Method for preparing crystalline silicon solar battery electrode by utilizing overprinting way

A technology for preparing solar cells and electrodes, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as electrical conductance and electrode contact, and achieve the effects of improving fill factor, avoiding disconnection, and good electrical conductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, completely symmetrical overprinting, overprinting patterns coincide, and its process steps are as follows:

[0024] 1. Put the semi-finished silicon wafer to be prepared on the printing table, and use aluminum paste to do the first electrode printing according to the printing pattern designed for contact. Then the silicon wafer is dried or sintered.

[0025] 2. Then use silver paste for the above-mentioned silicon chip to do the second electrode printing according to the printing pattern in step 1, completely cover and overprint on the first electrode printing pattern. The silicon wafer is dried or sintered.

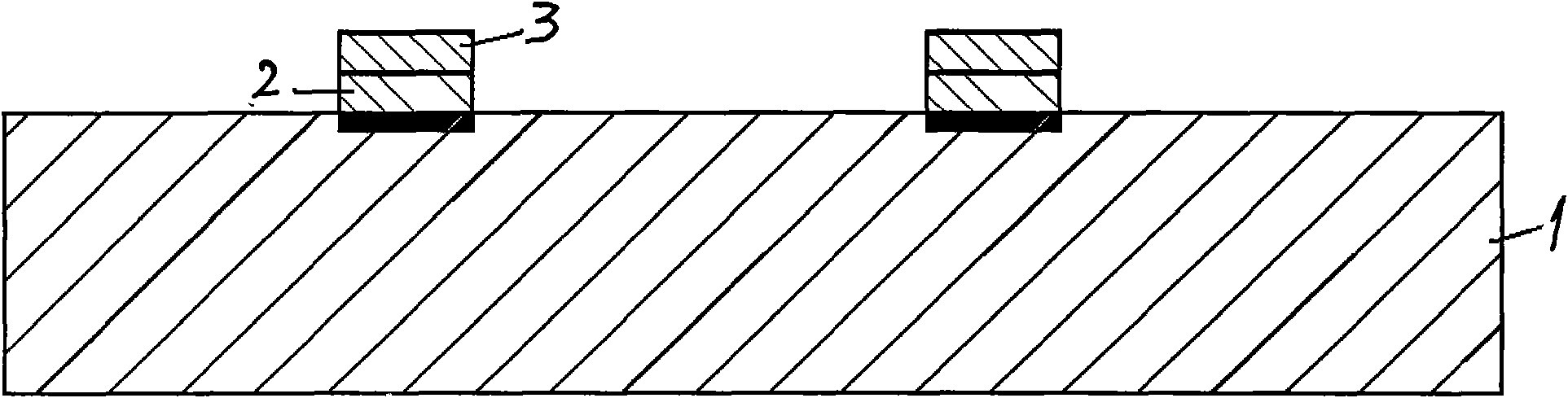

[0026] The side cross-sectional structure of the silicon wafer and the electrode after the electrode printing is completed is as follows: figure 1 shown.

Embodiment 2

[0027] Embodiment 2, non-completely symmetrical overprinting, its process step is as follows:

[0028] 1. Put the semi-finished silicon wafer to be prepared on the printing table, and use silver paste to do the first electrode printing according to the printing pattern designed for contact. The silicon wafer is dried or sintered.

[0029] 2. Then use silver paste for the above-mentioned silicon chip to do the second electrode printing according to the same printing pattern as step 1 but the pattern range is slightly larger (or slightly smaller), covering and overprinting on the first electrode printing pattern. The silicon wafer is dried or sintered.

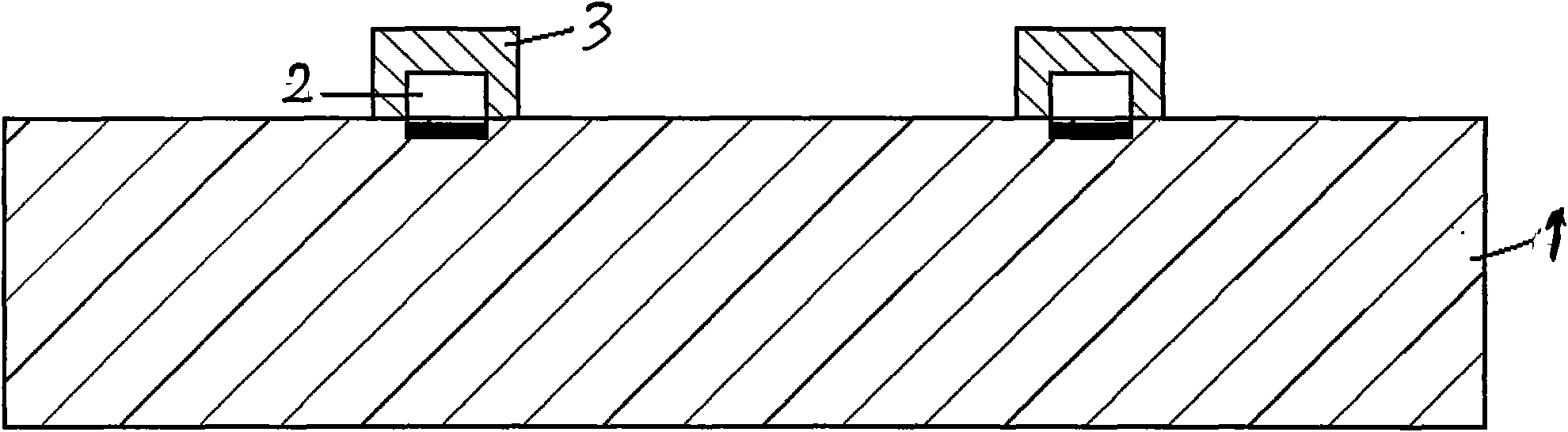

[0030] The side cross-sectional structure of the silicon wafer and the electrode after the electrode printing is completed is as follows: figure 2 shown.

Embodiment 3

[0031] Embodiment 3, complete asymmetric overprinting, its process steps are as follows:

[0032] 1. Put the semi-finished silicon wafer to prepare the electrode on the printing table, and do the first electrode printing according to the printing pattern designed for contact. The silicon wafer is dried or sintered.

[0033] 2. Then do the second electrode printing on the above-mentioned silicon wafer according to the printing pattern designed for the battery conductive resistance, overprint on the first electrode printing pattern, and connect the electrode contact parts obtained by the first electrode printing to form a complete conduction structure. The silicon wafer is dried or sintered.

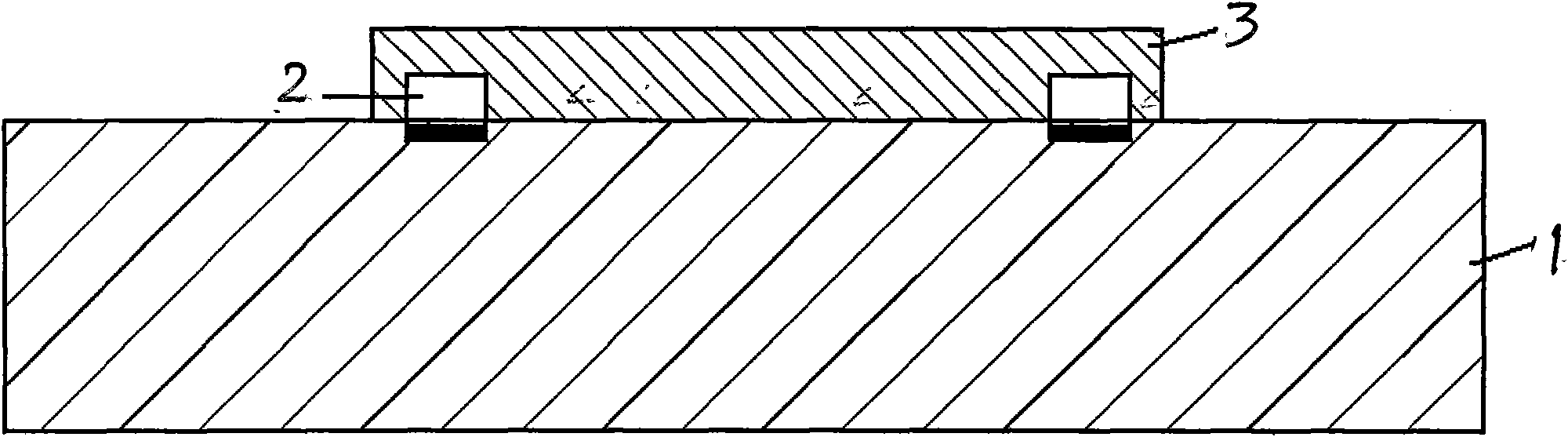

[0034] The side cross-sectional structure of the silicon wafer and the electrode after the electrode printing is completed is as follows: image 3 shown.

[0035] can be as Figure 4 as shown,

[0036] 1. You can choose aluminum paste, silver paste and other pastes with good penetrab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com