Organic/inorganic composite solid electrolyte with gradient interface structure, and all-solid-state lithium battery

A solid electrolyte, solid electrolyte layer technology, applied in solid electrolyte, non-aqueous electrolyte battery, lithium battery and other directions, can solve the problems of low lithium ion conduction performance and poor contact of the positive electrode, and achieve easy promotion, improved contact, and reduced interface impedance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

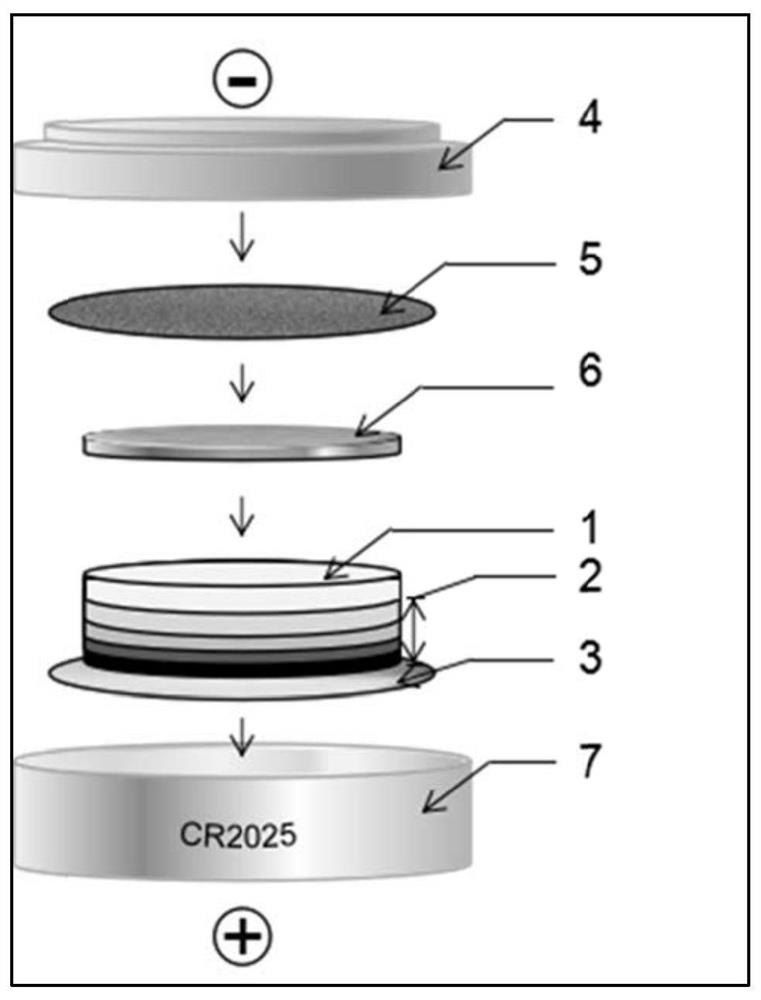

[0050] An all-solid-state lithium battery, the preparation method of which is as follows:

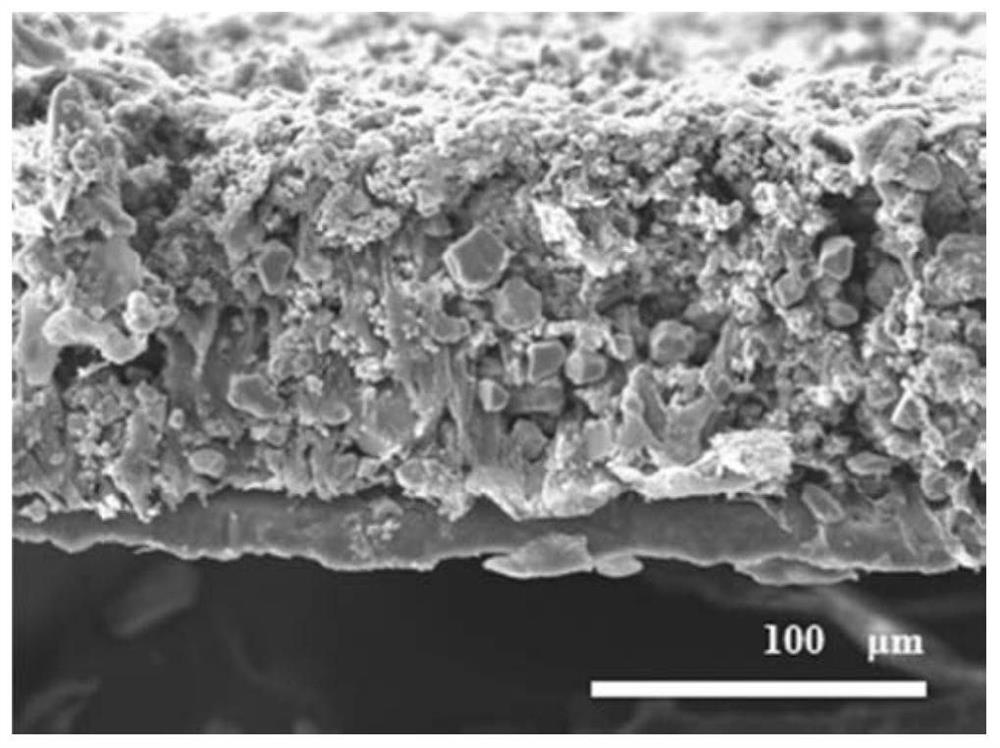

[0051] a. By the sol-gel method, under the condition of lithium excess of 16% (molar ratio), LLZO with high ion conductivity was synthesized through steps such as debinding and sintering (Li 7 La 3 Zr 2 o 12 ) powder, and sieved; the LCO powder was ball milled and refined, using isopropanol as a solvent, and ball milled at a speed of 300r / min for 12h;

[0052] b. Weigh 5 parts of polyethylene oxide (PEO), add 5 parts of acetonitrile to stir each part, the content of polyethylene oxide (PEO) in each part is 0.1g, acetonitrile 7mL, stir and heat at 60°C for 1.5h, the speed is maintained At 300r / min, polyethylene oxide (PEO) is fully dissolved in acetonitrile to form 5 parts of colloidal solutions S1, S2, ..., S5, wherein the S5 solution is used as the electrolyte layer, and the first four parts are used to prepare the gradient structure layer ( At the same time as the positive electro...

Embodiment 2

[0060] An all-solid-state lithium battery, the preparation method of which is as follows:

[0061] a. Through the traditional solid-state method, lithium excess 10% (molar ratio), through ball milling, pre-calcination, tablet sintering and other steps, synthesize LLZO with high ion conductivity (Li 7 La 3 Zr 2 o 12 ) powder for sieving treatment; using isopropanol as solvent, wet planetary ball milling at a speed of 300r / min for 12h to refine LCO (LiCoO 2 ) powder, and prepare conductive carbon, polyethylene oxide (PEO);

[0062] b. Weigh 4 parts of polyethylene oxide (PEO) and add them into 4 parts of acetonitrile and stir, the rotation speed is maintained at 300r / min, the content of polyethylene oxide (PEO) in each part is 0.1g, acetonitrile 6.5mL, stir at 60°C Heating for 1.5h to fully dissolve polyethylene oxide (PEO) in acetonitrile to form colloidal solutions S1, S2, S3, and S4 for preparing positive electrodes;

[0063] c. Keep stirring S1 to S4 at room temperature...

Embodiment 3

[0071] An all-solid-state lithium battery, the preparation method of which is as follows:

[0072] a. By plasma activation sintering, lithium excess 10% (molar ratio), synthesis of Li 5 La 3 Nb 2 o 12 The powder is sieved; using isopropanol as a solvent, wet planetary ball milling at a speed of 150r / min for 12 hours, refines the lithium iron phosphate powder, and prepares conductive carbon and polyethylene oxide (PEO);

[0073] b. Weigh 2 parts of polyethylene oxide (PEO) and add them into 2 parts of acetonitrile and stir, the rotation speed is maintained at 300r / min, the content of polyethylene oxide (PEO) in each part is 0.1g, acetonitrile 6.5mL, stir and heat at 60°C 1.5h, fully dissolve polyethylene oxide (PEO) in acetonitrile to form colloidal solutions S1 and S2, which are used as positive electrodes;

[0074] c. Keep stirring S1 and S2 at room temperature, while adding 0.1g of conductive carbon;

[0075] d. Proportionate Li according to the component gradient ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com