Reversing device and reversing system for waste water heat exchange

A reversing device and non-clean water technology, applied in the energy field, can solve problems such as poor reliability, difficult processing, and unreachable applications, and achieve the effects of solving blockage and entanglement, stable and reliable operation, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

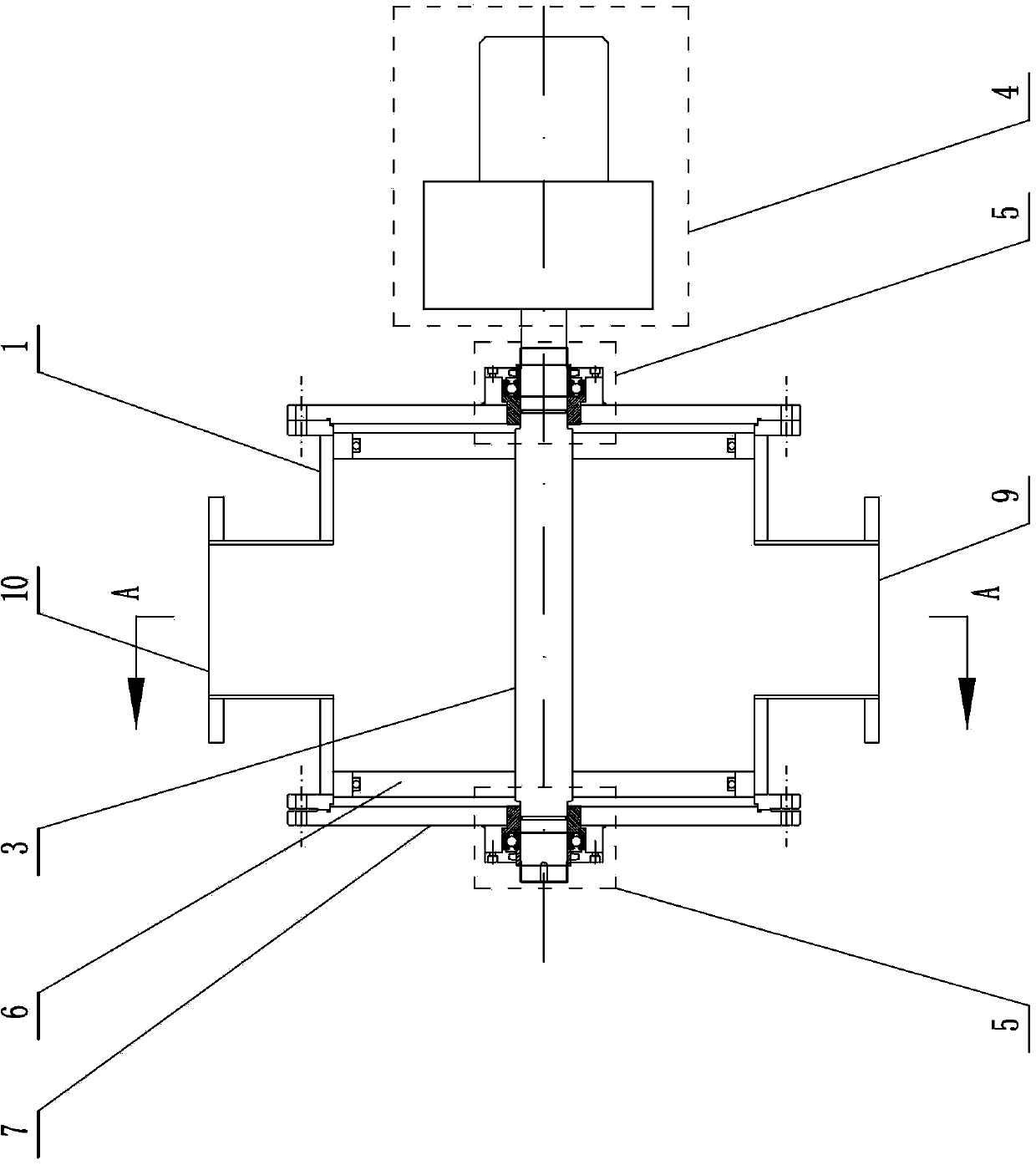

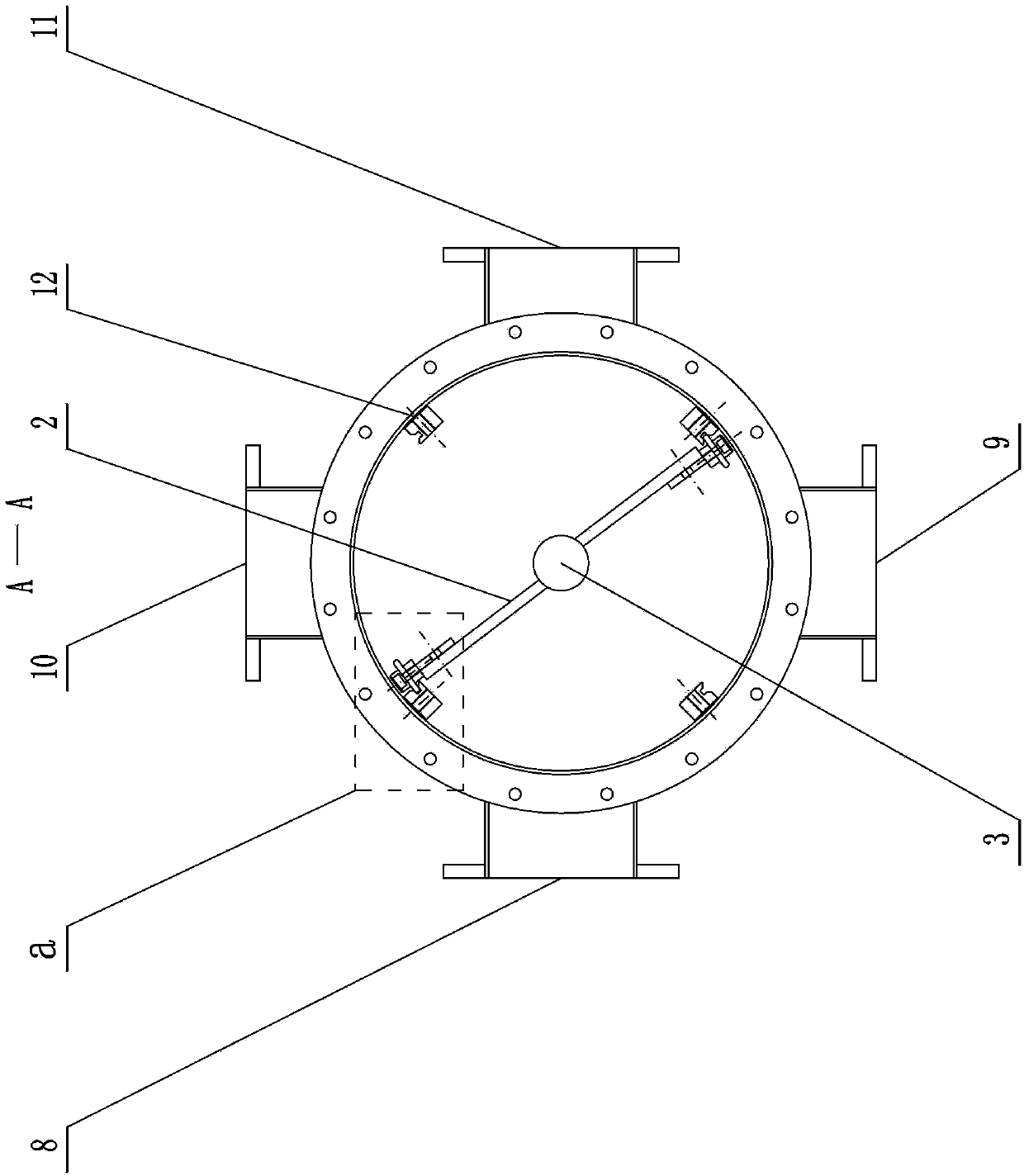

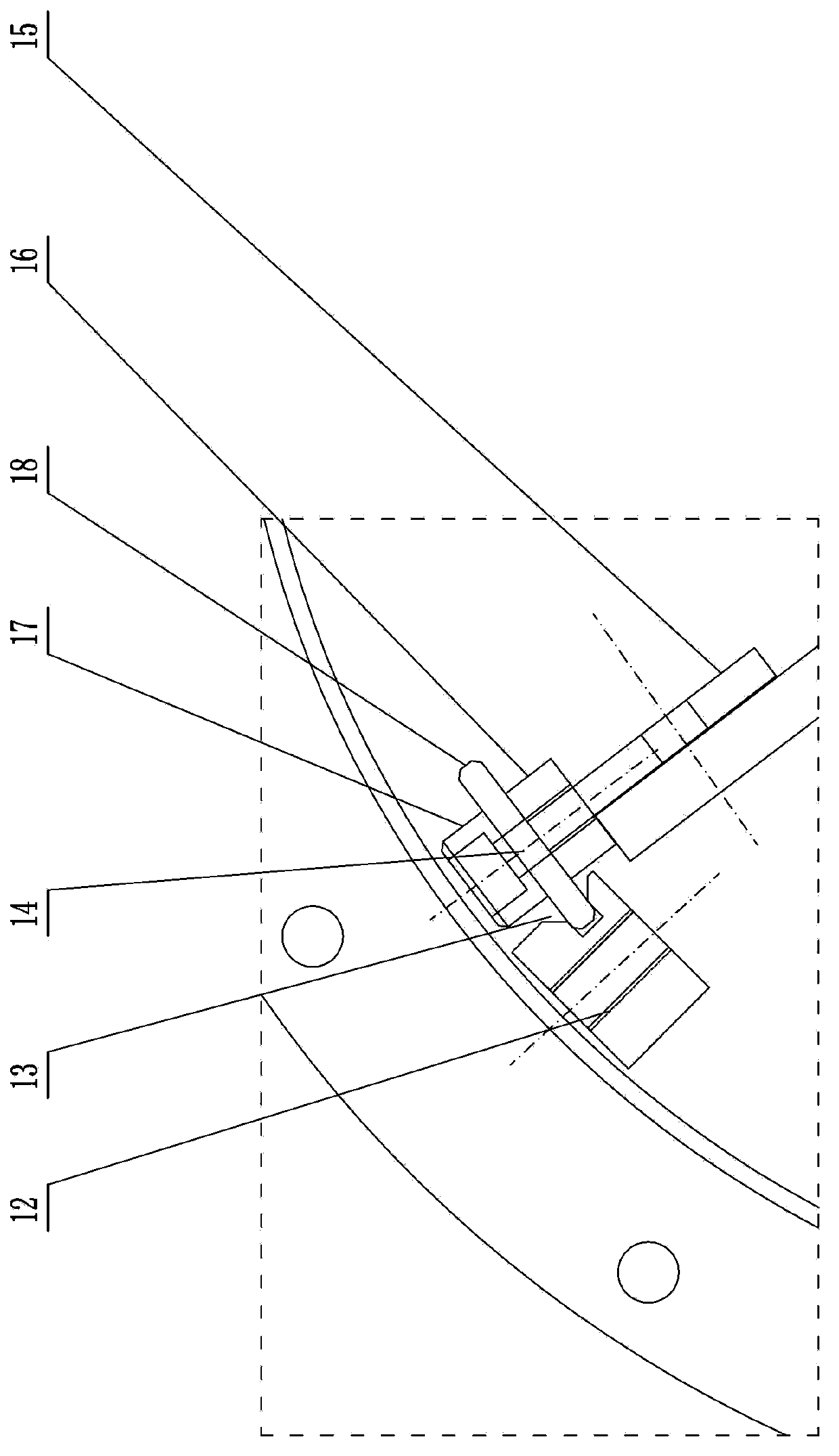

[0031] Specific implementation mode one: as Figure 1 ~ Figure 3 As shown, a reversing device for non-clean water heat exchange in this embodiment, the reversing device includes a housing 1, a valve plate 2, a rotating shaft 3, a decelerating drive mechanism 4, and two bearing seats 5 , two turntables 6, two flanges 7, water inlet 8, water outlet one 9, water outlet two 10, water outlet 11, four limit grooves 12, notch 13, rubber head 14, all The rubber head 14 includes a connecting plate 15, a terminal plate 16, a pressing plate 17 and a rubber strip 18, and the housing 1 is divided into four parts along the circumferential direction, and each part is connected with the water inlet 8, the water outlet and the return port 9 respectively. , the water outlet two 10 and the water outlet 11 are connected, and the water outlet one 9 and the water outlet two 10 are on both sides of the water inlet 8 and the water outlet 11 in the circumferential direction of the housing 1; the two s...

specific Embodiment approach 2

[0032] Specific implementation mode two: as Figure 4 As shown, a reversing device for non-clean water heat exchange in this embodiment, the water inlet 8 of the reversing device, the first water outlet and return port 9, the second water outlet and return port 10, and the drain port 11 are located in the housing 1 The top is at the same or different positions along the axial direction of the rotating shaft 3, and the others are the same as in the first embodiment. The pipe diameter of the drain port 11 is relatively large, and the size of the above-mentioned four ports in the circumferential direction of the housing 1 is limited. By arranging the four ports at different positions along the axial direction of the rotating shaft 3, the requirements of the housing 1 can be reduced. In addition, by arranging the four ports at different positions along the axial direction of the rotating shaft 3, the space required for connecting the four ports with the pipeline can be reduced.

specific Embodiment approach 3

[0033] Specific implementation mode three: as Figure 1 ~ Figure 4 As shown, a reversing device for non-clean water heat exchange according to this embodiment, the diameters of the water inlet 8, the water outlet one 9, the water outlet two 10 and the water outlet 11 of the reversing device are 100mm ~ 600mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com