Integrated double-cavity liquid storage tank for new energy vehicle

A new energy vehicle, liquid storage tank technology, applied in vehicle parts, heating/cooling equipment, air handling equipment and other directions, can solve the problem that the design of three liquid storage tanks cannot meet the requirements, etc., to save layout space, easy to implement, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

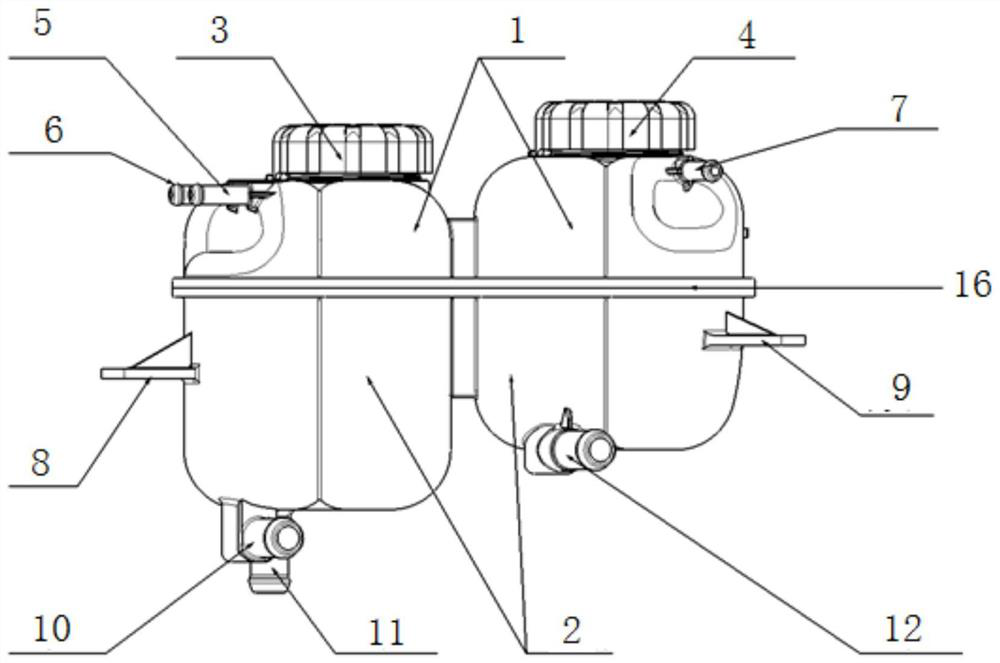

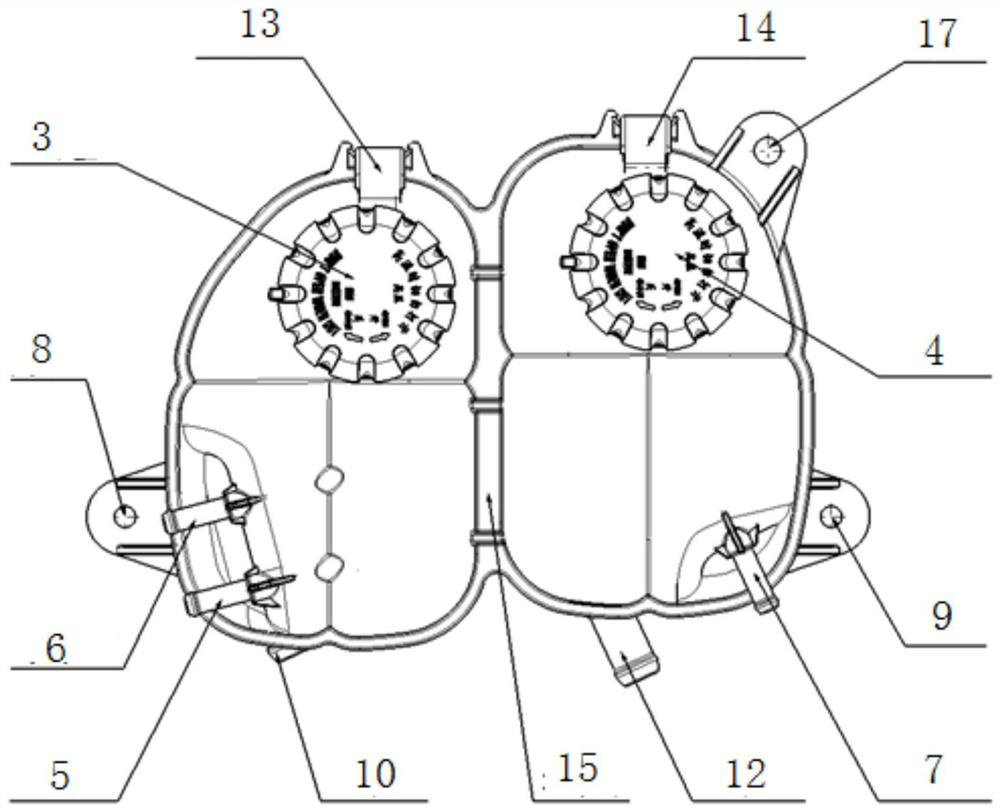

[0032] An integrated double-chamber liquid storage tank for new energy vehicles, including an upper shell 1, a lower shell 2, a pressure cover 3, a pressure cover 4, a first air return port 5, a second air return port 6, and a third air return port. Air return port 7, No. 1 water supply port 10, No. 2 water supply port 11, No. 3 water supply port 12, No. 1 overflow port 13, No. 2 overflow port 14, No. 1 bracket 8, No. 2 bracket 9, No. 3 bracket 17 .

[0033] The upper and lower shells are two injection molded shells, the upper shell 1 is provided with two cavities, the lower shell 2 is provided with two cavities corresponding to the positions of the cavities of the upper shell, and the upper shell The two cavities are connected by connecting ribs, and the two cavities of the lower shell are also connected by connecting ribs. After the upper and lower shells are welded by a hot plate, the upper and lower cavities are butted to form two completely independent cavities. That is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com