Industrial waste lubricating oil regeneration process

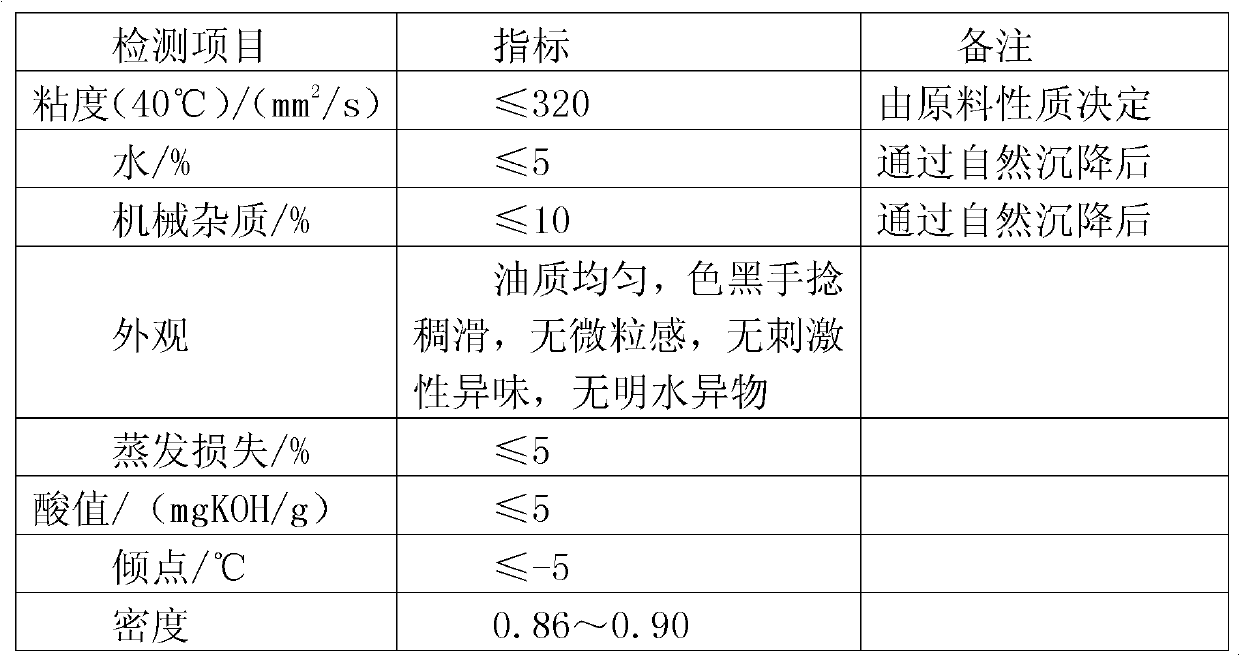

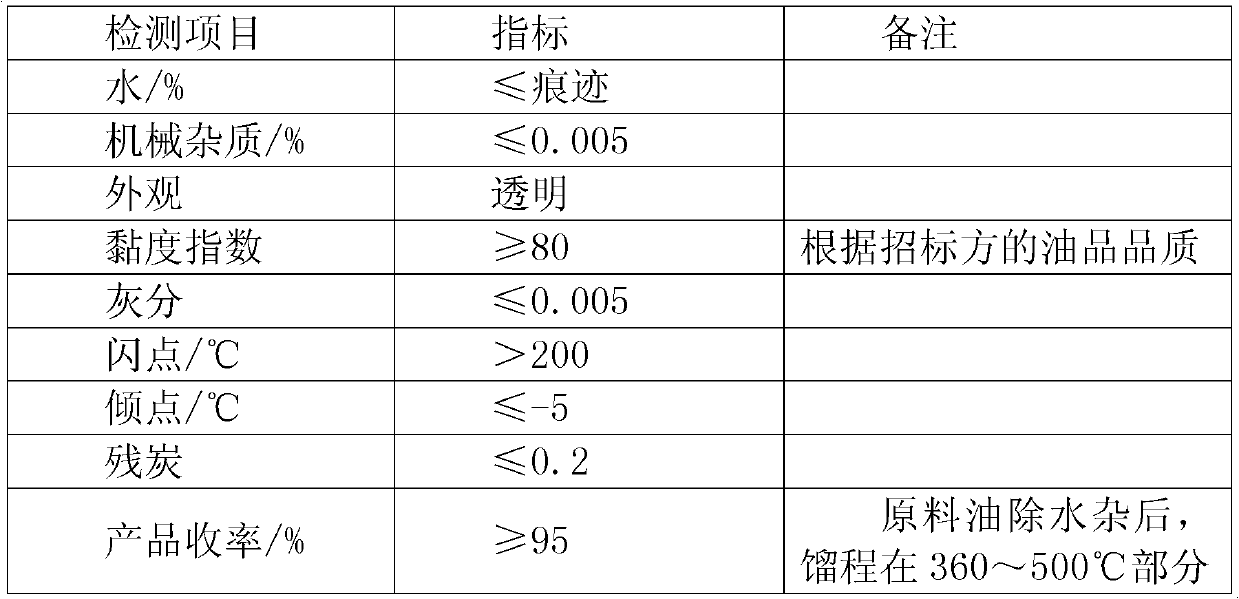

A waste lubricating oil and process technology, applied in the field of industrial waste lubricating oil regeneration process, can solve the problems of dark color, unstable quality and strong smell of diesel oil, and achieve the effect of saving energy, prolonging equipment life and saving lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Metal removal machine and impurities system: The metal mechanical impurities in the B-type waste oil after the sedimentation treatment are removed through a magnetic filter and a centrifugal oil purifier. 2) Weak negative pressure distillation system (vacuum is 2000Pa): the oil product after the removal of impurities is pumped to the preheater and the preheated material enters the middle of the distillation tower, and is heated to 120℃ in the reboiler (Working temperature) The water and gasoline in the waste oil are steamed from the top of the tower into the condenser for condensation, and then separated into the oil-water separator and discharged. The lubricating oil and high-boiling parts in the materials are separated at the bottom of the distillation tower. The materials from which water and gasoline are removed are sent from the bottom of the distillation to the thin-film evaporator through a transfer pump (the working vacuum is 200Pa, and the working temperature is:...

Embodiment 2

[0019] The other steps are the same, and the changes are as follows: the vacuum degree of the weak negative pressure distillation system is 4000 Pa, and the working temperature is 80°C; the working vacuum degree of the thin film evaporation system is 400 Pa, and the working temperature is 190 ℃. The working vacuum degree of the short-path distillation system is 10 Pa, and the working temperature is 250°C.

Embodiment 3

[0021] The other steps are the same, and the changes are: the vacuum degree of the weak negative pressure distillation system is 6000 Pa, and the working temperature is 100°C; the working vacuum degree of the thin film evaporation system is 600 Pa, and the working temperature is 200 ℃. The working vacuum degree of the short-path distillation system is 20 Pa, and the working temperature is 300°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com