Method for measuring bromine content in organic photoelectric material based on oxygen bomb combustion method

An organic photoelectric material and oxygen bomb combustion technology, applied in the field of detection, can solve the problems of affecting the detection limit of bromide ions, interfering with the detection of bromide ions, and difficult to meet the needs of bromide ion determination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

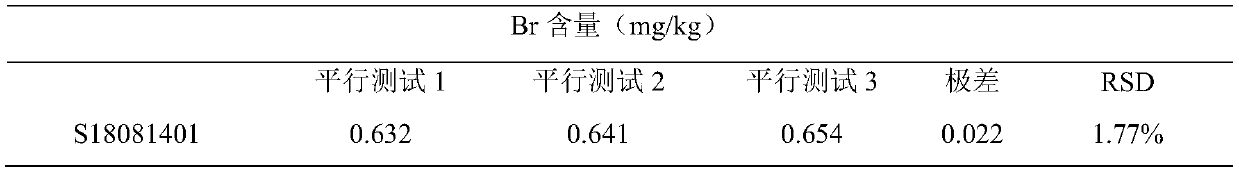

Embodiment 1

[0046] The first step: sample pretreatment:

[0047] 1. Use 4.5mM Na in the oxygen bomb when the oxygen bomb is out of service 2 CO 3 and 0.8mM NaHCO 3 Soaking, after pouring the soaking solution before use, use 10 times the volume of ultra-pure water to rinse the inner wall of the bomb to avoid environmental pollution of the oxygen bomb.

[0048] 2. Sample weighing: Weigh 0.5g of the sample (accurate to 0.0001g) into the sample cup of the oxygen bomb to promote the complete combustion of the sample, and wrap the sample with filter paper. The characteristics of the filter paper: bromide ion content ≤ 0.002mg / L.

[0049] 3. Install the ignition wire and sample: open the cover of the oxygen bomb, fix the sample cup containing the sample, fix the two ends of an ignition wire with a suitable length on the electrode column, and make it contact with the sample without touching the sample cup;

[0050] 4. Add absorption liquid:

[0051] 4.1 Preparation of absorption liquid: Na in...

Embodiment 2

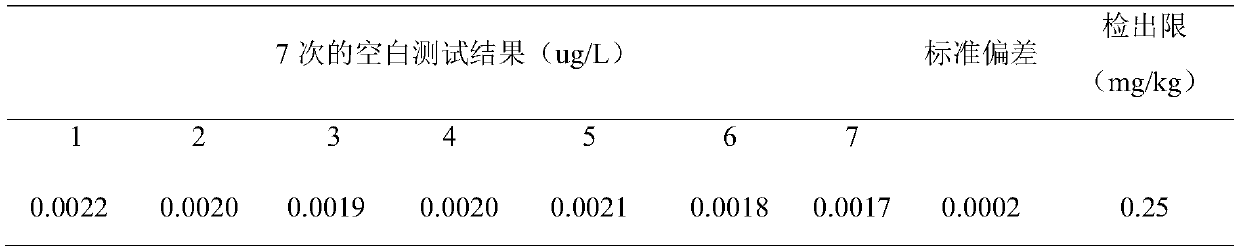

[0073] Embodiment 2 method detection limit

[0074] Continuously use the same pretreatment method to conduct 7 blank tests, and the detection limit of the method is 0.25 mg / kg obtained by superimposing the blank level with 3 times the standard deviation, as shown in Table 2 below.

[0075] Table 2 7 test results of bromide ion blank content

[0076]

Embodiment 3

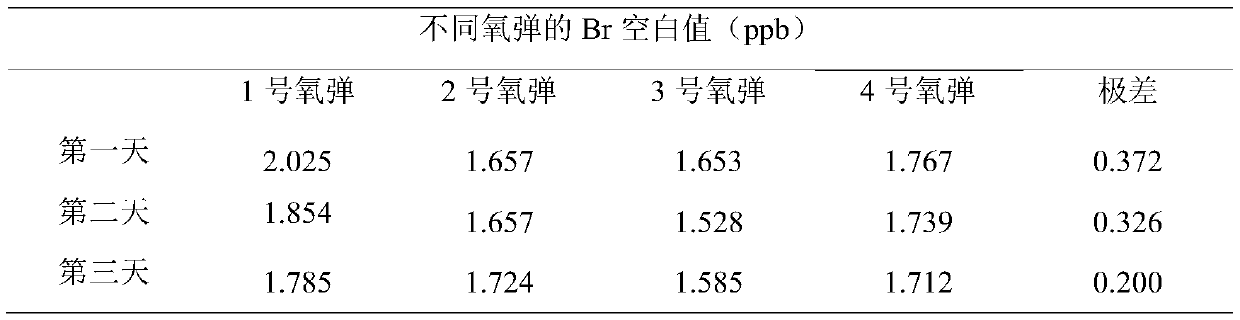

[0077] Embodiment 3 background blank stability verification

[0078] Monitor No. 1, No. 2, No. 3, and No. 4 oxygen bombs for three consecutive days and use the same sample pretreatment to conduct a blank test. The bromide ion blank value in Table 3 was obtained through the ICP-MS test, and the extremely poor result was 0.2-0.4ppb. It shows that the relative deviation of bromide ion content in different oxygen bombs is small, and it can be considered that there is no significant difference between different oxygen bombs, indicating that the background blank is stable. If the deviation of the blank test is greater than the detection limit (0.25mg / kg), that is, the absolute deviation of the blank is greater than 2.5ppb, it is necessary to re-use 4.5mM Na in the oxygen bomb 2 CO 3 and 0.8mM NaHCO 3 Soaking, after pouring the soaking solution before use, use 10 times the volume of ultra-pure water to rinse the inner wall of the bomb until the deviation of the blank test is less t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com