Compressed air energy storage system and method

A technology of compressed air energy storage and air, applied in the field of energy storage, can solve the problems of throttling loss and unstable inlet pressure of the expander.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

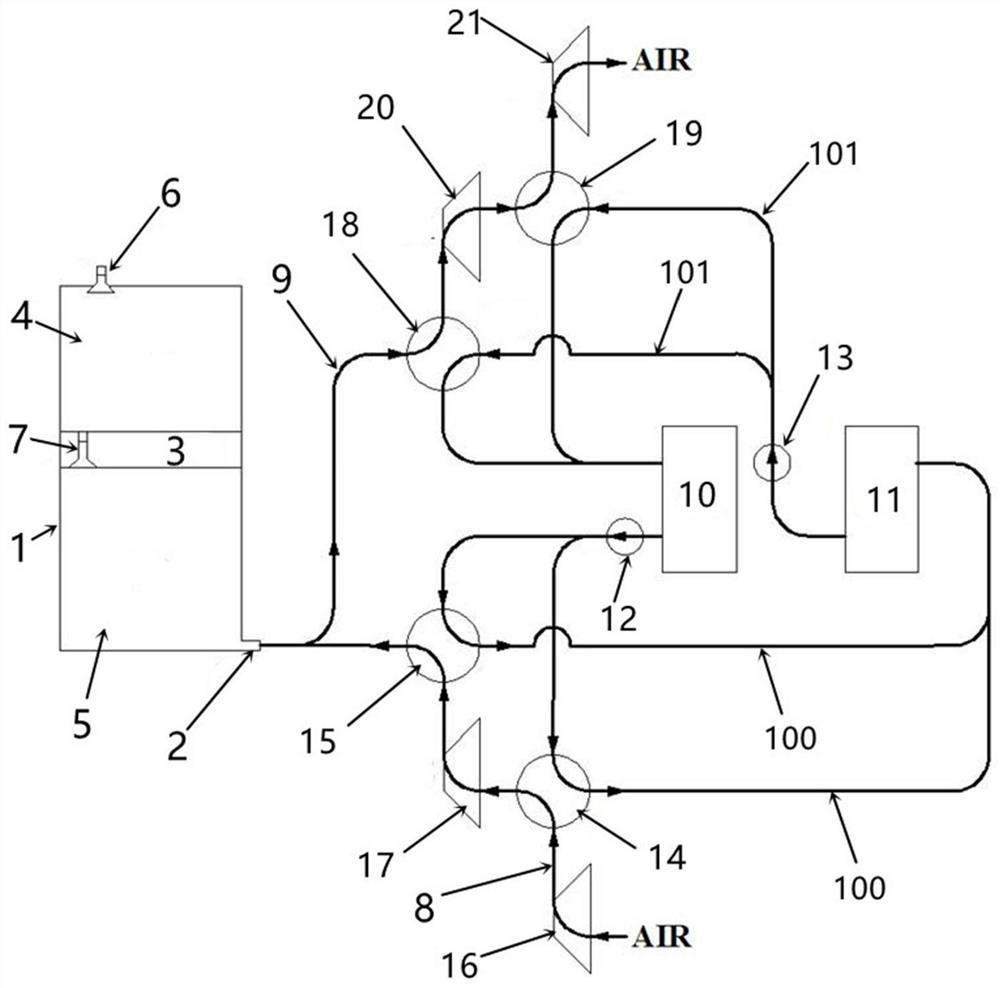

[0050] Combine below figure 1 Describe a compressed air energy storage system of the present invention, a compressed air energy storage system, including an air chamber 1 and an air charging and discharging nozzle 2, and a piston 3 that can move up and down is installed in the air chamber 1, and the piston 3 and the air chamber 1. The inner walls are sealed and lubricated well, and can move up and down freely. The piston 3 separates the air chamber 1 into the upper low-pressure chamber 4 and the lower high-pressure chamber 5. When the piston 3 moves up and down, the volume of the high-pressure chamber 5 and the low-pressure chamber 4 The low-pressure chamber 4 is provided with a low-pressure communication port 6 that can be connected to the outside world. When the low-pressure communication port 6 is opened, the low-pressure chamber 4 communicates with the external environment and the pressure is balanced. Connect the high-pressure communication port 7 of the low-pressure cham...

Embodiment 2

[0078] This embodiment is similar to Embodiment 1, the difference is that the inflation method in the operation method is different, as follows:

[0079] S1, using a braking mechanism to control the piston 3 to be stationary;

[0080] S2, open the high-pressure communication port 7, connect the low-pressure chamber 4 to the high-pressure chamber 5, balance the pressure in the high-pressure chamber 5 and the low-pressure chamber 4, and balance the pressure P2

[0081] S3, open the inflation and discharge nozzle 2 and the air compression pipeline 8, start the first-stage compressor 16 and the second-stage compressor 17, and ignore the resistance loss along the way, the initial back pressure of the second-stage compressor 17 is P2, here The power consumption of the air compressor unit is W2;

[0082] The outside air is continuously compressed by the first-stage compressor 16 and the second-stage compressor 17 during the process of entering the high-pressure chamber 5 from th...

Embodiment 3

[0088] This embodiment is similar to Embodiment 1, the difference is that the inflation method in the operation method is different, as follows:

[0089] When inflation is required, the following steps are included:

[0090] S1, open the low-pressure communication port 6, the inflation and deflation pipe port 2 and the air compression pipeline 8, so that the pressure in the high-pressure chamber 5 and the low-pressure chamber 4 is balanced, and the balance pressure P2<P1;

[0091] S2, start the first-stage compressor 16 and the second-stage compressor 17, and the external air is continuously compressed by the first-stage compressor 16 and the second-stage compressor 17 after entering the high-pressure chamber 5 from the air compression pipeline 8, so as to Make the air pressure in the high-pressure chamber 5 continue to rise and push the piston 3 to move upward, and the initial back pressure of the secondary compressor 17 is P2;

[0092] S3, while performing step S2, open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com