Roller chain used for external additive production device

A technology of production equipment and external additives, applied in the field of roller chains, can solve problems such as unsightly, easy to be stained with dust and sand, and affect the normal operation of the chain, and achieve the effect of saving lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

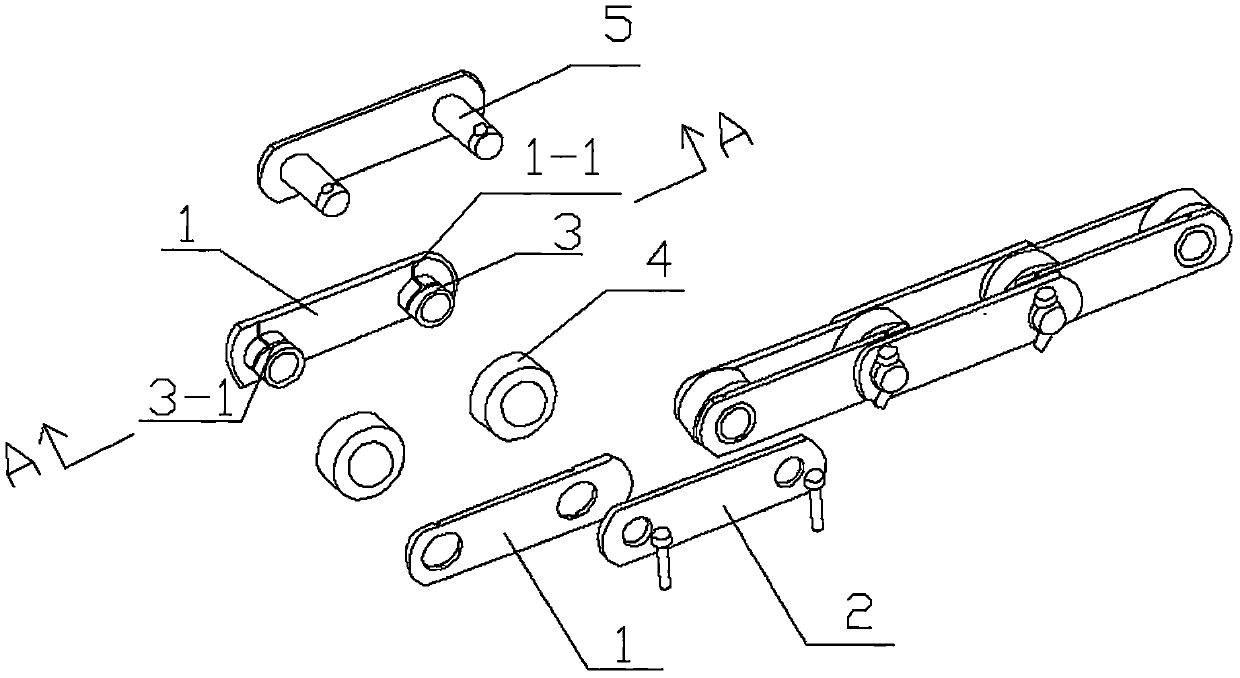

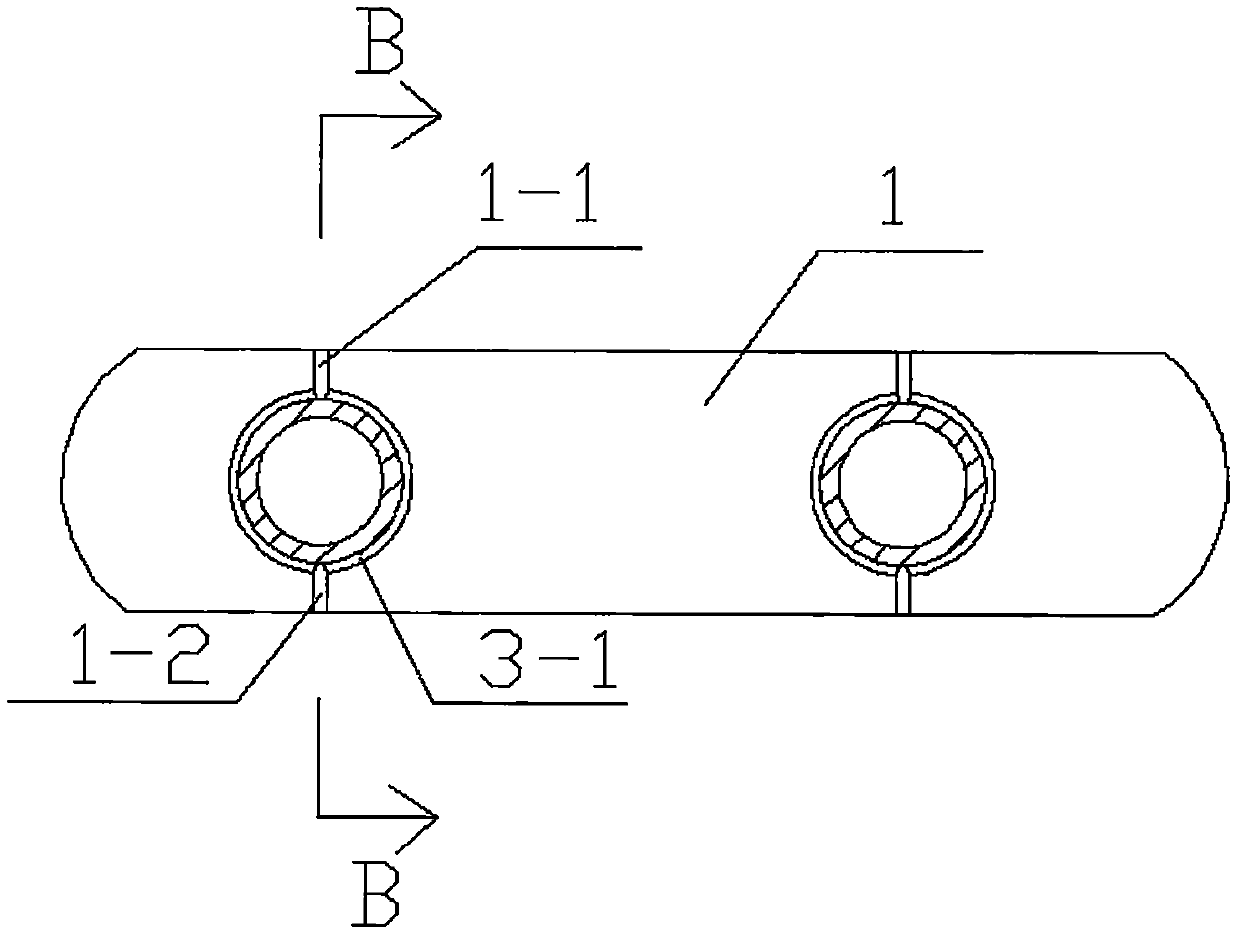

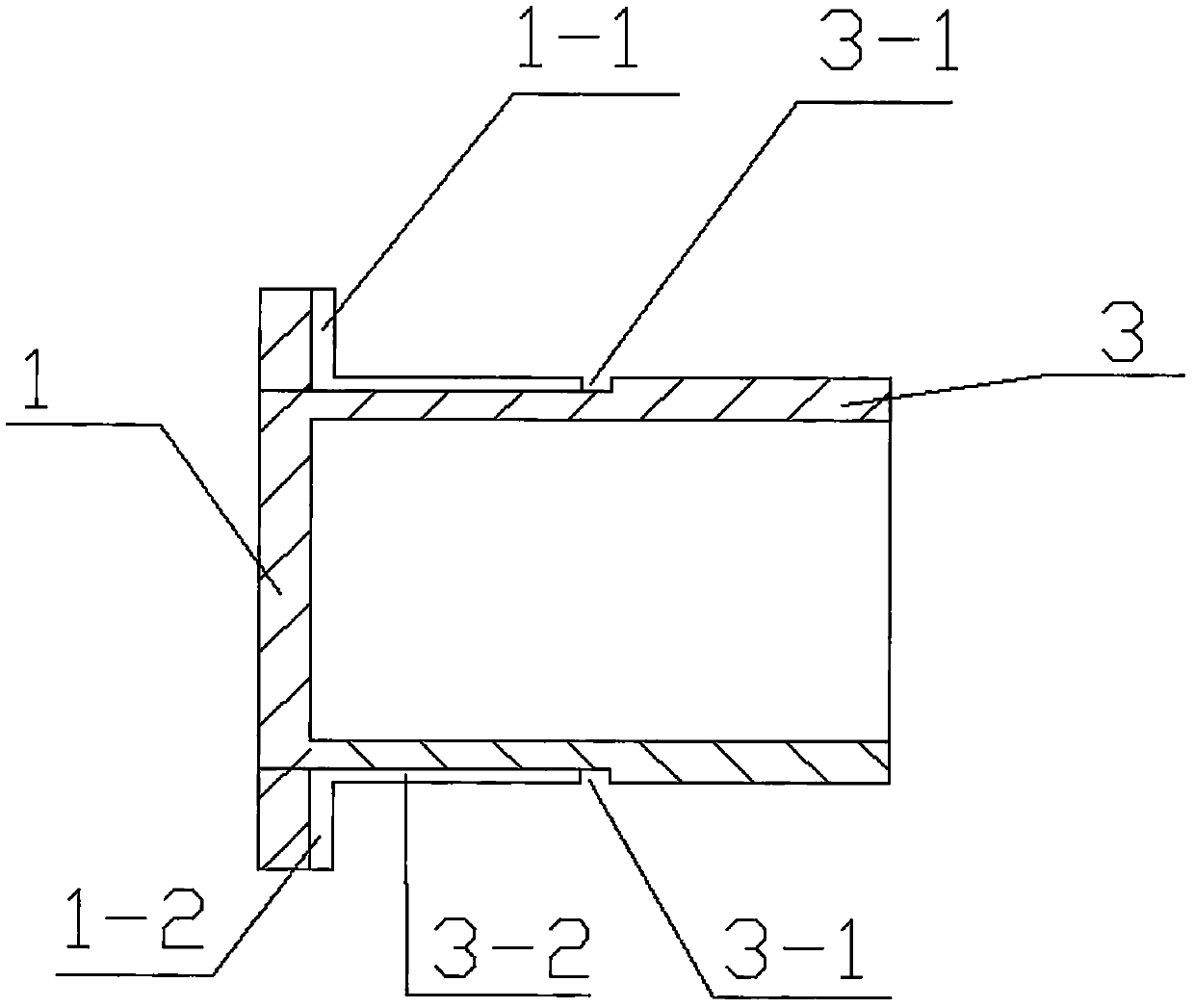

[0015] see Figure 1 to Figure 3 , the technical solution of the present invention is to provide a roller chain for external additive production equipment, comprising: a pair of left and right inner chain plates 1, a pair of left and right outer chain plates 2 arranged on the two outer sides of the inner chain plate 1, Sleeve 3 press-fitted into the sleeve hole of inner link plate 1, roller 4 freely rotatable on sleeve 3, outer link plate 2 and pin press-fitted into the pin hole of outer link plate 2 Shaft 5, a plurality of inner chain plates 1 and outer chain plates 2 are alternately connected; the inner wall of the inner chain plate 1 is provided with an oil guide groove A1-1 corresponding to each sleeve 3, and the oil guide groove A1-1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com