Vacuum pressure continuous control process for polysilicon ingot casting process and control system thereof

A technology of vacuum pressure and control method, applied in the direction of polycrystalline material growth, chemical instruments and methods, crystal growth, etc., can solve the problems of affecting the performance of polycrystalline silicon, unsuitable for long-term operation, easy to produce overshoot in vacuum pressure, etc., and achieve ideal control effect. , The effect of saving input gas consumption and exhausting at the same time is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

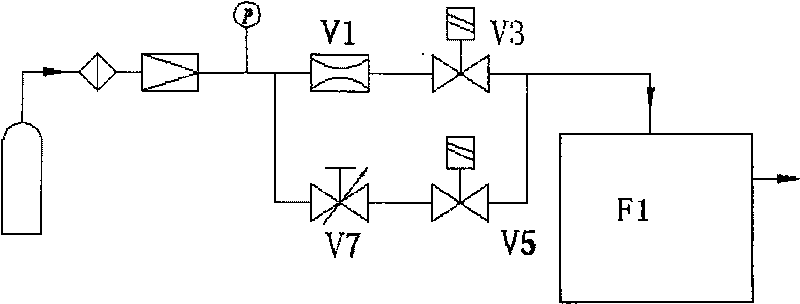

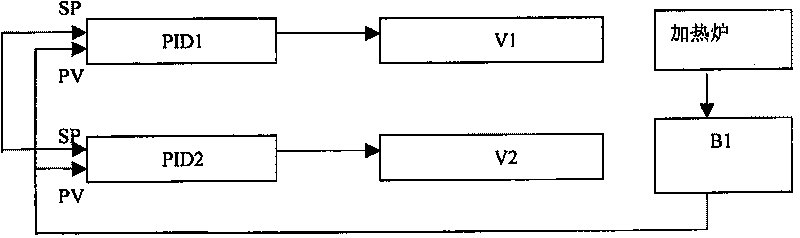

[0040] see Figure 1 to Figure 3 , the specific description of this embodiment is as follows:

[0041] Intake flow control adopts gas mass flow controller V1, input standard control voltage 0.0-5.0V, corresponding to gas control flow 0-full scale, continuous linear control mode. At the same time, a gas input bypass branch composed of a manual bypass intake regulating valve V7 and a bypass intake solenoid valve V5 is set up, which is used for the occasion of manual intake of large flow in the heating furnace F1, and does not participate in the continuous control of furnace pressure.

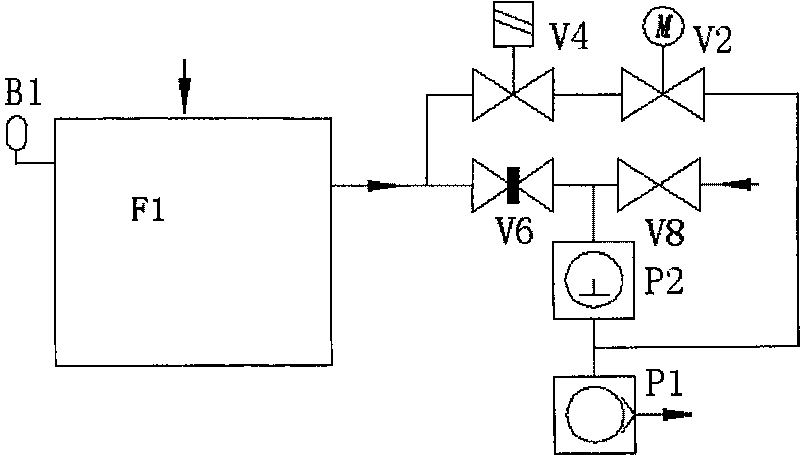

[0042] The vacuum exhaust control adopts the vacuum exhaust proportional valve V2, the input standard control current is 4.0-20.0mA, the corresponding output opening is 0.0-100.0%, and the continuous linear control mode.

[0043] Vacuum pressure detection adopts capacitive pressure sensor B1, that is, vacuum gauge, whose feedback voltage is 0-10V, corresponding to vacuum pressure 0-1333mbar, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com