Scroll type linear tooth head structure of scroll compressor and correcting method thereof

A technology of scroll compressors and spiral teeth, which is applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the difficulty of increasing the detection of parts, violate the original intention of design and development, and reduce the difficulty of parts production, etc. problems, to achieve the effect of reducing processing difficulty, reducing mechanical noise and electromagnetic noise, and improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

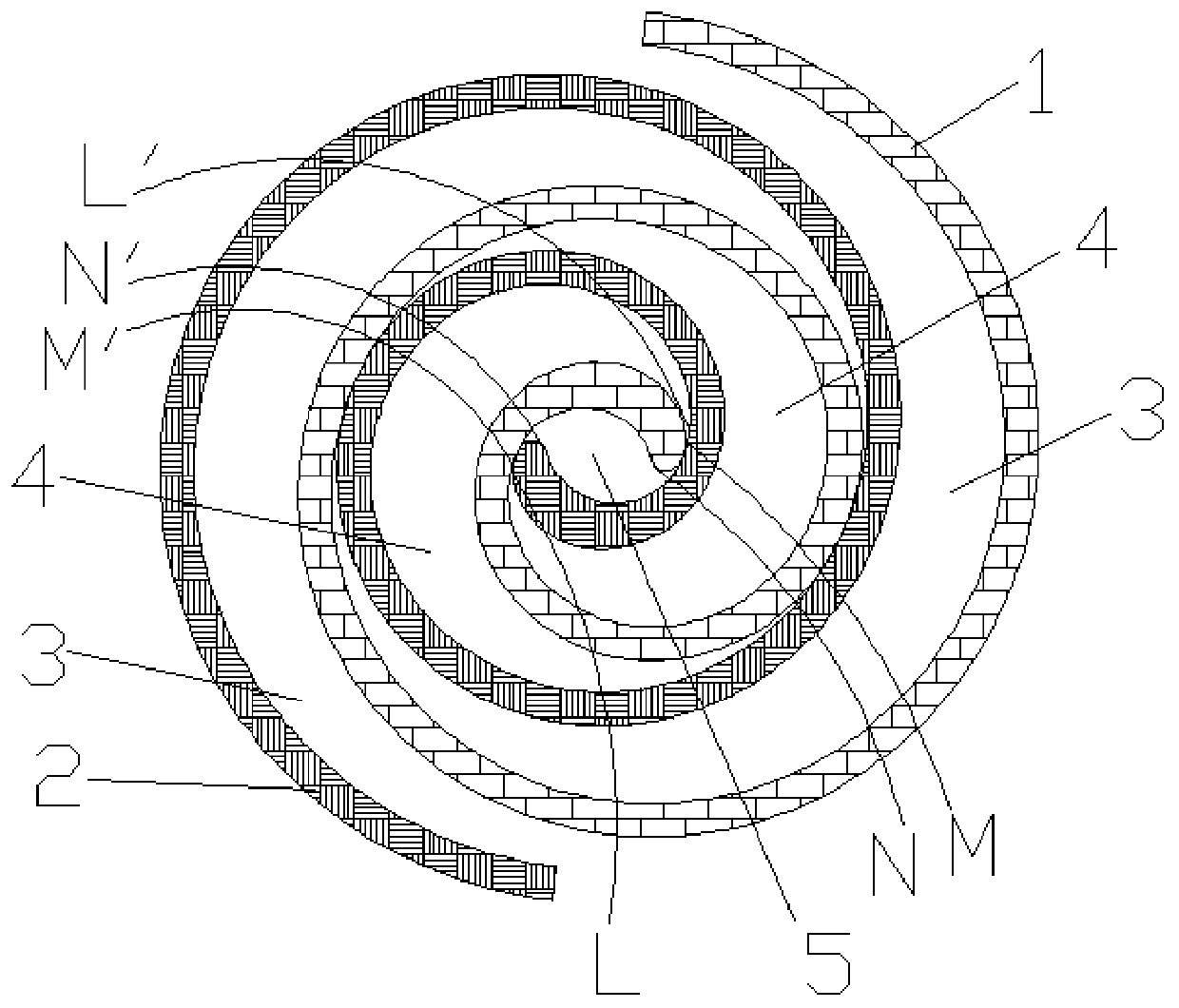

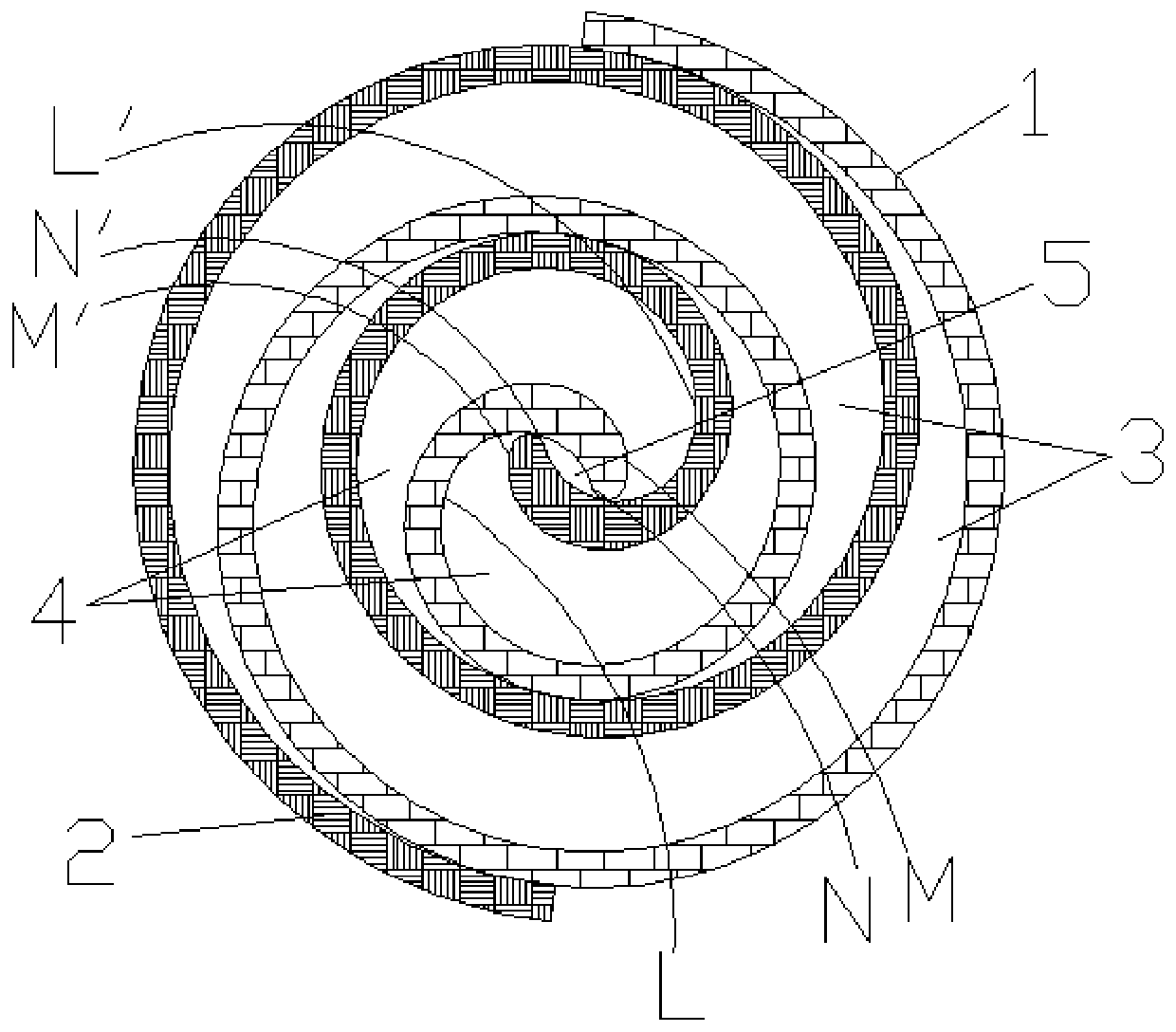

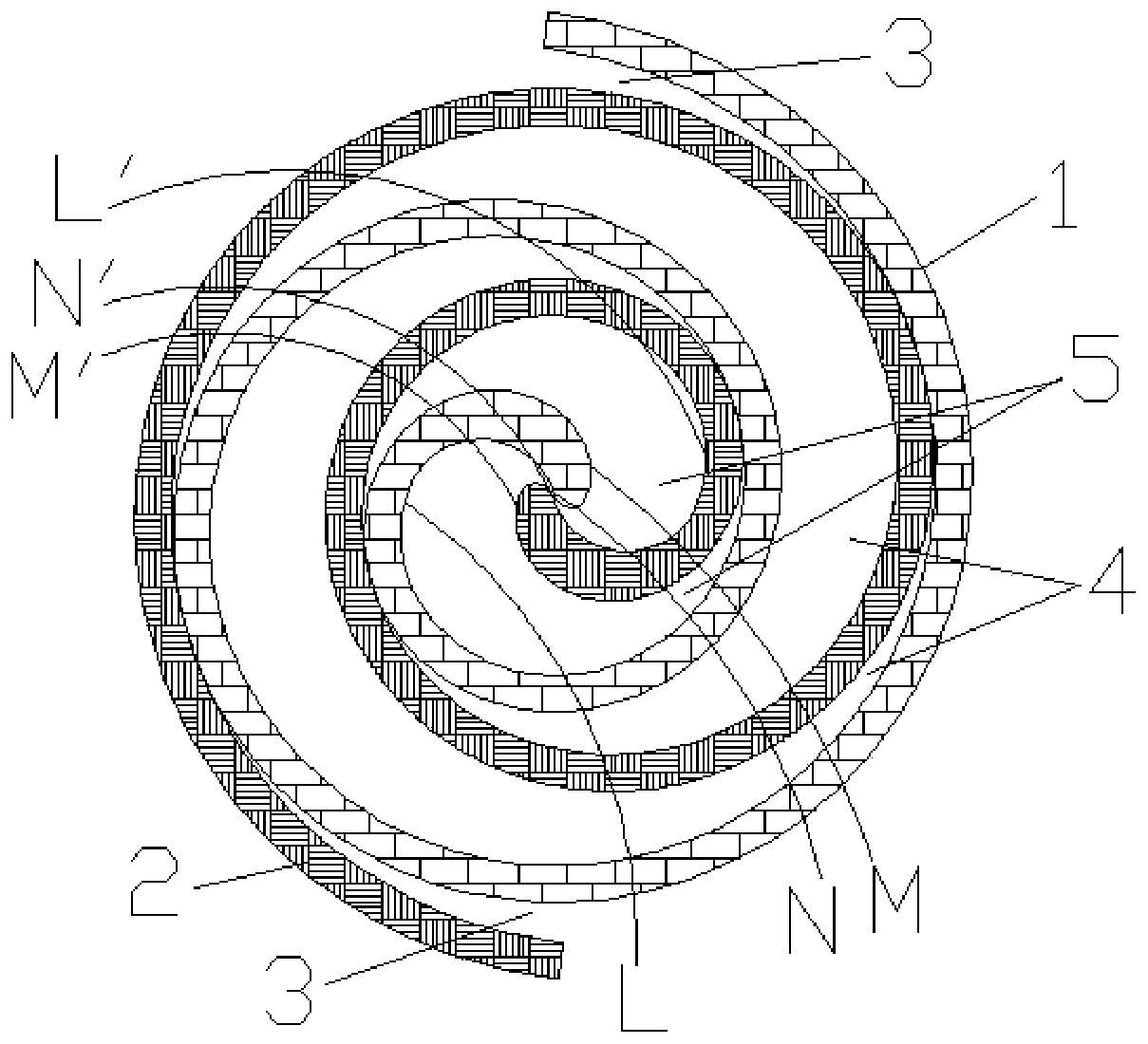

[0049] This embodiment provides a scroll compressor scroll tooth head structure, its structure is detailed in the attached Figure 1-4 As shown: it includes a fixed scroll 1 and a movable scroll 2, the fixed scroll 1 and the movable scroll 2 have the same structure and scroll tooth profile, and the fixed scroll 1 and the movable scroll 2 are arranged opposite to each other. The spiral teeth of the movable scroll 2 and the spiral teeth of the fixed scroll 1 cooperate to form the suction chamber 3, the medium pressure chamber 4 and the exhaust chamber 5 from the tail to the head; the spiral teeth of the fixed scroll 1 The profile line includes a first central head section MN and a first central inner arc segment NL, both of which are close to the tooth head of the fixed scroll 1 ; The spiral profile of the movable scroll 2 includes a second center head section M'N' and a second center inner arc section N'L', the second center head section M'N' and The second central inner arc s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com