Large-scale rotary press

A printing press, large-scale technology, applied in rotary printing presses, printing presses, printing and other directions, can solve the problems of the reduction of the life of the transmission device and the strength of the components, the wear of the transmission belt elements, the manufacturing cost, etc., to achieve long service life and good transfer effect. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

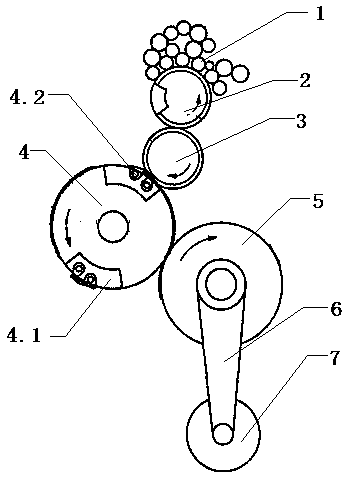

[0012] This embodiment provides a large-scale rotary printing machine, which is characterized in that: the large-scale rotary printing machine includes an inking device (1), a plate cylinder (2), a transfer cylinder (3), an impression cylinder (4 ), channel (4.1), grabber (4.2), feed roller (5), sprocket (6), main drive wheel (7);

[0013] Among them: the roller of the inking device (1) is configured for the plate cylinder (2), the plate cylinder (2) and the transfer cylinder (3) are externally engaged, and the transfer cylinder (3) and the impression cylinder (4) are externally engaged. Cut and bite, the impression cylinder (4) and the paper feed roller (5) cut and bite, the paper feed roller (5) is connected and installed with the main drive wheel (7) through the sprocket (6), and the impression cylinder (4) There are two channels (4.1) for mounting the grippers (4.2).

[0014] Said grabber (4.2) sinks into the corresponding channel (4.1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com