Rapid exhaust valves for railway vehicles and piping systems for railway vehicles

A technology for railway vehicles and exhaust valves, which is applied in the direction of sliding valves, multi-way valves, valve devices, etc., which can solve the problems of longer discharge time, shortened exhaust, and difficulty in adjusting the area of the exhaust port, so as to improve the opening and closing Operability and sealing performance, effect of preventing air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

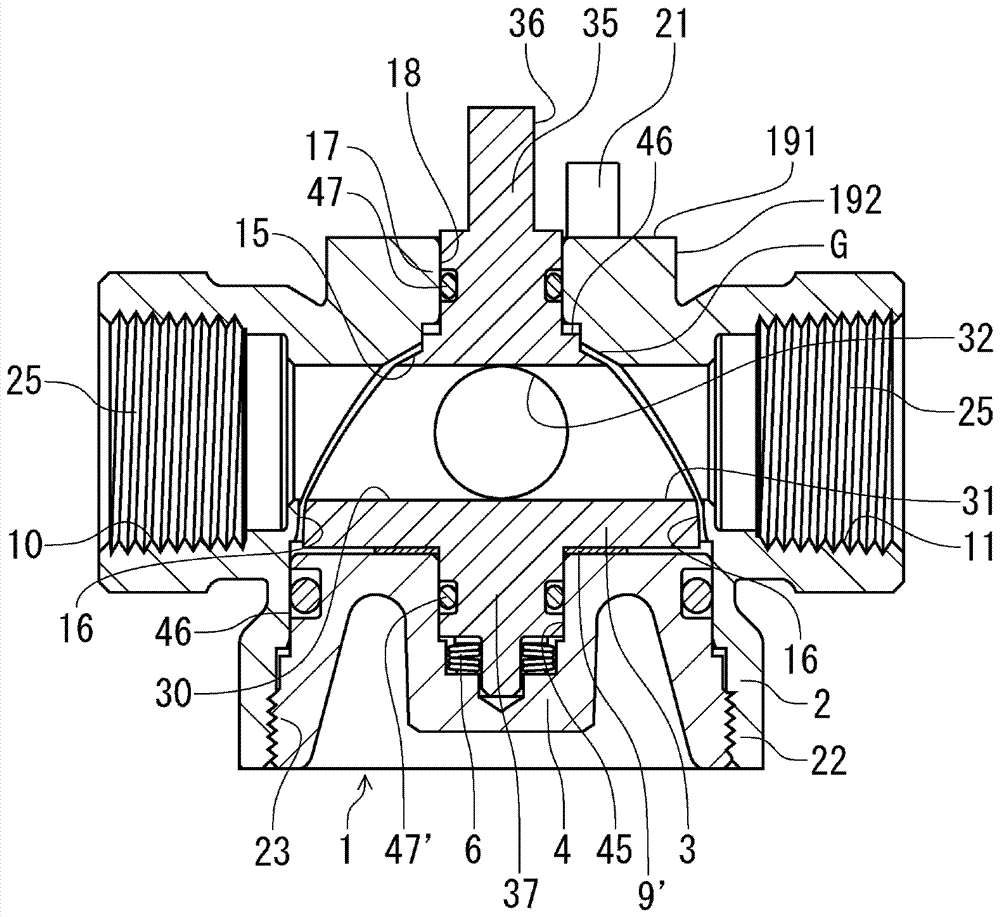

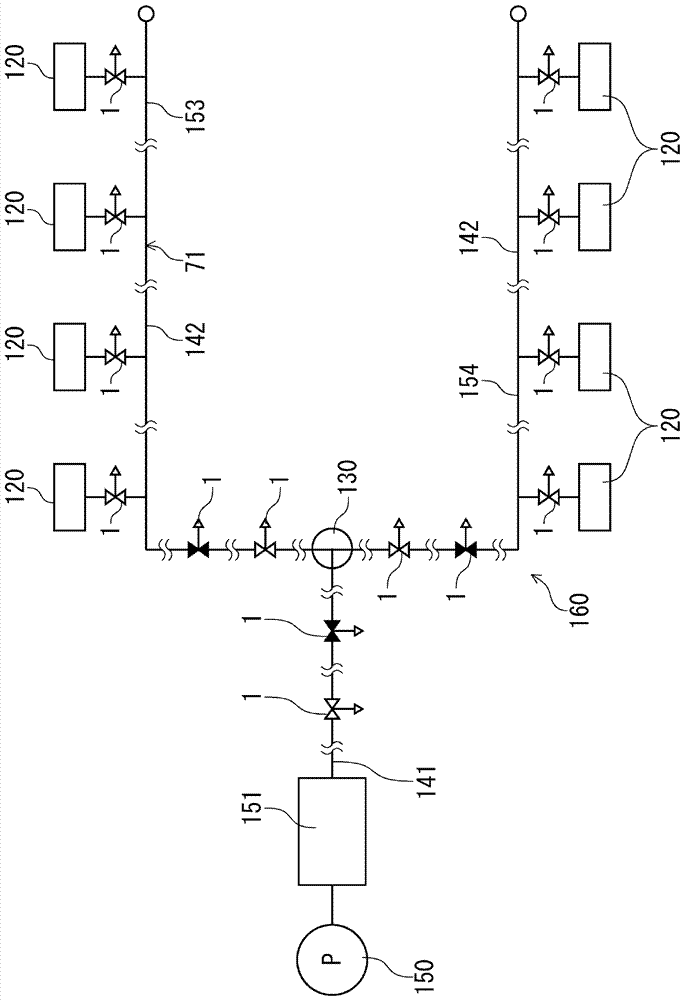

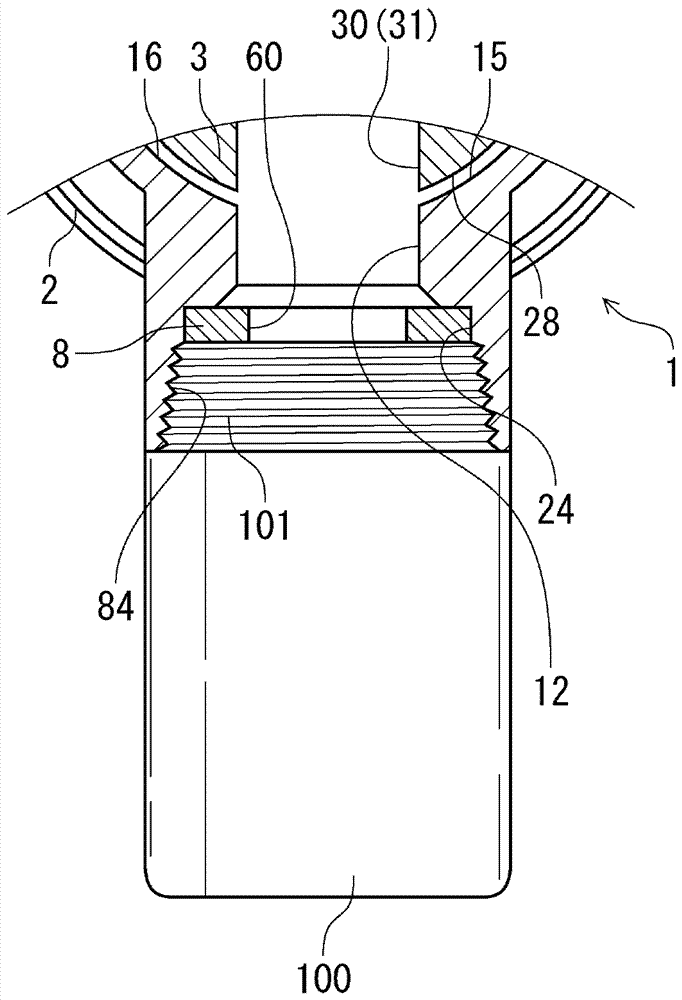

[0093] Hereinafter, embodiments of the rapid exhaust valve for railroad vehicles and the piping system for railroad vehicles of the present invention will be described in detail based on the drawings. exist figure 1 , which shows a perspective view of the first embodiment of the rapid exhaust valve for railway vehicles of the present invention, in figure 2 in, means figure 1 The longitudinal enlarged cross-sectional view of the rapid exhaust valve. The rapid exhaust valve for railway vehicles (hereinafter referred to as the valve main body 1) of the present invention has a valve body 2, a valve body 3, a cover member 4, a sealing member 5, a spring member 6 composed of a disc spring, and a handle 7 for manual operation. , The orifice 8 that exhaust is used.

[0094] exist figure 2 Among them, the valve body 2 of the valve main body 1 is formed into a single structure by materials such as bronze or brass, stainless steel, etc., and has inflow inlets 10, 11, and an exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com