An engine-driven generator set

An engine-driven, generator-set technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve problems such as reducing engine oil temperature, noise, etc., and achieve a low oil temperature, obvious cooling effect, and high exhaust efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

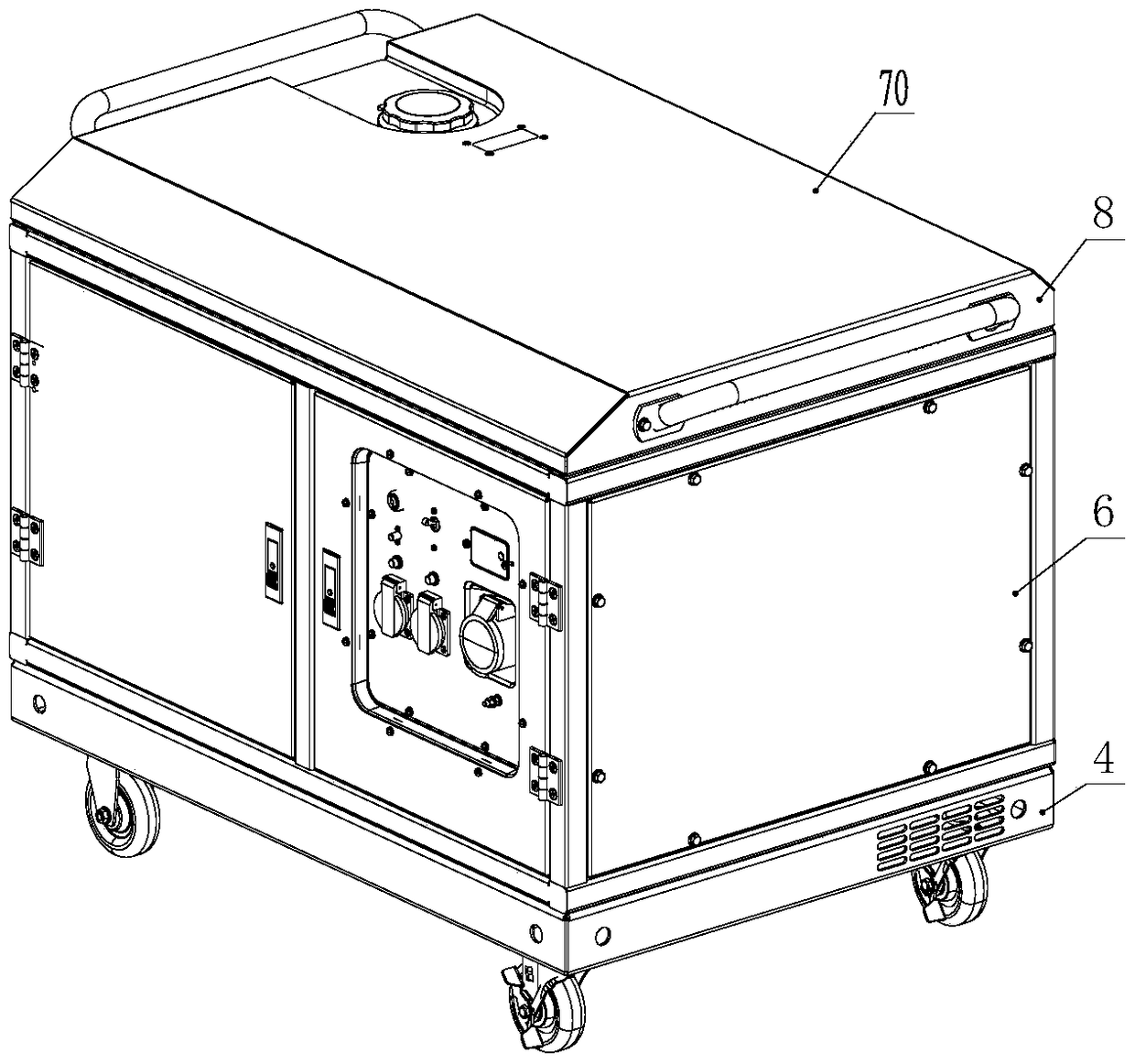

[0044] Such as figure 1 As shown, the engine-driven generator set 100 includes a soundproof box 70 , wherein the soundproof box 70 is composed of a chassis 4 , a side wall 6 and an upper cover 8 .

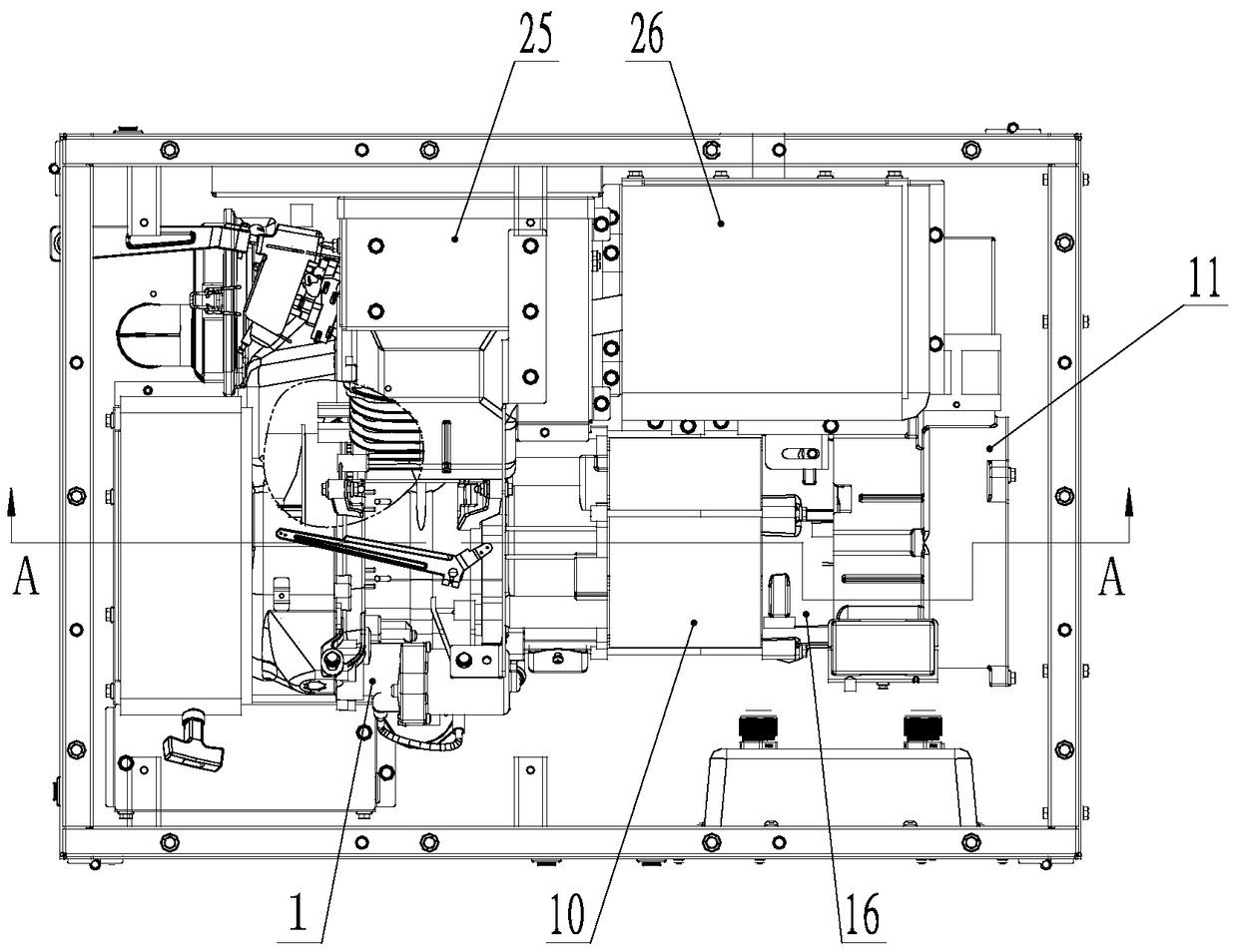

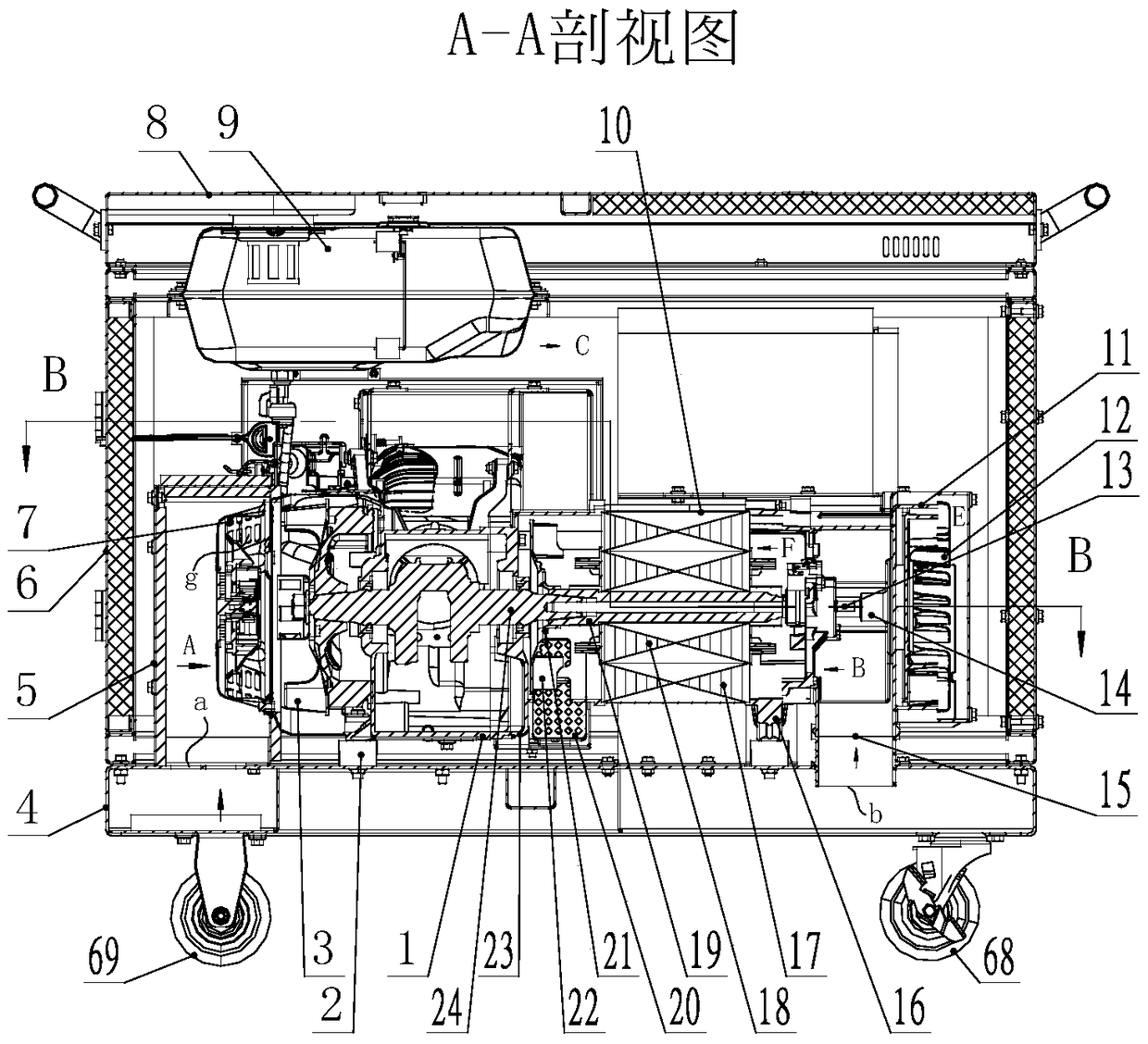

[0045] Such as figure 2 , image 3 and Figure 4 As shown, engine 1, generator 10, motor support 16, air induction shell 11 and oil tank 9 are arranged in the soundproof box, and independent muffler exhaust chamber 26 and hot air exhaust chamber 25, exhaust muffler 36 Arranged in the muffler exhaust chamber 26, one end is connected with the engine exhaust port through the exhaust pipe 34.

[0046] The engine 1 is connected to the chassis 4 through the shock pad 2, which can effectively reduce the vibration of the generator set during the working process. The engine 1 is arranged in the soundproof box 70, and a coaxially connected generator 10, a motor bracket 16, and an air-introduction shell 11 are arranged successively from left to right. The side wall 6 is fixed on the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com