Airway pressure relief valve

A technology of airway pressure and safety valve, applied in the direction of safety valve, valve, valve details, etc., can solve the problems of safety valve operation, easy to exceed, complicated control method, etc., to achieve the effect of smooth exhaust and safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

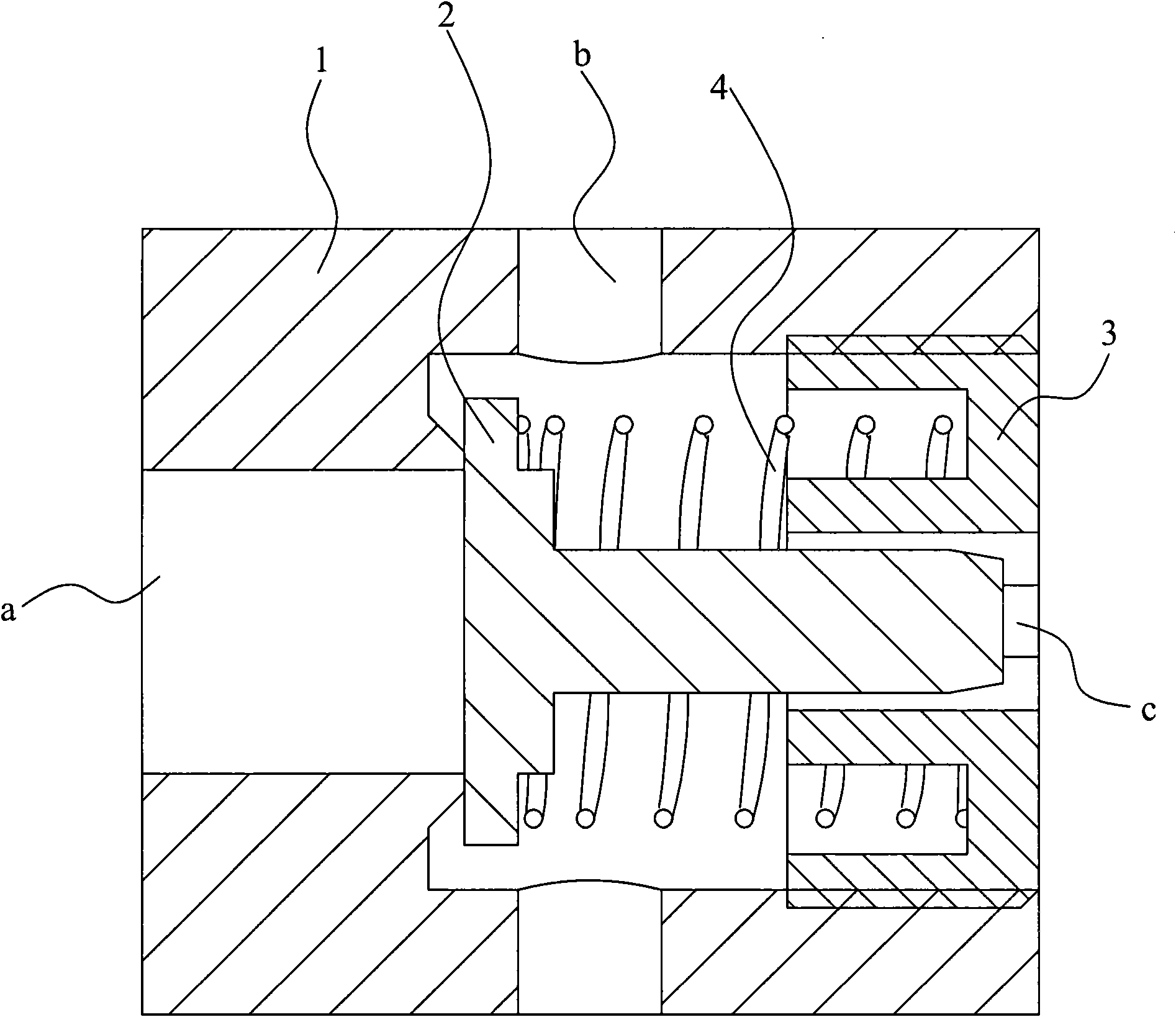

Image

Examples

Embodiment Construction

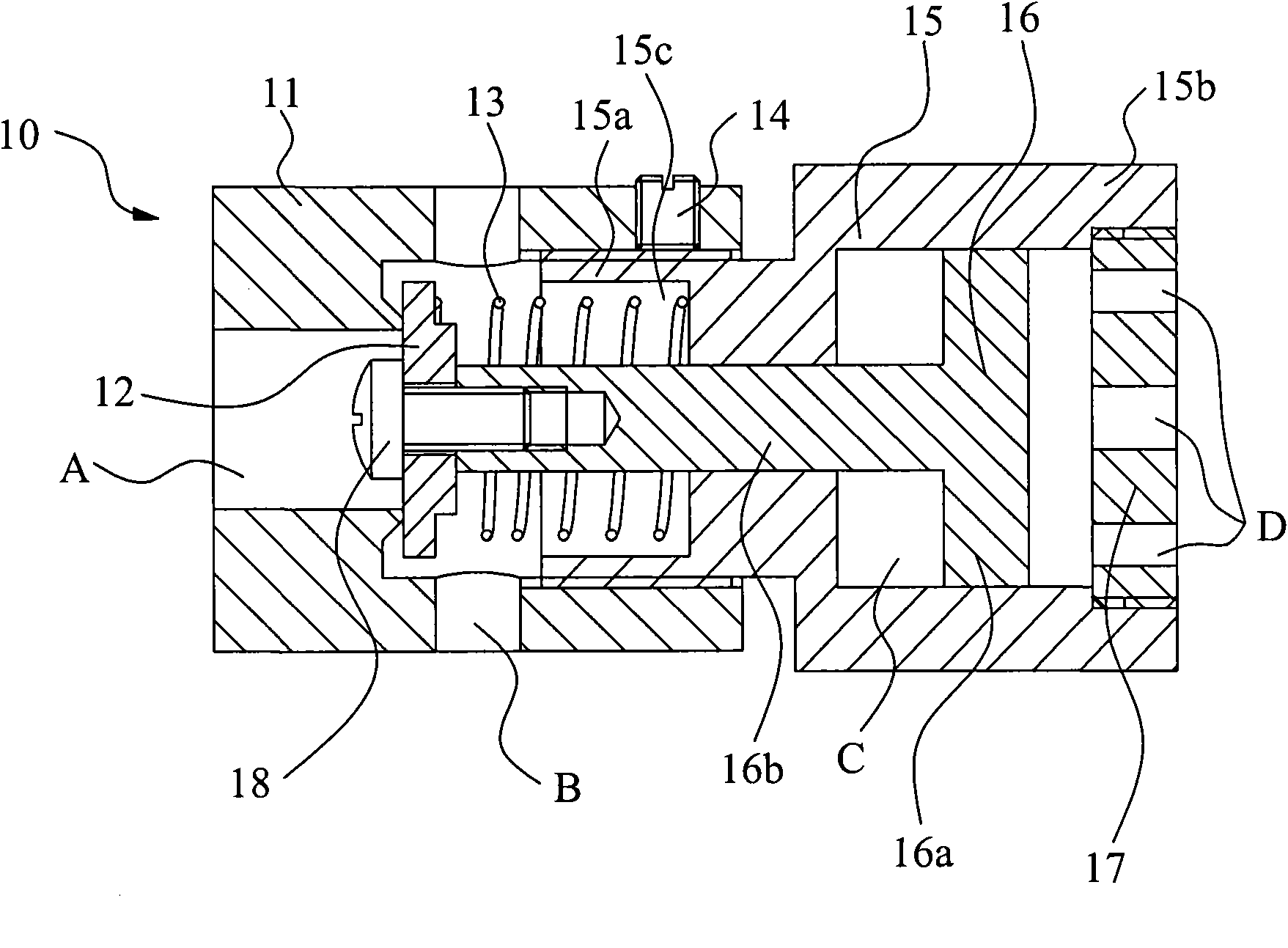

[0023] The specific implementation of the present invention will be described below with reference to the accompanying drawings and in conjunction with the preferred embodiments of the present invention.

[0024] Reference figure 2 , Which shows a schematic cross-sectional structure diagram of an airway pressure safety valve according to a preferred embodiment of the present invention. The airway pressure safety valve mainly includes: a valve body 11, which has a first vent hole A communicating with the patient’s airway and a second vent hole B communicating with the atmosphere; a sealing ring (that is, the second end of the piston 16, In this case, the second end of the piston is detachable) 12, which is arranged in the chamber of the valve body 11 and abuts on the first vent hole A to seal the first vent hole A when the safety valve is not opened. Spiral spring (elastic member) 13, which is arranged in the cavity of the valve body 11 and one end biases the sealing ring 12, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com