Process for preparing positioning transfer decoration surface

A preparation process and decorative surface technology, applied in post-processing of printing, ink transfer from original manuscript, printing, etc., can solve problems such as slow drying speed, low production efficiency, and large site occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

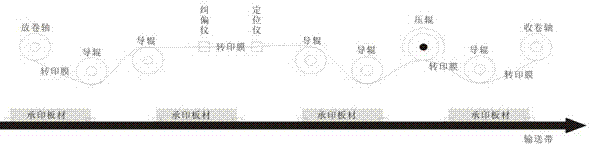

[0023] Such as figure 1 As shown, the preparation process of a positioning transfer decoration surface disclosed by the present invention comprises the following steps:

[0024] (1) Install the transfer film printed with decorative patterns and identification cursors on the positioning transfer machine;

[0025] (2) Place the printing plate on the conveyor belt of the positioning transfer machine and fix the position;

[0026] (3) Input the corresponding parameters on the control interface of the positioning transfer machine, the unwinding tension parameter setting parameters, the rewinding shaft tension parameters, and the conveyor belt speed;

[0027] (4) Manually adjust the position of the contact point between the front cut surface of the printing plate on the conveyor belt and the pressing roller;

[0028] (5) Start the positioning transfer printing machine for continuous production, the unwinding tension controller of the positioning transfer printing machine receives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com