Concave-convex wheel rocker arm type valve distribution mechanism and matched internal combustion engine

A gas distribution mechanism and rocker arm type technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of the crankshaft of internal combustion engines, such as the difficulty of increasing the load and efficiency, and achieve reliable performance, sufficient opening, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

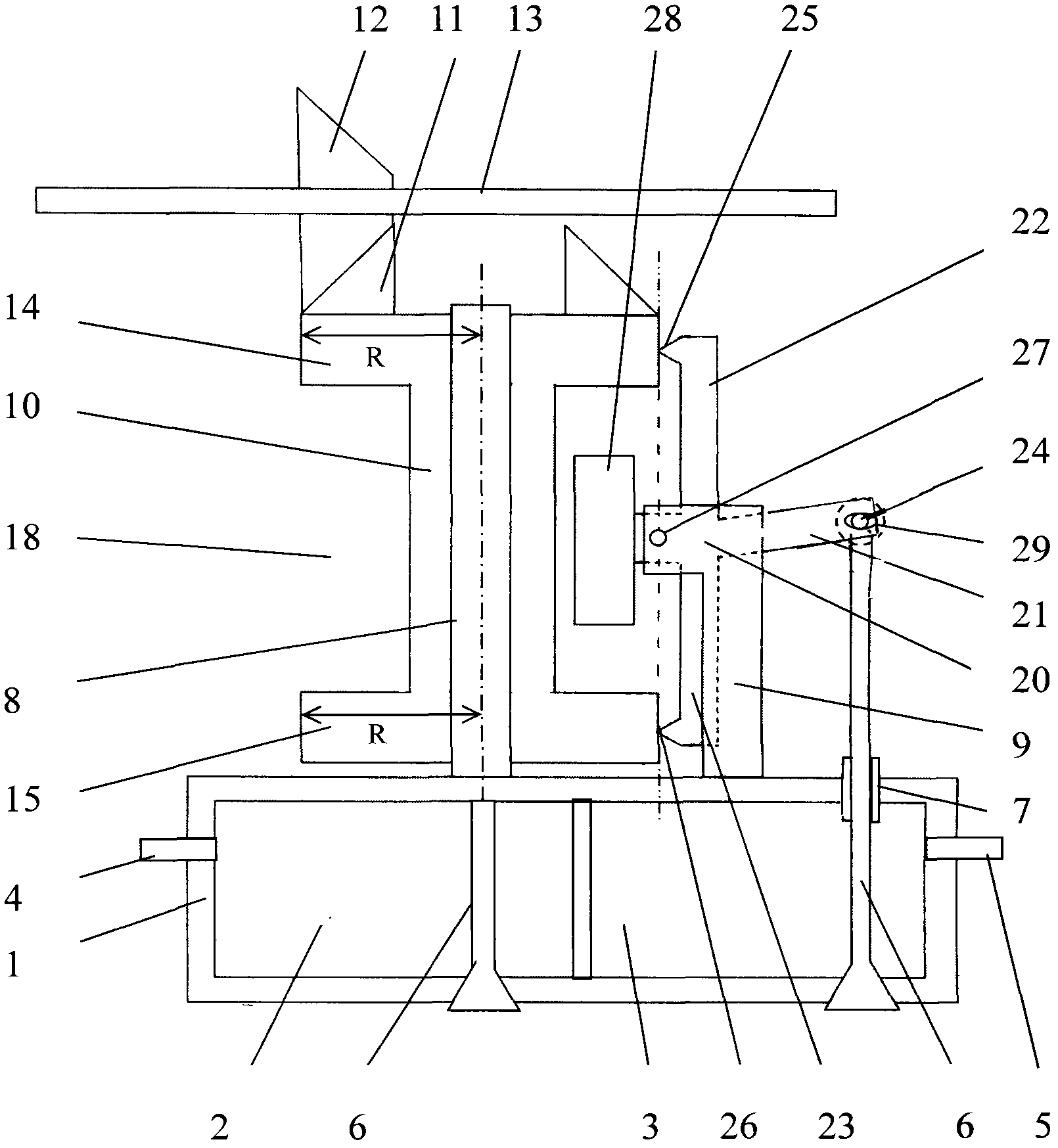

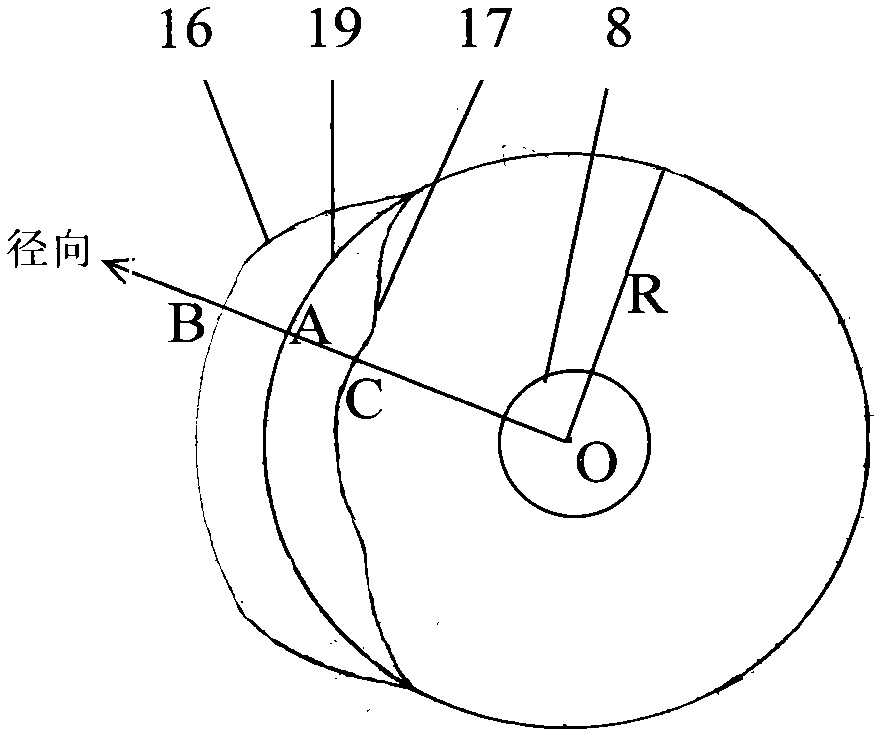

[0041] Such as figure 1 figure 2 image 3 Figure 4 As shown, the convex-concave-wheel rocker arm type air distribution mechanism includes a cylinder head 1. The cylinder head 1 is provided with an intake chamber 2 and an exhaust chamber 3, and the intake chamber 2 is provided with an intake pipe 4 and an exhaust chamber 3. The exhaust pipe 5 is provided on the upper part, and the intake chamber 2 and the exhaust chamber 3 are each provided with a valve 6, that is, an intake valve and an exhaust valve. The valve 6 extends through the guide pipe 7 on the top of the cylinder head 1. surface;

[0042] The cylinder head 1 is provided with a vertical shaft 8 and two rocker arms 9 ( figure 1 Only one rocker arm frame 9 is drawn in the middle, and the other rocker arm frame 9 is located behind the vertical shaft 8);

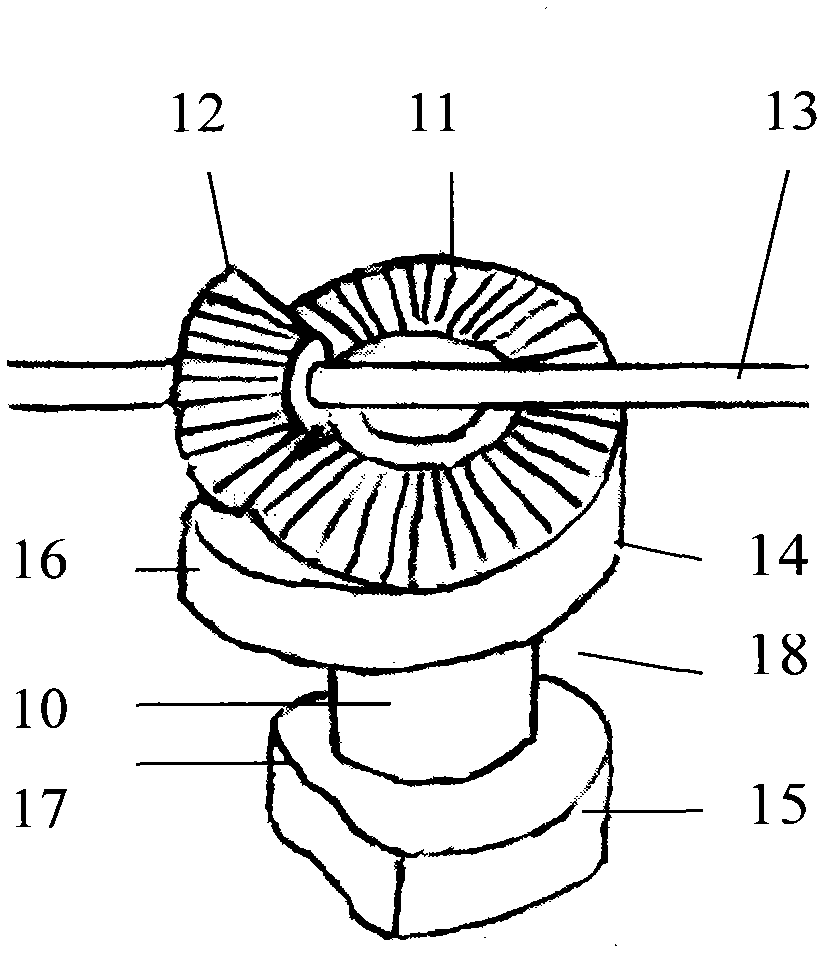

[0043] The vertical shaft 8 is provided with a convex-concave wheel 10, the top of the convex-concave wheel 10 is provided with a bevel-shaped tooth 11, a bevel-shaped gear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com