Novel multi-oil-passage lubrication gear

An oil channel and gear technology, which is applied to a new type of multi-oil channel lubricating gear. It can solve the problems of high labor intensity, low work efficiency and insufficient lubrication, and achieve the effect of good lubrication effect, saving lubricating oil and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

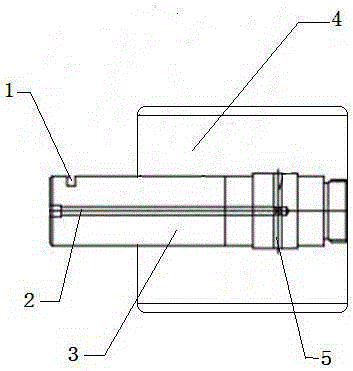

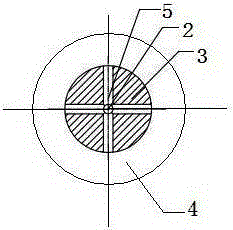

[0012] This embodiment provides a novel multi-oil channel lubricating gear, which is characterized in that: the novel multi-oil channel lubricating gear includes a mounting slot (1), a transverse oil channel (2), a gear shaft (3), a gear ( 4), longitudinal oil passage (5);

[0013] Among them: the power output end of the gear shaft (3) is provided with an installation card slot (1), the gear shaft (3) and the gear (4) are installed in a traditional way, and an oil chamber is provided at the connection installation, which is connected with the oil passage on the gear shaft (3) In the same way, the gear shaft (3) is provided with a horizontal oil passage (2) and a longitudinal oil passage (5), the horizontal oil passage (2) is arranged at the axial center of the gear shaft (3), and the longitudinal oil passage (5) is arranged at the center of the gear shaft (3). The horizontal oil passage (2) is at a vertical position and communicates with the horizontal oil passage (2), and one...

Embodiment 2

[0015] This embodiment provides a novel multi-oil channel lubricating gear, which is characterized in that: the novel multi-oil channel lubricating gear includes a mounting slot (1), a transverse oil channel (2), a gear shaft (3), a gear ( 4), longitudinal oil passage (5);

[0016] Among them: the power output end of the gear shaft (3) is provided with an installation card slot (1), the gear shaft (3) and the gear (4) are installed in a traditional way, and an oil chamber is provided at the connection installation, which is connected with the oil passage on the gear shaft (3) In the same way, the gear shaft (3) is provided with a horizontal oil passage (2) and a longitudinal oil passage (5), the horizontal oil passage (2) is arranged at the axial center of the gear shaft (3), and the longitudinal oil passage (5) is arranged at the center of the gear shaft (3). The horizontal oil passage (2) is at a vertical position and communicates with the horizontal oil passage (2), and thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com