Self-lubricating gear

A self-lubricating, gear technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as shortened service life, wear, and single function of gears, so as to avoid wear and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

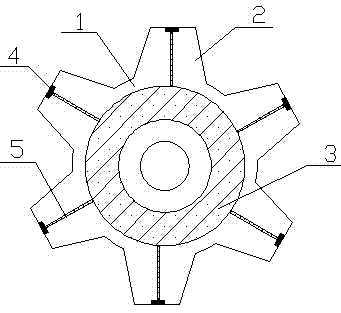

[0009] Such as figure 1 It is a structural schematic diagram of the present invention, a self-lubricating gear, including a gear body 1 and gear teeth 2 installed on the periphery of the gear body 1, the gear body 1 is provided with an oil storage ring 3, and the end of the gear teeth 2 is provided with an outlet The oil hole 4, the oil outlet hole 4 and the oil storage ring 3 are connected through the oil guide pipe 5. During the transmission process, the oil in the oil storage ring 3 flows out from the oil outlet hole 4 through the oil guide pipe 5 to play the role of lubrication.

[0010] The improved self-lubricating gear realizes automatic lubrication to avoid wear and prolong the service life of the gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com