Inkjet printing method and inkjet printing equipment for realizing method

A technology of inkjet printing and inkjet printing, which is applied in the post-processing, printing, printing machine and other directions of printing to achieve the effect of ensuring clarity, quality and reducing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

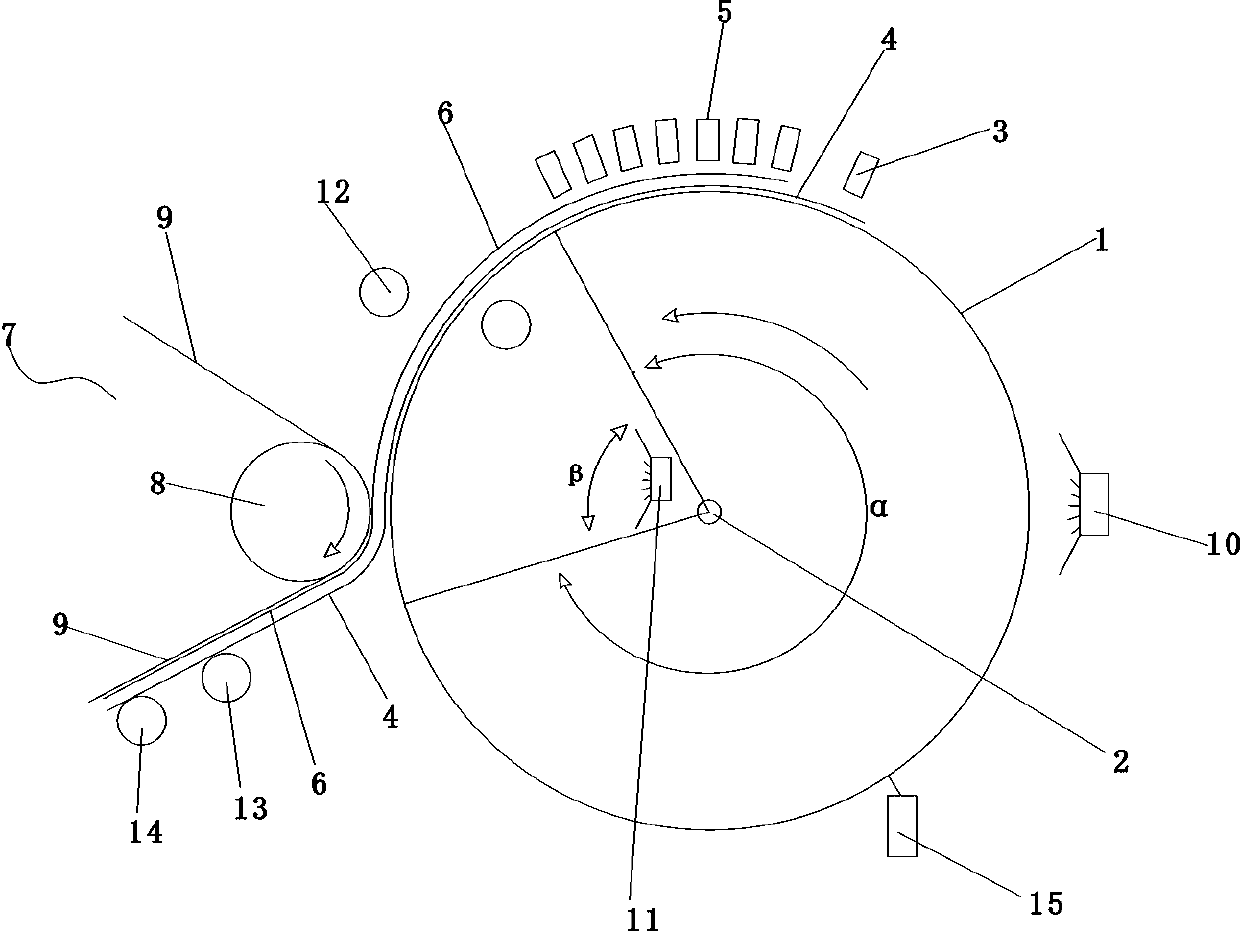

[0036] like figure 1 As shown, the inkjet printing device of the present invention includes a chrome-plated intermediate transfer body 1, and the intermediate transfer body rotates counterclockwise around the axis 2;

[0037]The varnish inkjet printing head 3 located above the intermediate transfer body uses colorless UV varnish ink, and the photosensitive wavelength band of the photoinitiator contained in it is <360nm. The printing head can be designed according to the width of the printing. The rotation of the transfer body forms a varnish layer 4 in a specific area on the surface of the intermediate transfer body; the UV varnish formula used in the present invention is: epoxy acrylate 40-60%, hexanediol diacrylate 20-40% %, active amine 5-15% and Irgacure127 photoinitiator 3-20%; when the ink is heated to 50°C, the viscosity is 18s, which is suitable for printing, and when the temperature drops to 9°C, the viscosity rises to 40s;

[0038] The multi-color ink-jet printing n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com