Exposed gear automatic lubricating device

An automatic lubrication and open gear technology, which is applied in the direction of gear lubrication/cooling, can solve the problems of easy intrusion of foreign debris, easy wear of gear teeth, and poor working environment of gears, so as to improve adaptability and installation flexibility. Satisfy the effect of lubricating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

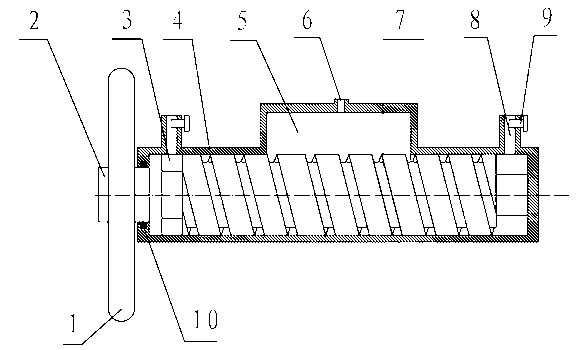

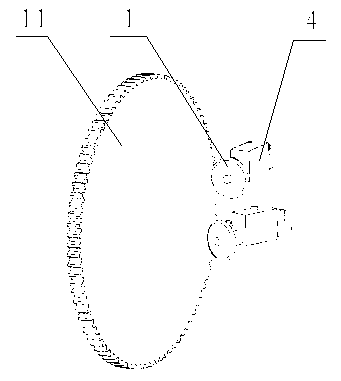

[0014] The embodiment of open gear automatic lubricating device of the present invention: as figure 1 , figure 2 As shown, it includes a closed casing 4, and the inner chamber of the casing 4 is composed of two circular hole sections extending in the left and right directions and a rectangular hole section connected in series at the middle position of the two circular hole sections, so that the two circular hole sections segment is divided into two fitting hole segments by a rectangular hole segment, and a rectangular cavity is formed between the two fitting hole segments. 5 communicates with the oil injection hole 6 through which lubricating oil can be injected into the oil storage chamber 5 . Rotating shaft 2 is inserted in the coaxial gap in the circular hole section. The rotating shaft 2 is a stepped shaft. The large diameter section is mounted on the top between the shell end covers at the two ports of the shell, and the small diameter section passes through the left sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com