Air blowing pre-ventilation device of injection blowing molding machine

A technology of blowing pre-passing and forming machine, applied in the field of thermoplastic molding, can solve the problems of easy bursting and deformation of products, difficult opening of air vents, long action cycle, etc., and achieve the effects of simple structure, short exhaust time and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

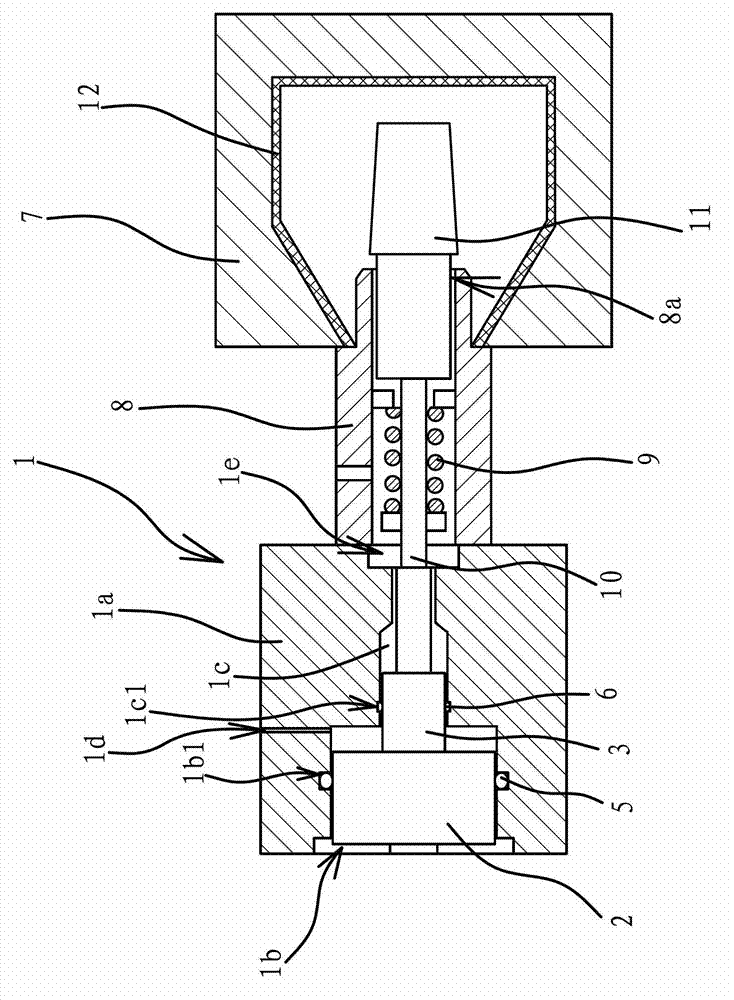

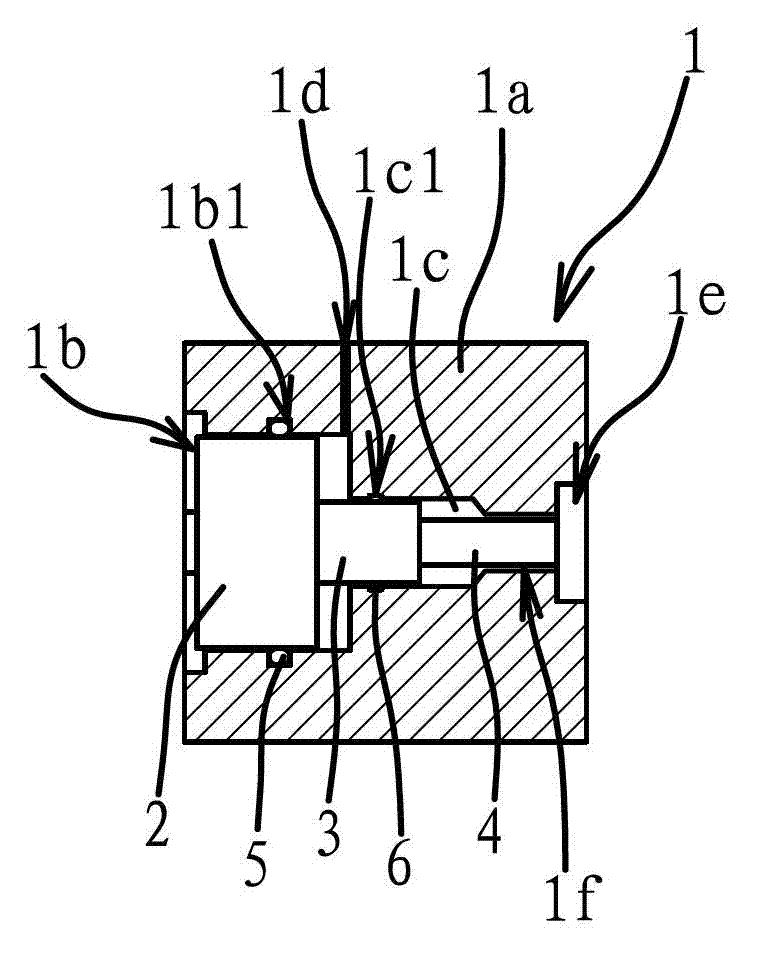

[0028] Such as figure 1 As shown, a blowing pre-passing device for an injection-blow hollow molding machine includes a double-diameter cylinder 1, and the double-diameter cylinder 1 includes a cylinder body 1a. The diameter of body one 1b is twice the diameter of cavity two 1c. Cavity one 1b and cavity two 1c are provided with matching piston one 2 and piston two 3 respectively, and the outside of piston two 3 communicates with the outside of cylinder 1a. The inner wall of cavity one 1b is provided with an annular groove one 1b1, and a sealing ring one 5 is embedded in the annular groove one 1b1; the inner wall of cavity two 1c is provided with an annular groove two 1c1, and a sealing ring is embedded in the annular groove two 1c1 Circle two 6. The side of the piston-2 is in contact with the sealing ring-5 to form a seal. When the piston-2 moves, the inner wall of the cavity-1b of the cylinder 1a does not wear, so that the cylinder 1a can have a longer service life. The si...

Embodiment 2

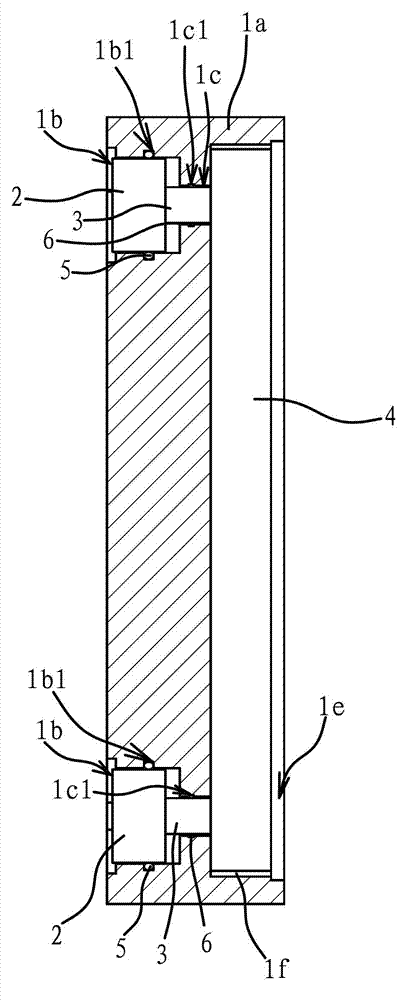

[0034] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: figure 2 and 3 As shown, the blowing pre-passing device also includes a strip-shaped linkage top plate 4, the two ends of the linkage top plate 4 are provided with parallel and dual-diameter cylinders 1 arranged in the same direction, and the sides of the double-diameter cylinders 1 are provided with supply The groove 1f through which the linkage top plate 4 passes, and the groove 1f communicates with the cavity 2 1c. The same side wall of the linkage top plate 4 all leans against the corresponding piston 2 3 . Two double-diameter cylinders 1 are arranged at both ends of the linkage top plate 4, so that the linkage top plate 4 can simultaneously pre-pass the vents 8a of multiple blow molds, so that the injection-blow hollow molding machine can be installed with multiple blow molds. Simultaneous production improves work efficiency; the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com