Exhaust gas sampling apparatus

A technology of sampling device and exhaust flow, applied in the direction of sampling device, sampling, measuring device, etc., can solve the problems of complex calculation, control flow change, measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

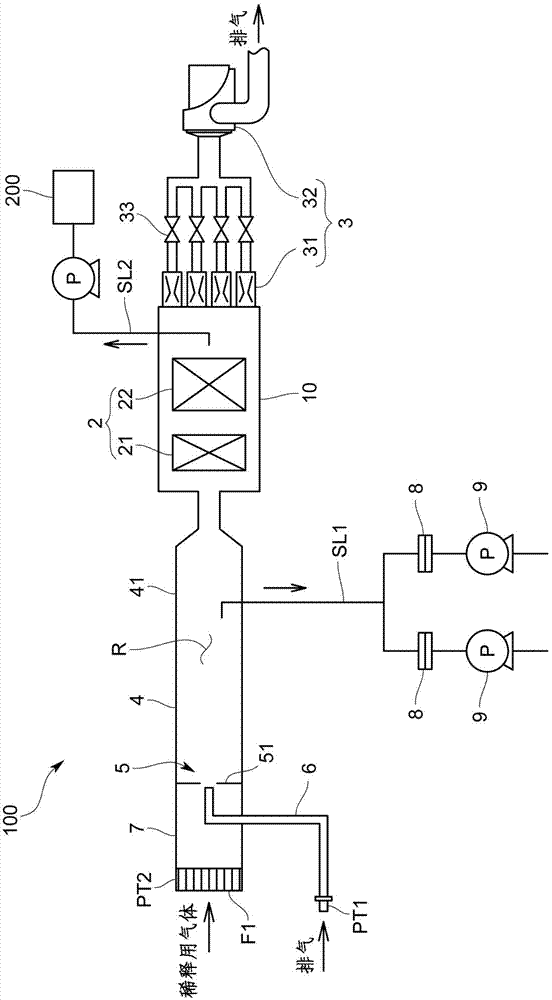

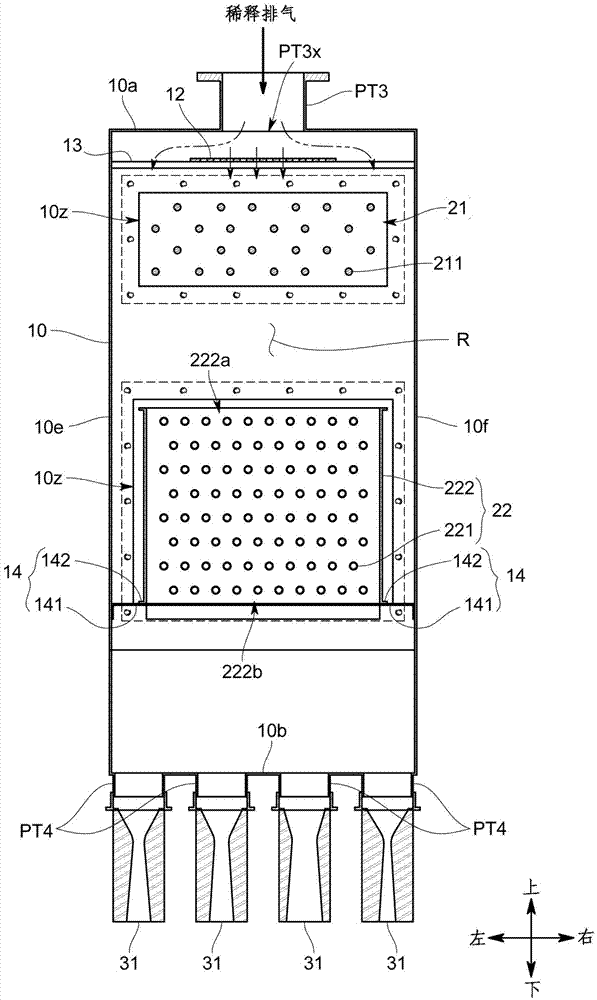

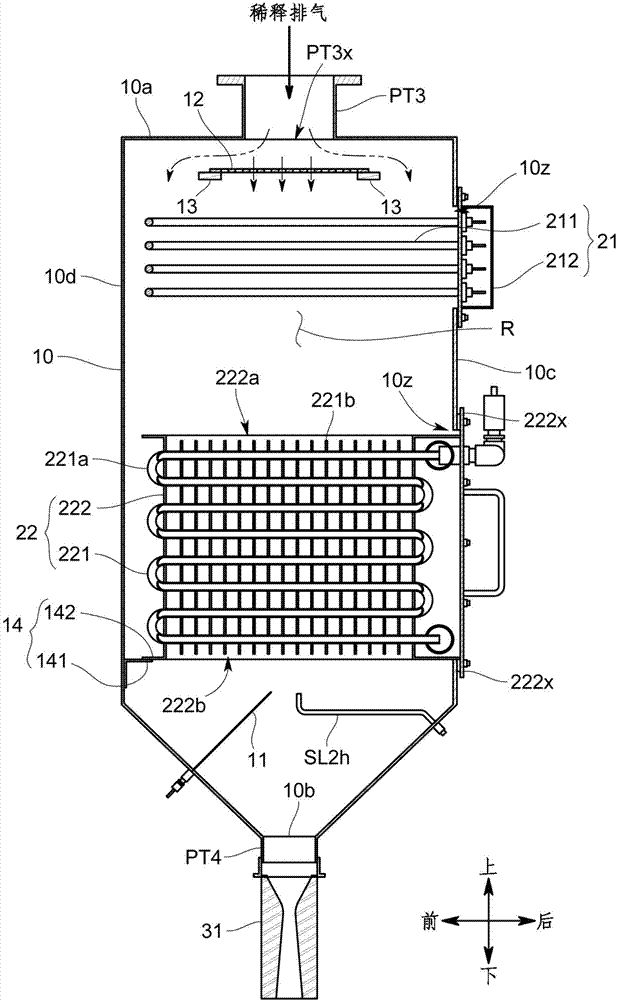

[0053] Hereinafter, one embodiment of the exhaust gas sampling device of the present invention will be described with reference to the drawings.

[0054] The exhaust gas sampling device 100 of this embodiment is used, for example, in a gas analysis system for analyzing components contained in exhaust gas discharged from an engine, etc., and the exhaust gas is diluted several times with a dilution gas such as the atmosphere (air for dilution). (For example, 10 times to 20 times), and a device that performs concentration measurement in a dilution sampling manner.

[0055] Specifically, as figure 1 As shown, the exhaust gas sampling device 100 includes: a diluted exhaust gas channel R, through which the diluted exhaust gas obtained by diluting the exhaust gas with a dilution gas flows; a temperature adjustment mechanism 2, It is arranged on the diluted exhaust flow path R to adjust the temperature of the diluted exhaust gas; the flow control mechanism 3 (constant volume sampling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com