Reactive dye printing and dyeing transfer device and method without steaming and washing

A technology of reactive dyes and transfer devices, applied in printing, printing presses, transfer printing and other directions, can solve the problems of prone to water marks, unsatisfactory environmental protection, energy consumption and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

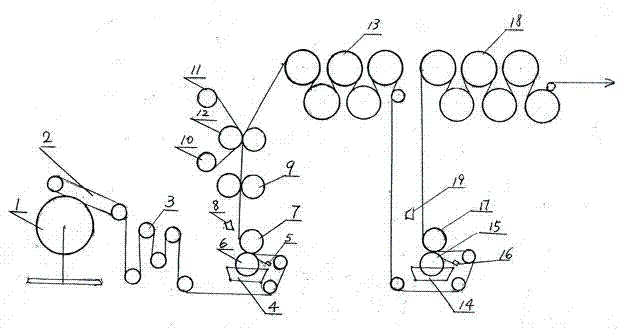

[0026] according to figure 1 As shown, the present invention has a tension-free transmission guide belt and a tension-adjusting guide roller group, which includes a cloth release roll 1, a tension-free transmission guide belt 2, and 5 tension guide rollers 3, which can send any fabric into the belt scraper. A repetitive dampening solution tank device, said device includes a dampening solution tank 4, an anilox gravure roller 6 is fixed in the wetting solution tank 4, and a scraper 5 is fixed on the side of the anilox gravure roller 6, There is a pressure roller 7 at the top of the anilox gravure roller 6, and two guide rollers are arranged to smoothly deliver the fabric to between the anilox gravure roller 6 and the pressure roller 7 to give wet, or to wet with the sprayer 8. After dyeing the wet liquid, it can be dyed through a pair of rubber rollers 9 to squeeze and press. The transfer printing press roller group includes a film releasing device 10, a film collecting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com