Lead-acid storage battery cover

A technology of lead-acid battery and cover sheet, which is applied in the direction of battery pack parts, circuits, electrical components, etc., to achieve the effect of exhausting thoroughly and ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

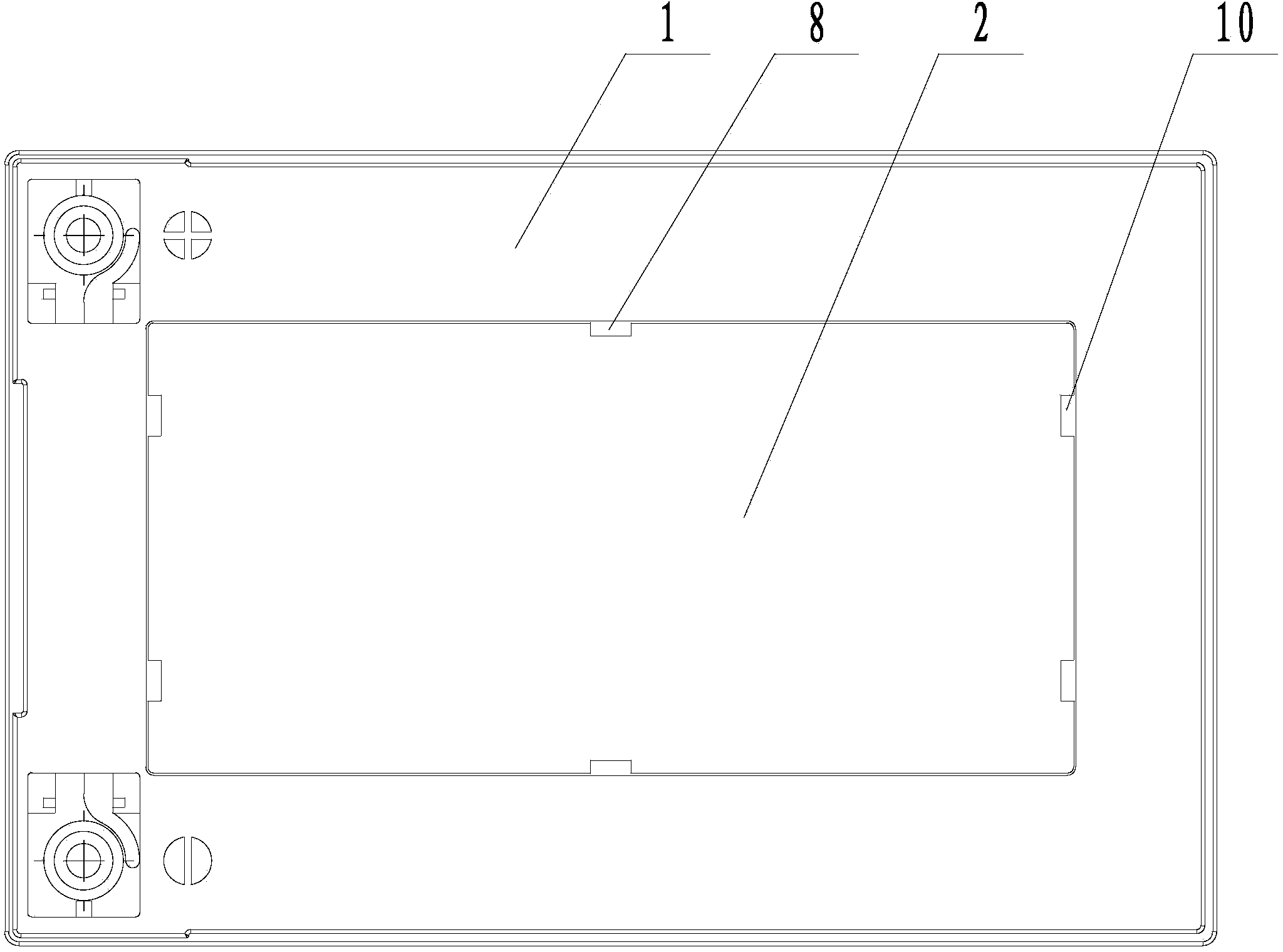

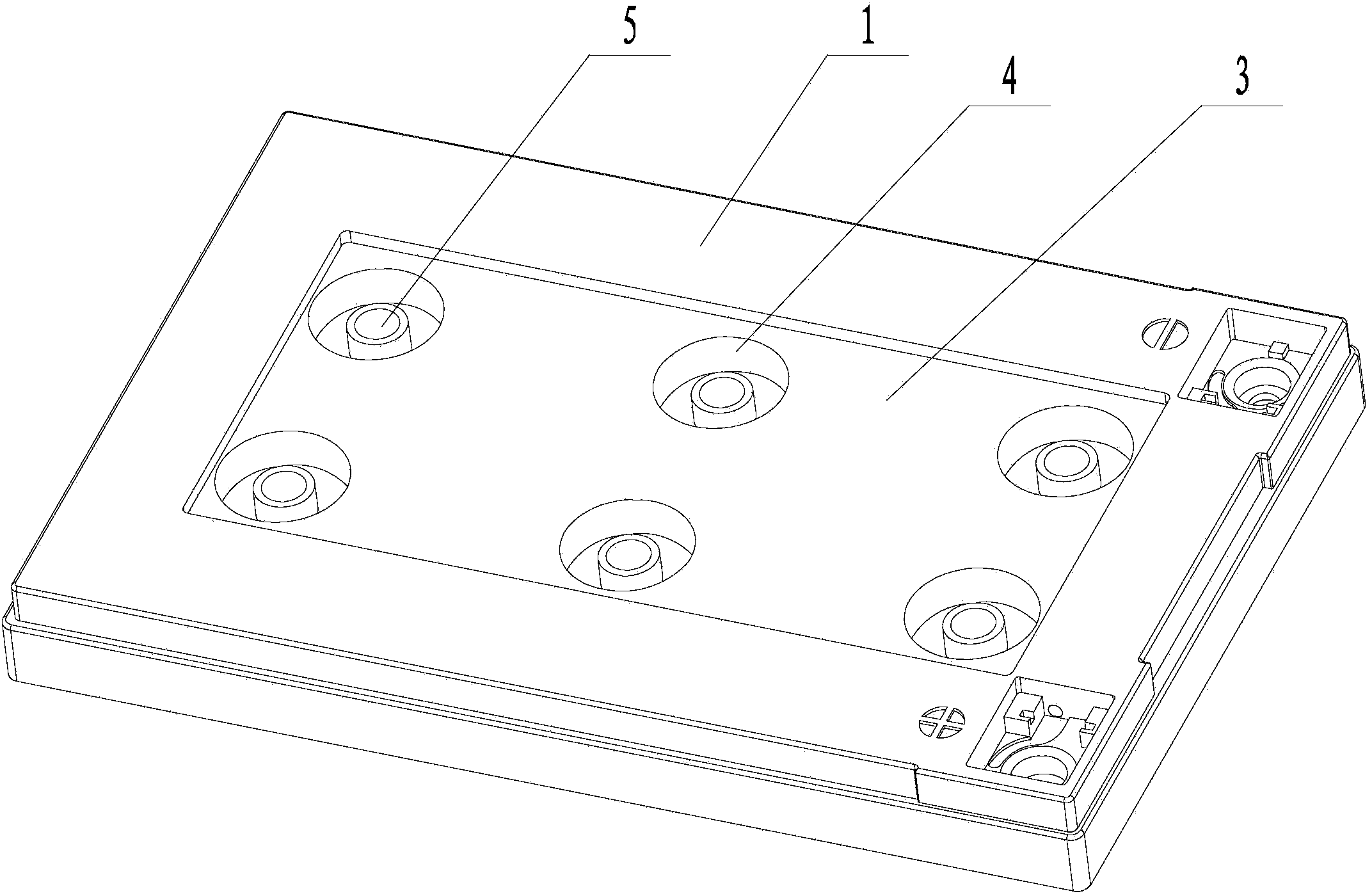

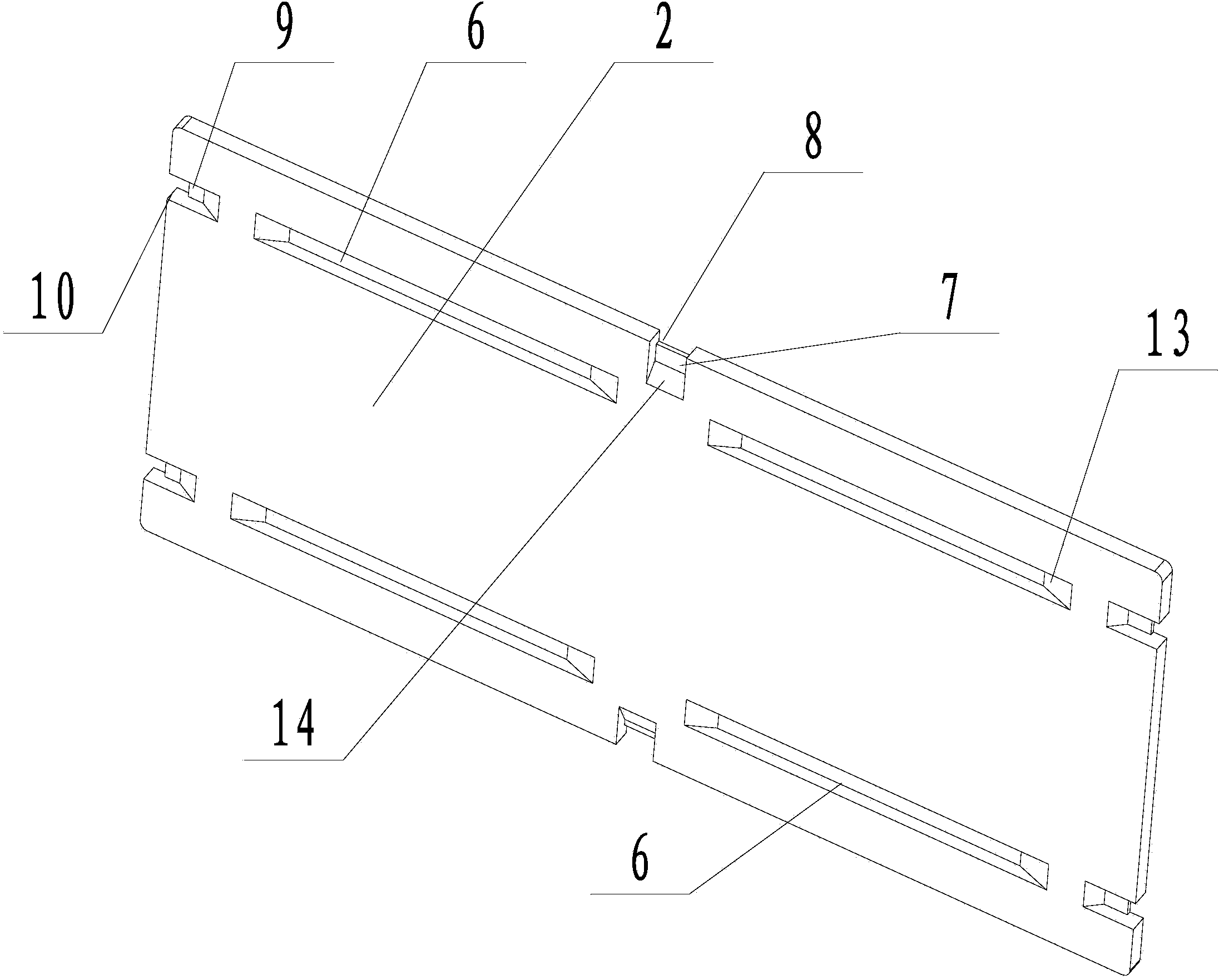

[0020] Embodiment 1: a kind of lead-acid battery cover (referring to attached figure 1 , attached figure 2 , attached image 3 ), including a rectangular cover body 1 and a rectangular cover piece 2, a rectangular cover piece installation groove 3 is provided on the upper surface of the cover body, and two rows of accommodating slot holes 4 are provided on the bottom surface of the cover piece installation groove, and each row is provided with three accommodating slots Hole, a liquid injection hole 5 is provided in the accommodation slot, the cover sheet is bonded and installed in the cover installation slot, and an exhaust slot 6 is arranged between the adjacent two accommodation slots set in the same row, and the exhaust slot They are all arranged on the lower end surface of the cover sheet, and the two ends of the exhaust groove are respectively connected with the two accommodating slots, and the long side air outlet groove 7 is arranged between the adjacent two exhaust g...

Embodiment 2

[0022] Embodiment 2: a kind of lead-acid battery cover (referring to attached Figure 4 , attached Figure 5 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, the lower end surface of the cover sheet is provided with wide-side air outlet slots near the two ends of each row of accommodating slots, and the side wall of the cover sheet installation groove and the width The side air outlet slots are provided with blast holes 11 one by one. The blast holes run through the cover body. The opening size of the blast holes increases gradually from the inside to the outside. The air holes are relatively arranged one by one. The cross section of the blowing hole is a rectangular structure, the width of the blowing hole gradually increases from the inside to the outside, and the height remains unchanged. An acid filter sheet 12 is arranged in the blast hole.

[0023] On the one hand, the blower hole is used as exhaust; on the other han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com