Winch with automatic lubricating device

An automatic lubrication and winch technology, applied in the direction of engine lubrication, hoisting device, engine components, etc., can solve problems such as uneven lubrication, and achieve the effect of solving uneven lubrication of wire ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

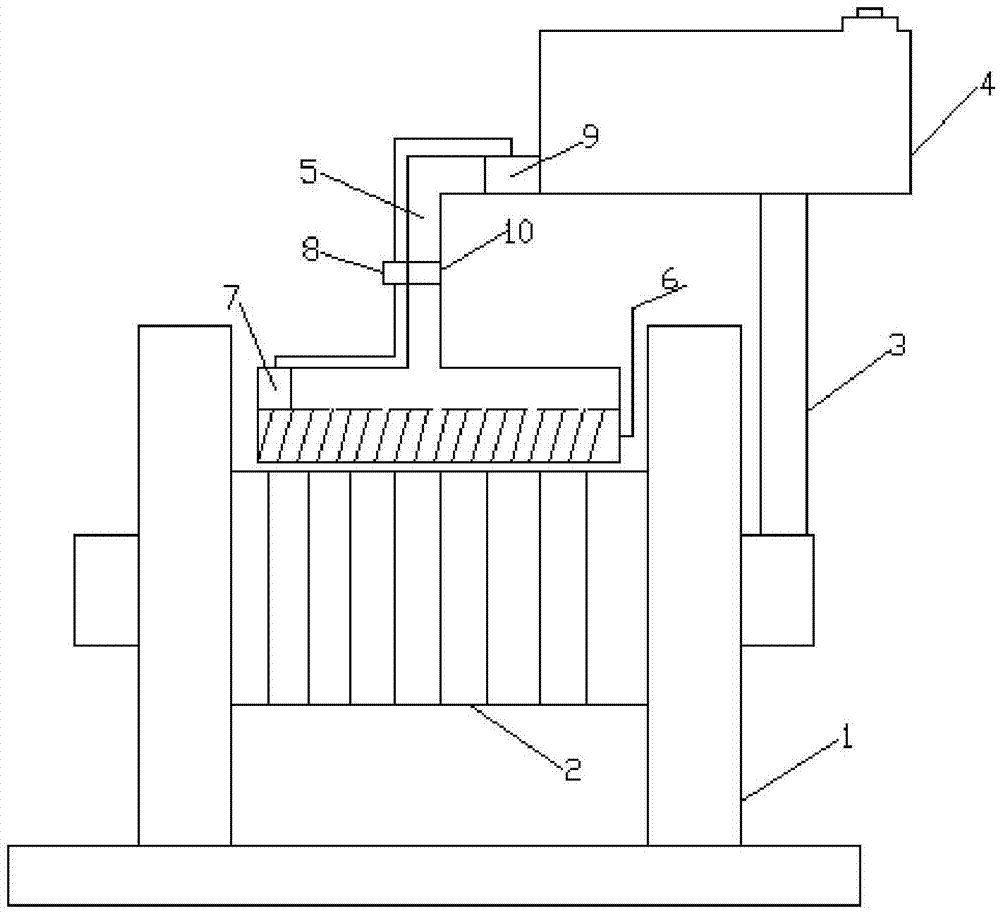

[0018] Such as figure 1 As shown, a winch with an automatic lubrication device includes a body 1, a drum 2, and a lifting rod 3, an oil storage tank 4, a brush handle 5, bristles 6, a speed sensor 7, a microprocessor 8, and a flow rate regulator. 9. Height regulator 10; the two ends of the roller 2 are fixed in the middle of the body 1, the bottom end of the elevating rod 3 is fixed on the right side of the body 1, and the upper end is fixed in the lower part of the oil storage tank 4; one end of the brush handle 5 is connected to the bristles 6, The speed sensor 7 is connected, and one end is connected with the oil storage tank 4 through the flow rate regulator 9; the height regulator 10 is installed on the brush handle 5 and connected with the microprocessor 8; the speed sensor 7 is connected with the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com