Air cylinder

A cylinder and cylinder block technology, applied in the field of pneumatic transmission, can solve the problems of large mechanical damage, increased wear and deformation, and limited application range of the cylinder, so as to reduce mechanical damage, reduce wear and deformation, and expand the application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

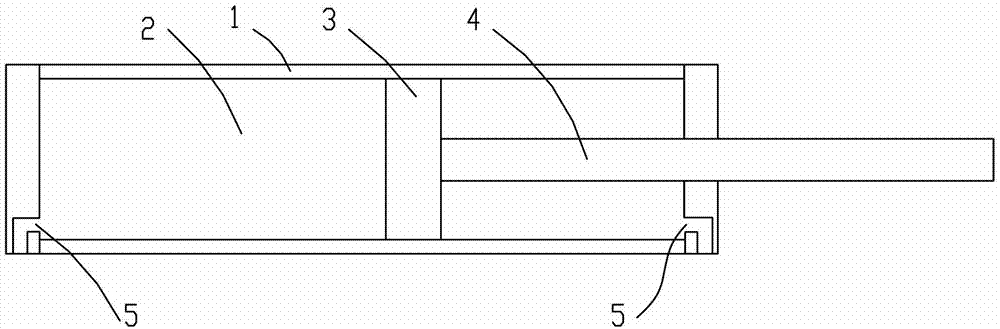

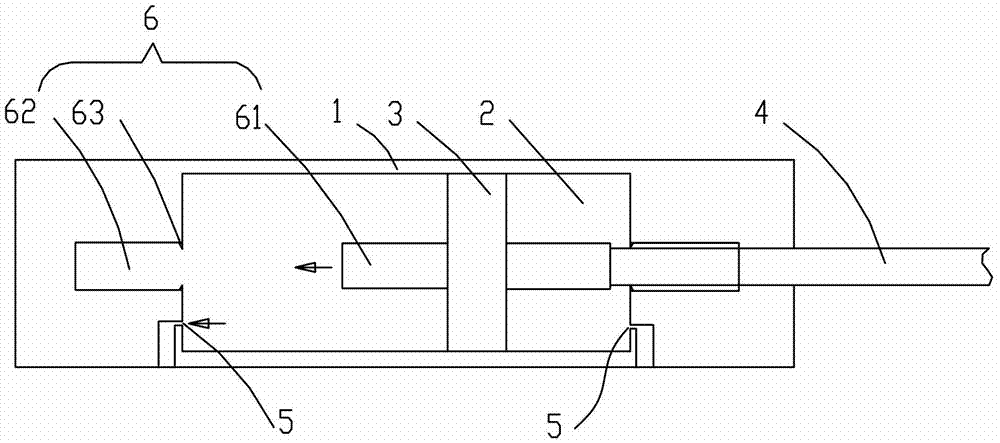

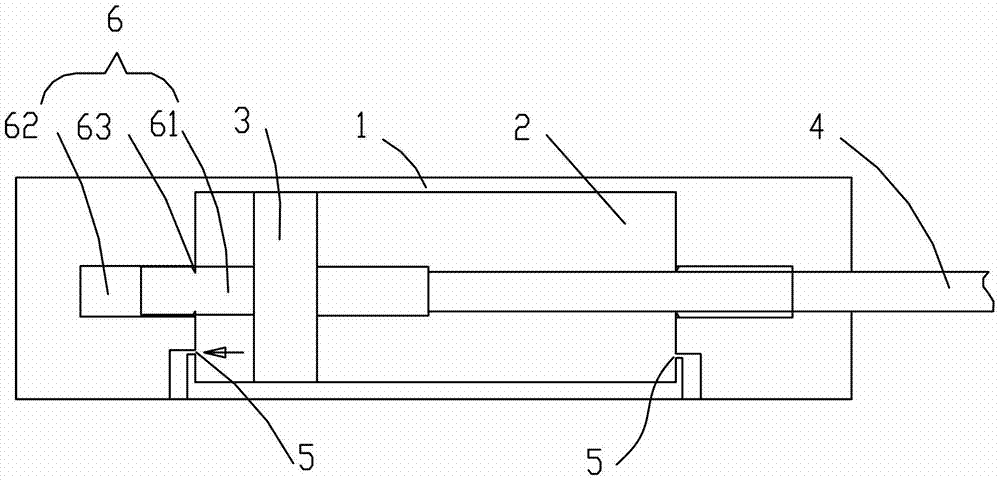

[0022] The invention discloses a cylinder, as the first embodiment of the cylinder of the invention, such as figure 2 and image 3 As shown, the cylinder includes a cylinder body 1, a main chamber body 2, a piston 3 and a piston rod 4, and both ends of the cylinder body 1 are provided with air inlet and outlet ports 5, and the cylinder is also provided with an anti-collision structure 6, an anti-collision structure 6 Including a buffer rod 61, the buffer rod 61 is arranged on the piston 3, the cylinder body 1 is provided with a receiving hole 62 corresponding to the buffer rod 61, and the receiving hole 62 is provided with a seal for the buffer rod 61 and accommodating The gap between the holes 62 is the first sealing ring 63 . In this embodiment, both ends of the cylinder are provided with anti-collision structures 6 , and the first sealing ring 63 is provided at the innermost side of the receiving hole 62 .

[0023] In this embodiment, the axis of the buffer rod 61 coinci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com