Large-size rotatable machine tool equipment used for machining special workpieces

A special workpiece and large-scale technology, applied in the field of large-scale rotatable machine tool equipment, can solve the problems of low labor intensity, high equipment investment cost, and low work efficiency, and achieve high work efficiency, reasonable structure, and high-quality processed workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

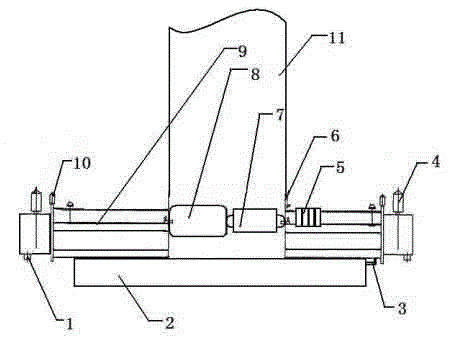

[0012] This embodiment provides a large rotatable machine tool for processing special workpieces, characterized in that: the large rotatable machine tool for processing special workpieces includes a cutter head (1), a chassis (2), a horizontal Limit switch (3), cutter head horizontal motor (4), counterweight (5), vertical limit switch (6), speed limiter (7), motor (8), beam (9), cutter head Vertical motor (10), vertical beam (11);

[0013] Among them: the beam (9) passes through the inside of the vertical beam (11), the lower end of the vertical beam (11) is provided with a chassis (2), the two ends of the beam (9) are provided with a processing device, and the processing device is controlled by a cutter head horizontal motor (4) , the cutter head vertical motor (10) and the cutter head (1), the vertical beam (11) is provided with an electrical box, the electrical box is provided with a motor (8) and a speed limiter (7) connected to the motor (8), The crossbeam (9) is covered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com