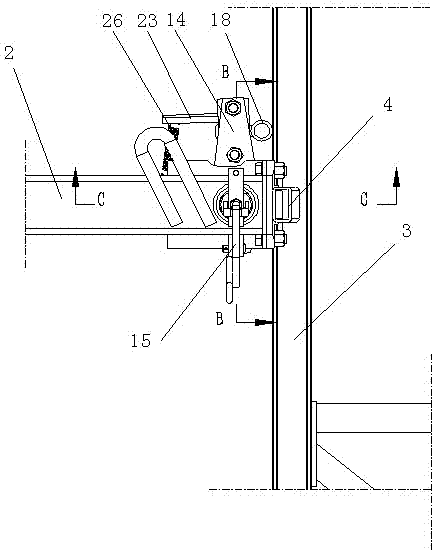

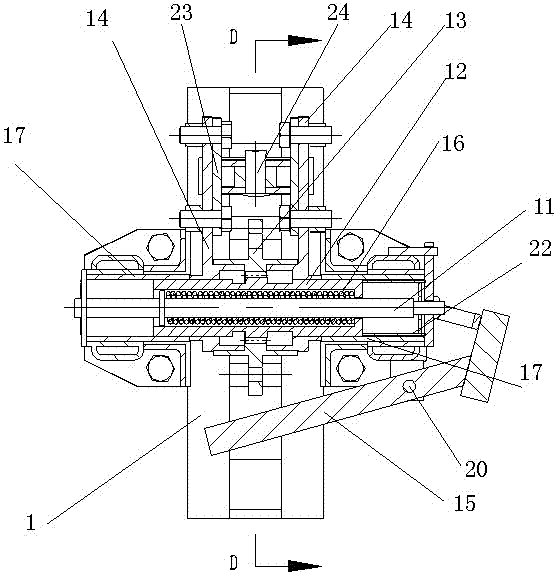

[0024] Such as figure 1 , 2 , 3, and 4, the force feedback type anti-drop locking mechanism of the overall lifting scaffold of the present invention is arranged on the wall-attached support 2 of the overall lifting scaffold, and is connected with the vertical main frame 1 of the overall lifting scaffold, and the overall lifting scaffold The vertical main frame 1 usually has two to three wall-attached supports 2 on the hanging point, which are fixed to the building through the wall-attached supports 2, and the left and right locking guide blocks 4 on the wall-attached supports 2 snap into the vertical In the grooves of the left and right guide channel steel 3 of the main frame 1, play the effect of guiding and sliding, and also compress the inboard of the channel steel 3 when the anti-drop is locked. The vertical main frame 1 and the wall-attached support 2 of the overall lifting scaffold are prior art and will not be further described here.

[0025] The force feedback type a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com