Automatic feeding and discharging device

A technology of feeding device and discharging device, which is applied in the direction of metal chains, etc., can solve the problems of backward technology of feeding and discharging devices, easy generation of dust and noise, and inability to form large-scale production, etc., and achieves simple and reasonable structure, small occupied space, The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

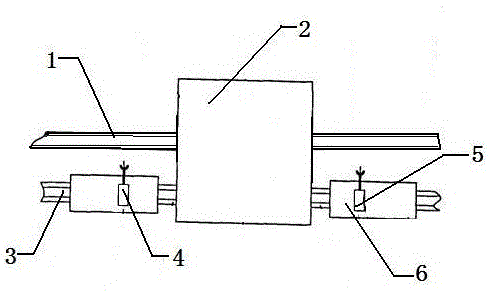

[0012] This embodiment provides an automatic feeding and discharging device, which is characterized in that: the automatic feeding and discharging device includes a screw (1), a numerically controlled driving device (2), a feeding device (3), a manipulator A (4), Manipulator B (5), discharge device (6);

[0013] Among them: the lead screw (1) passes through the numerical control driving device (2), the feed device (3) is arranged under the lead screw (1) and the left side of the numerical control drive device (2), and the discharge device (6) is arranged on the left side , The feed port of the feeding device (3) is provided with a manipulator A (4), and the discharge port of the discharge device (6) is provided with a manipulator B (5).

[0014] A private motor can be installed in the numerically controlled driving device (2).

[0015] Example 1

[0016] This embodiment provides an automatic feeding and discharging device, which is characterized in that: the automatic feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com