Inlet flow mixing pipe of desulfurizing tower

An air intake pipe and integrated technology, which is applied in the direction of ship propulsion, propulsion components, outboard propulsion devices, etc., can solve the problems of affecting the operation of the main engine and generator, large back pressure of exhaust gas emission, and large space occupation, and achieves a simple and beautiful connection method , smooth exhaust, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

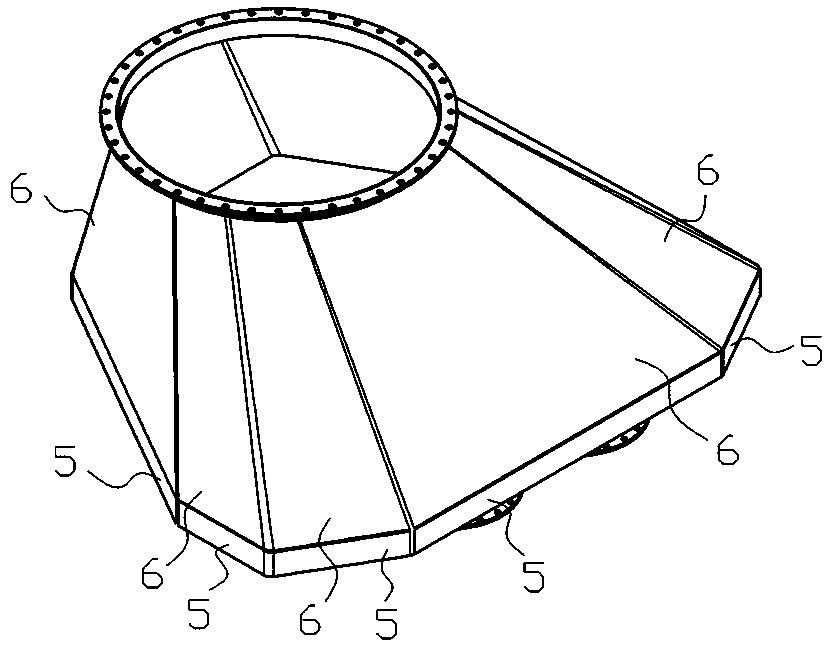

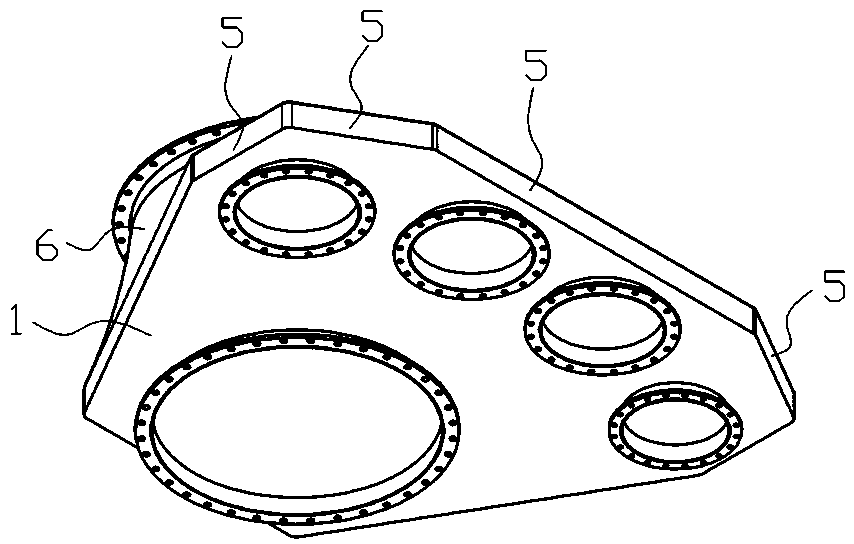

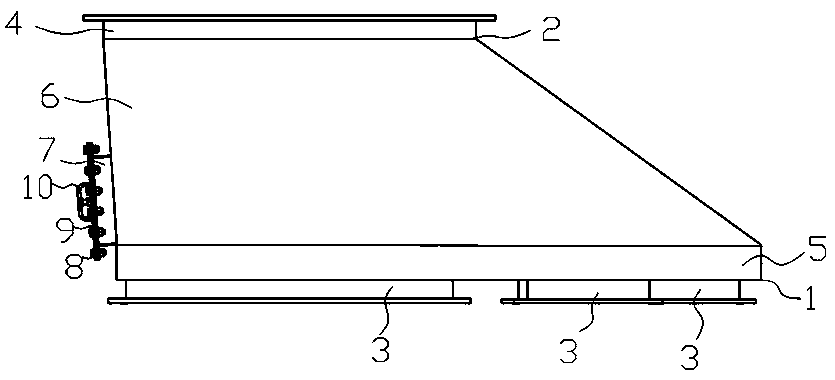

[0008] An inlet mixed flow pipe of a desulfurization tower, such as figure 1 value image 3 As shown, it includes a bottom seal plate 1 and a connection plate 2 above the bottom seal plate 1, the bottom seal plate 1 and the connection plate 2 are connected as a whole through a peripheral plate, the bottom seal plate 1, the connection plate 2 and the peripheral plate The inner space for exhaust gas is enclosed; the bottom seal plate 1 is provided with generator air intake holes, main engine air intake holes and boiler air intake holes, and the connection plate 2 is provided with air outlet holes, and the generator hole, the air inlet of the main engine and the air inlet of the boiler are all provided with an air inlet pipe 3, and an air outlet pipe 4 is arranged at the air outlet, the center of the air inlet of the main engine, the air inlet pipe 3 arranged at the air inlet of the main engine The center, the center of the air outlet on the connecting plate 2 and the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com