Core disc structure for connecting locomotive and steering frame

A technology of bogies and core discs, which is applied in the direction of the device for lateral relative movement between the bottom frame and the bogie, which can solve the problems of low bearing capacity of core discs, large consumption of lubricating oil, dust and noise, etc., and extend the service life of parts Long life, no energy loss, and the effect of saving lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

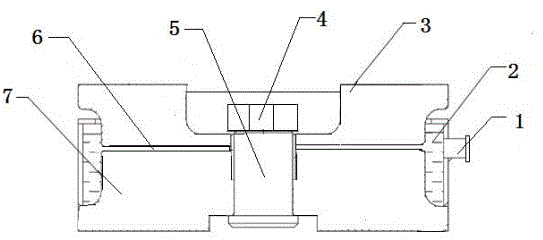

[0011] This embodiment provides a core plate structure for connecting a locomotive and a bogie, characterized in that: the core plate structure for connecting a locomotive and a bogie includes an oil port (1), a lubricant groove (2) , upper core plate (3), nut (4), bolt shaft (5), lubrication gap (6), lower core plate (7);

[0012] Among them: the device is equipped with an upper core disc (3) and an upper core disc (7), the center of the upper core disc (3) is provided with a nut (4), and the upper core disc (3) and the lower core disc (7) are provided with a lubrication gap (6 ), the contact plane of the core discs is a flat surface to reduce wear, and a pin shaft (5) is set between the upper and lower core discs (3, 7), and the pin shaft (5) connects the upper and lower core discs (3, 7) in series Connected together, the lower end of the bolt shaft (5) is sealed and welded to the lower core disk (7), the upper end of the bolt shaft (5) is connected to the upper core dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com