Storage box for receiving disk parts

A technology for disk parts and storage boxes, applied in tool storage devices, manufacturing tools, etc., can solve problems such as pressure on disk parts, affecting the quality of parts, and disorderly placement of disk parts, so as to reduce stress and reduce The effect of weight and smooth running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

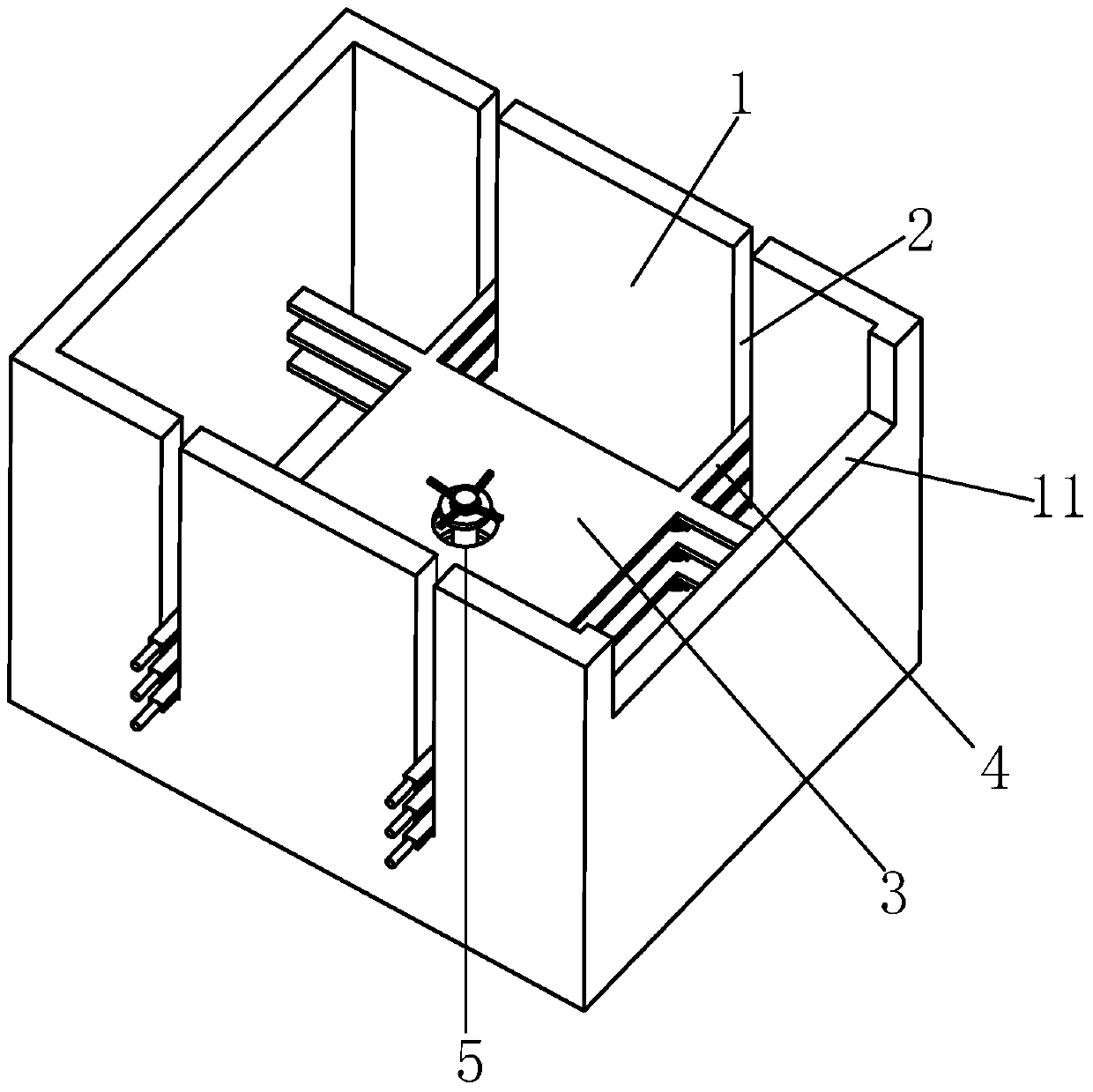

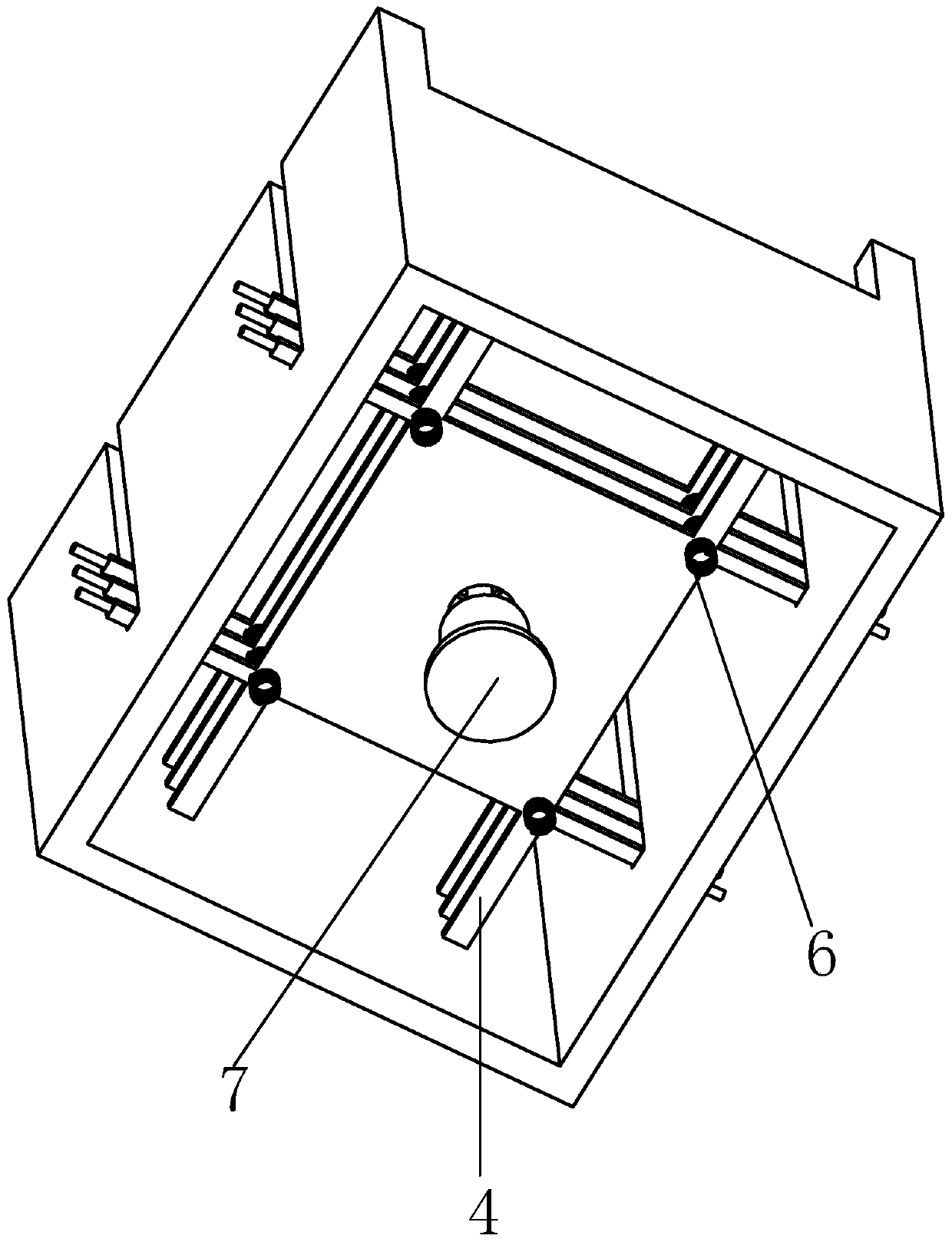

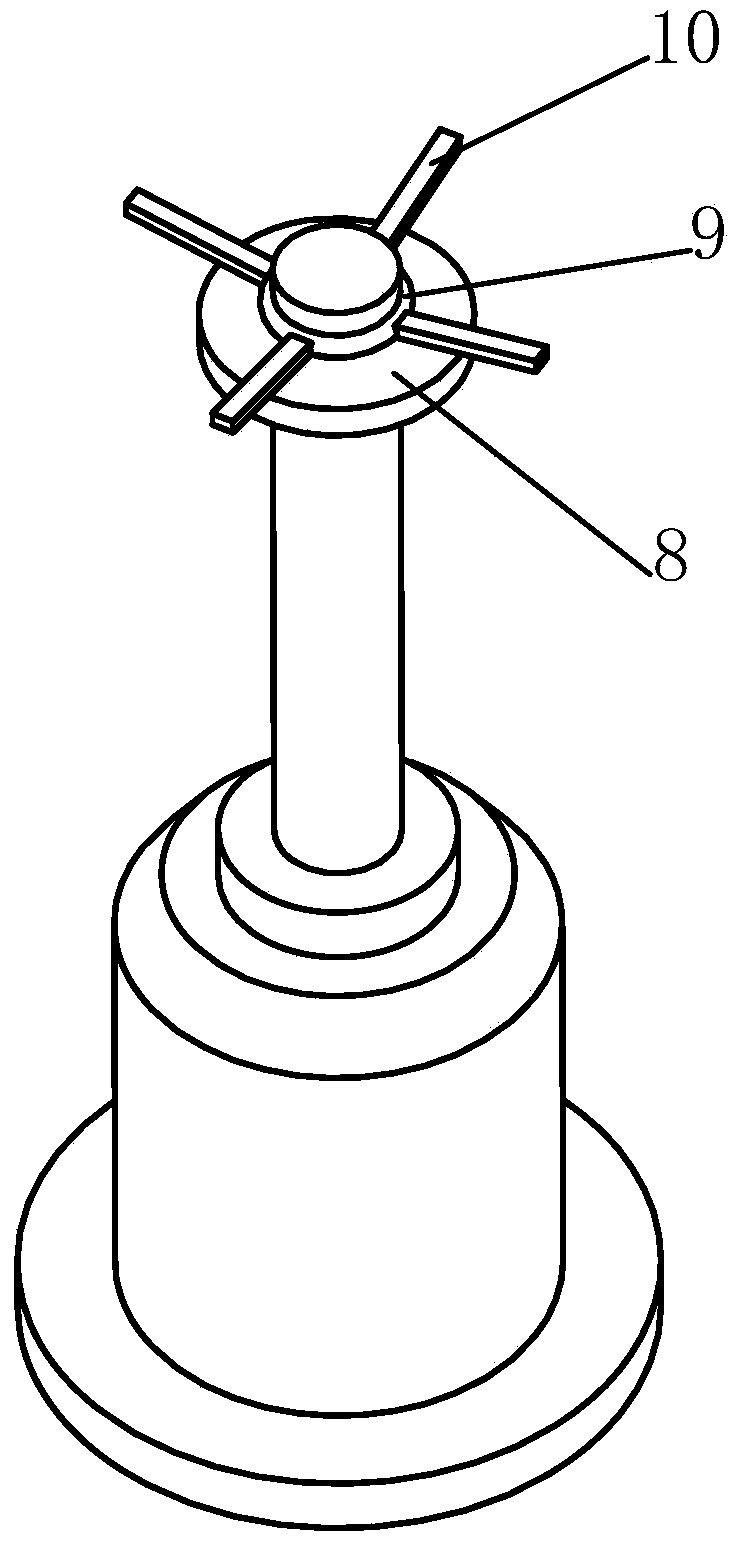

[0014] Such as Figure 1 to Figure 3 As shown, a disk-like parts receiving storage box includes a box body 1, the left and right sides of the front side of the box body 1, and the left and right sides of the rear side are respectively provided with a vertical strip groove 2, the box body 1 There are a number of horizontally placed support plates 3 inside, and clip strips 4 are evenly distributed around the support plate 3, and the clip strips 4 are respectively located in the corresponding strip grooves 2 on the front side and the rear side of the box body 1. The outer ends of the clip bars 4 are provided with handles for the convenience of the operator to lift the support plate 3. The center of the support plate 3 is provided with a through hole 5, and a number of support springs 6 are evenly distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com