Biomass particle combustion drying equipment

A technology of biomass particles and drying equipment, which is applied in drying, dryers, lighting and heating equipment, etc., can solve the problems of continuous high temperature, limited combustion energy, and low temperature of industrial drying equipment, and ensure The effect of safety and combustion stability, convenient operation and sufficient air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

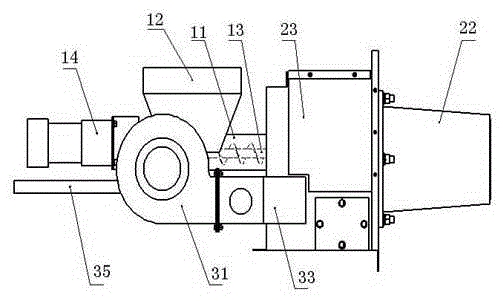

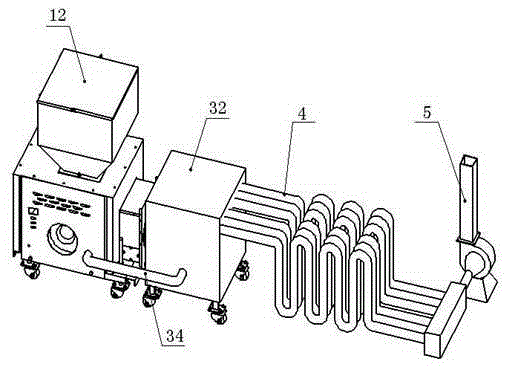

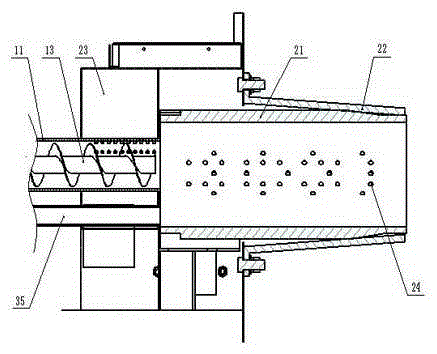

[0032] like Figure 1-3 As shown, the biomass particle combustion and drying equipment of the present invention includes a feed system 1 and a combustion system 2. The feed system 1 includes a feed pipe 11; the combustion system 2 includes a fire outlet pipe 21, a fire guide Pipe 22 and bellows 23; described fire outlet pipe 21 is communicated with feed pipe 11 through bellows 23, and the part of fire outlet pipe 21 that is positioned at bellows 23 is provided with ventilation hole 24; Described fire outlet guide pipe 22 is sleeved on fire outlet pipe 21 Outside, there is a gap between the fire guide pipe 22 and the fire pipe 21 , and the gap communicates with the bellows 23 .

[0033] The feed system 1 also includes a feed box 12, a feed auger 13, a reduction motor 14, the feed auger 13 is installed in the material pipe 11, the reduction motor 14 and the feed auger 13 The linkage drives the feeding auger 13 to rotate and feed in the material pipe 11; one end of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com