Special vertical crushing device

A crushing device, vertical technology, applied in the field of special vertical crushing device, can solve the problems of easy blockage in the inner and upper part of the dryer, affecting normal production, high viscosity, etc., to achieve convenient installation and disassembly, long service life, and effective Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

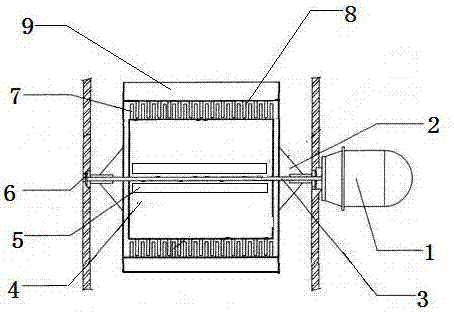

[0013] This embodiment provides a dedicated vertical crushing device, which is characterized in that: the special vertical crushing device includes a driving machine (1), a connecting fixed plate (2), a rotating shaft (3), an inner rotating crushing and drying cylinder (4), discharge port (5), shaft seat (6), inner cylinder crushing teeth (7), outer rotating crushing and drying cylinder (8), outer cylinder crushing teeth (9);

[0014] Among them: the device is composed of a driving machine (1) and a drying and crushing system. The power output end of the driving machine (1) is fixedly connected to the rotating shaft (3), and the other end of the rotating shaft (3) is rotatably connected to the shaft seat (6), and the rotating shaft (3) ) by connecting the fixed plate (2) to fixedly install the inner rotating crushing and drying cylinder (4), and the outer edge of the inner rotating crushing and drying cylinder (4) is evenly equipped with inner cylinder crushing teeth (7).

[0...

Embodiment 2

[0018] A special vertical crushing device, characterized in that the special vertical crushing device includes a driving machine (1), a connecting fixed plate (2), a rotating shaft (3), an inner rotating crushing and drying cylinder (4), an outlet Material opening (5), shaft seat (6), inner cylinder crushing teeth (7), outer rotating crushing and drying cylinder (8), outer cylinder crushing teeth (9);

[0019] Among them: the device is composed of a driving machine (1) and a drying and crushing system. The power output end of the driving machine (1) is fixedly connected to the rotating shaft (3), and the other end of the rotating shaft (3) is rotatably connected to the shaft seat (6), and the rotating shaft (3) ) by connecting the fixed plate (2) to fixedly install the inner rotating crushing and drying cylinder (4), and the outer edge of the inner rotating crushing and drying cylinder (4) is evenly equipped with inner cylinder crushing teeth (7).

[0020] The driving machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com