Swing arm rotation type compressor

A rotary compressor technology, which is applied to swing piston machinery, swing piston pumps, rotary piston/swing piston pump components, etc., to improve performance and compression efficiency, reduce leakage, and increase engine power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

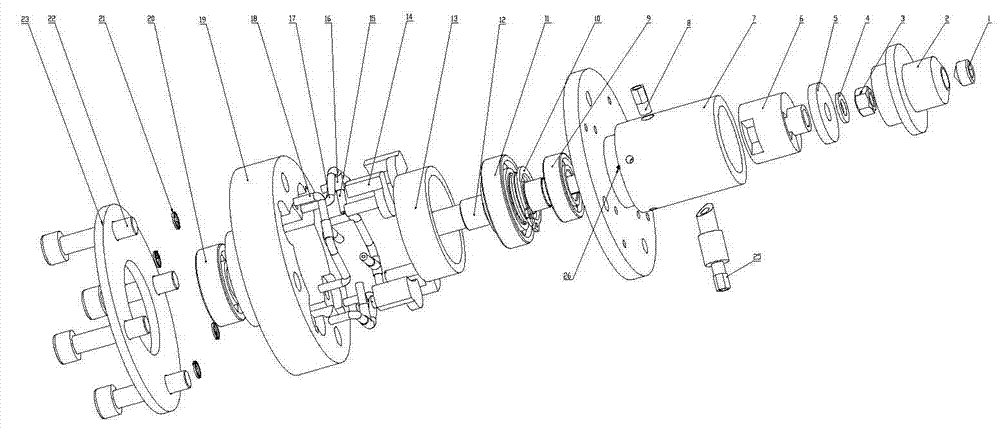

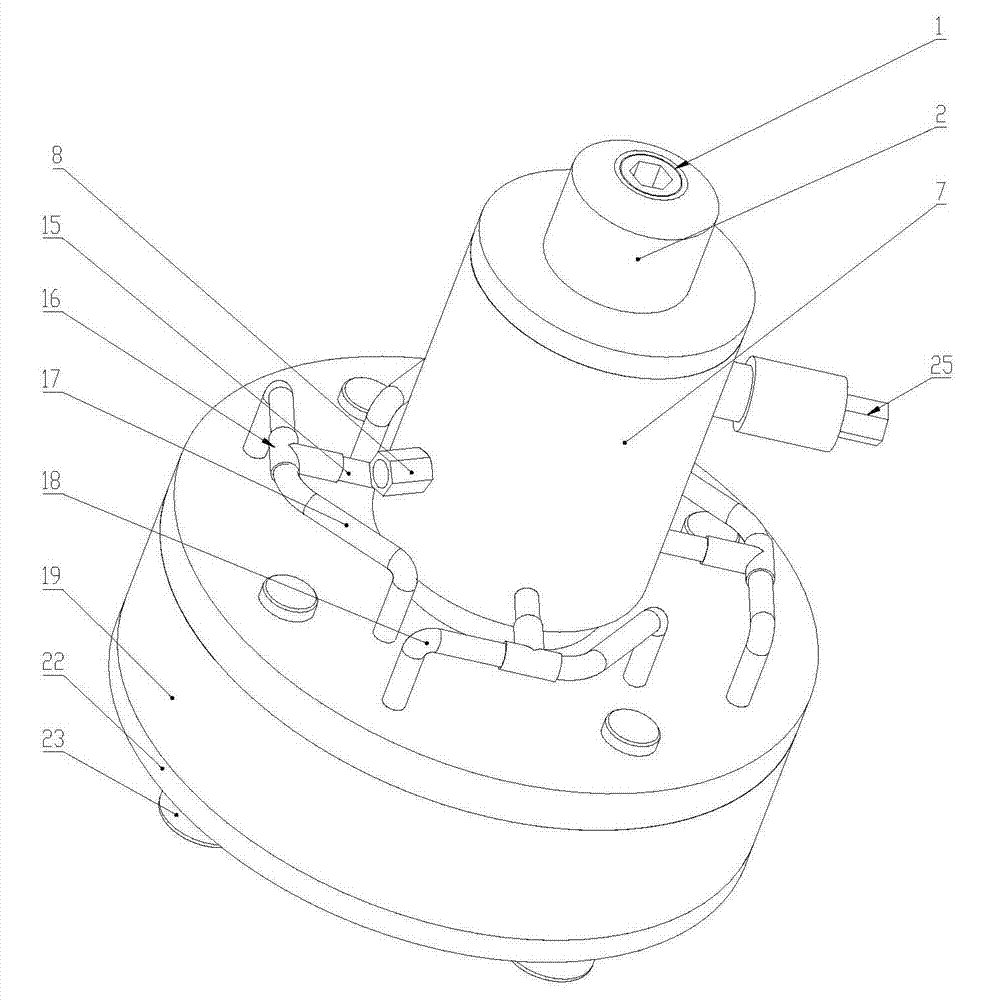

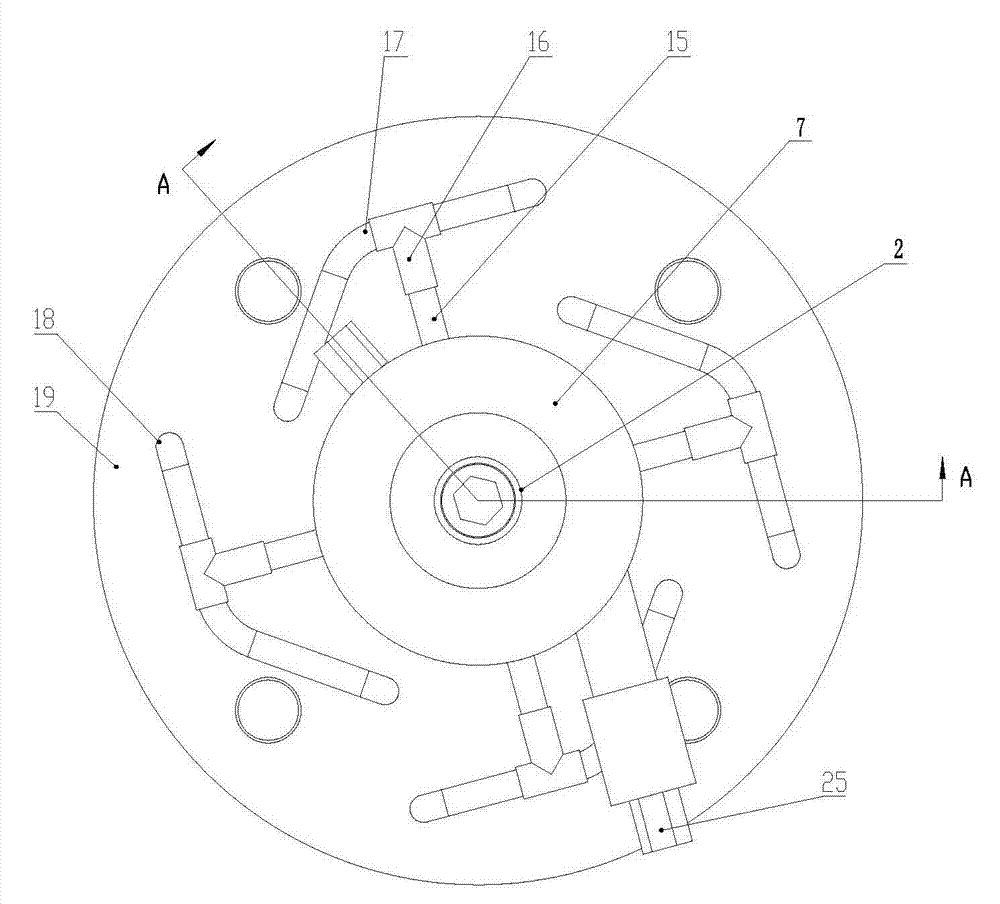

[0051] Such as Figure 1~4 As shown, a swing arm rotary compressor provided by a preferred embodiment of the present invention includes a housing 19 and a main shaft 12 installed coaxially with the housing. The upper end surface of the housing 19 is sealed by screwing an upper bearing seat 7, the top of the upper bearing seat 7 is provided with a gland 2, and the top of the gland 2 is provided with a plug 1 for rotating the gland 2 to close or open it. , can also realize axial intake or exhaust layout. The middle section of the main shaft 12 is an eccentric shaft section 120, and a rotary sleeve 13 is arranged in the inner cavity of the housing 19. The inner circle of the rotary sleeve 13 is connected with the eccentric shaft section 120 of the main shaft 23 through a sleeve bearing 11. The sleeve bearing 11 is axially secured by the shoulder and the snap r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com