Overpressure exhaust device

A technology of exhaust device and valve body, which is applied in the direction of valve device, valve operation/release device, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

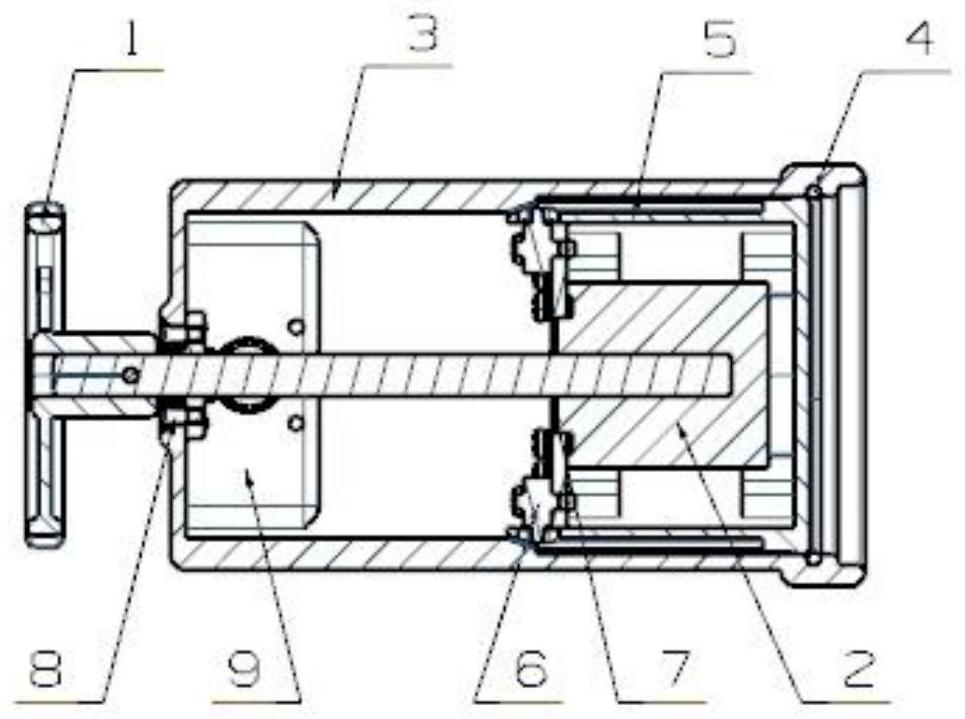

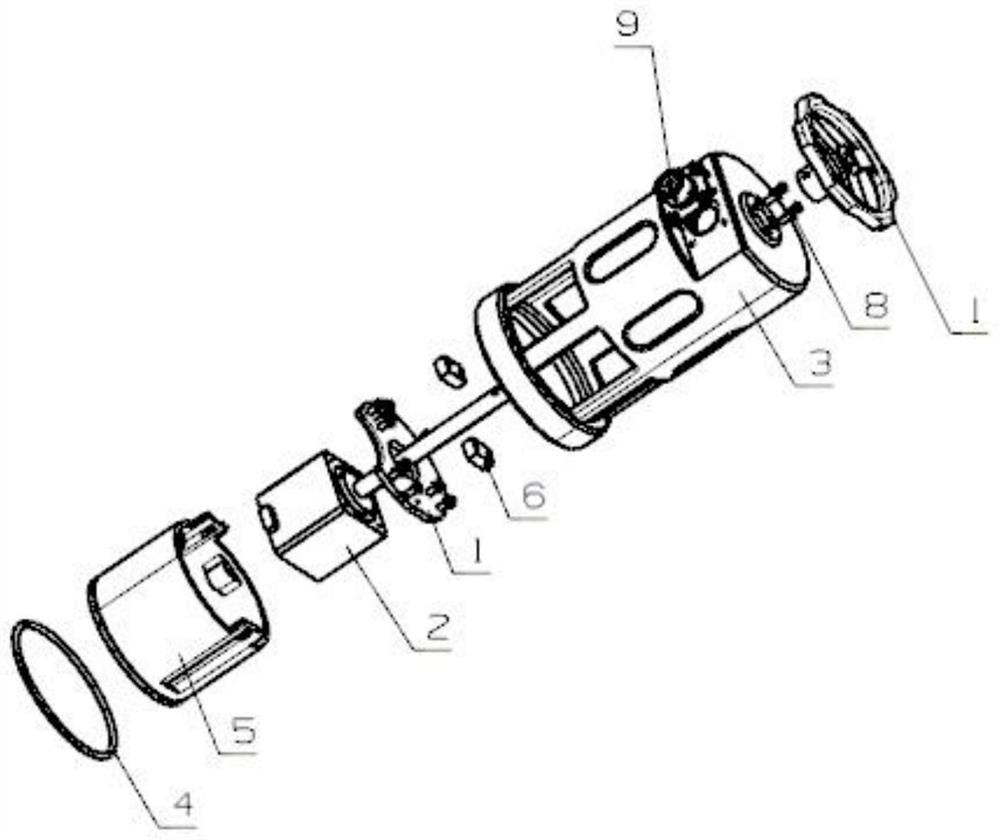

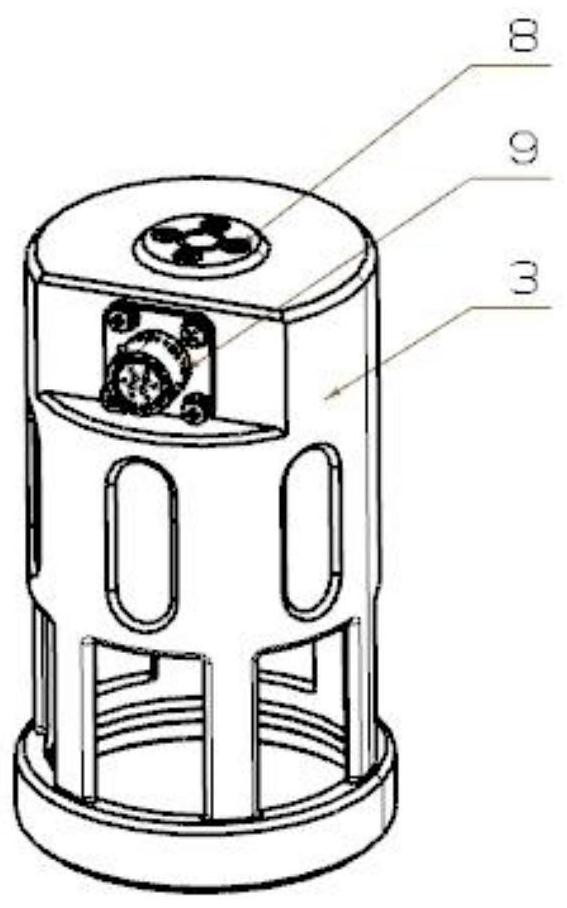

[0027] This embodiment proposes an overpressure exhaust device, the structure of which is as follows: figure 1 with 2 As shown, it includes a hand wheel 1, a screw stepper motor 2, a valve body 3, a sealing ring 4, a valve core 5, a position switch 6, a support plate 7, a ring nut 8 and an electrical connector 9. Among them, such as Figure 3-6 As shown, the valve body 3 , the ring nut 8 and the electrical connector 9 form a valve body assembly 10 . The spool 5 , the support plate 7 , the screw stepping motor 2 and the position switch 6 form a spool assembly 11 .

[0028] The valve body 3 adopts an asymmetric structure as a whole, and the ring wall of the valve body is processed with six identical exhaust windows. c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com