Cam with symmetrical profile lines

A shape and symmetrical technology, applied in the field of internal combustion engine parts, can solve the problems of unsatisfactory emission performance, high exhaust temperature, loud noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

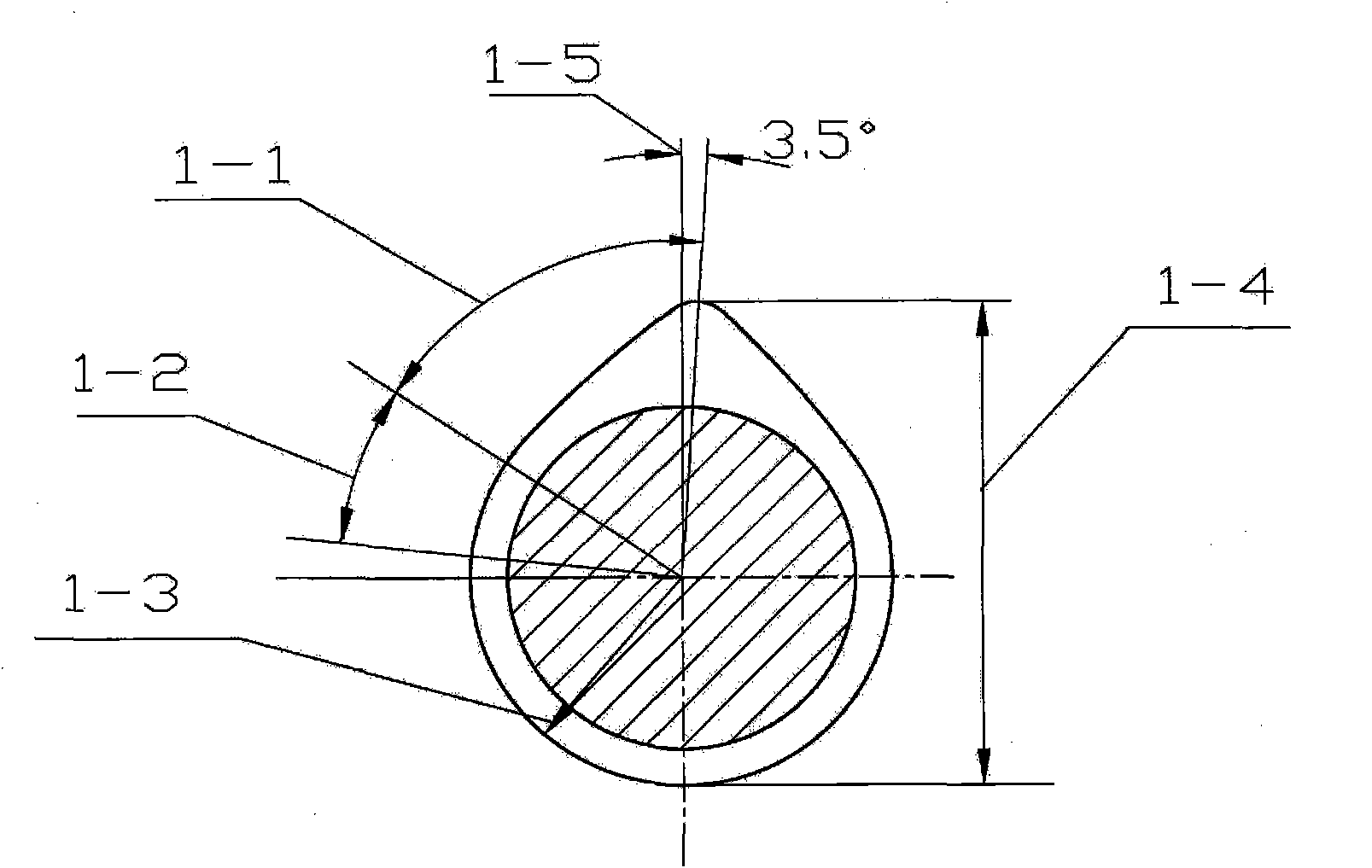

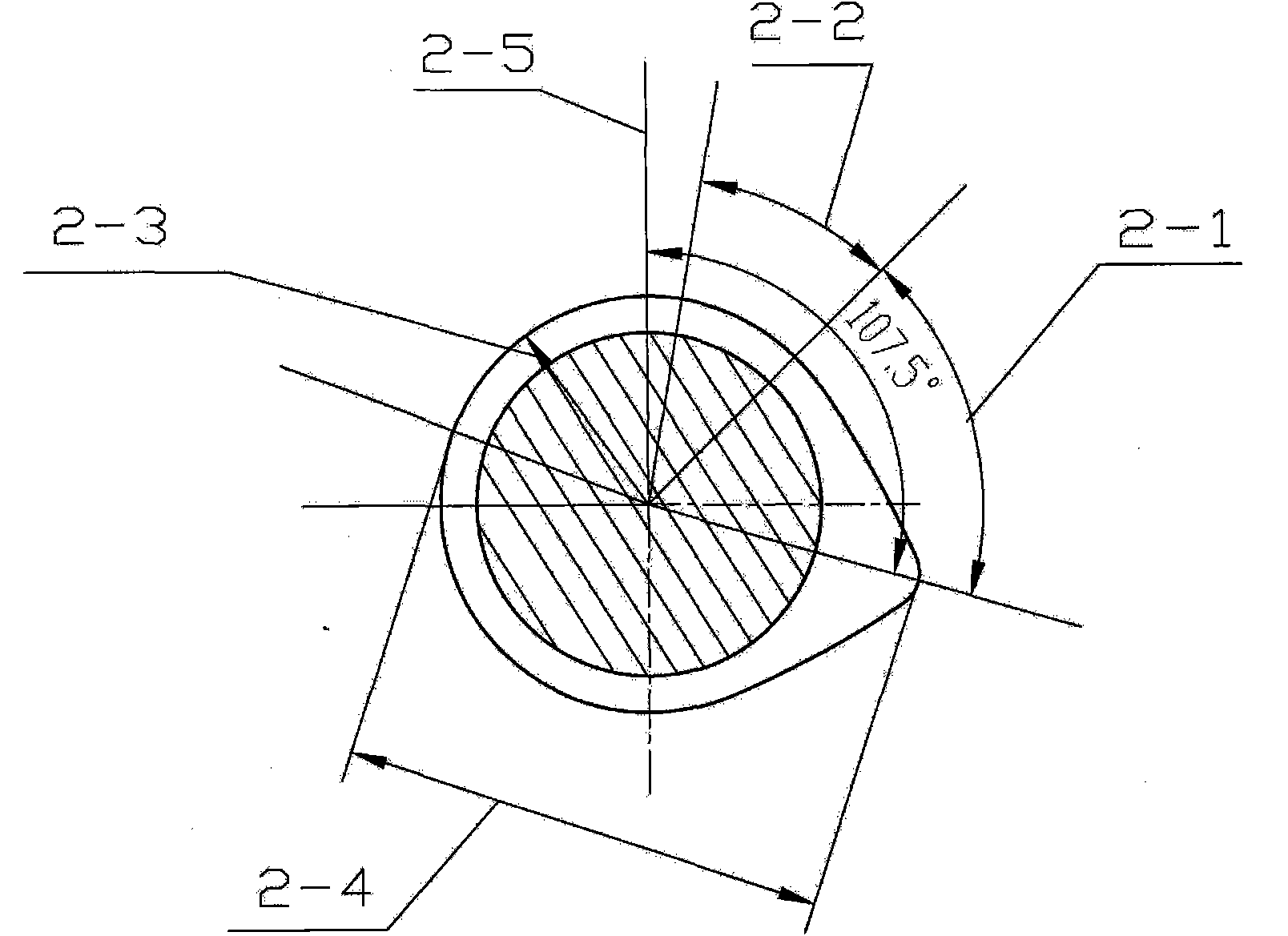

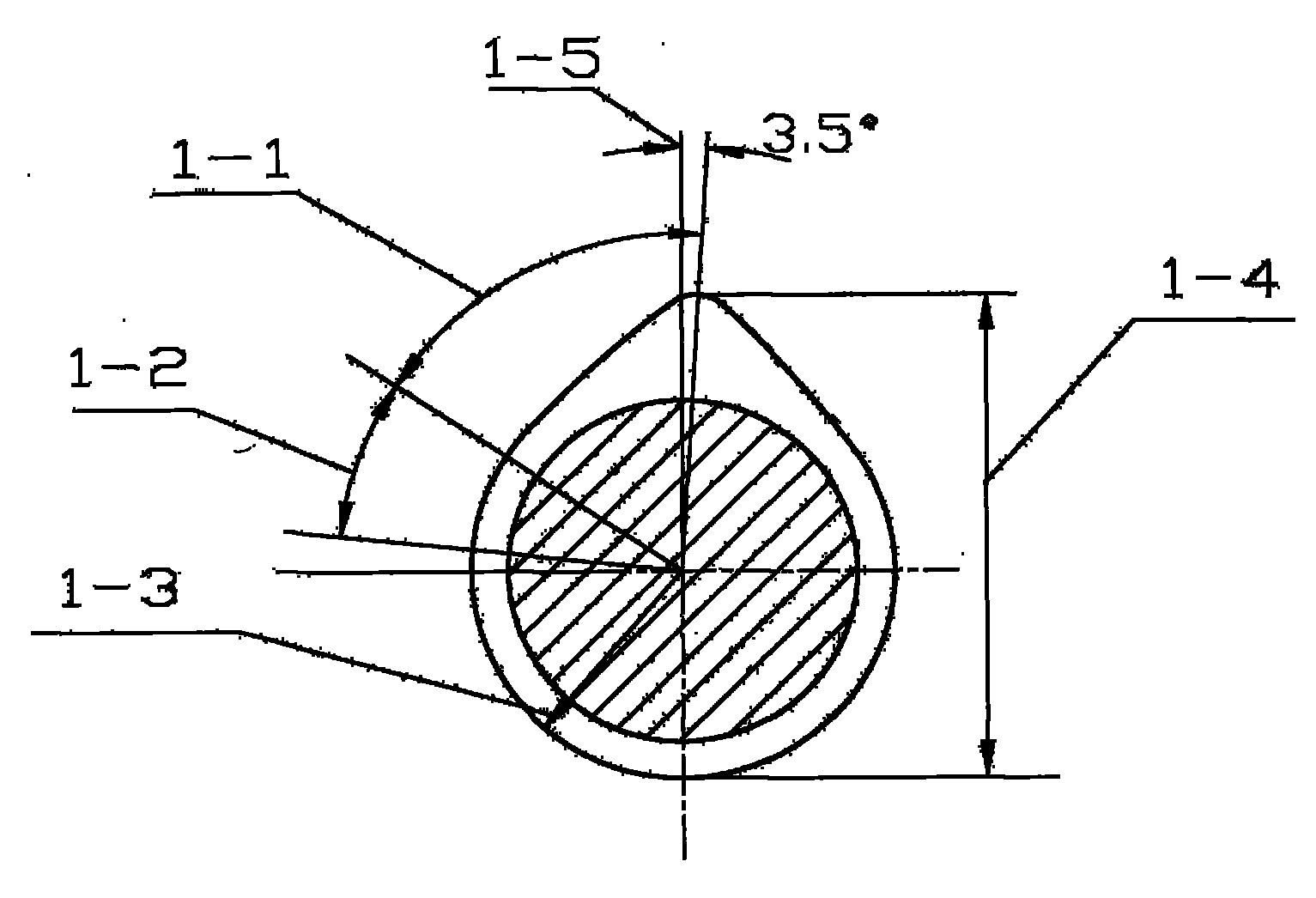

[0007] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples. Symmetric profile cams include intake cams and exhaust cams. The specific parameters of the two cams are: intake cam working section 1-1 is 54.2°, intake cam transition section 1-2 is 25°, intake cam circle The radius of the arc section 1-3 is 20.6±0.0625mm, the overall height of the intake cam profile 1-4 is 48.09±0.05mm, and the centerline of the intake camshaft keyway 1-5 is 3.5°. The working section 2-1 of the exhaust cam is 60.5°, the transition section 2-2 of the exhaust cam is 29°, the radius of the arc section 2-3 of the exhaust cam is 20±0.0625mm, and the overall height of the exhaust cam profile 2-4 is 47.916±0.05mm, the exhaust camshaft keyway centerline 2-5 is 107.5°. The first cylinder air intake lobe and the second, third, and fourth cylinder air intake lobe are separated by 90°, 180°, and 270° respectively. The sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com