Reverse filling exhaust method of hydraulic pipeline of clutch booster

A technology of hydraulic pipelines and boosters, which is applied in the directions of fluid pressure actuation devices, fluid pressure actuation system components, control devices, etc., can solve the problems of wasting clutch oil, difficult to discharge gas, and poor exhaust effect, etc. Shorten exhaust time, prevent incomplete separation, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

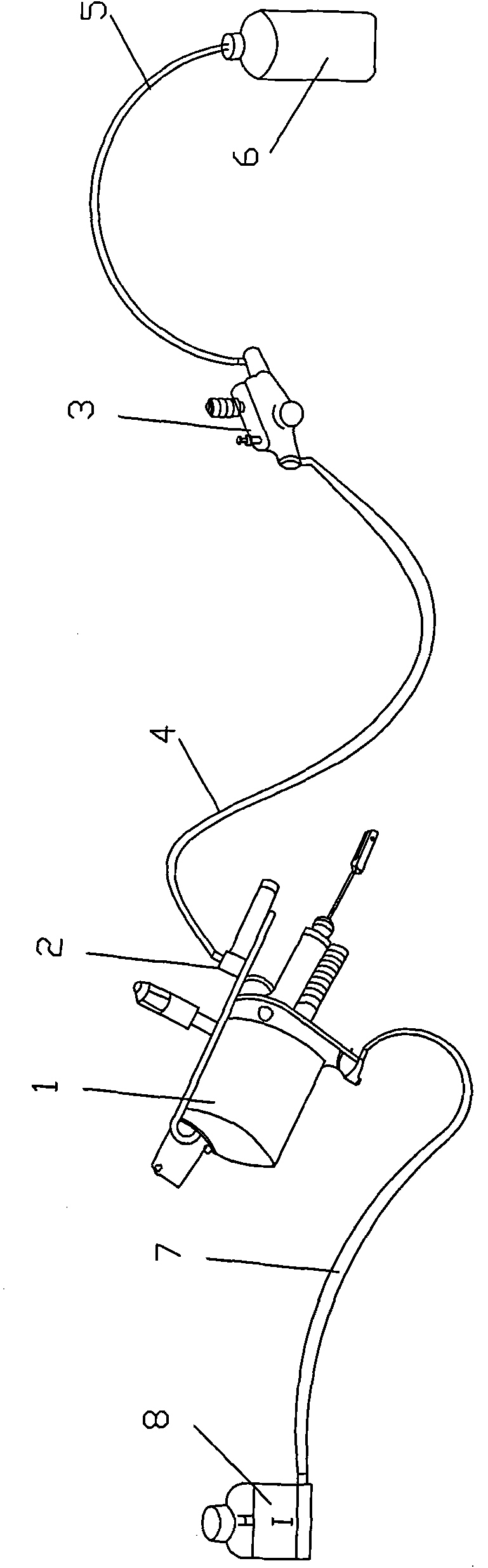

[0015] As shown in the figure, the reverse filling and exhausting method of the hydraulic pipeline of the clutch booster of the present invention includes the following steps:

[0016] 1. Connect one end of two suitable oil pipes to the inlet and outlet ports of the manual oil pump or small electric oil pump respectively. If there is a rubber cover on the air release bolt of the clutch booster, first remove the clutch and replace it with the rubber cover, and replace it with the rubber cover. The other end of the oil pipe connected to the outlet end of the manual oil pump or small electric oil pump is connected to the air release bolt, and the other end of the oil pipe connected to the inlet end of the manual oil pump or small electric oil pump is inserted into a container containing clutch oil;

[0017] 2. Loosen the bleed bolt to keep the hydraulic pipeline of the clutch booster unblocked; press the manual oil pump or start the small electric oil pump, so that the clutch oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com