Environmentally friendly air dust removal equipment for chemical workshop and using method thereof

An air dust removal and chemical technology, applied in the direction of the swirling flow can be reversed in the direction of the device, swirl device, etc., can solve the problems of environmental protection, environmental impact, easy accumulation of dust in the exhaust pipe, etc., to achieve smooth exhaust, The effect of slowing down the wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

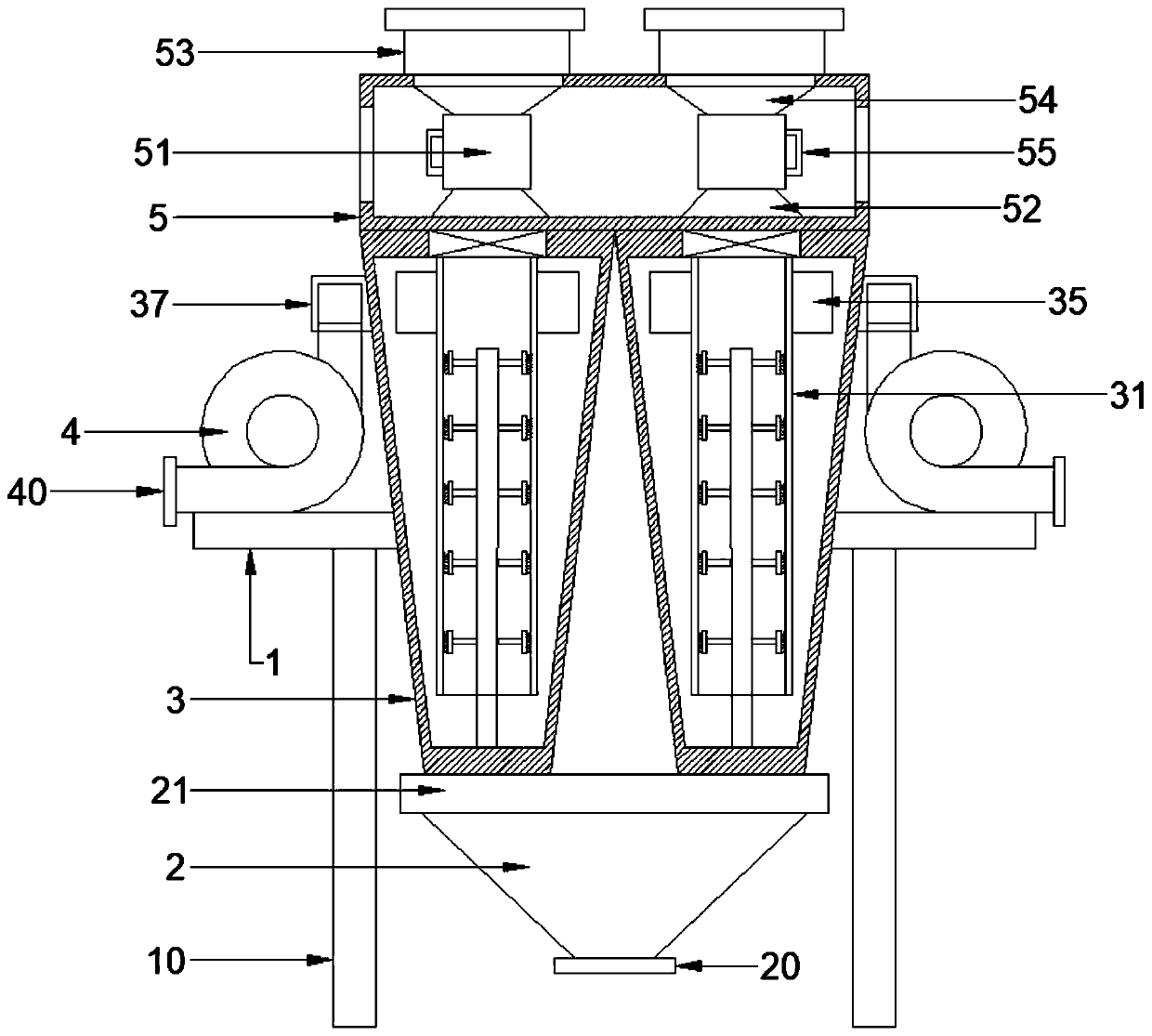

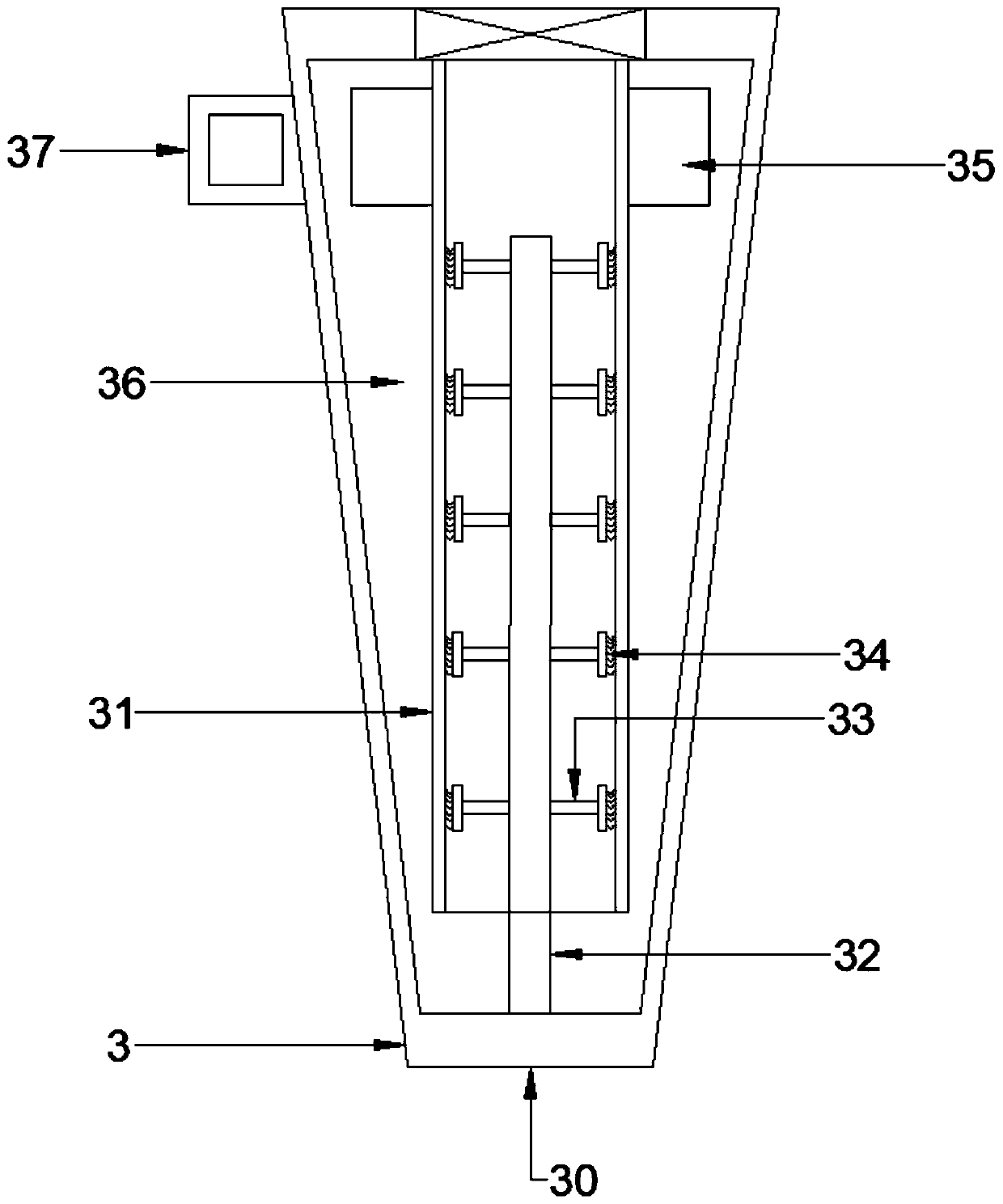

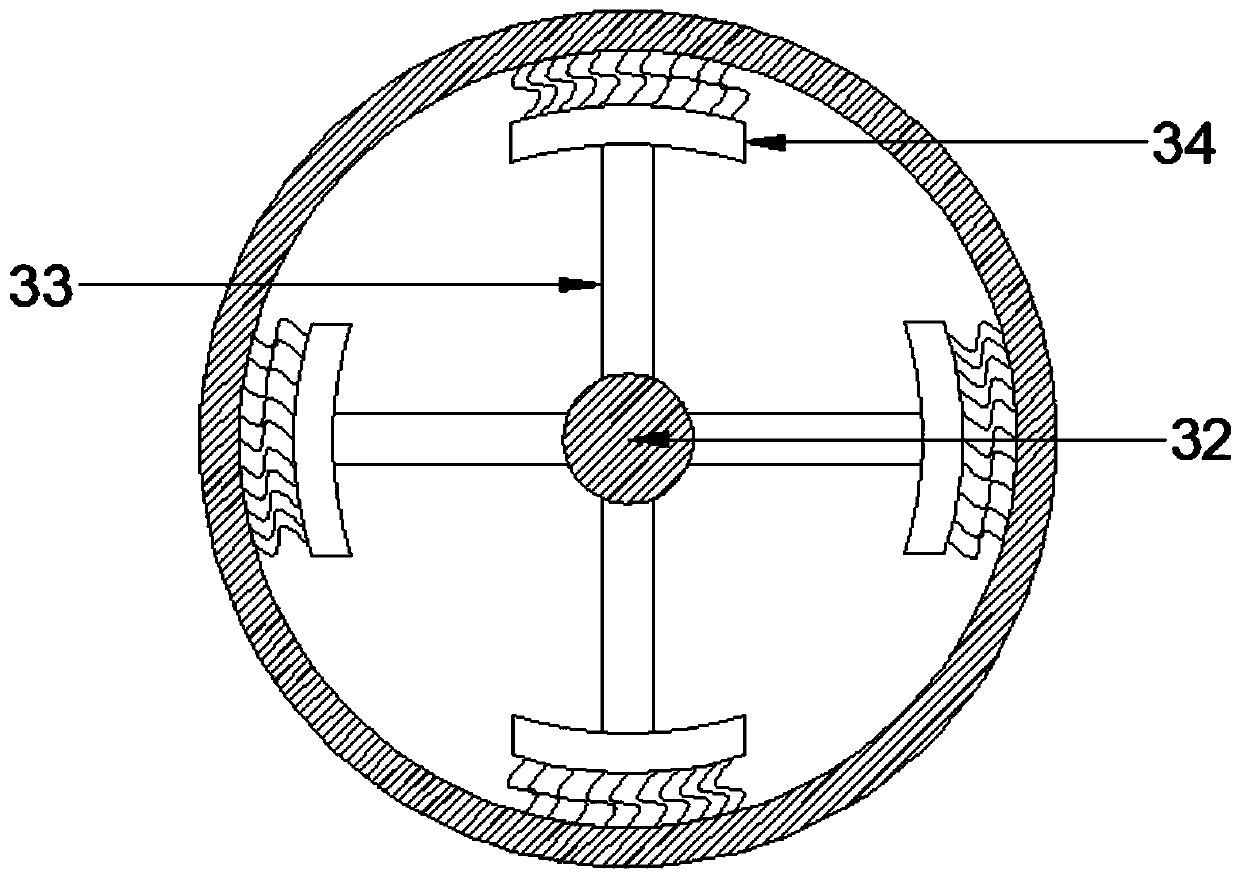

[0033] see Figure 1-5 , an environment-friendly air dust removal equipment for chemical workshops, including a support platform 1, a sewage bucket 2, a cyclone dust removal box 3, an air pump 4, and a secondary filter box 5, and a plurality of support columns are fixed on the bottom surface of the support platform 1 10. Two cyclone dust collectors 3 arranged side by side are installed on the top surface of the support platform 1. Two air suction pumps 4 are installed on both sides of the top surface of the support platform 1. The exhaust end of the air suction pump 4 is connected to Next to the air inlet 40, the exhaust end of the air pump 4 is connected to the air inlet 37, and the air inlet 37 is set at the top position of the outer wall of the cyclone dust collector 3 along the tangential position of the side wall of the cyclone dust collector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com