Rotating wheel type block prevention device for sewage or surface water source heat pump system

A surface water source heat pump and surface water technology, which is applied in the energy field, can solve the problems of difficult processing accuracy, blockage of heat exchange equipment and pipelines, mixing of recoil return water into water, etc., and achieves simple and reliable structure. The effect of motor and operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

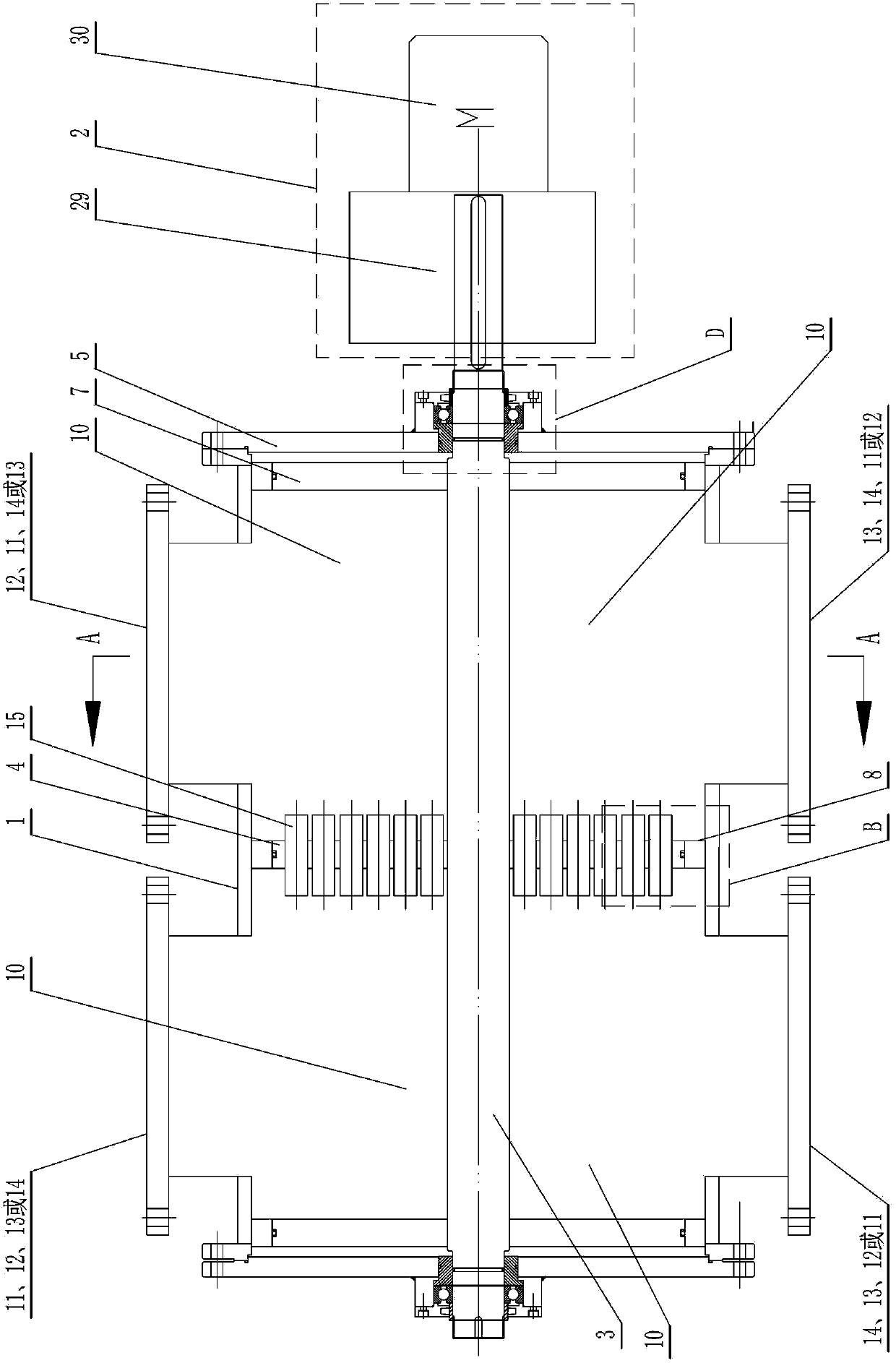

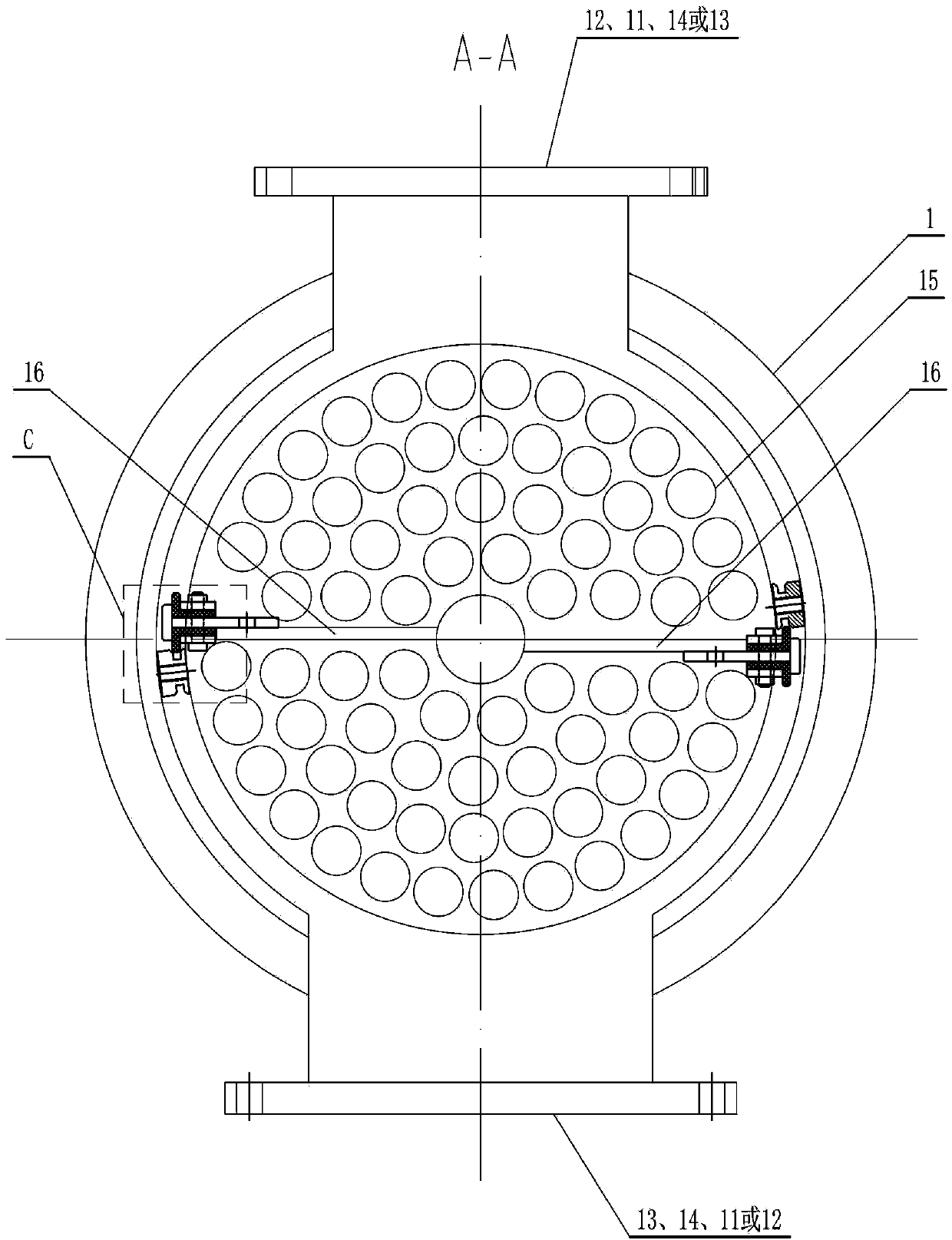

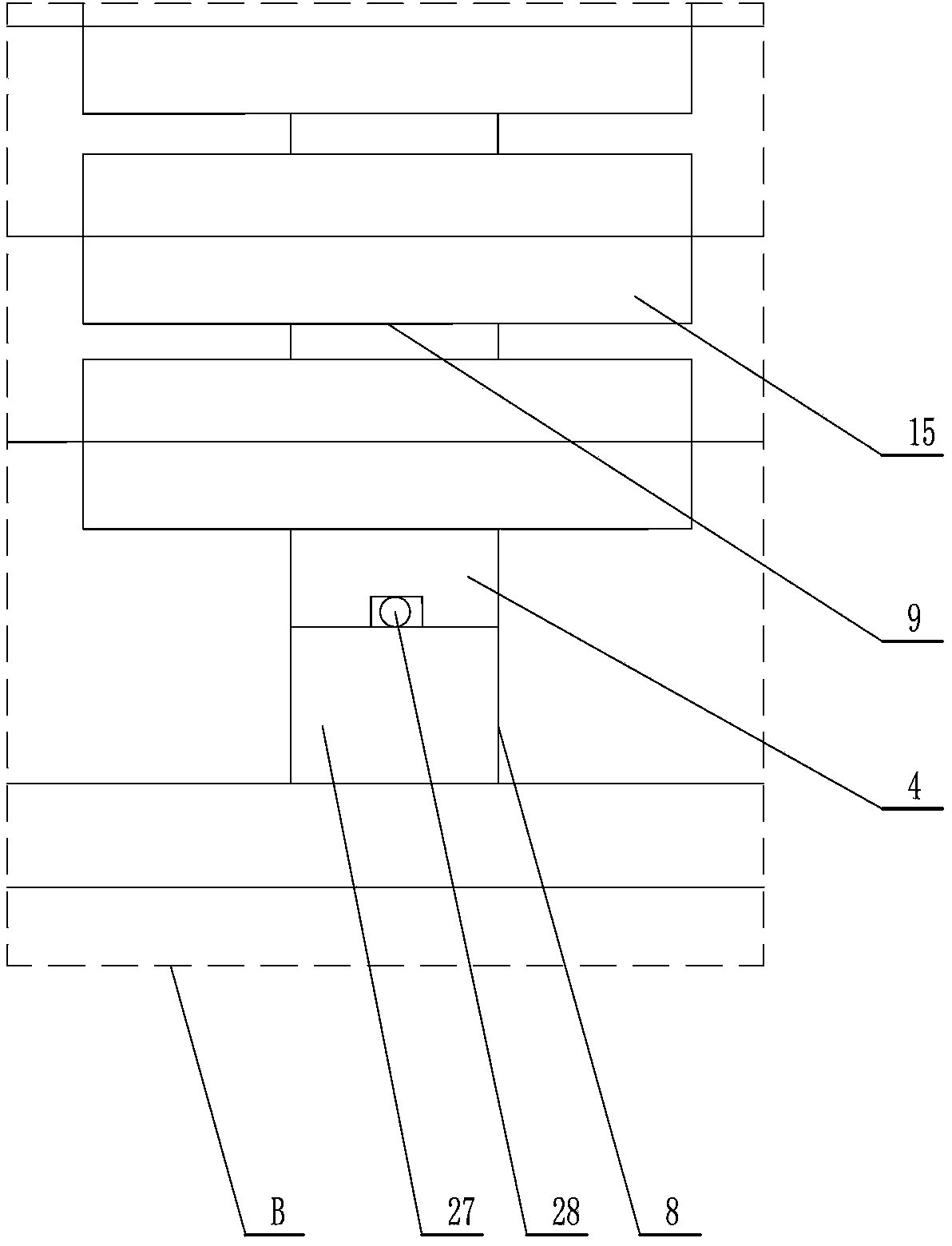

[0029] Specific implementation mode one: as Figure 1~Figure 3 and Figure 5As shown, the rotary wheel type anti-blocking device of the sewage or surface water source heat pump system in this embodiment includes a housing 1, a deceleration drive mechanism 2, a rotating shaft 3, a wheel filter plate 4, a method Blue plate 5, baffle plate 7, annular sealing device 8, partition plate 16, sewage or surface water inlet 11, sewage or surface water outlet 12, sewage or surface water return port 13 and sewage or surface water outlet 14 , the two ends of the housing 1 are detachably connected to the two flanges 5, the rotating shaft 3 is arranged on the centerline in the length direction of the housing 1, and the two ends of the rotating shaft 3 are rotated with the two flanges 5 and Sealed connection, one end of the rotating shaft 3 is in transmission connection with the deceleration drive mechanism 2, the centers of the runner filter disc 4 and the two baffle discs 7 are respectivel...

specific Embodiment approach 2

[0030] Specific implementation mode two: as figure 1 and image 3 As shown, the sewage or surface water source heat pump system anti-blocking device described in Embodiment 1, each filter through hole 9 on the rotor filter plate 4 is fixedly fitted with a filter sleeve 15 .

specific Embodiment approach 3

[0031] Specific implementation mode three: as figure 1 and image 3 As shown, in the second embodiment of the sewage or surface water source heat pump system runner type anti-blocking device, the length of the filter sleeve 15 is 5 mm to 400 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com