Patents

Literature

58results about How to "Guaranteed heat exchange efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

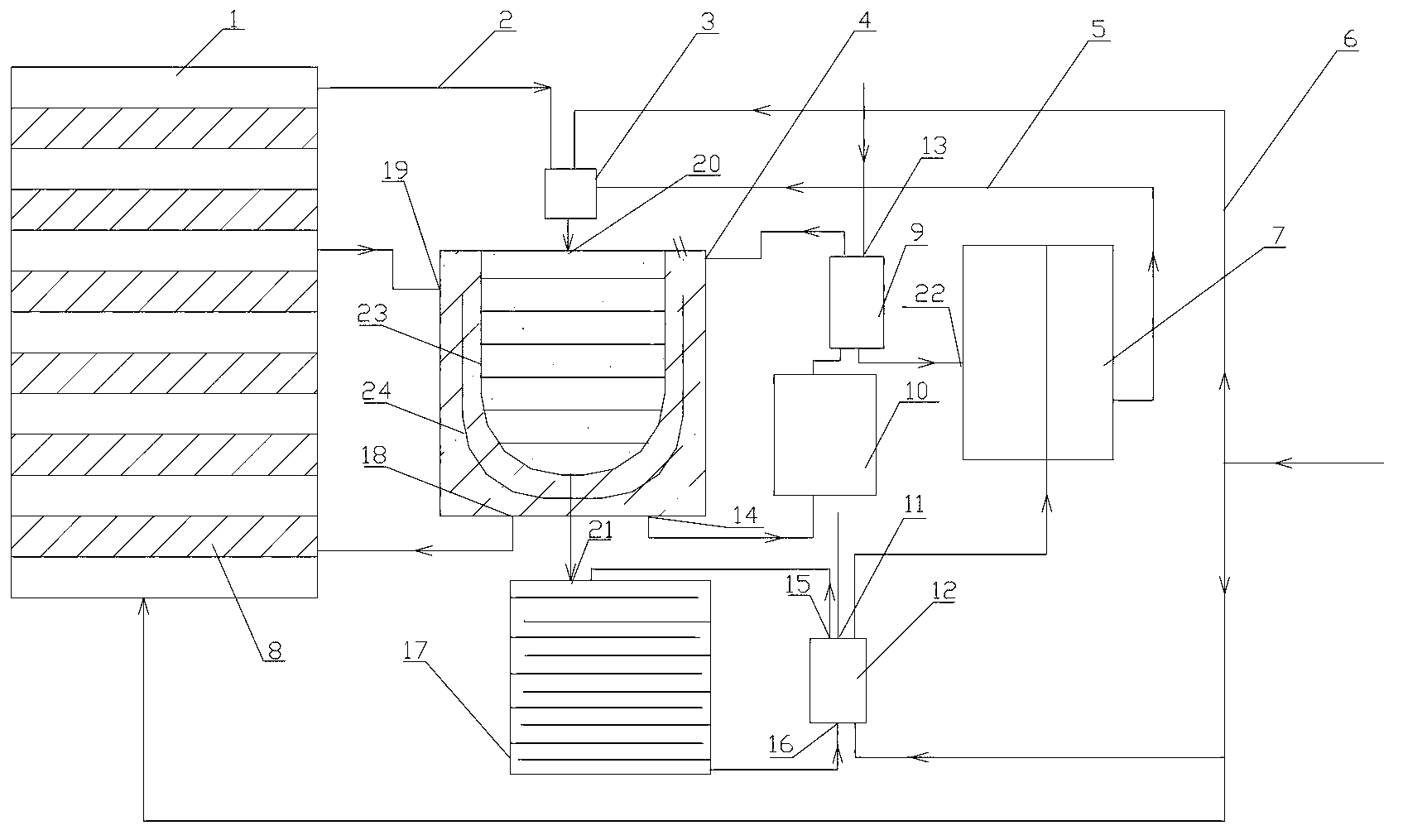

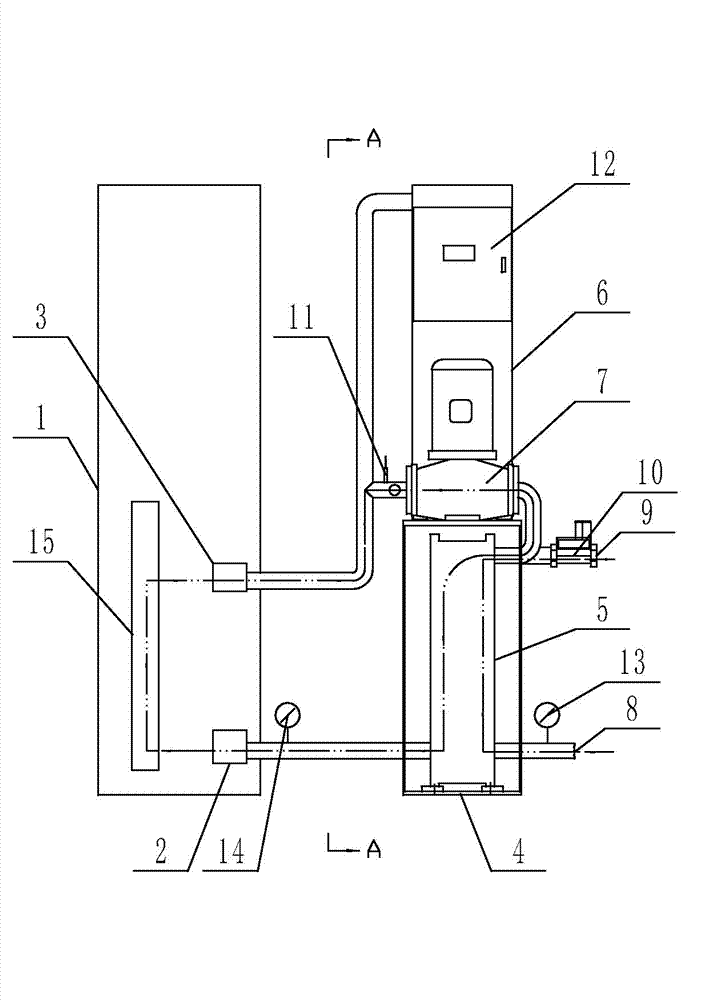

Process for recovering aluminum ions and sulfuric acid from aluminum alloy anodic oxidation tank

ActiveCN103911651AAchieve recyclingEliminate hidden dangers of production stoppageAnodisationCellsAluminum IonEconomic benefits

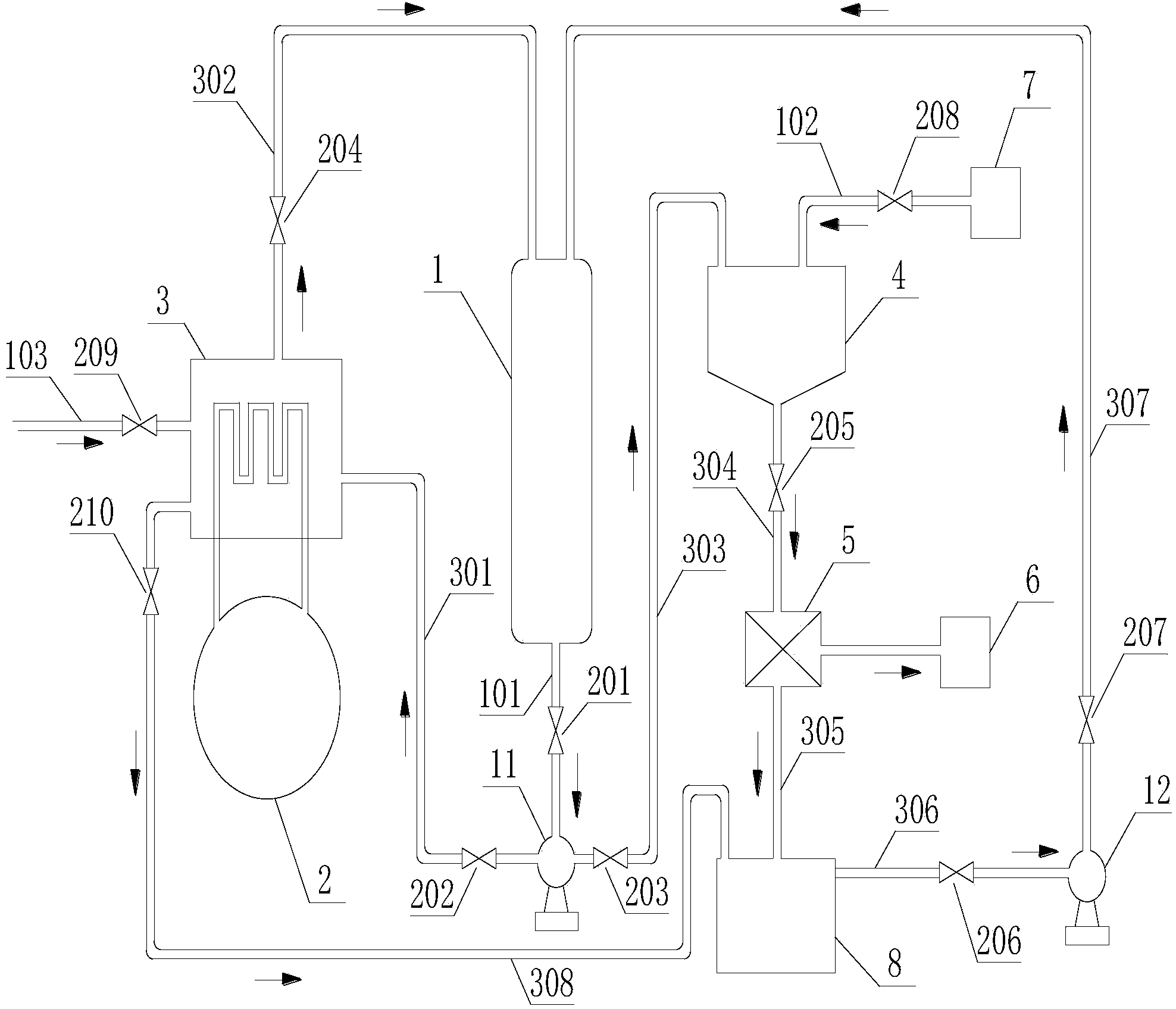

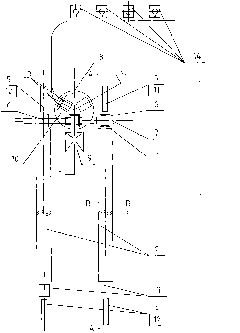

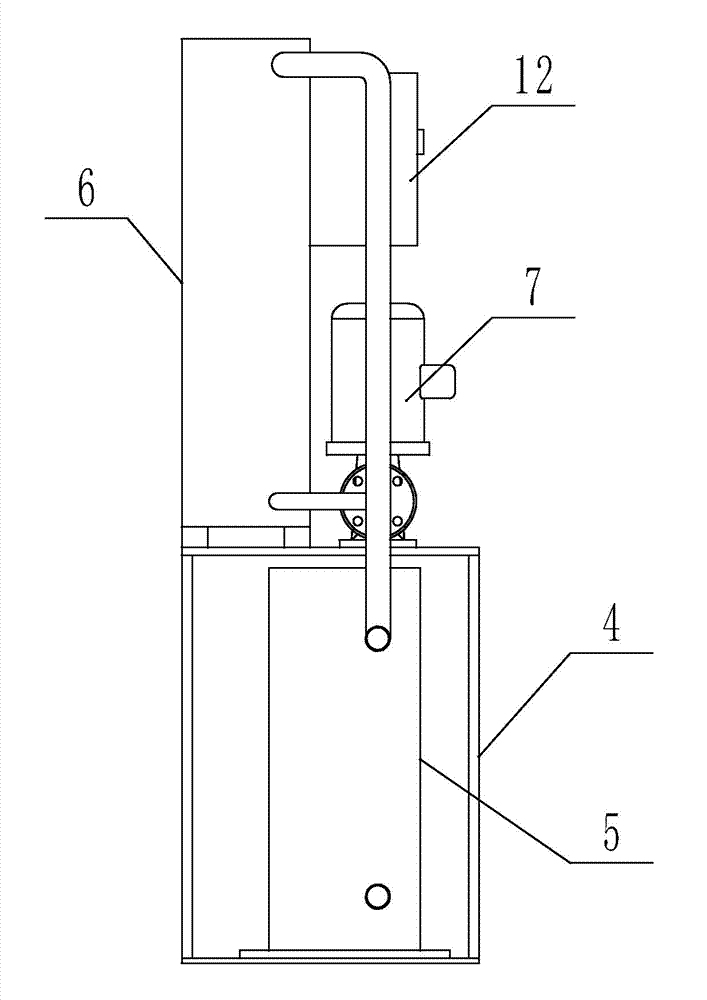

The invention aims at the chemical engineering field, relates to a treatment process of an aluminum alloy anodic oxidation waste liquid and specifically relates to a process for recovering aluminum ions and sulfuric acid from an aluminum alloy anodic oxidation tank. The process comprises a step of circularly cooling an oxidation liquid, a step of crystalizing aluminum ions and recovering side-products, a step of recovering a sulfuric acid oxidization liquid, a step of air agitation and a step of defrosting an exchanger. The invention provides a brand-new treatment process which is capable of completely recovering the aluminum ions in the anodic oxidation waste liquid by virtue of crystallization treatment and realizing circulating utilization of a crystallization mother liquor, and therefore, the treatment process can be used for realizing turning waste into wealth and changing from passive to active; in addition, the aluminum ion concentration working range of the oxidation tank liquid is reduced to the optimal range of 3-10g / L from 10-20g / L for the first time, and therefore, the structure of an aluminum alloy oxide film is optimized, the resistance of the tank liquid is reduced and oxidization energy conservation is realized. The process is a comprehensive circulating process which is reasonable in design, and consequently, the production cost of an aluminum processing enterprise is reduced and remarkable economic benefit can be achieved.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

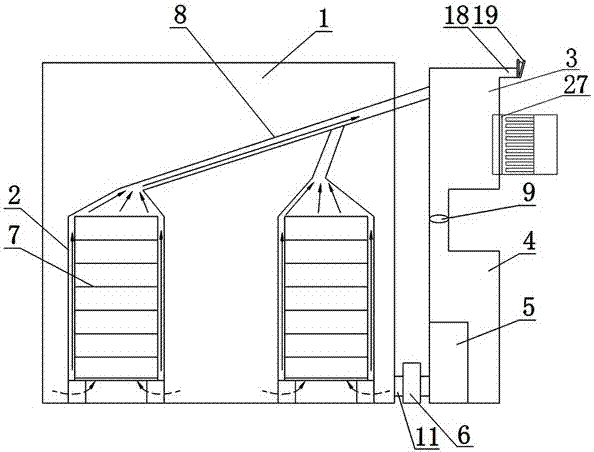

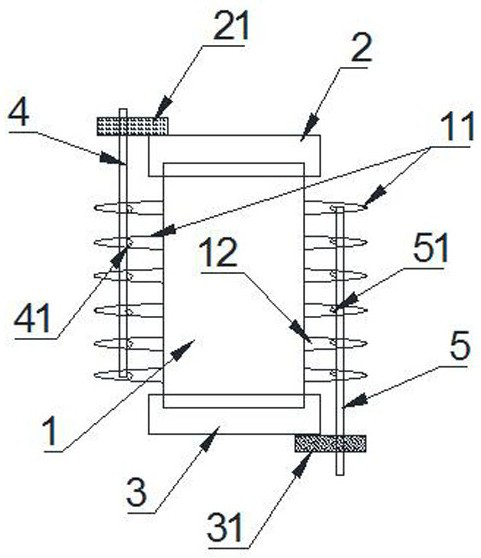

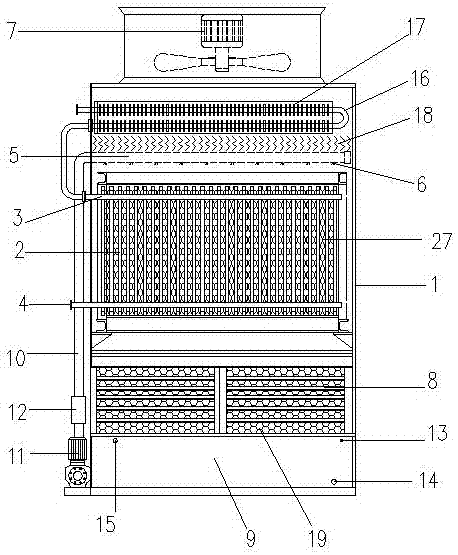

Water circulation evaporation heat exchange cooling type condenser

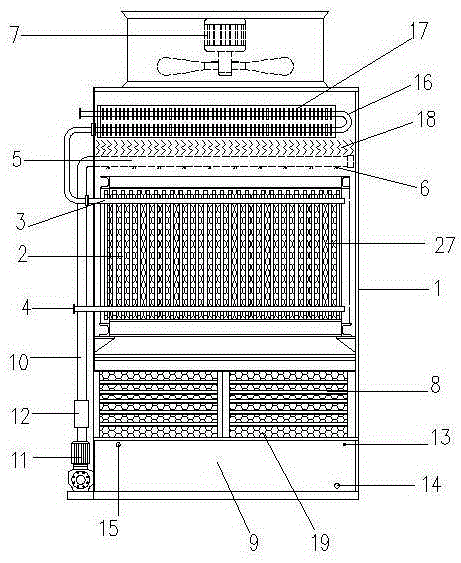

The invention relates to the technical field of condensers and discloses a water circulation evaporation heat exchange cooling type condenser. The condenser comprises a condenser shell. A heat exchanger is arranged in the middle of the condenser shell. A liquid inlet pipe is arranged on the side face of the upper end of the heat exchanger. A liquid outlet pipe is arranged on the side face of the lower end of the heat exchanger. A water distribution pipe is arranged on the portion, located at the upper end of the heat exchanger, of the interior of the condenser shell. A plurality of nozzles are evenly arranged on the lower side of the water distribution pipe. An exhaust fan is arranged on the top of the condenser shell. An air intake grid is arranged on the side face of the lower end of the condenser shell. A water collection tank is arranged at the bottom of the condenser shell. A backflow pipe is arranged on the side face of the condenser shell. The lower end of the backflow pipe is connected with the water collection tank, and the upper end of the backflow pipe is connected with the water distribution pipe. A water pump is arranged on the backflow pipe, and a water collector is arranged on the upper side of the water distribution pipe. The water circulation evaporation heat exchange cooling type condenser has the beneficial effects that cooling water waste can be reduced, and the cooling water utilization rate can be increased.

Owner:浙江宝丰科技股份有限公司

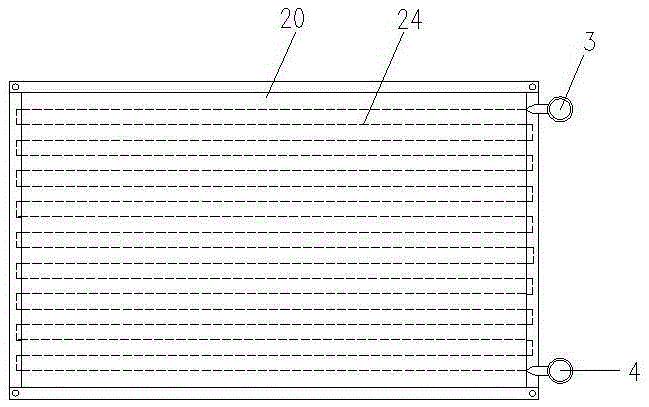

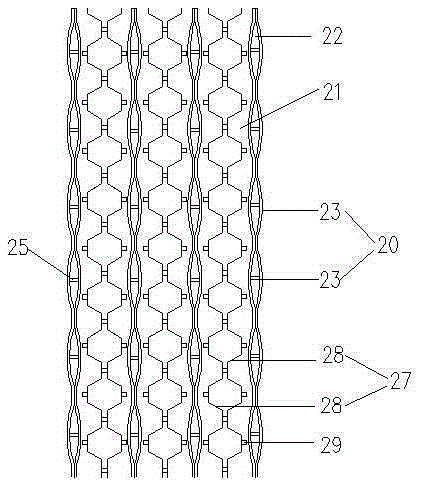

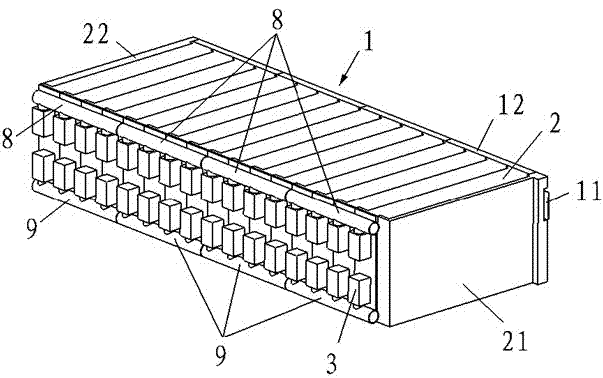

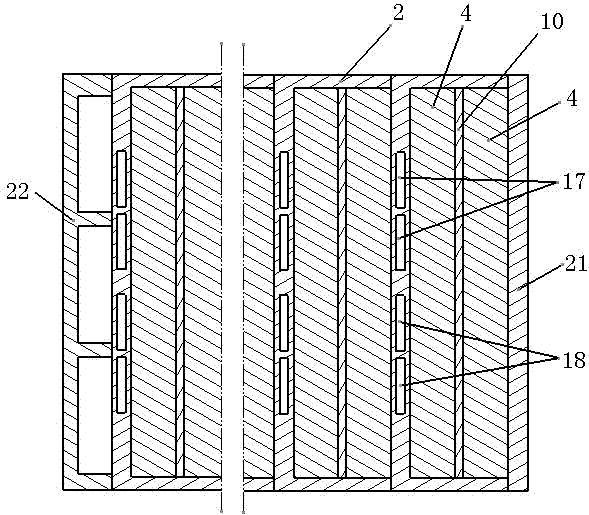

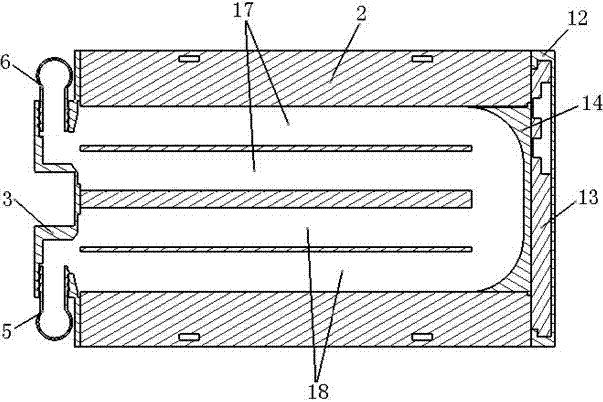

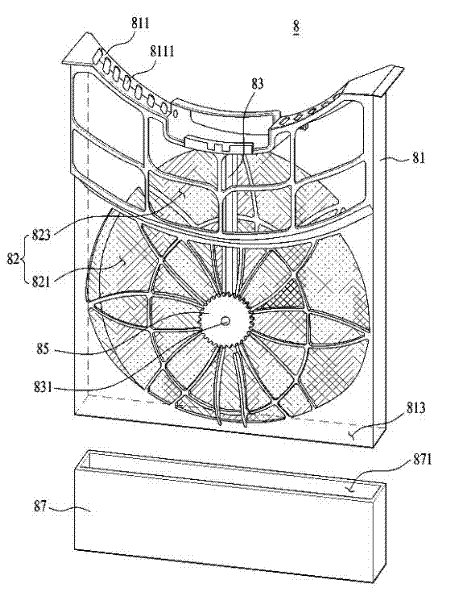

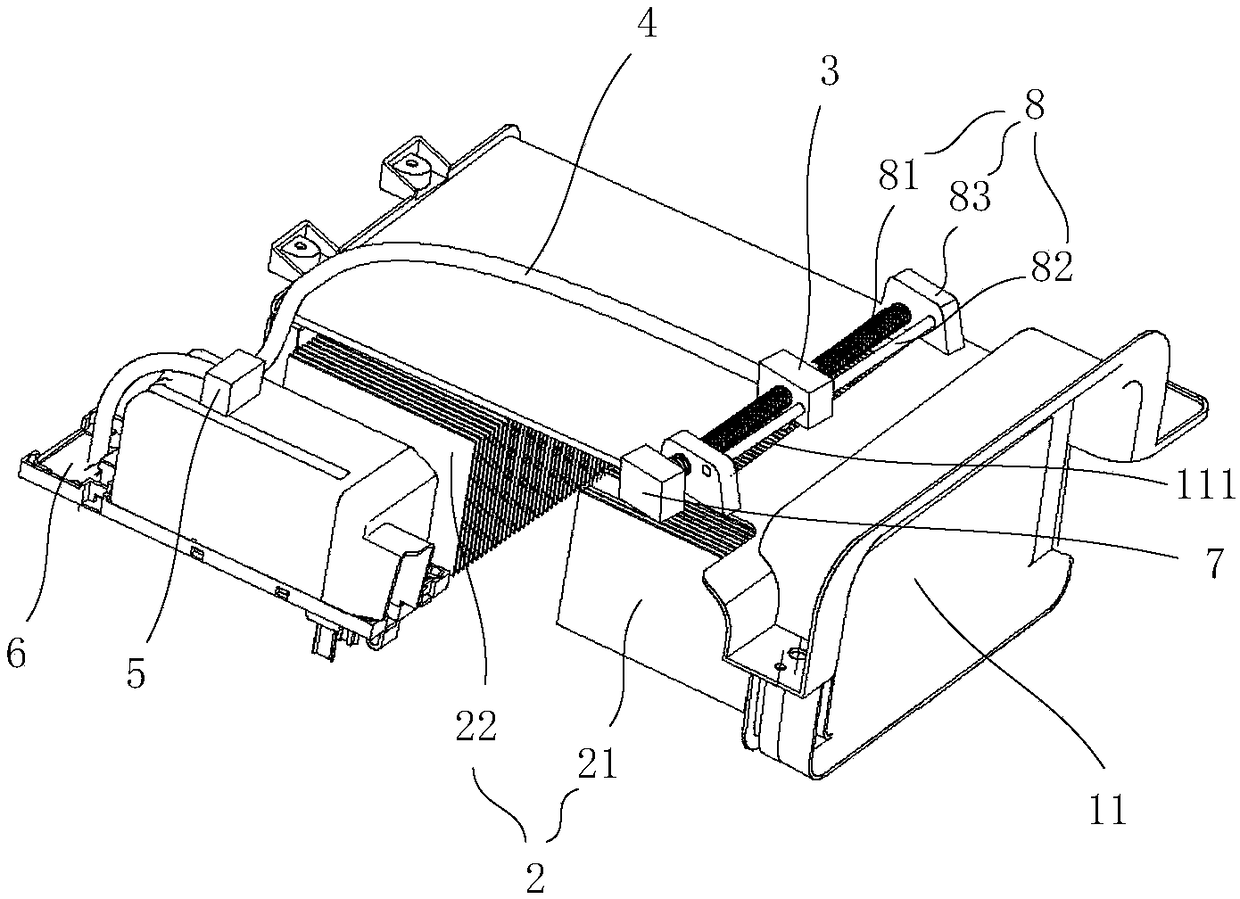

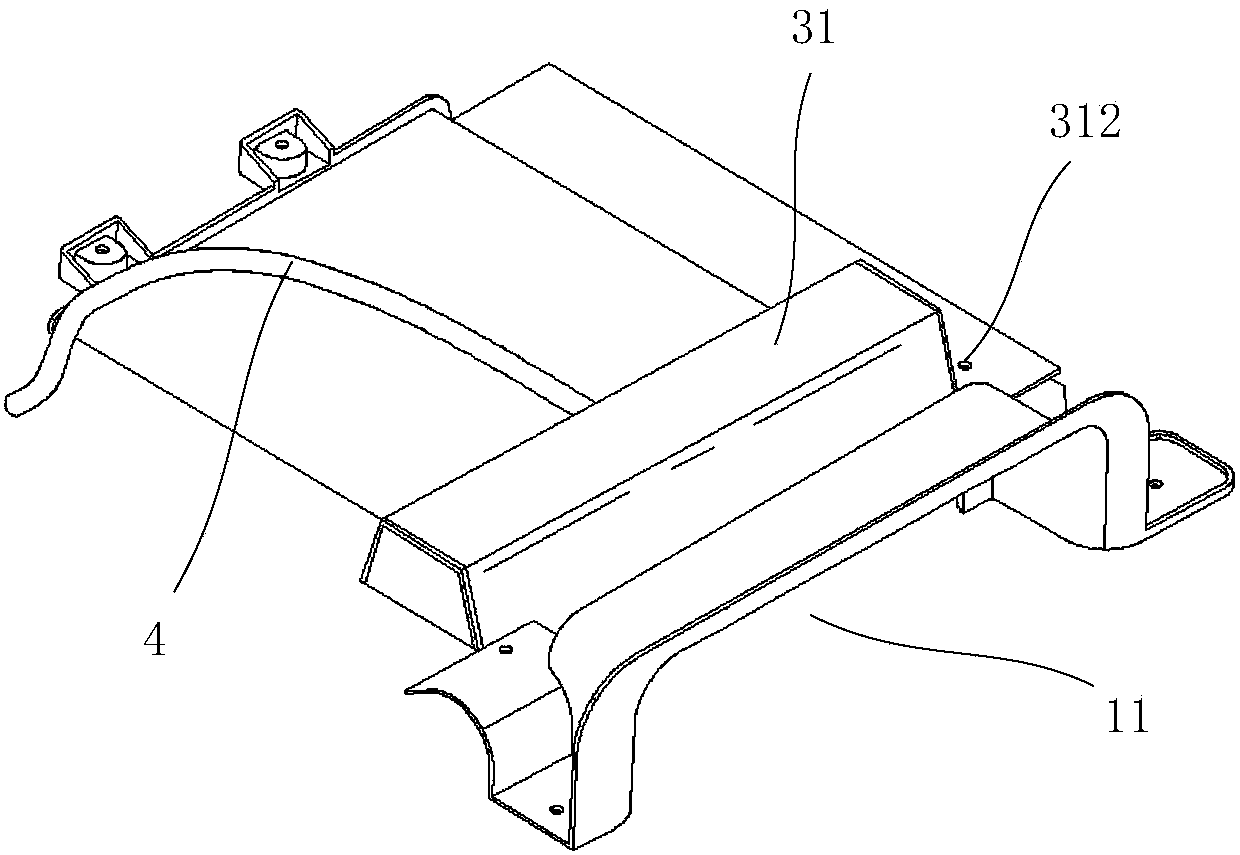

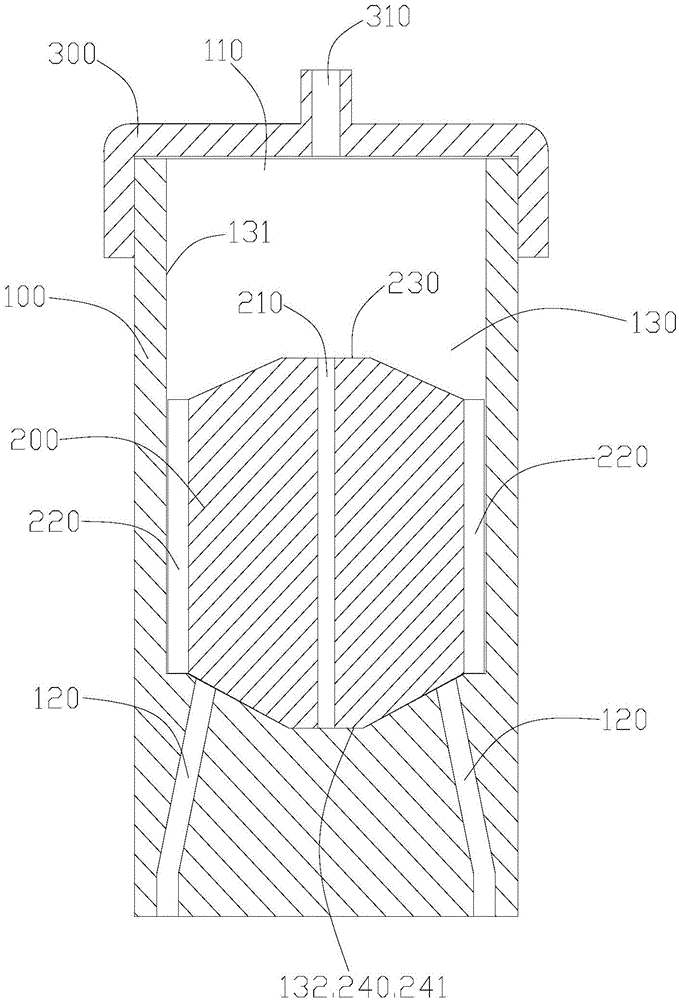

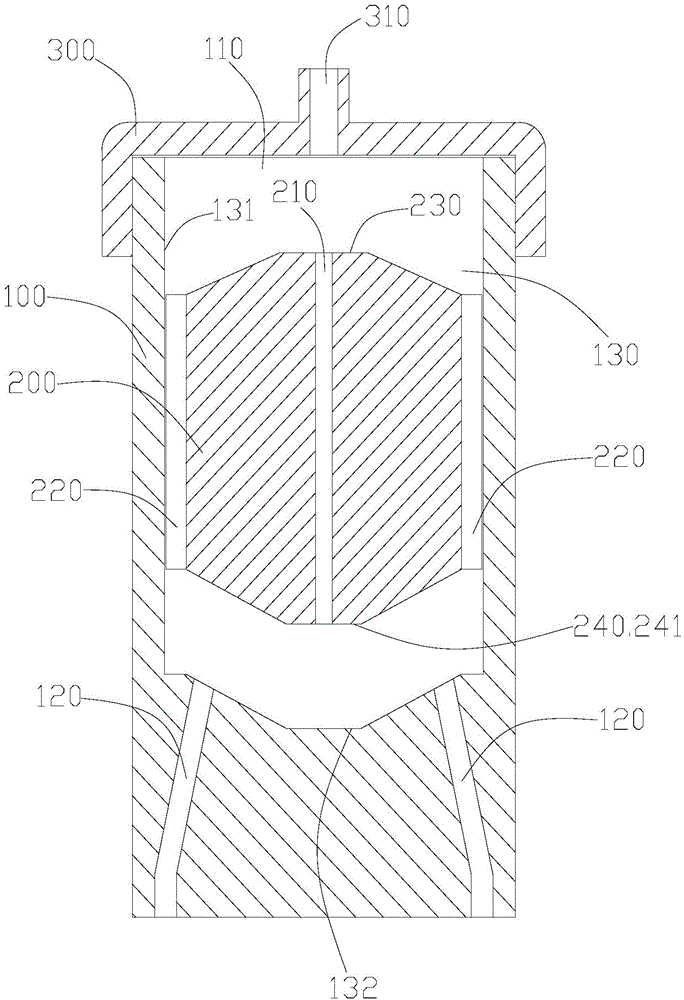

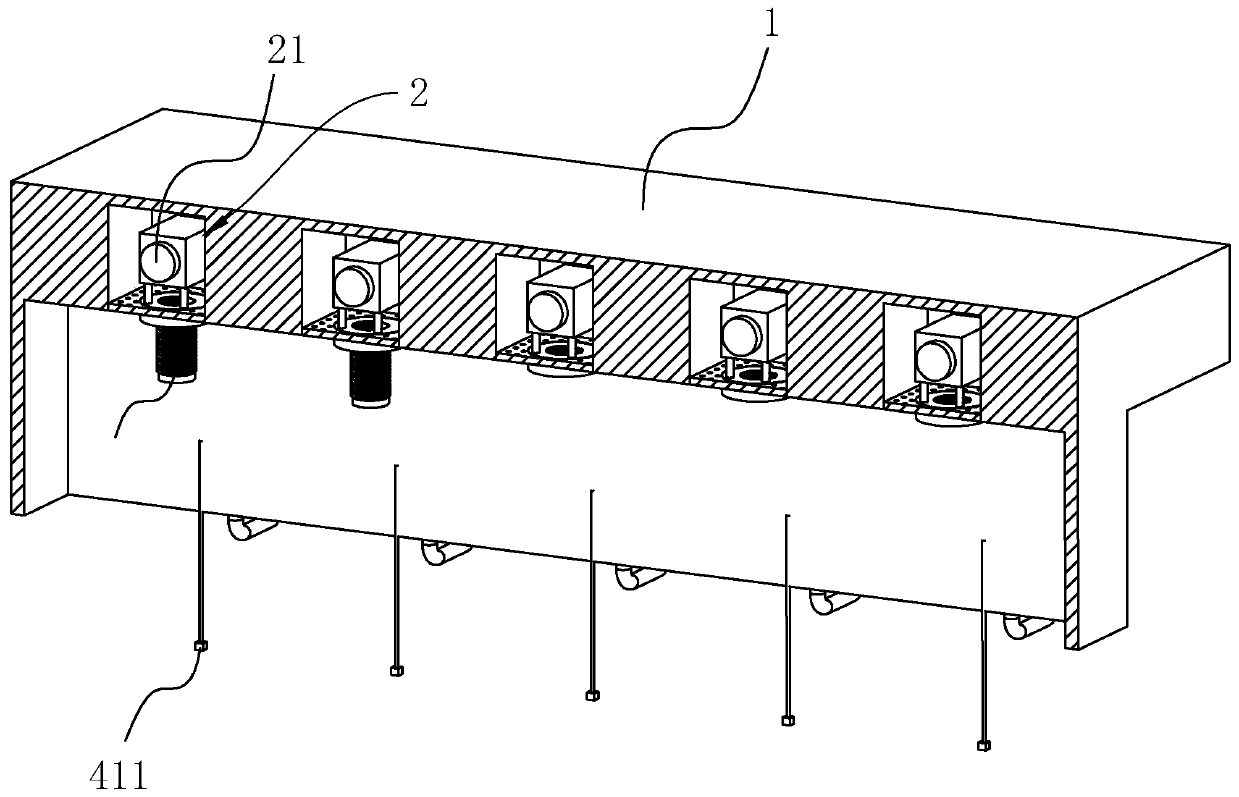

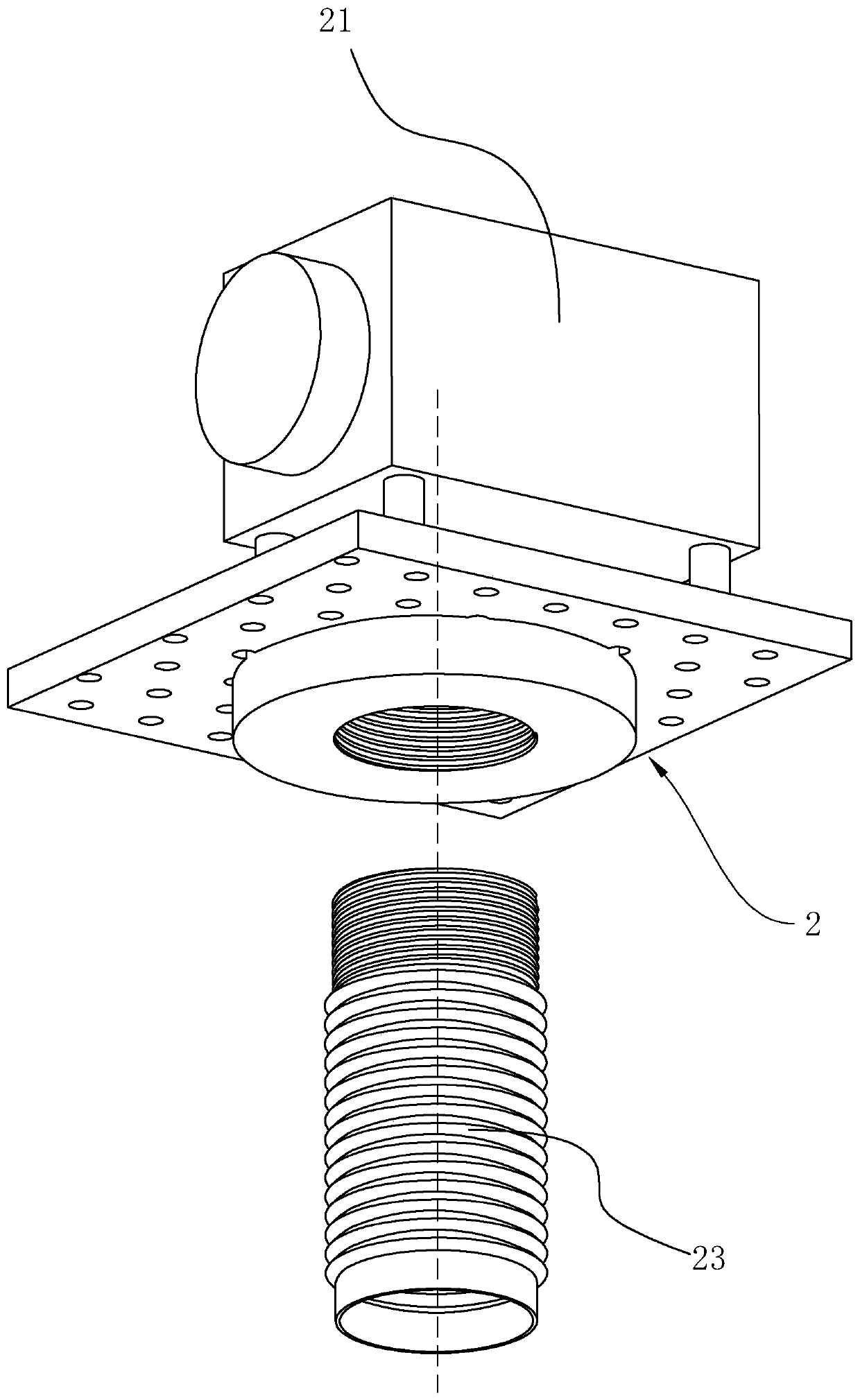

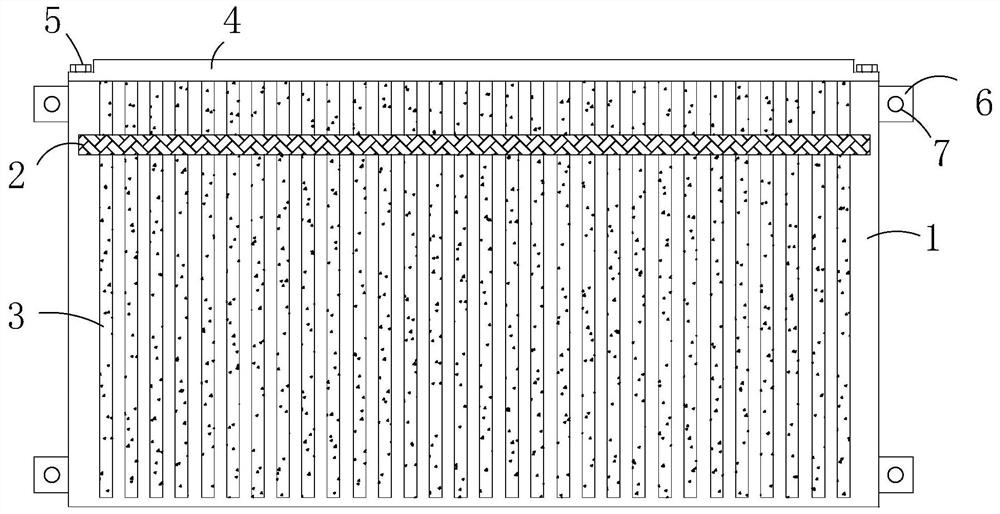

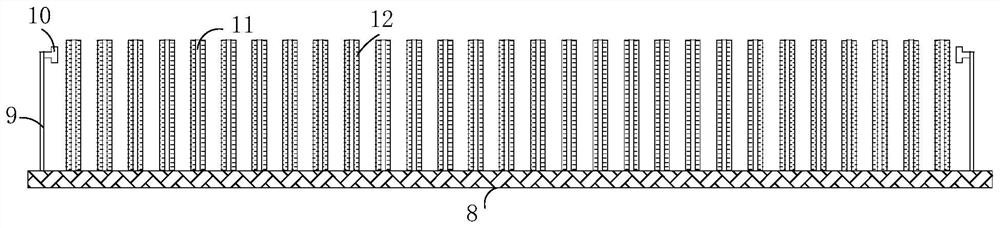

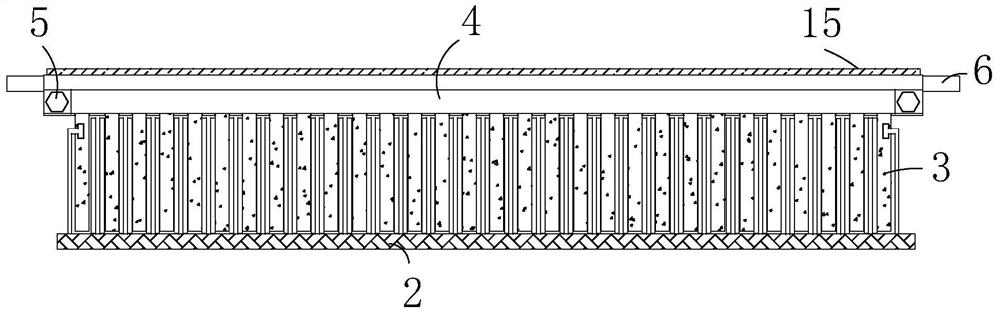

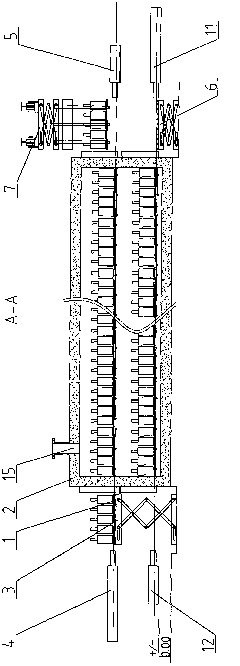

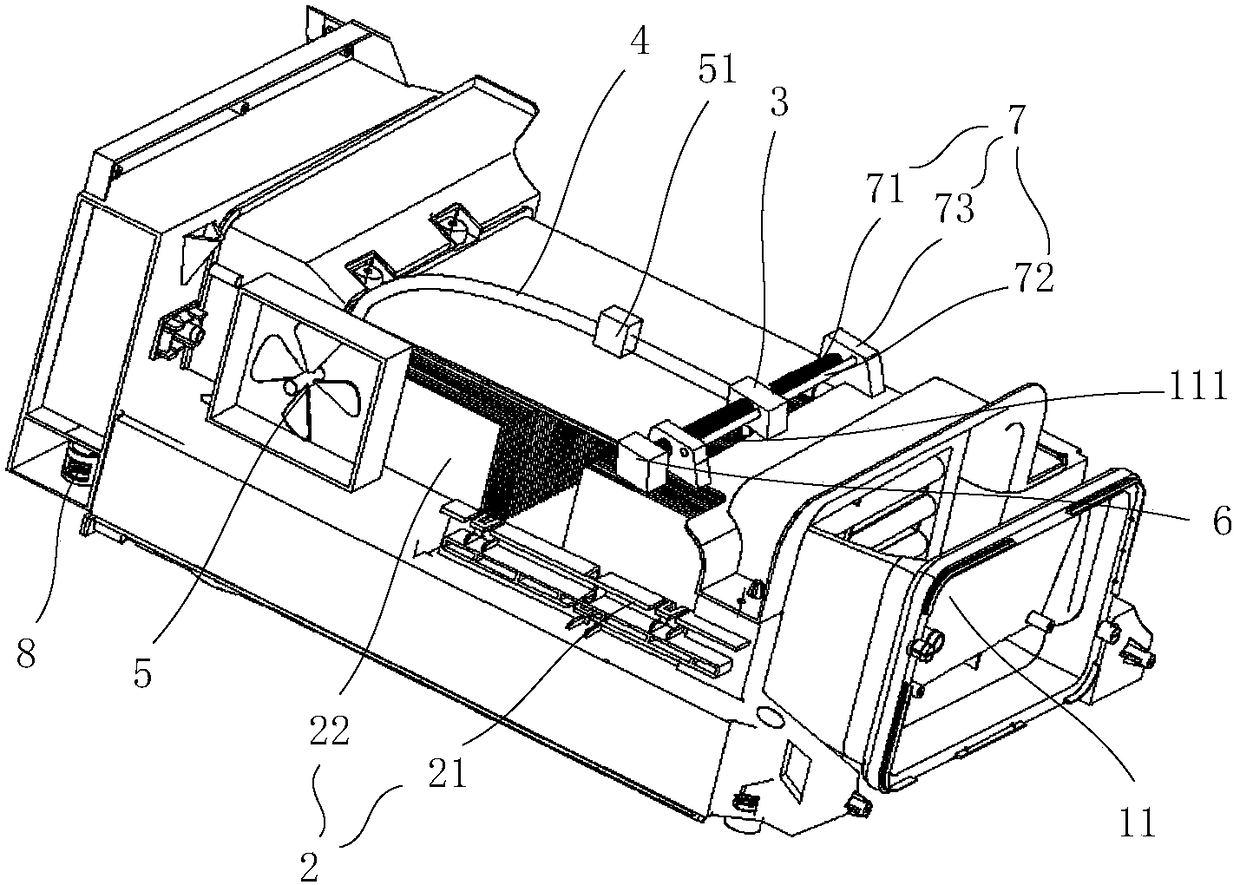

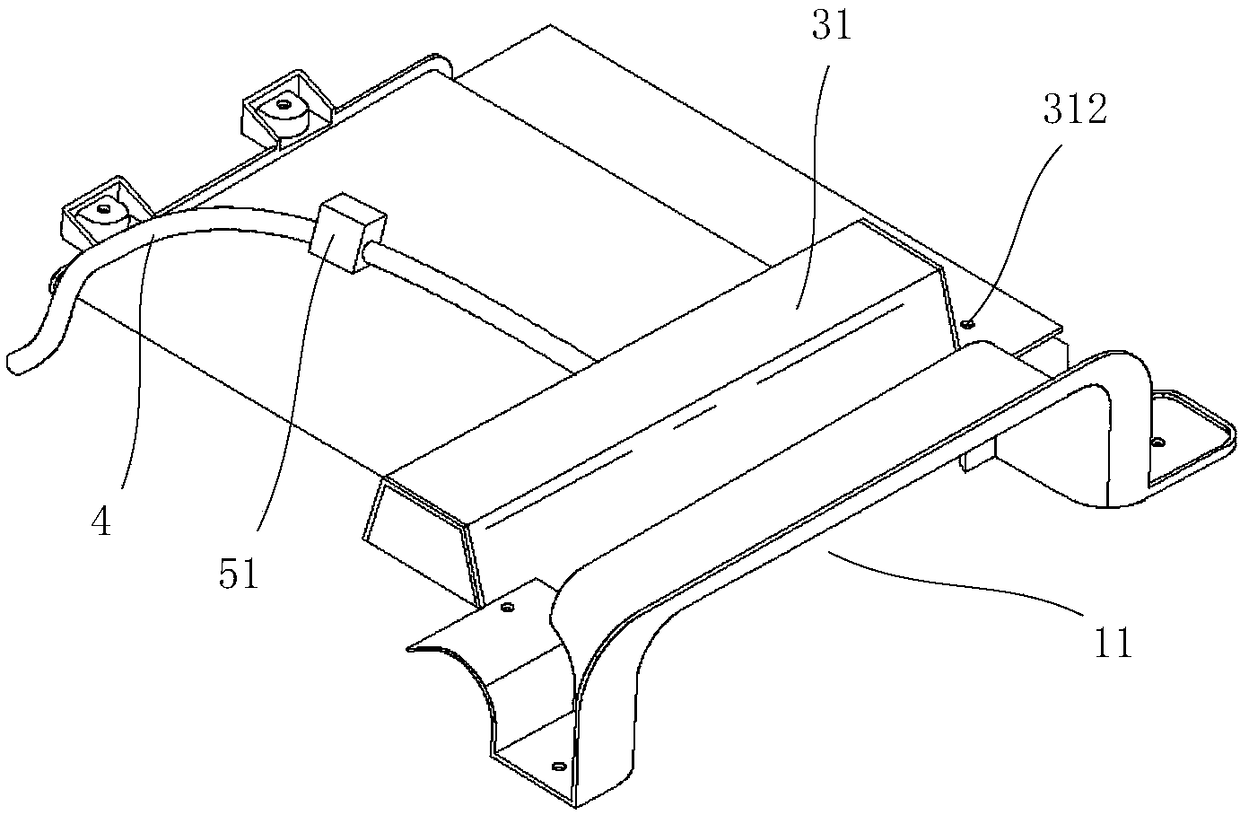

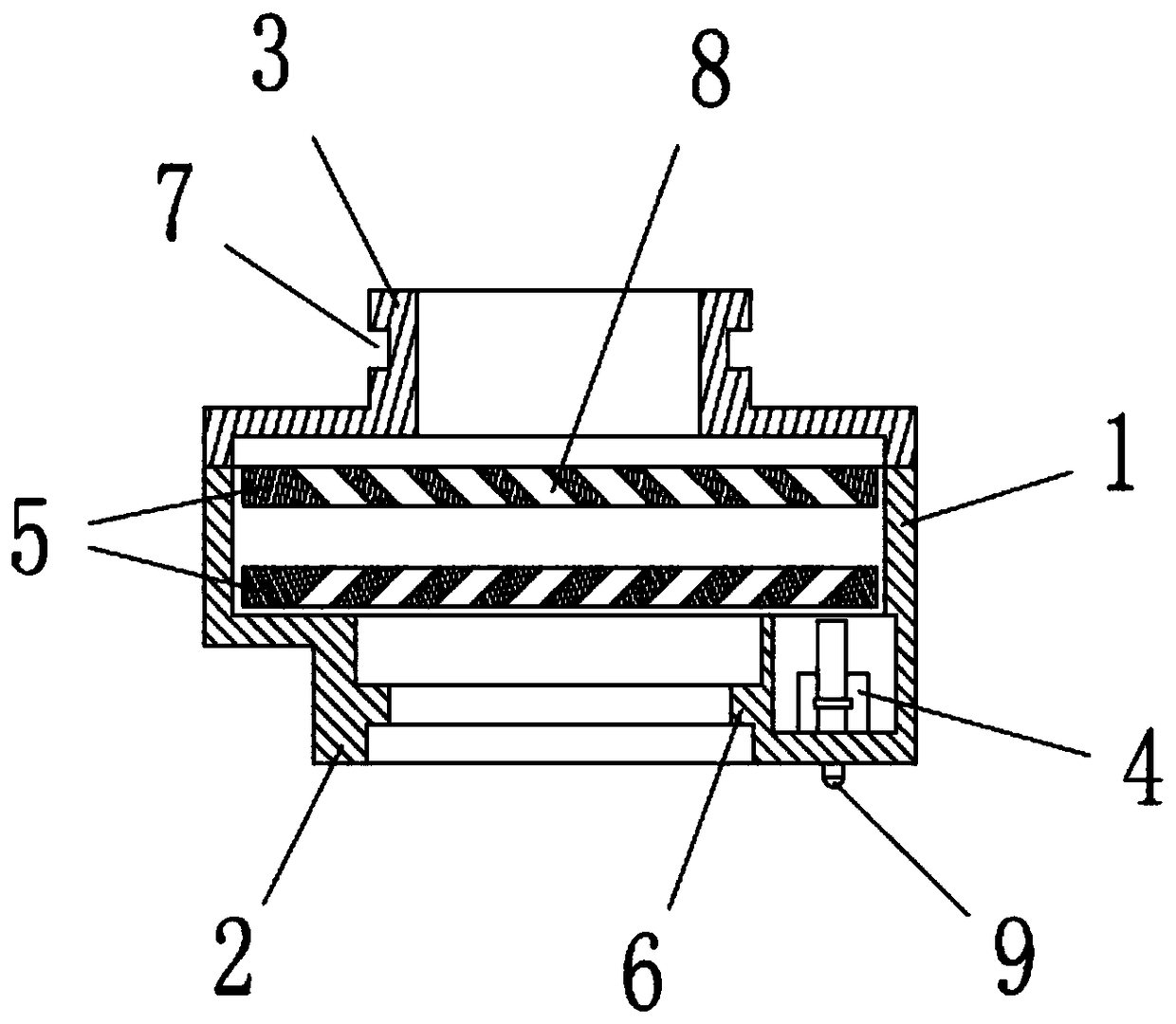

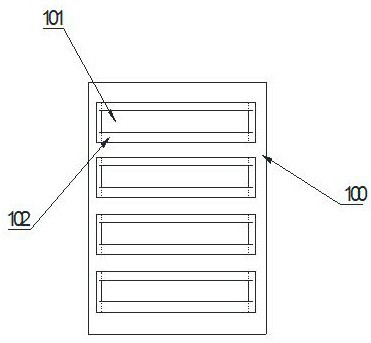

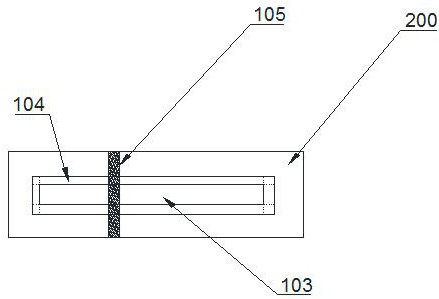

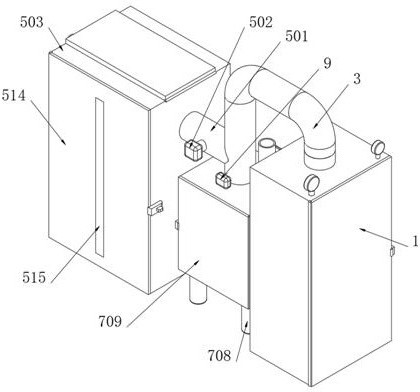

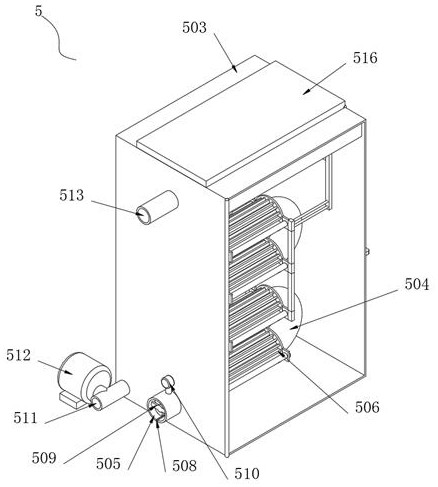

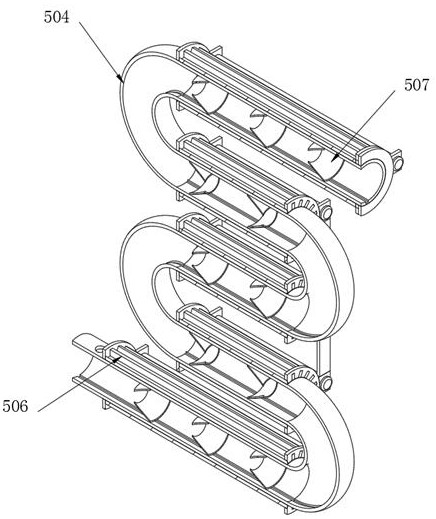

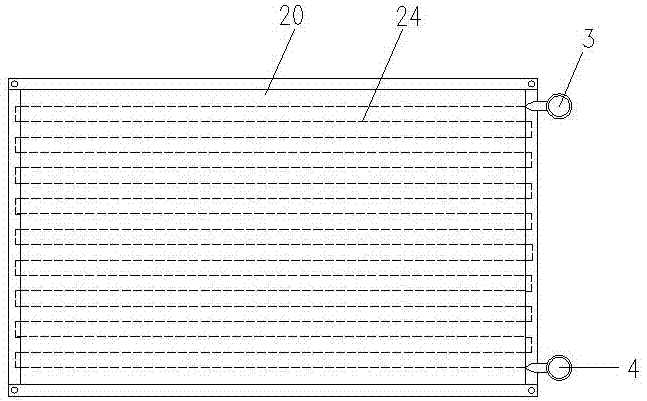

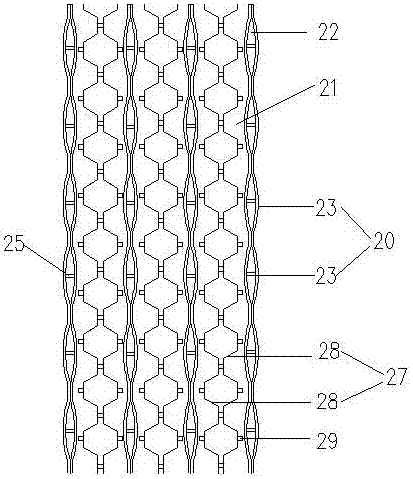

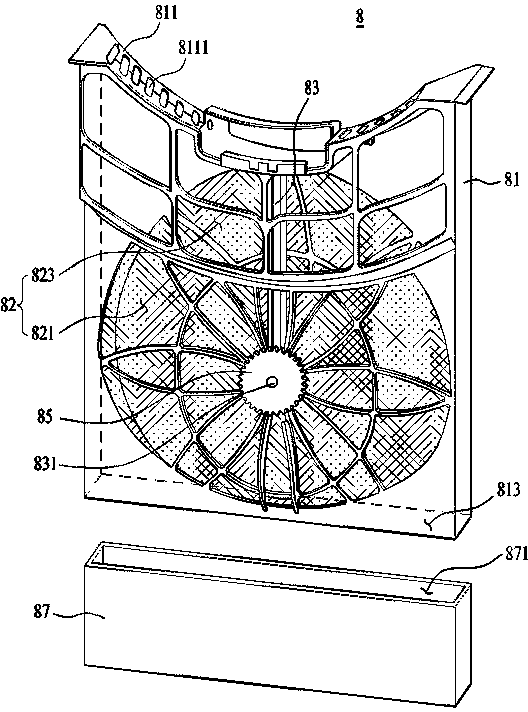

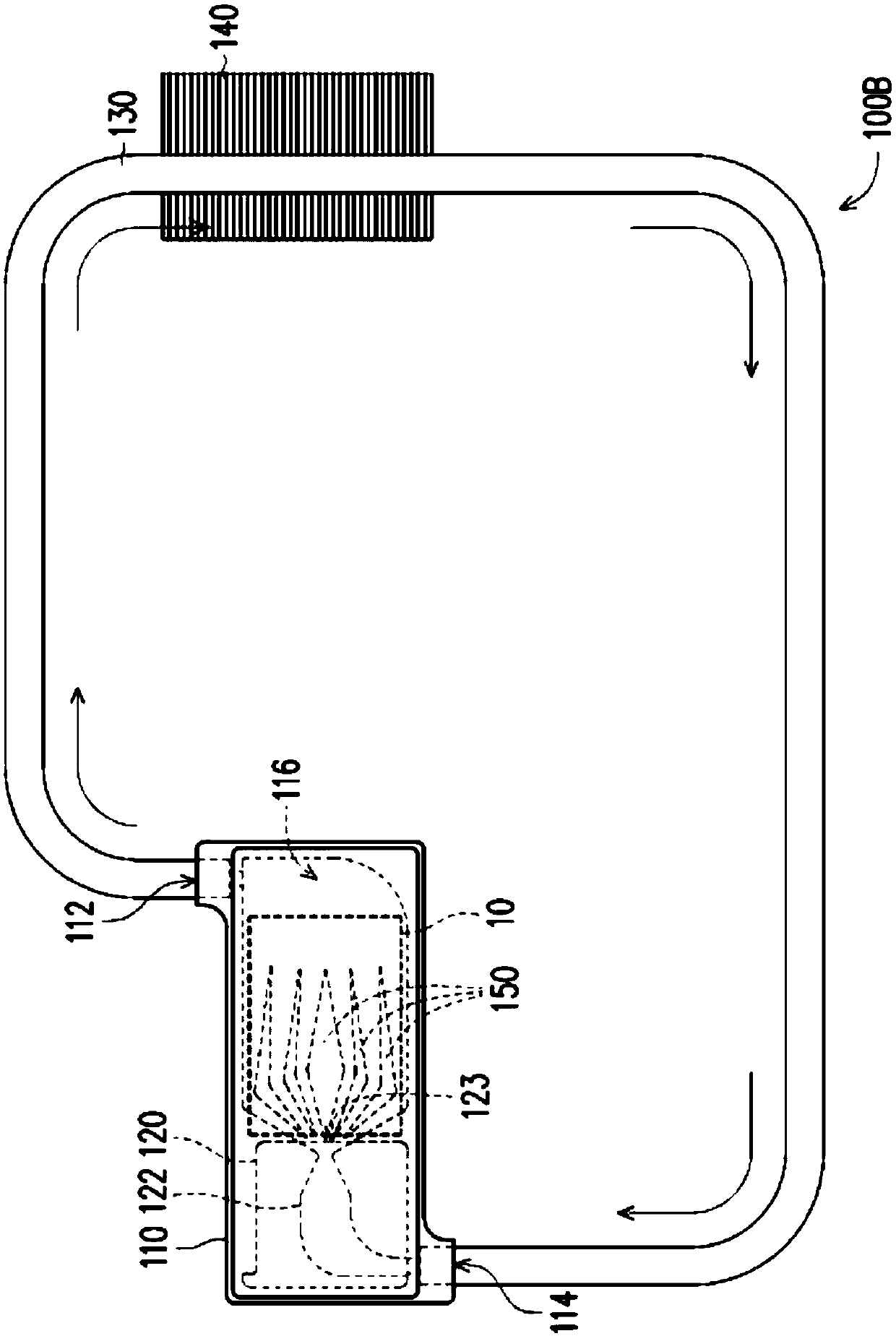

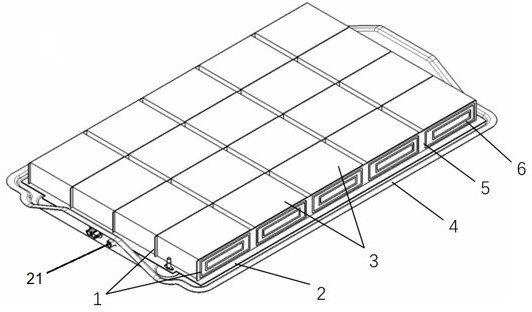

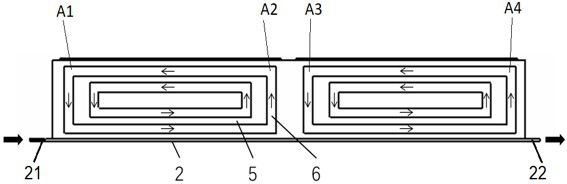

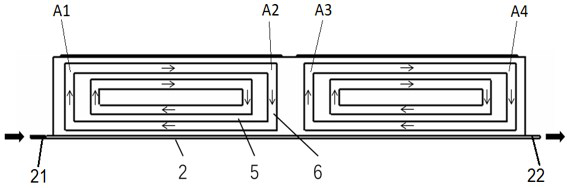

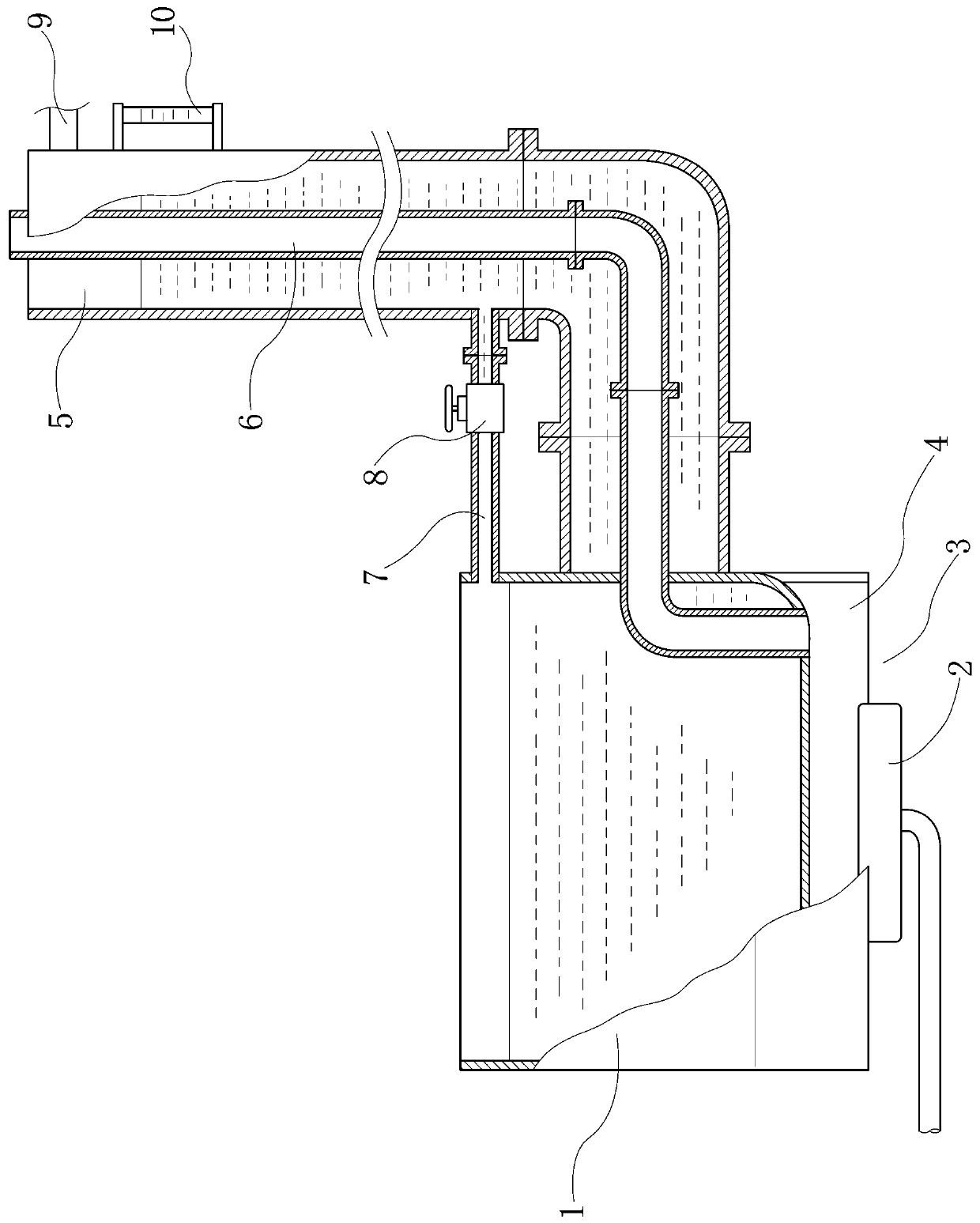

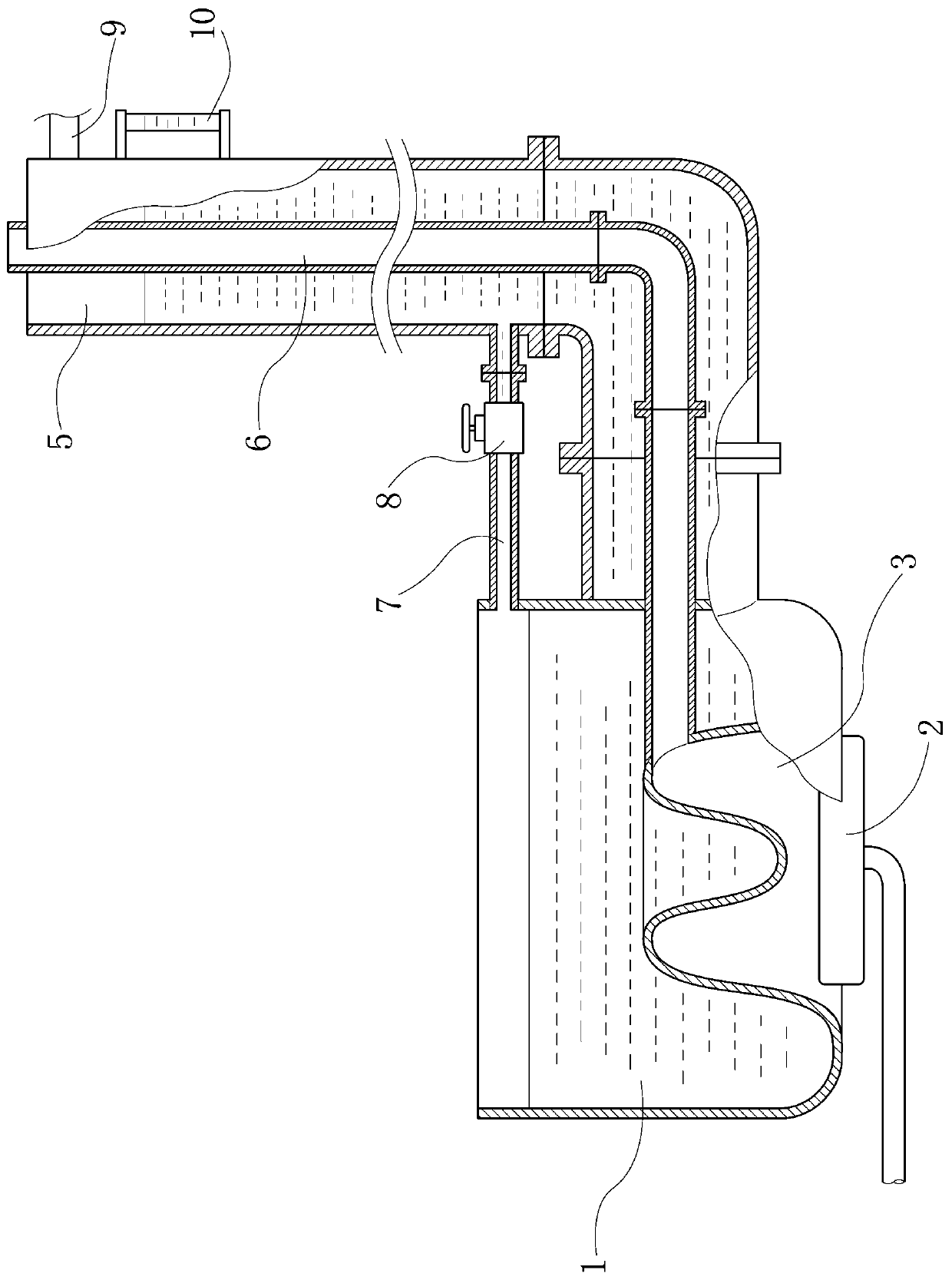

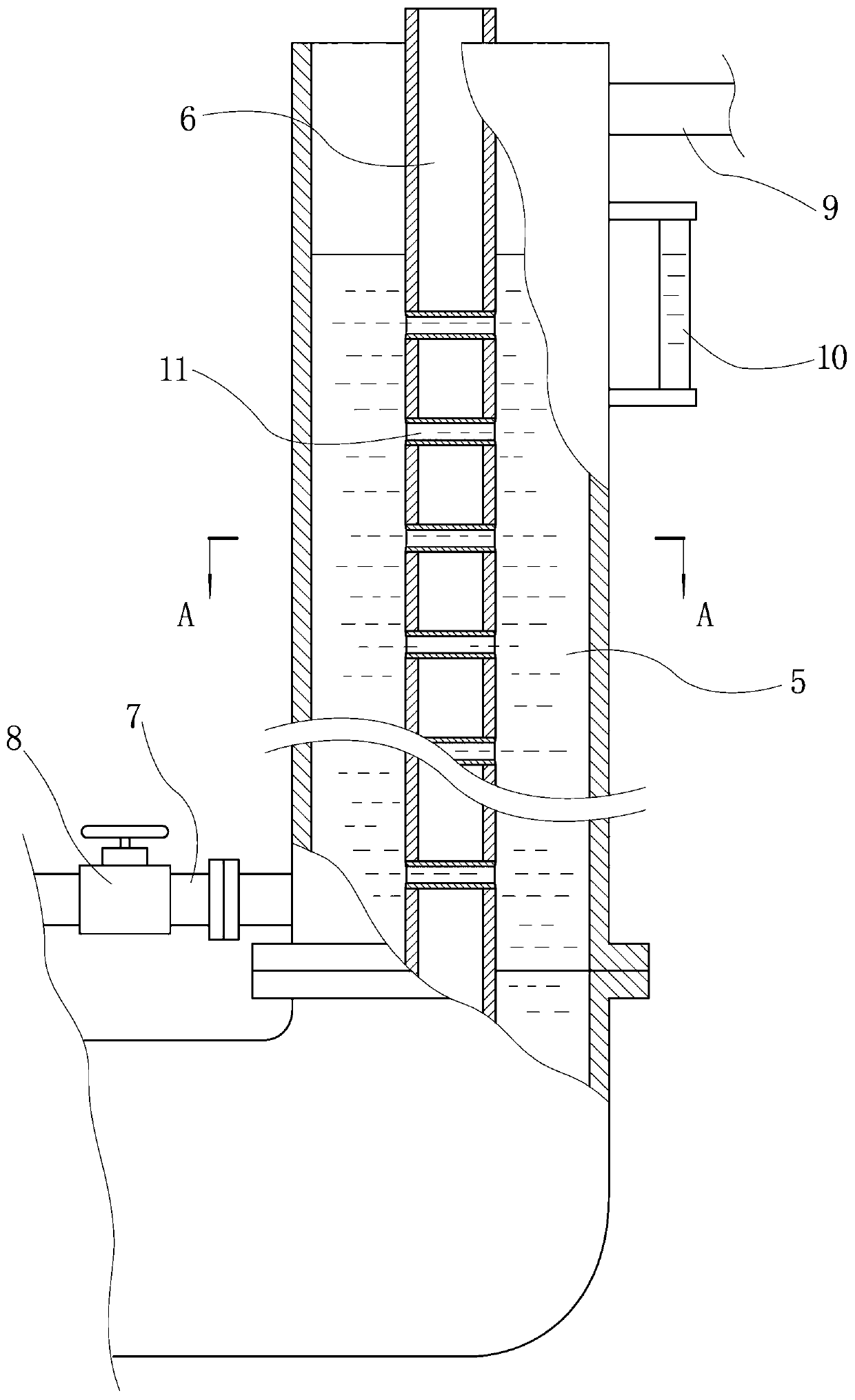

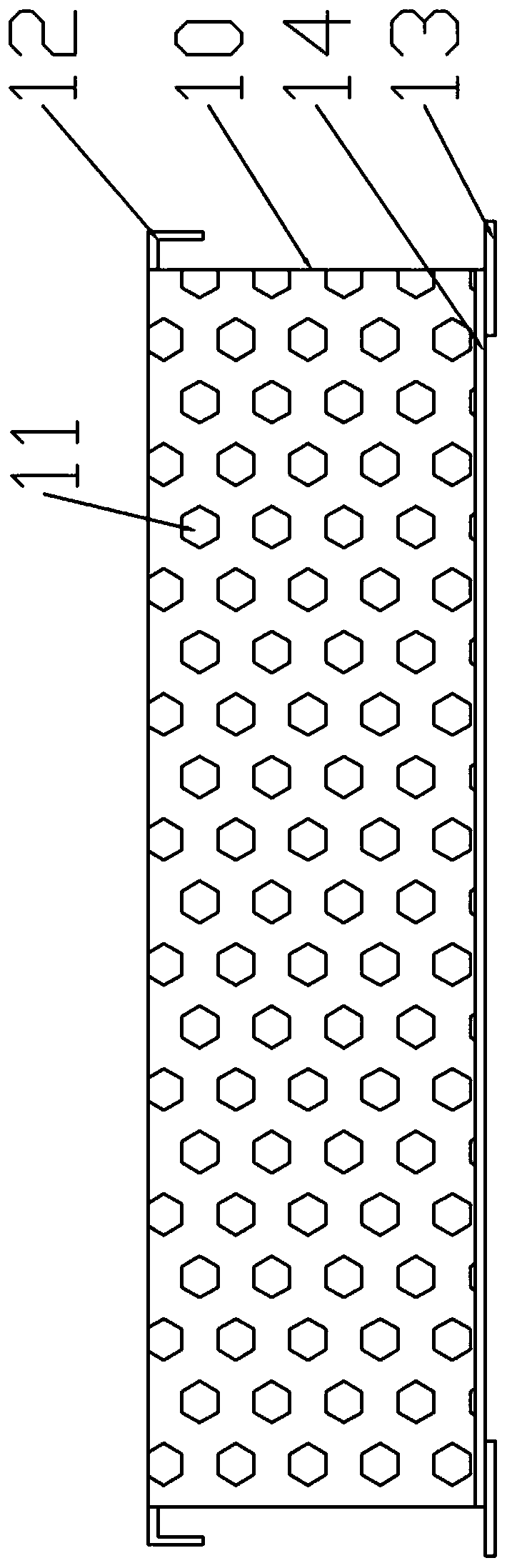

Battery module with fluid cooling passage

InactiveCN103904383AGuaranteed heat exchange efficiencyEasy to groupCell temperature controlBatteriesElectrical batteryElectric vehicle

The invention relates to the field of battery modules, in particular to a battery module for supplying power to an electric vehicle. A battery module with a fluid cooling passage comprises a plurality of liquid heat exchange managing units, wherein each liquid heat exchange managing unit is internally provided with a plurality of battery cells side by side; two adjacent battery cells in the same liquid heat exchange managing unit are insulated from each other through a battery grating spacing; the liquid heat exchange managing units are connected side by side to form the battery module; a tab protecting cover covers the rear end of the whole battery module; a left side cover and a right side cover are arranged on the two sides of the battery module. According to the battery module, heat management is carried out on each battery cell in the battery module, so that the heat exchange efficiency of the battery cells and the uniformity of temperature among the different battery cells are ensured, the battery module adopts an extensible module structure, and the composition is flexible according to requirements; moreover, the types of components are reduced, so that the assembly technology of a water jacket housing assembly is simple, and the battery module is extremely convenient to use.

Owner:SAIC MOTOR

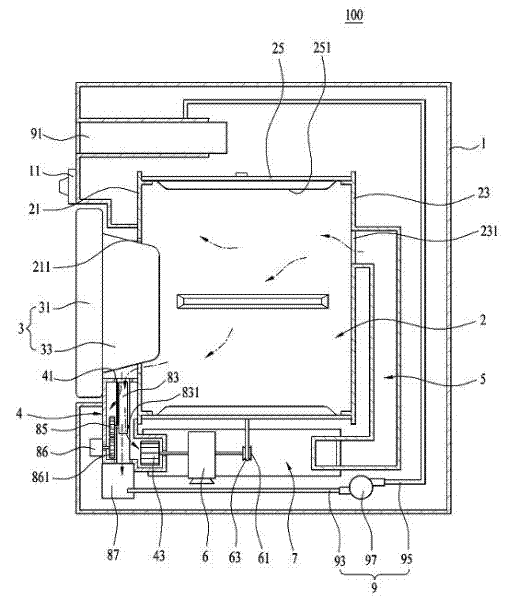

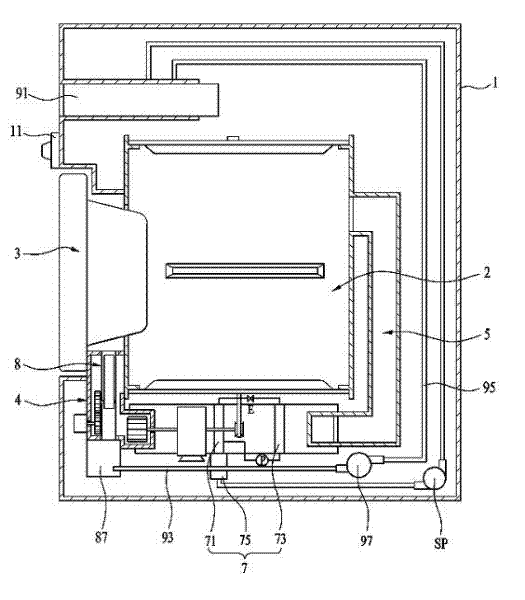

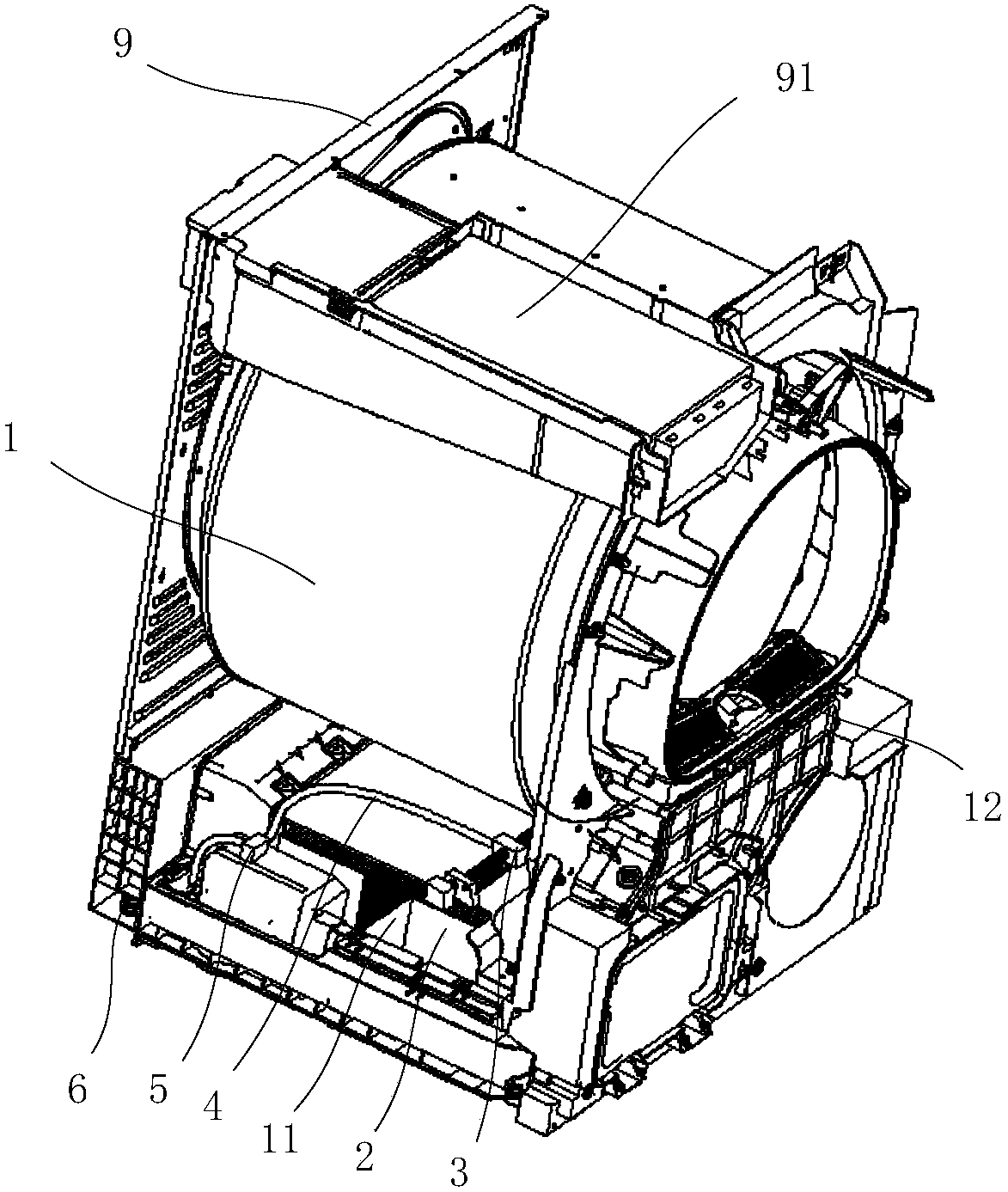

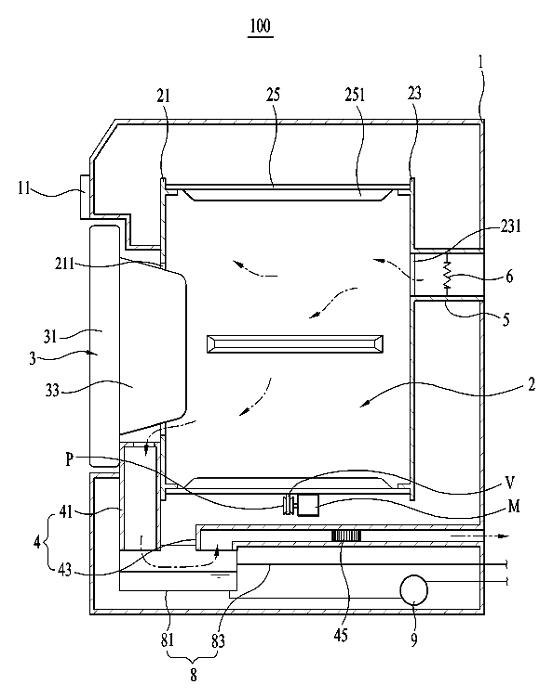

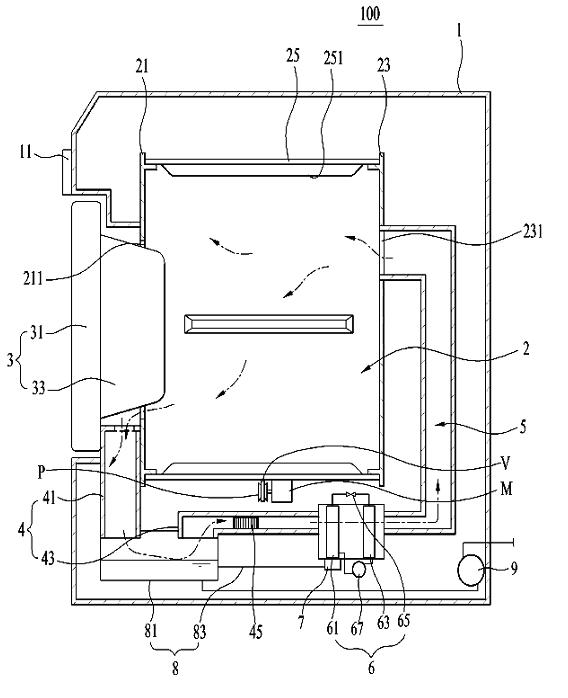

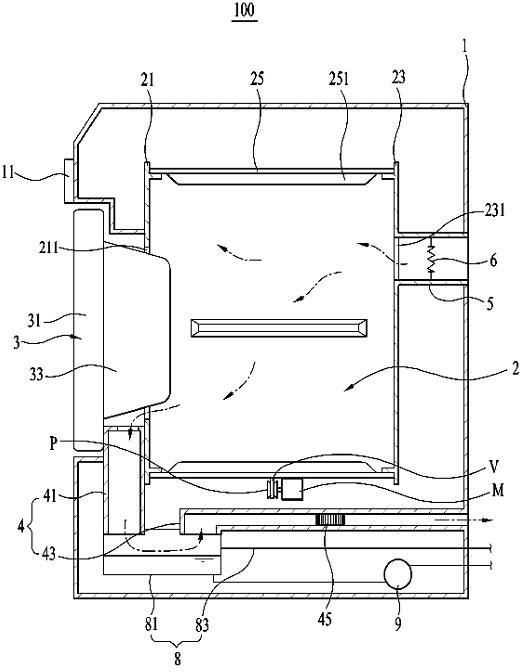

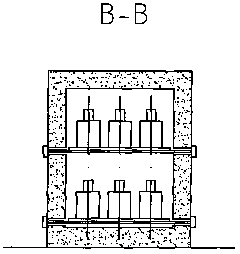

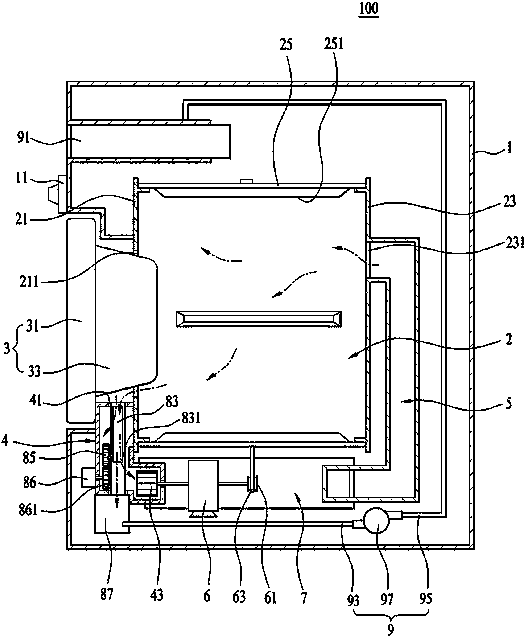

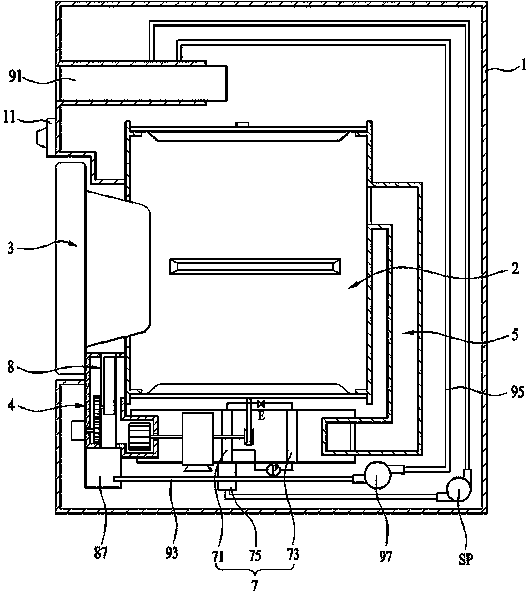

Clothes processing device

InactiveCN102535129AWith cleaning functionEfficient removalDrying gas arrangementsOther washing machinesWaste management

The invention relates to a clothes processing device, comprising a housing forming the appearance, an accommodating space which is disposed in the housing for accommodating clothes, an air supply device for supplying air in the accommodating space, a discharging channel for discharging air in the accommodating space, a filter assembly for removing exotic matter from air flowing in the discharging channel, a storing space which can be taken out and is disposed in the housing, and an exotic matter removing part for moving the exotic matter collected by the filter assembly to a moving device of the storing space. With the arrangement of the filter assembly, exotic matter can be effectively removed from air discharged from the accommodating space, ensuring the efficiency of heat exchange. With the arrangement of the exotic matter removing part, the function of cleaning filter assembly which is discharging exotic matter collected in the filter assembly outside of the filter assembly is provided.

Owner:NANJING LG PANDA APPLIANCES

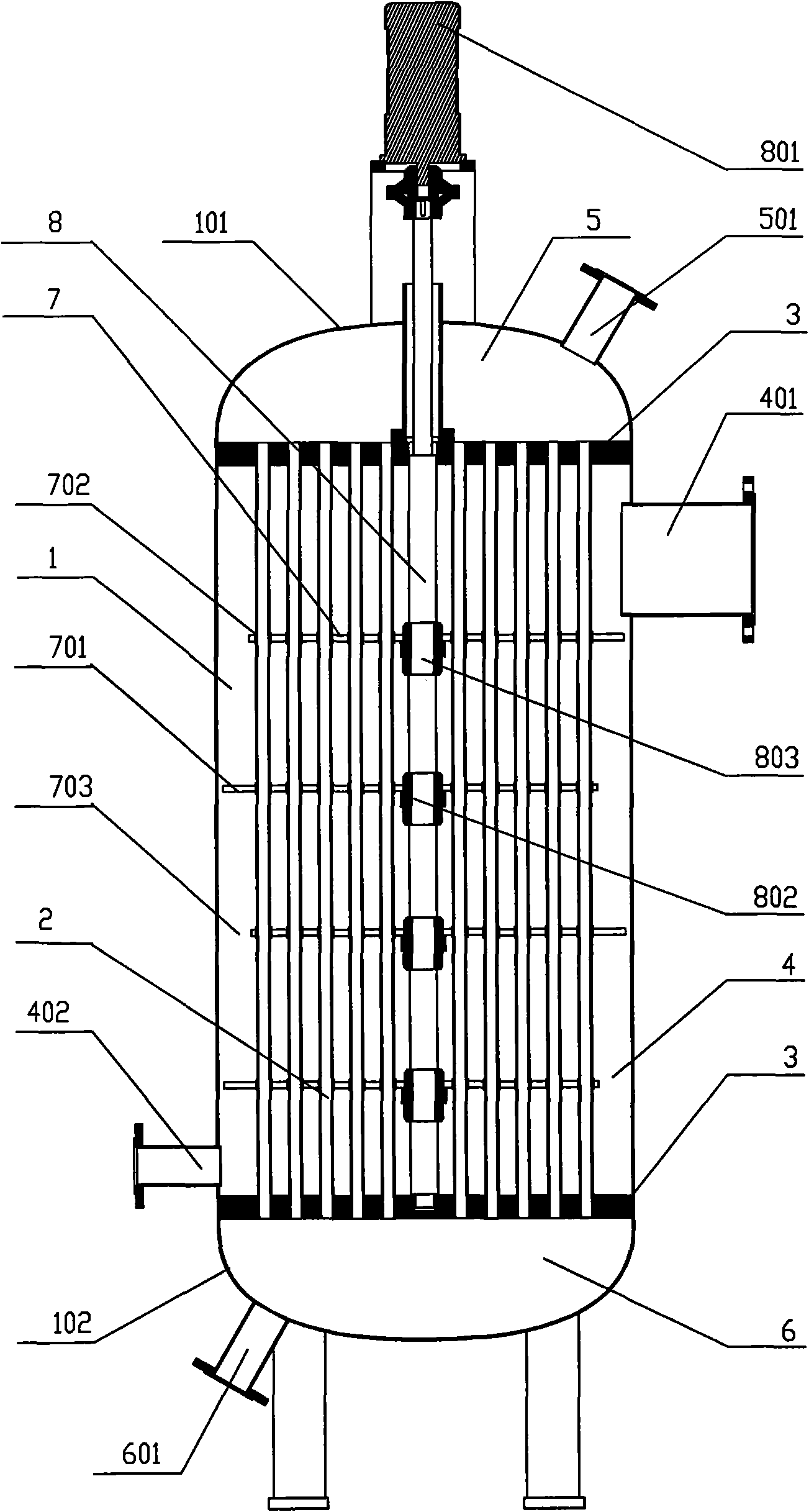

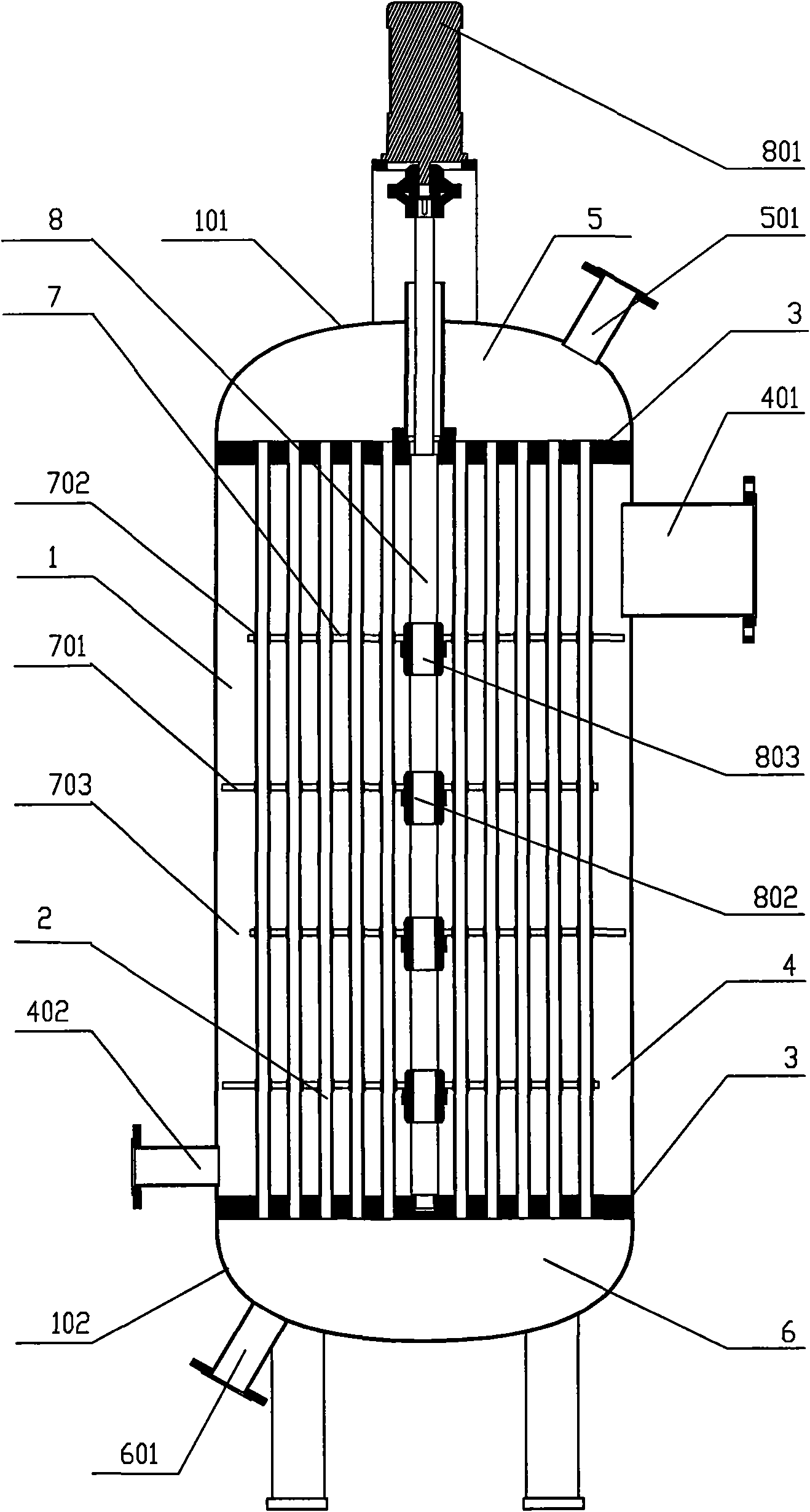

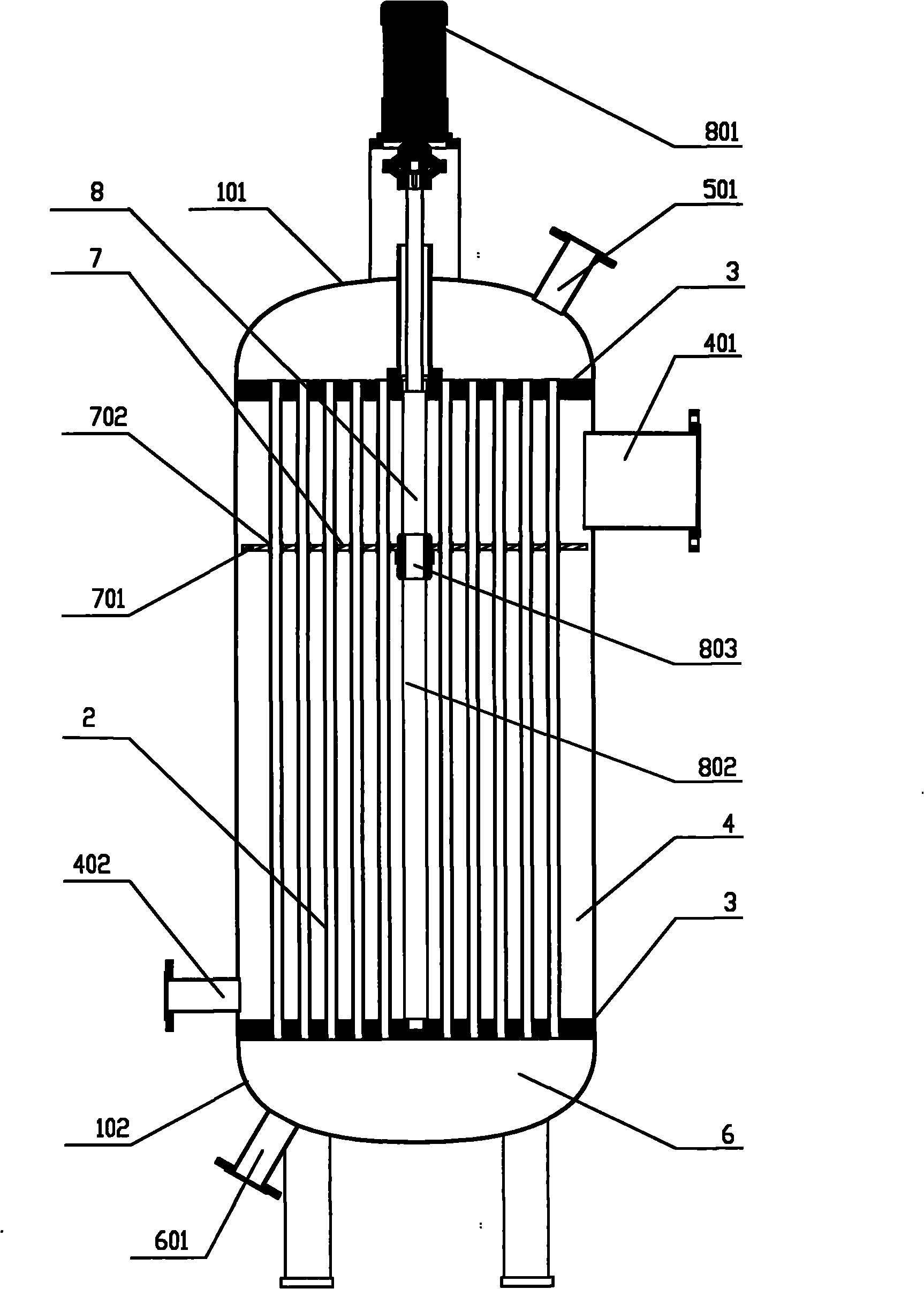

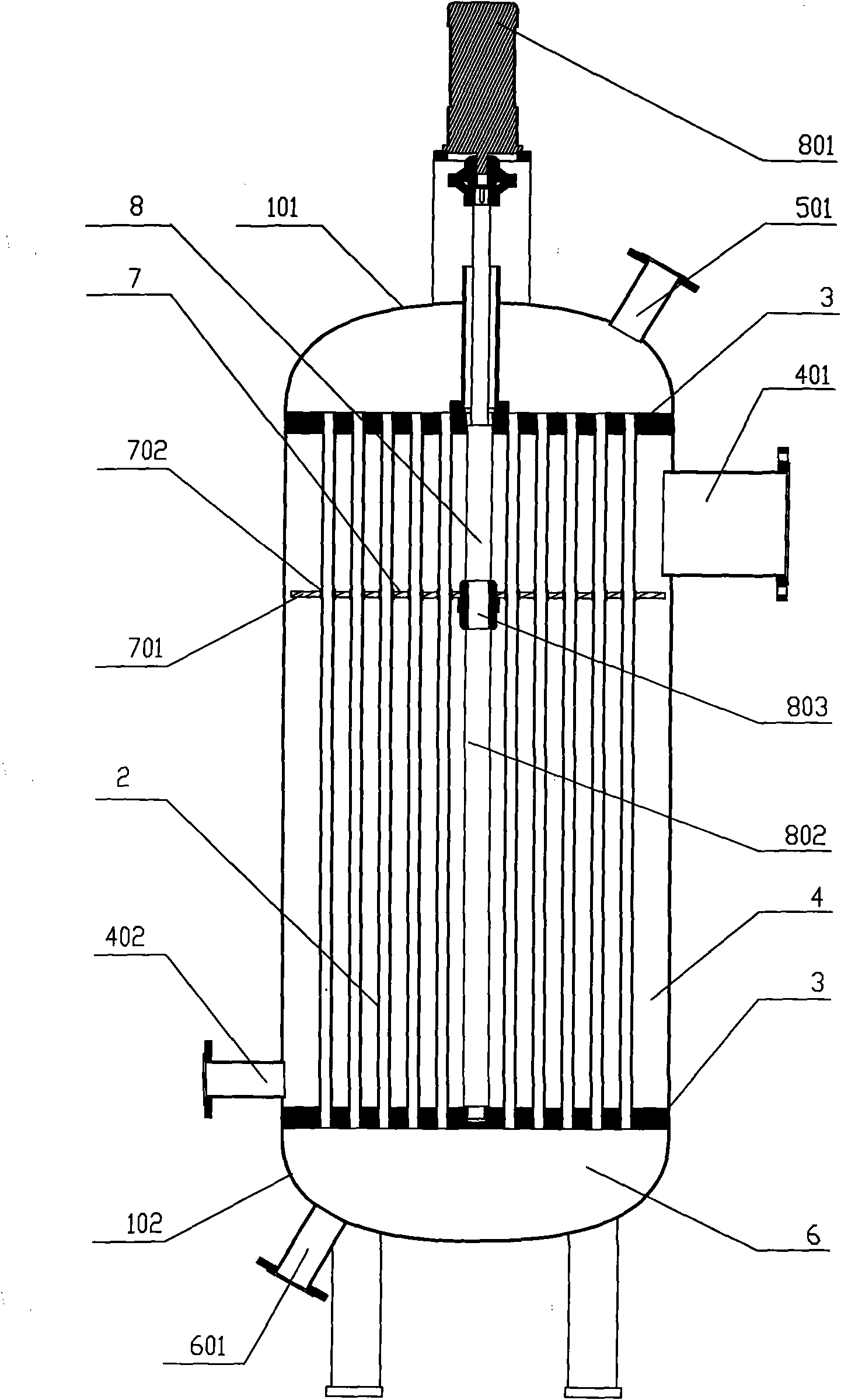

Self-cleaning heat exchanger

InactiveCN102012179AAvoid erosionMaintain heat exchange efficiencyHeat exchanger casingsStationary tubular conduit assembliesHeat transfer tubeEngineering

The invention provides a self-cleaning heat exchanger. The heat exchanger comprises a cylinder body, a set of mutually-parallel heat transfer tubes, and an automatic cleaning device, wherein the two ends of the cylinder body are respectively provided with an end cover, and a medium A inlet and a medium A outlet are respectively arranged at the two ends of the cylinder body wall; the heat transfer tube is a straight tube, the two end parts of the heat transfer tube are respectively fixed on a mounting plate, and a heat transfer cavity is formed between each of the two mounting plates and the cylinder body wall; a medium B inlet cushion cavity is formed between one of the two mounting plates and the end cover of the cylinder at the outer side of the one mounting plate; a medium B outlet cushion cavity is formed between the other mounting plate and the end cover of the cylinder at the outer side of the other mounting plate; and the automatic cleaning device comprises a cleaning frame, a scrubbing annular sheet and a driving device, and the cleaning device is driven to carry out reciprocating motion along the axial direction of the heat transfer tubes by the driving device. The heat exchanger of the invention can be widely applied to the industries requiring for refrigeration, such as the cooling systems of pharmaceutical factories, power plants and boilers, etc.

Owner:FUJIAN NEWLAND ENTECH CO LTD

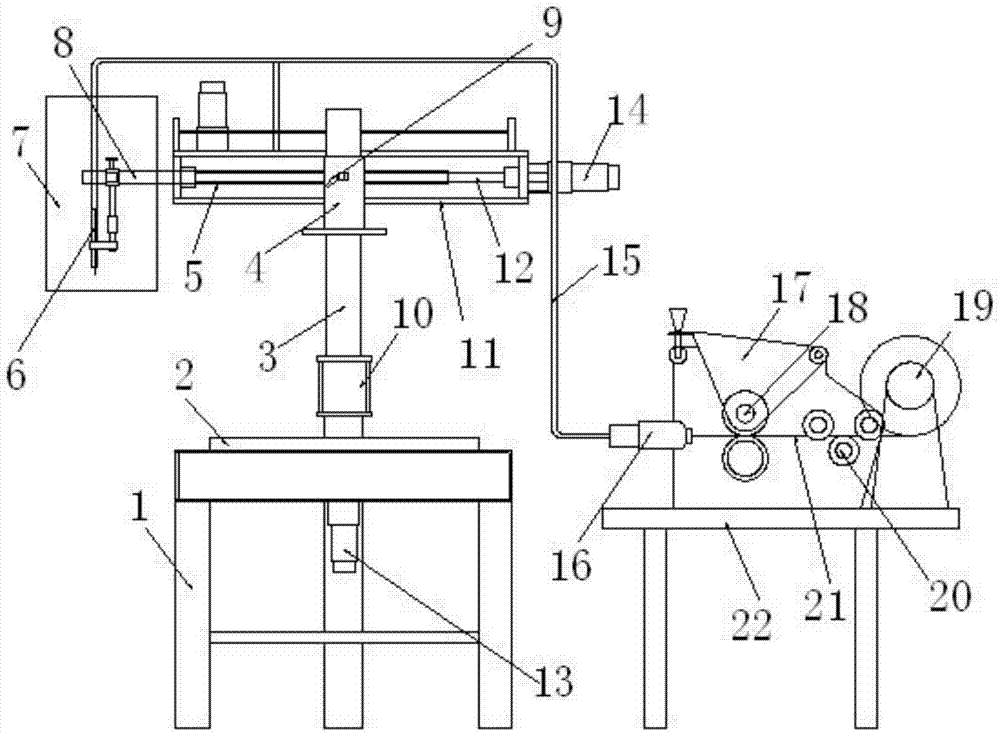

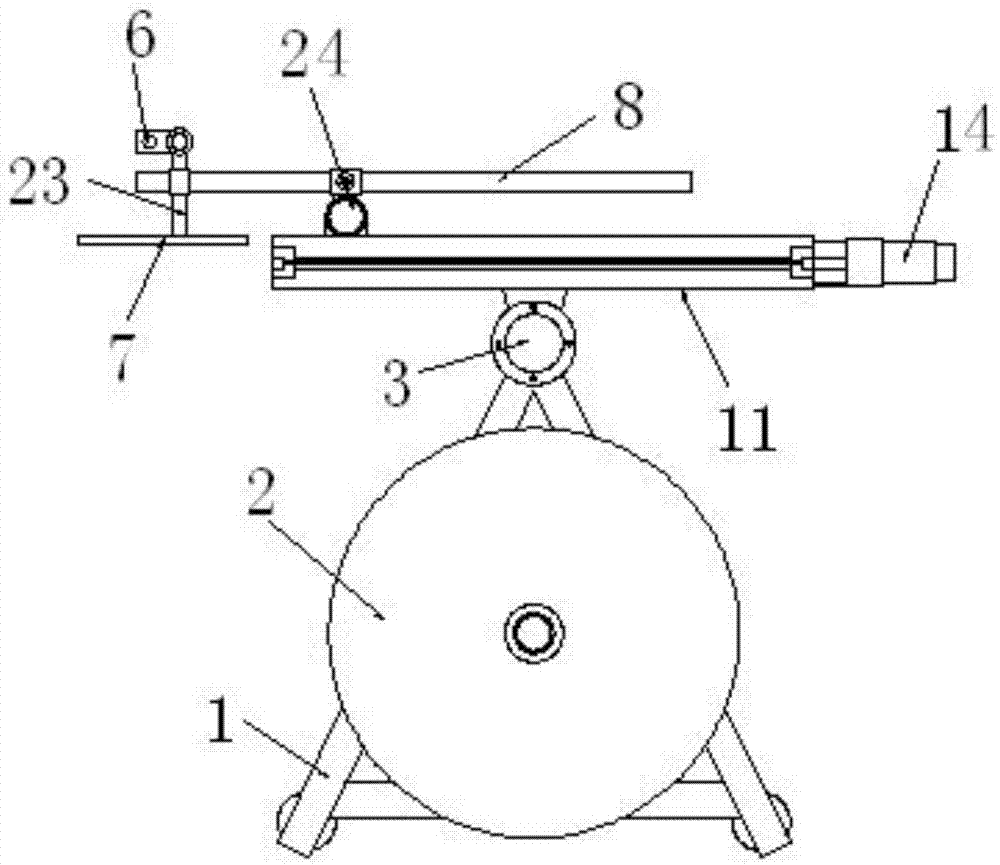

Spiral-plate heat exchanger welding machine

ActiveCN103769722AGuaranteed heat exchange efficiencyNot easy to cause interpenetrationWelding/cutting auxillary devicesElectrode supporting devicesPlate heat exchangerEngineering

The invention discloses a spiral-plate heat exchanger welding machine is a very suitable machine for machining spiral-plate heat exchangers. According to the adopted technical measures, the spiral-plate heat exchanger welding machine comprises a rack, a rotary disk is arranged on the rack, and a welding gun is arranged on the outer side of the rotary disk. The spiral-plate heat exchanger welding machine is characterized in that a transverse beam is connected to a stand column in the horizontal direction, the welding gun is connected to a clamping mechanism, the clamping mechanism is connected with a pushing mechanism arranged on the transverse beam, a probe used for detecting the position of a spiral plate is arranged in the position of the welding gun, the probe is connected with the pushing mechanism through a controller and used for controlling work of the pushing mechanism, and the welding gun moves in the length direction of the transverse beam under the action of the pushing mechanism; the controller is further used for controlling the rotation speed of the rotary disk after receiving signals of the probe; an automatic wire feeder is used for automatically delivering welding wires to the welding gun. The welding machine is high in operation speed and very suitable for welding integral heat exchange plates.

Owner:TAIZHOU HENGS THAI MEDICAL EQUIP

Heat exchanger with automatic cleaning device

InactiveCN101979952AAvoid erosionGuaranteed heat exchange efficiencyStationary tubular conduit assembliesNon-rotary device cleaningHeat transfer tubeReciprocating motion

The invention provides a heat exchanger with an automatic cleaning device. The heat exchanger comprises a barrel, a group of parallel heat transfer tubes and the automatic cleaning device, wherein the two end parts of the barrel are provided with end covers; a medium A inlet and a medium A outlet are formed at the two ends of a barrel wall; the heat transfer tube is a straight tube; the two end parts of the heat transfer tube are respectively fixed on an installation plate; a heat exchange chamber is formed between two installation plates and the barrel wall; a medium B inlet buffer chamber is formed between one installation plate and the barrel end cover on the outer side of the one installation plate; a medium B outlet buffer chamber is formed between the other installation plate and the barrel end cover on the outer side of the other installation plate; the automatic cleaning device comprises a cleaning frame, a scrubbing ring piece and a driving device; and the cleaning device is driven to do reciprocating motion along the axial direction of the heat transfer tubes by the driving device. The heat exchanger with the automatic cleaning device can be widely applied to cooling systems of a pharmaceutical factory, a power plant, a boiler and the like in the industries needing refrigeration.

Owner:FUJIAN NEWLAND ENTECH CO LTD

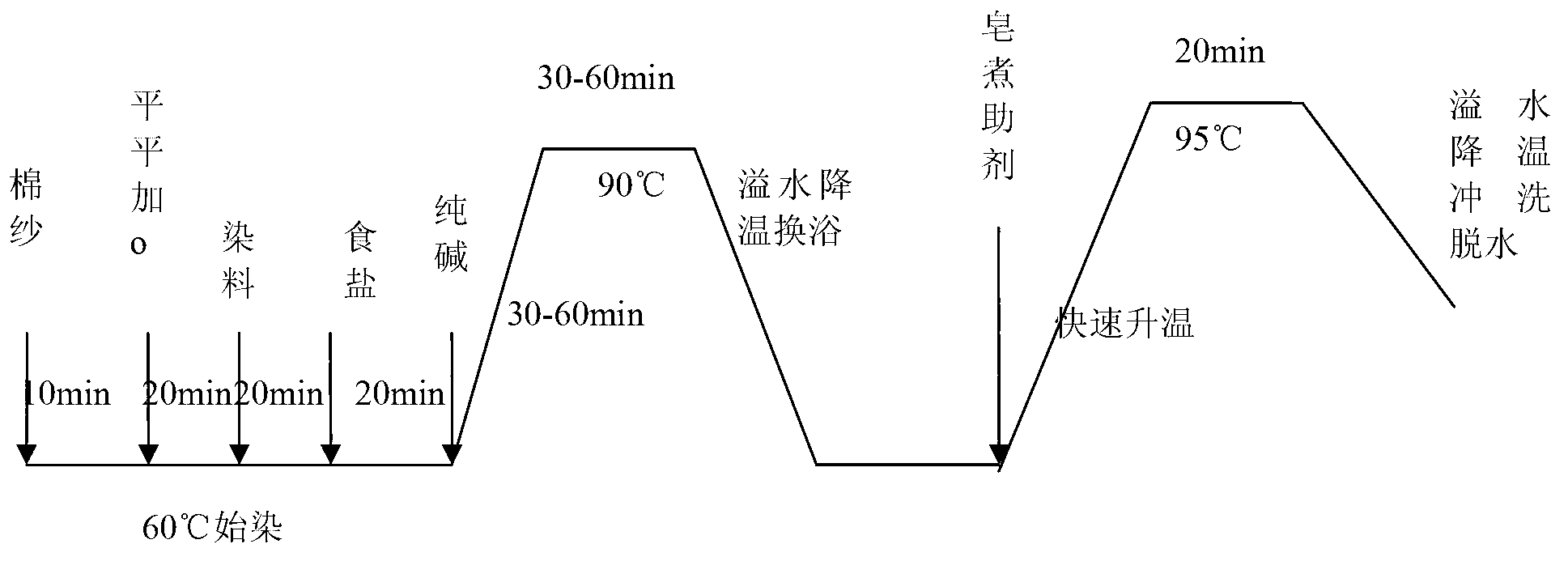

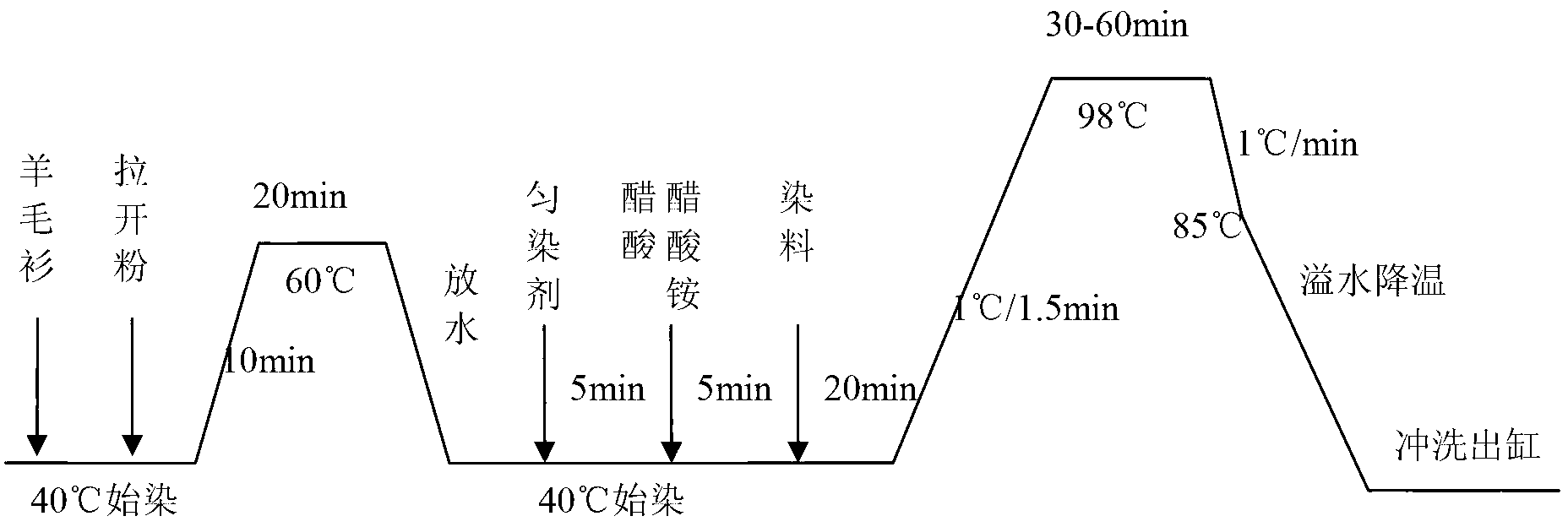

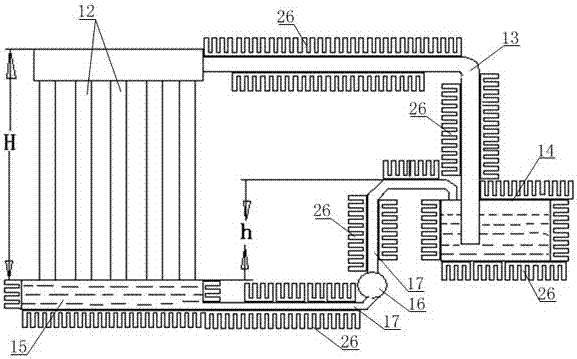

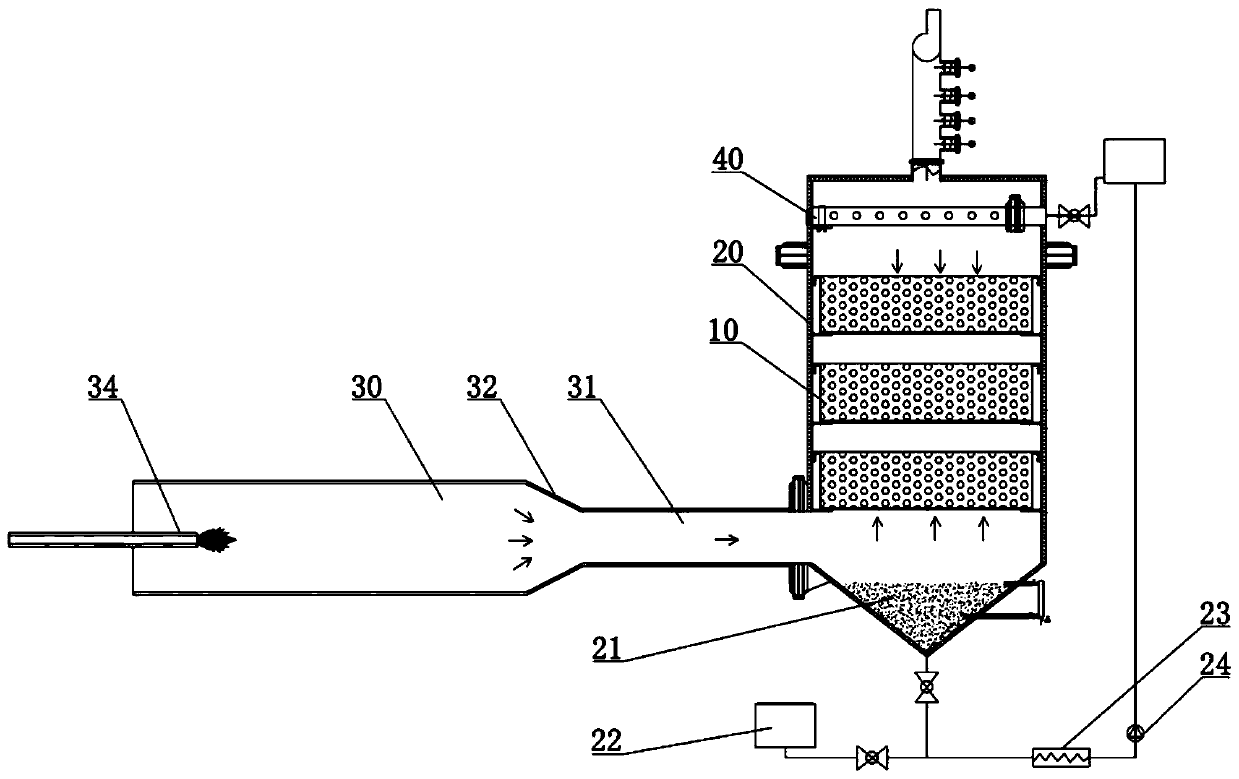

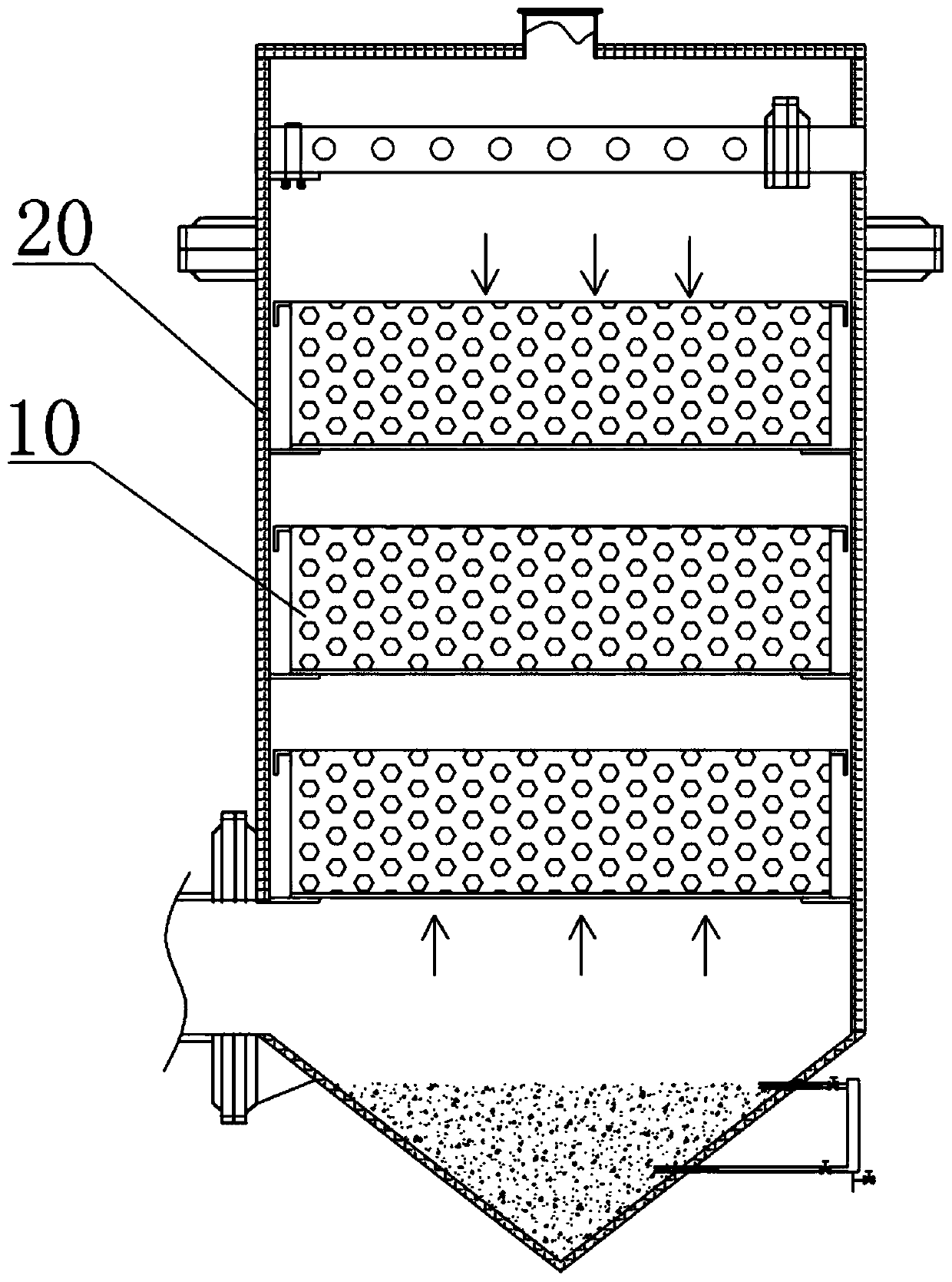

Solar dyeing machine system with function of gradient use of heat

ActiveCN103290633ATake advantage ofRealize cascade utilizationTextile treatment machine arrangementsTextile/flexible product manufactureThermal energyFiber

The invention discloses a solar dyeing machine system with a function of gradient use of heat. At present, waste water discharged in the production processes of desizing, scouring, dyeing and the like is at the temperature of more than 80 DEG C, direct discharging of the waste water causes energy waste, discharging the waste water into a waste water treatment tank makes all waste water to be at the temperature of more than 46 DEG C, and aerobic biochemical treatment is severely influenced. The solar dyeing machine system comprises a solar heating system, a waste heat recovery system, a high-temperature heat supply and compensation system, a dyeing machine system and a cooling system. The solar heating system form two-loop circulation, one loop is a water circulation loop formed by a plurality of serially connected solar vacuum tubes for heating water, a cold water pipeline and a hot water pipeline, and the other loop is an oil circulation loop formed by a plurality of serially connected solar vacuum tubes and an oil pipeline. The solar dyeing machine system has the advantages that temperature segmented recovery of heat is realized, the problem of surplus low-temperature heat in the existing waste heat recovery device is solved, and the solar dyeing machine system is applicable to various fiber dyeing processes and is more than 50% in comprehensive energy saving.

Owner:ZHEJIANG SIDITE NEW ENERGY

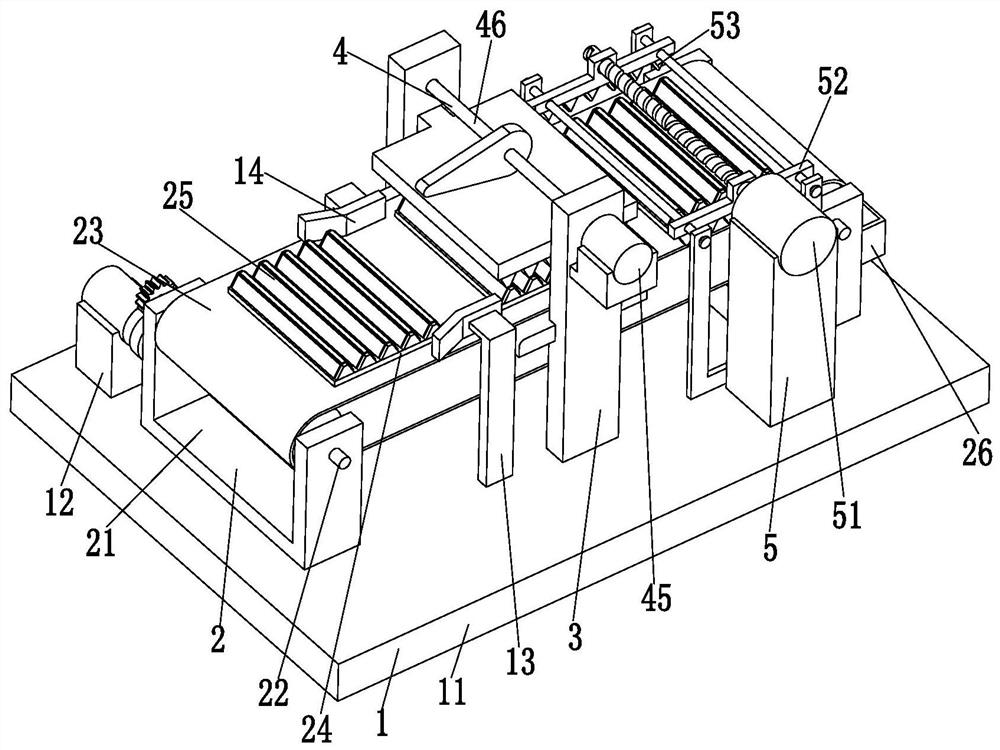

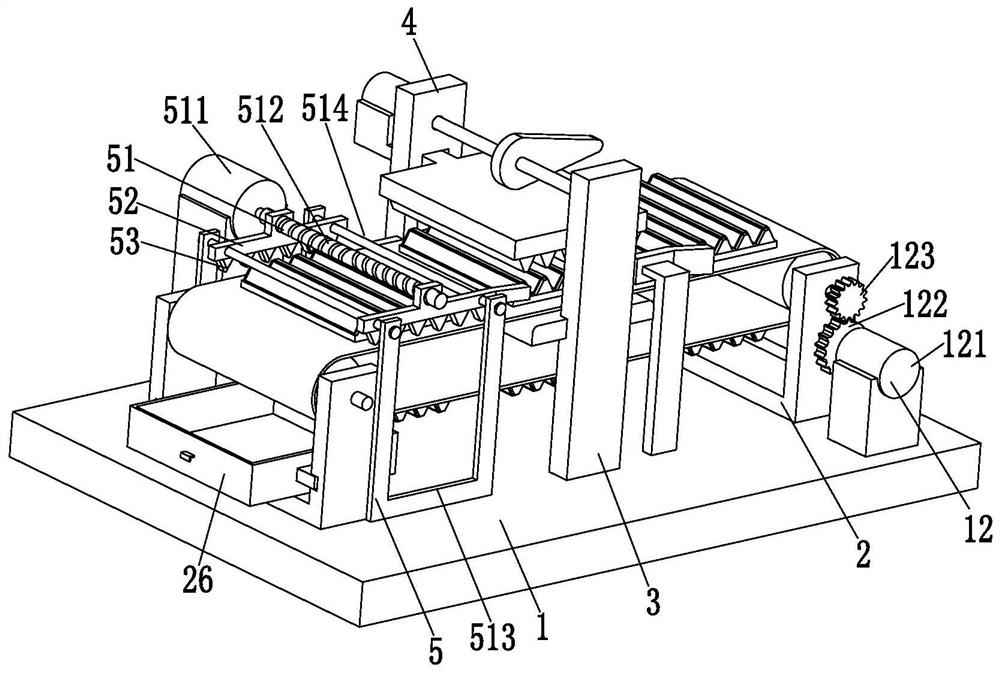

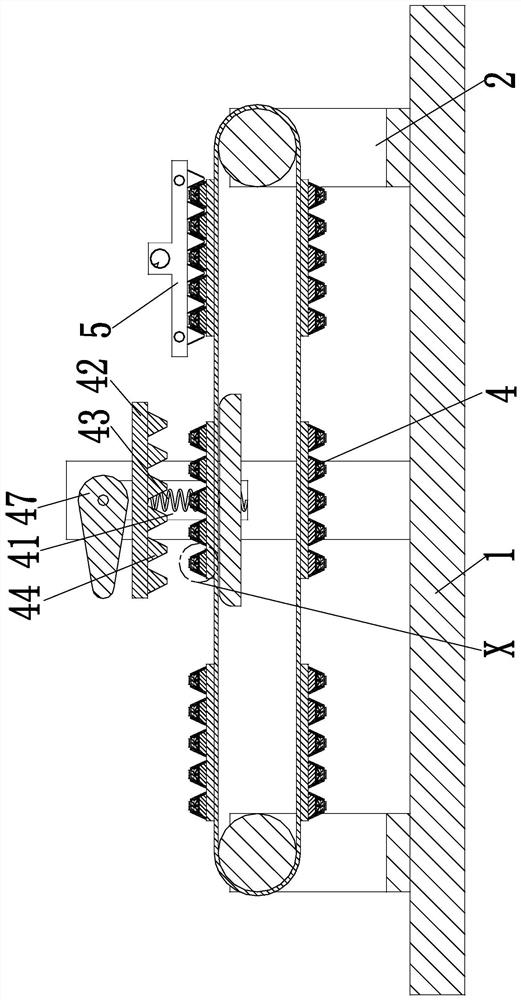

Manufacturing, forming and machining system for heat exchanger fins

InactiveCN112570492AReduce appearanceImprove smoothnessMetal-working feeding devicesHeat exchange apparatusMachining systemMechanical engineering

The invention relates to a manufacturing, forming and machining system for heat exchanger fins. The manufacturing, forming and machining system comprises a fixing base, U-shaped frames, rectangular plates, correcting mechanisms and a cleaning mechanism; the U-shaped frames are symmetrically installed on the left side and the right side of the upper end of the fixing base; the rectangular plates are symmetrically fixed to the front side and the rear side of the middle of the upper end of the fixing base; the correcting mechanisms are arranged on the rectangular plates correspondingly; and the cleaning mechanism is arranged on the right side of the upper end of the fixing base. The manufacturing, forming and machining system provided by the invention can solve the problems that according toa traditional manufacturing, forming and machining method for heat exchanger fins, after fin manufacturing is completed, the surface of each fin is usually uneven, due to the existence of some irregular recesses or protrusions, the appearance effect of the heat exchanger fins is reduced; meanwhile, the heat exchange rate of the heat exchanger fins is affected as well, burrs are prone to appearingon the surfaces of the fins; moreover, the shape of a straight fin is special, so burrs are tedious to be removed manually, the treatment effect is poor, and the working effect of the heat exchanger fins is affected as well, and the like.

Owner:南京华斯特机械科技有限公司

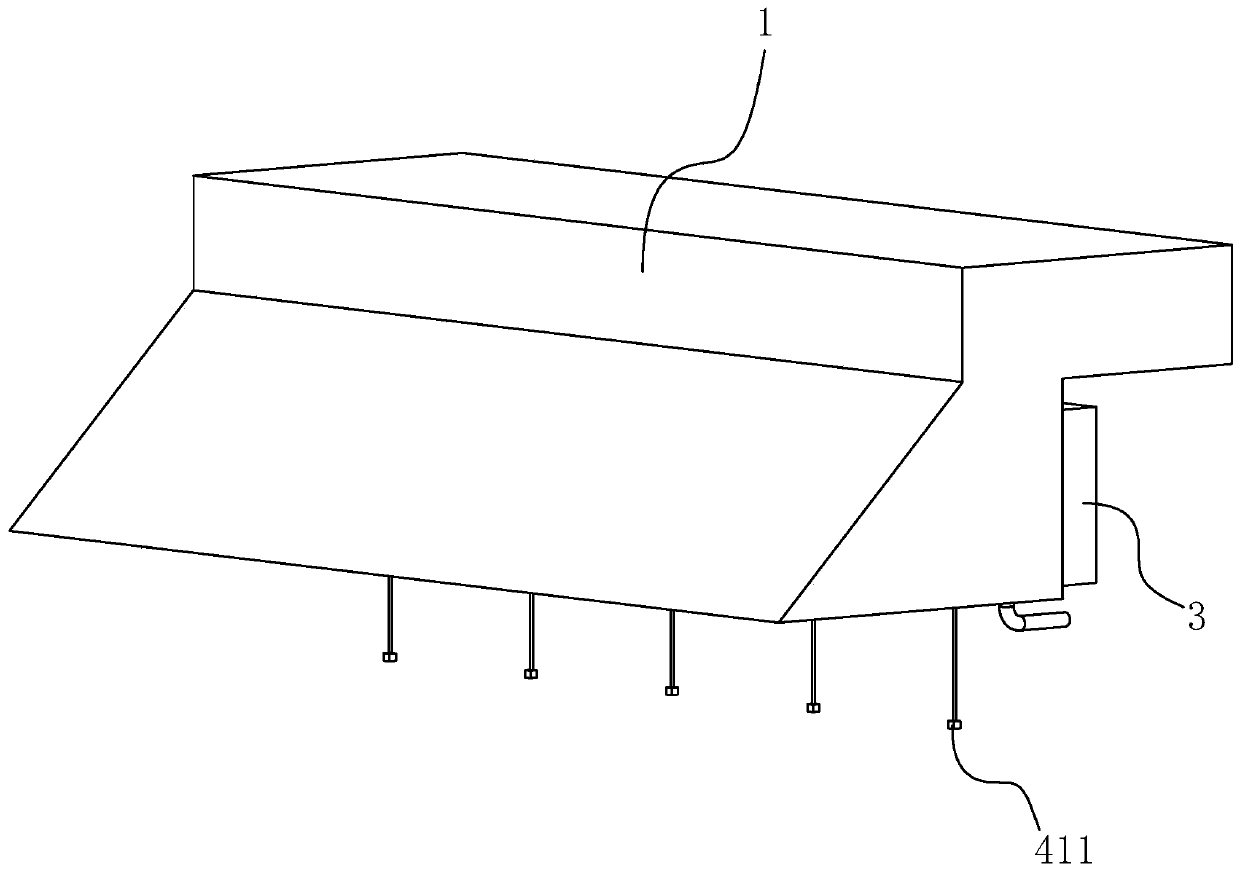

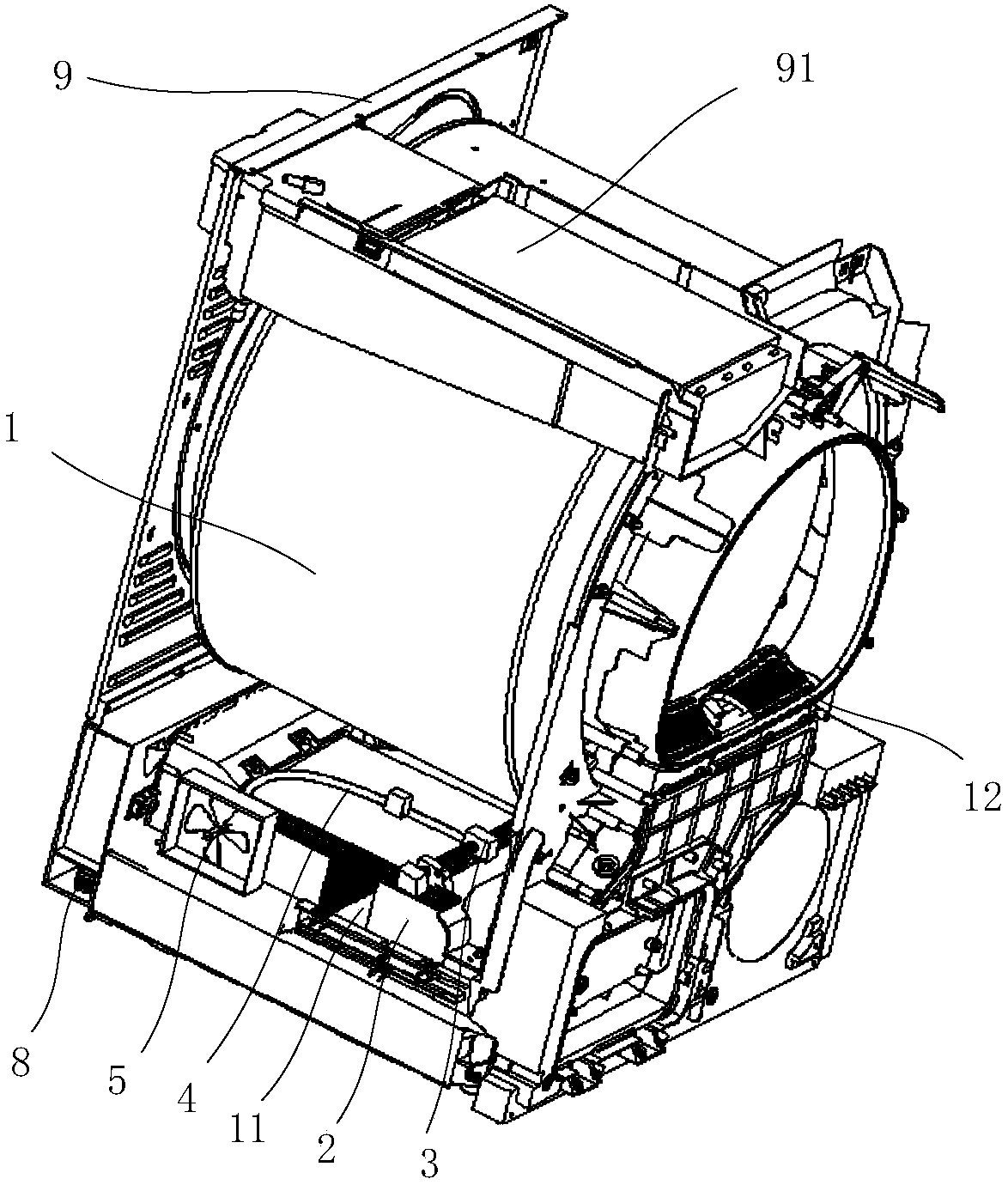

Heat pump type clothes dryer capable of washing heat exchanger with water

ActiveCN108570837AGuaranteed heat exchange efficiencyTextiles and paperLaundry driersEngineeringMoisture

The invention discloses a heat pump type clothes dryer capable of washing a heat exchanger with water, and relates to the technical field of clothes dryers, wherein the heat pump type clothes dryer can remove thread scraps and other debris on the heat exchanger and ensure the heat exchange efficiency. The heat pump type clothes dryer capable of washing the heat exchanger with water comprises a barrel body and an air channel communicating with the barrel body and used for drying to-be-dried articles in the barrel body, wherein a fan and the heat exchanger are arranged in the air duct; the heatexchanger comprises an evaporator and a condenser; the fan is used for blowing moisture from the barrel body to the evaporator; the evaporator is used for reducing the temperature of hot humid air toform condensed water; the air after passing through the evaporator is heated by the condenser and then enters the barrel body again; the heat pump type clothes dryer further comprises a nozzle devicefor rinsing the heat exchanger; and the nozzle device communicates with a water supply device through a water pipe. The heat pump type clothes dryer provided by the invention is used to dry clothes.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Clothing processing device

InactiveCN102605590AEfficient removalGuaranteed heat exchange efficiencyOther washing machinesWashing machine with receptaclesForeign matterWaste management

The invention refers to a clothing processing device, comprising the following components: a housing; an accommodating space arranged in the inner of the housing for accommodating clothing; an air supply device for supplying air for the inner of the accommodating space; a discharging channel for discharging the air in the inner of accommodating space to the external part of the accommodating space; a filtering unit which can stores liquid, make the air into the discharging channel contact with the stored liquid and eliminate foreign matters in the air. According to the invention, the filtering unit can effectively eliminate foreign matters in the air discharged from the accommodating space and guarantees a sensible heat exchange efficiency. In addition, according to the invention, the air discharged from the accommodating space can contact with the liquid to eliminate the foreign matters in the air.

Owner:NANJING LG PANDA APPLIANCES

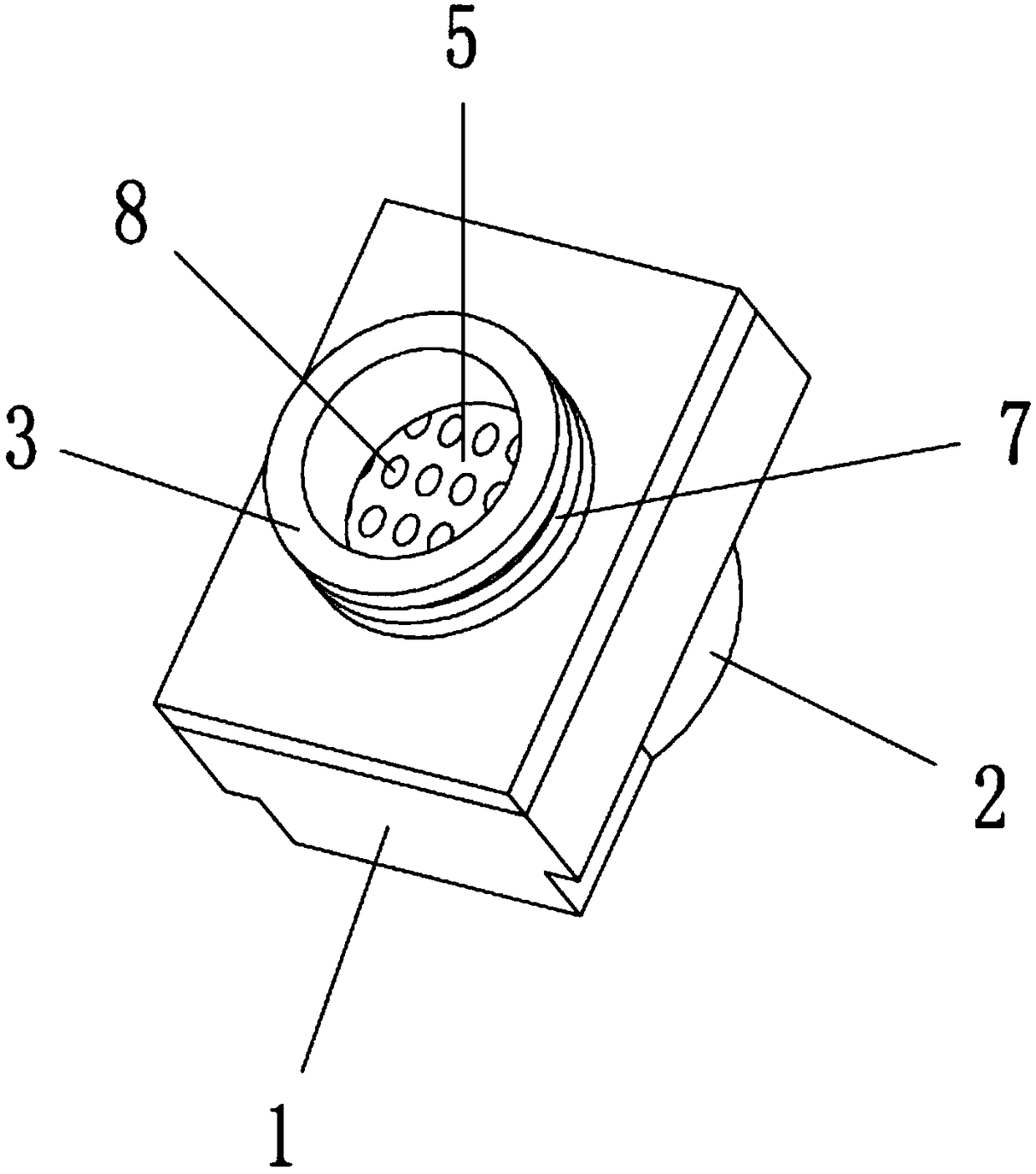

Liquid distributor

InactiveCN104913552ADispensing pressure is uniformGuaranteed heat exchange efficiencyMechanical apparatusFluid circulation arrangementMixed flowEngineering

The invention discloses a liquid distributor. The liquid distributor comprises a liquid distributor main body, a mixed flow suspension core body and a pressing cover for the liquid distributor. An opening is formed in the upper end of the liquid distributor main body, a plurality of liquid outlets are formed in the lower end of the liquid distributor main body, and a liquid distributing inner cavity communicated with the opening and the liquid outlets is constituted in the liquid distributor main body. The mixed flow suspension core body is in a cylindrical shape approximately, a center hole channel penetrating through the upper end face of the mixed flow suspension core body and the lower end face of the mixed flow suspension core body axially is formed in the mixed flow suspension core body, and multiple liquid distributing through grooves are arranged in the mixed flow suspension core body along the circumferential direction of a cylindrical surface at intervals. An liquid inlet communicated with the liquid distributing inner cavity is formed in the pressing cover for the liquid distributor. The liquid distributor has the advantages that the liquid distributing pressure of each liquid outlet is adjusted through the mixed flow suspension core body, the liquid distributing pressure of each liquid outlet is uniform, the sustained pressure for each evaporator is guaranteed to be balanced, and the heat exchanging efficiency of the evaporators and the cooling effect of an air conditioner are guaranteed.

Owner:SHANGHAI LONGYANG PRECISE COMPOUND COPPER TUBE CO LTD +1

Intelligent energy-saving exhaust hood

ActiveCN110345535AAutomatically reduce the number of startupsAvoid false startDomestic stoves or rangesLighting and heating apparatusAutomatic controlControl system

The invention discloses an intelligent energy-saving exhaust hood, and belongs to the technical field of kitchen equipment. The intelligent energy-saving exhaust hood comprises a hood body and a plurality of fume hoods which are arranged in the hood body and used for drafting; each fume hood is internally provided with a draft fan, and the draft fan is connected with a control system; and the control system comprises a cooking fume monitoring module for detecting the concentration of cooking fume in the bottom area of each fume hood, a primary control module which is used for automatically controlling the draft fans to be started when the value of the corresponding cooking fume concentration is larger than the preset value, and a secondary control module which is used for controlling the draft fans started by the primary control module to be powered off according to the cooking fume concentration of the adjacent areas. The intelligent energy-saving exhaust hood has the effects that thedraft fans can be automatically controlled to be started, in addition, the draft fans which do not need to work are controlled to be powered off according to the cooking fume concentration situation,and energy consumption can be effectively reduced.

Owner:深圳市中威厨房设备有限公司

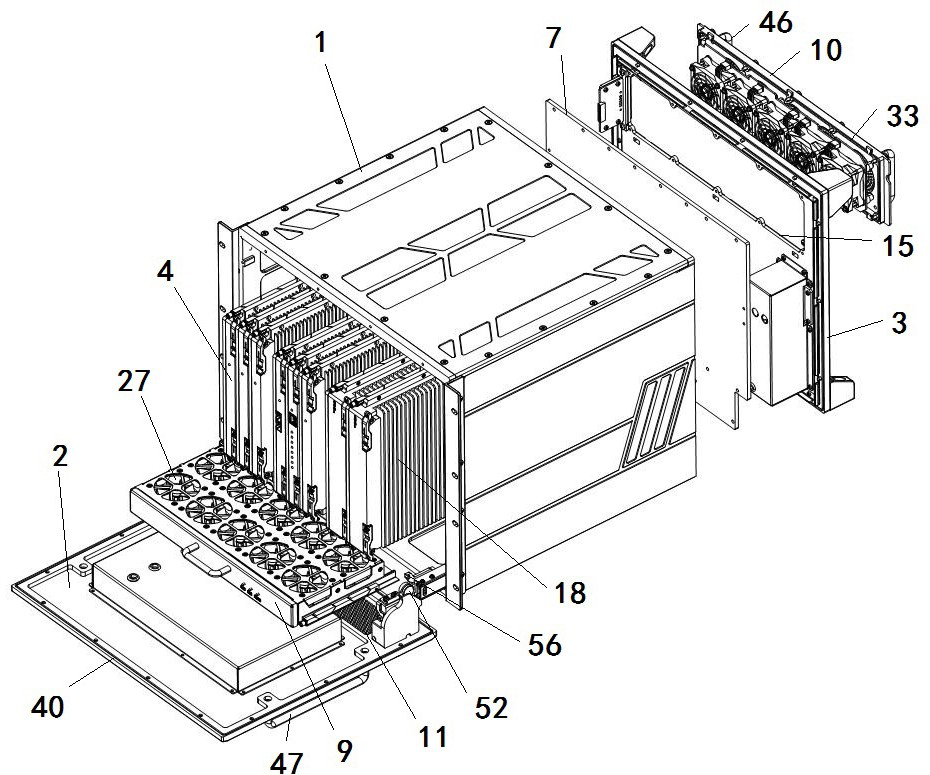

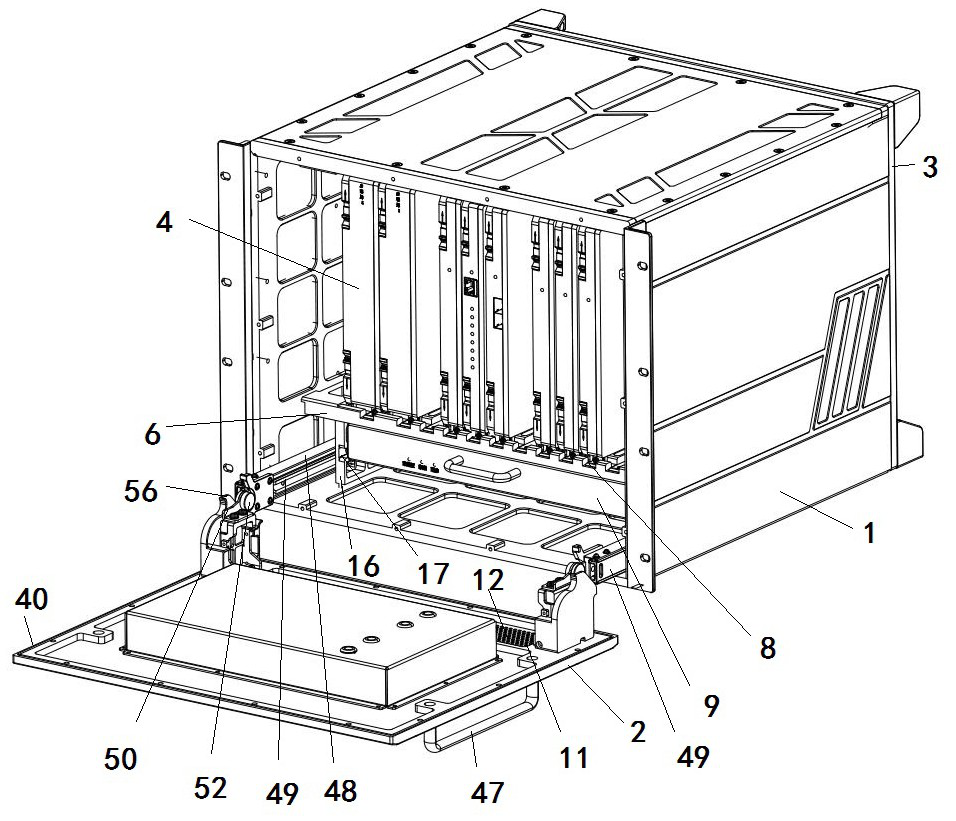

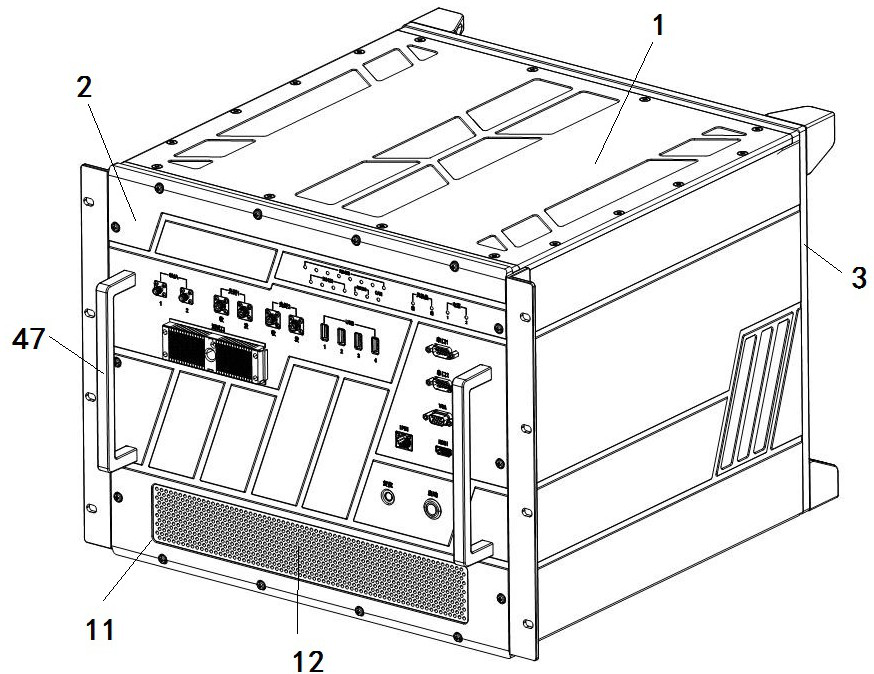

Air-cooled fully-reinforced computer suitable for various series buses

PendingCN112860035ATo achieve the purpose of heat dissipationQuick disassemblyDigital processing power distributionEngineeringElectromagnetic shielding

The invention discloses an air-cooled fully-reinforced computer suitable for various series buses, which comprises a box body, a front panel, a rear panel, a connecting assembly, a track bracket assembly, a heat dissipation assembly, a wire arrangement assembly and an electromagnetic shielding assembly; the rear panel is fixedly arranged at the rear end of the box body, and the front panel is arranged at the front end of the box body through the connecting assembly; the front panel is matched with the end face of the box body, a rail support used for installing a bus board card is arranged in the box body, a wire arranging assembly is arranged on the inner surface of the side wall of the box body, an air cooling heat dissipation assembly used for discharging heat generated on the bus board card is arranged on the box body, and electromagnetic shielding assemblies matched with the end face of the box body are arranged on the front panel and the rear panel. In the computer, the box body has a very good heat dissipation function, so that quick maintenance operation of a plurality of components in the box body can be realized, and the box body can also have a very good electromagnetic shielding effect.

Owner:成都前锋信息技术有限公司

Heat exchanger fins

PendingCN111854504AEasy to installAvoid Weld Through ConditionsHeat exchanger casingsLaminated elementsEngineeringSlide plate

The invention relates to the field of fins, in particular to heat exchanger fins. The heat exchanger fins involve a fin plate, a dust wiping mechanism, fin bodies, a sealing plate, bolts, mounting lugs, mounting holes, a dust wiping plate mounting plate, a positioning sliding plate, a sliding block, a dust wiping plate, a brush, a sliding groove, a threaded hole, a strip-shaped sliding block and aheat conduction film. The heat exchanger fins involve the fin plate, the fin bodies are installed on the fin plate in a sliding mode, after the fin bodies are installed, only the fin plate needs to be installed on the outer wall of a box-type base tube, welding is not needed, the situation that the base tube is welded in a penetrating mode when the fin bodies are welded is avoided, and installation of the fin bodies is greatly facilitated; and when the dust wiping mechanism slides, the brush on the dust wiping plate of the dust wiping mechanism wipes off dust on the outer walls of the fin bodies, cleaning of dust adhering to the outer walls of the fin bodies is facilitated, cleaning of the device is greatly facilitated, the situation that the heat exchange efficiency is reduced due to thefact that the dust adhere to the fin bodies is greatly reduced, and the heat exchange efficiency of the device is guaranteed.

Owner:汤宝宝

Energy-saving roasting method in formwork investment casting

InactiveCN102189222AGood effectReduce the temperatureFoundry mouldsFoundry coresInvestment castingLiquid metal

The invention discloses an energy-saving roasting method in formwork investment casting. The method is characterized in that a dewaxed formwork is dried and roasted by using accumulated heat of the formwork after liquid metal casting. The method has the advantages of high system heat efficiency, low energy consumption and low cost.

Owner:应万才

Heat pump type clothes dryer with heat exchanger blow wash function

ActiveCN108486838AGuaranteed heat exchange efficiencyTextiles and paperLaundry driersPlate heat exchangerEngineering

The invention discloses a heat pump type clothes dryer with a heat exchanger blow wash function, and relates to the technical field of clothes dryers. The heat pump type clothes dryer with the heat exchanger blow wash function comprises a barrel, an air channel and a blow wash nozzle. The air channel is connected with the barrel and used for drying to-be-dried articles in the barrel, first fans and a heat exchanger are arranged in the air channel, the heat exchanger comprises an evaporator and a condenser, the first fans are used for blowing moisture in the barrel to the evaporator, and the evaporator is used for reducing the temperature of damp and hot air so that condensed water can be formed; air which flows through the evaporator further can be heated by the condenser and then can flowinto the barrel again, and the blow wash nozzle is used for carrying out blow wash on the heat exchanger and is communicated with an air feed device via an air supply pipeline. The heat pump type clothes dryer has the advantages that sundries such as thread scraps on the heat exchanger can be cleared away, and accordingly the heat exchange efficiency can be guaranteed; the heat pump type clothesdryer is used for drying clothes.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

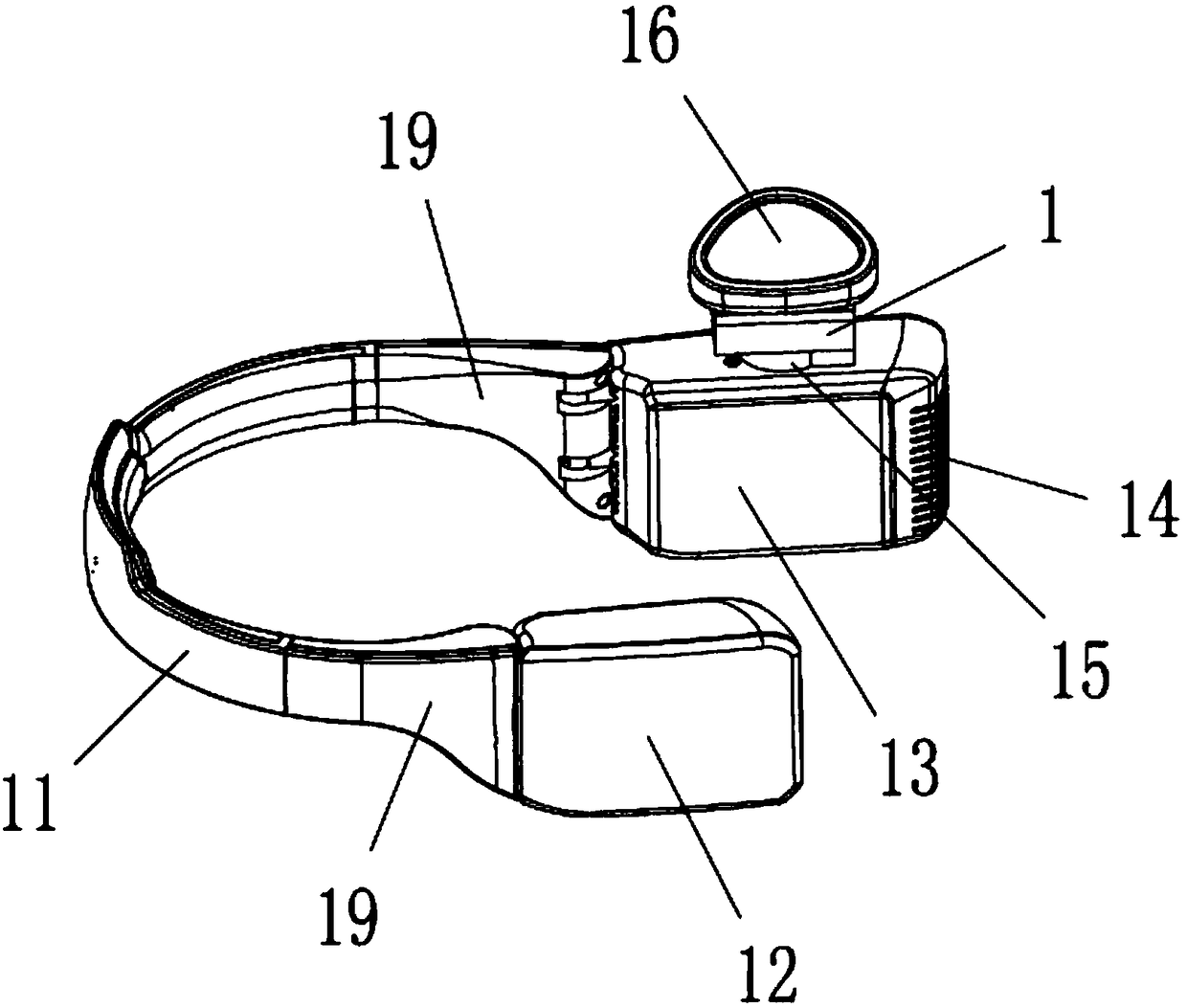

Portable air purifier with heating part

The invention discloses a portable air purifier with a heating part. The portable air purifier comprises a neck strap, a control device, a purifying device, an open air distributor and the heating part, wherein the control device and the purifying device are correspondingly arranged at two ends of the neck strap; an air inlet and a connecting port are arranged on the purifying device; the heatingpart comprises a shell body; the shell body is provided with an air inlet connector and an air outlet connector; a power module and at least one layer of electric heating sheet are arranged in the shell body; the electronic heating sheet is positioned between the air inlet connector and the air outlet connector; the air inlet connector is connected with the connecting port; and the air outlet connector is connected with the open air distributor. According to the portable air purifier disclosed by the invention, supplied air is heated through the heating part arranged between the purifying device and the open air distributor, and the using effect of a personal purifier in winter is improved; the heating part is connected with the portable air purifier through the air inlet connector and theair outlet connector, convenient to mount, dismount and replace, light in weight, flexible to use, large in air handling capacity, and low in air pressure loss; and the heat exchange efficiency is guaranteed.

Owner:苏州美瑞康医疗科技有限公司

High-temperature flue gas quenching method

InactiveCN108955299ADoes not increase stressAvoid mixingDirect contact heat exchangersFlue gasLiquid metal

The invention discloses a high-temperature flue gas quenching method. The high-temperature flue gas quenching method comprises the following steps that 1, flue gas is guided; 2, liquid metal is primarily dispersed; 3, secondary dispersion is carried out on the liquid metal, 4, the liquid metal is recycled; and 5, the flue gas is discharged. The high-temperature flue gas quenching method can guarantee the normal temperature of a high-temperature flue gas quenching experiment.

Owner:北京宏帆态金节能科技有限公司

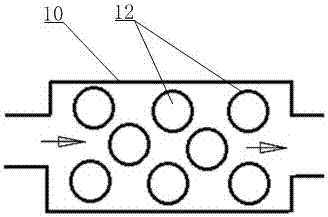

Energy-saving and cooling system for communication room with pre-dehumidification and cooling structure

ActiveCN104819529BMaintain humiditySimple structureLighting and heating apparatusSpace heating and ventilation detailsCommunications systemCooling effect

The invention discloses a communication machine room energy-saving cooling system. The communication machine room energy-saving cooling system comprises a machine room and a wind inlet pipe arranged at the bottom of the machine room, and further comprises a grillwork room, a wind return area, a wind inlet room, cooling equipment and dust removing equipment arranged in the machine room, wherein the top of the grillwork room is communicated with the wind return area through an air guide pipe; the wind return area is communicated with the wind inlet room through a pipe; a fan is arranged on the pipe; the cooling equipment is arranged in the wind inlet room; a heat exchange cavity is formed in the cooling equipment; a wind inlet and a wind outlet are respectively formed in the two ends of the heat exchange cavity; the wind inlet is communicated with the wind inlet room; the wind outlet is communicated with the wind inlet pipe through the dust removing equipment; multiple heat exchange pipes perpendicular to the wind direction in the heat exchange cavity are arranged in the heat exchange cavity; the top ends of the heat exchange pipes are communicated with a water inlet tank through pipelines A, and the bottom ends of the heat exchange pipes are communicated with a water outlet tank; the water outlet tank is communicated with the water inlet tank through a water pump and a water conveying pipe; and a semiconductor refrigerator is arranged in a wind return area. The system can pre-dehumidify air to keep the air humidity, and continuously blows wind to cool water to achieve good cooling effect.

Owner:SICHUAN YUANCHANG NEW ENERGY TECH

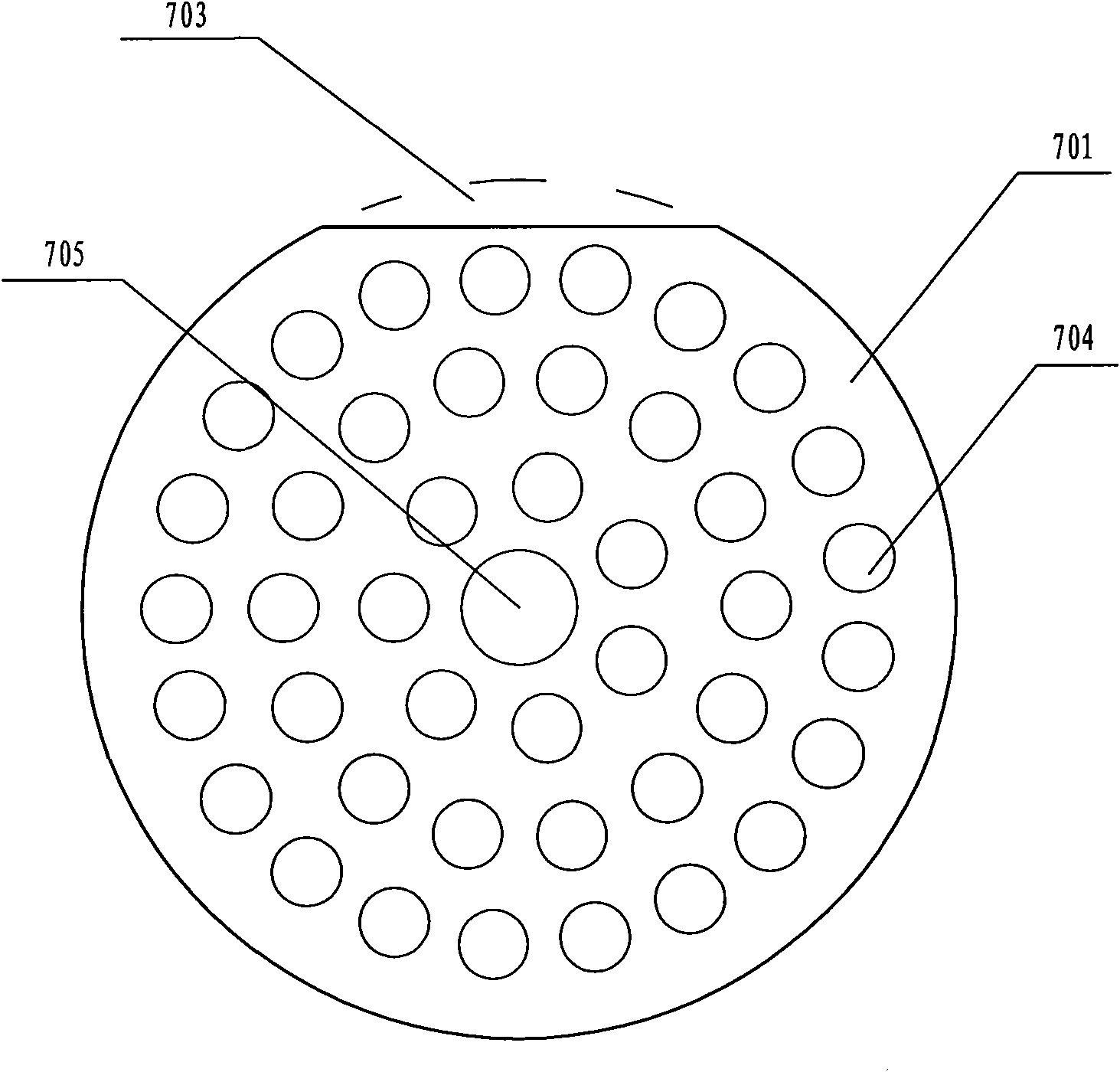

Sleeving shell of round block hole type graphite heat exchanger and production process thereof

ActiveCN112577348AImprove cycle efficiencyGuaranteed heat exchange efficiencyMaterial gluingHeat exchange apparatusOutfallGraphite

The invention discloses a sleeving shell of a round block hole type graphite heat exchanger and a production process thereof. The sleeving shell structurally comprises a water inlet pipe and a water outlet pipe, a plurality of annular protrusions are distributed on a middle shell body from top to bottom, an upper flange cover extends outwards to form an upper fixing plate, and a lower flange coverextends outwards to form a lower fixing plate; the water inlet pipe is fixed to the upper fixing plate and perpendicularly penetrate through the interiors of the annular protrusions downwards one byone, and a plurality of water inlets communicating with the annular protrusions one by one are formed in the water inlet pipe; and the water outlet pipe is fixed to the lower fixing plate and perpendicularly penetrates through the interiors of the annular protrusions upwards one by one, a plurality of water outlets communicating with the annular protrusions one by one are formed in the water outlet pipe, and the water inlet pipe and the water outlet pipe are oppositely arranged at the two sides of the middle shell body. According to the sleeving shell, rapid water inlet and rapid water outletin a flow guide groove are achieved through the multiple water inlets and the multiple water outlets, the circulation efficiency of cooling water in the middle shell body is improved, and therefore, the heat exchange efficiency of the cooling water and waste gas is ensured.

Owner:南通润中石墨设备有限公司

Cooling device of heating element

ActiveCN102395256BSimple structureLow costCooling/ventilation/heating modificationsEngineeringCirculating pump

The invention relates to a cooling device of a heating element. The cooling device comprises a heat exchange tube that is arranged in a power supply cabinet; an inner medium inflow set part and an inner medium outflow set part are arranged at a cabinet wall of the power supply cabinet; and two ends of the heat exchange tube are respectively connected with the inner medium inflow set part and the inner medium outflow set part. Besides, one side of the power supply cabinet is provided with a rack; a plate type heat exchanger is arranged in the rack and an inner medium container and a circulating pump are arranged on the rack; an inlet of the inner medium container is connected with the inner medium outflow set part through a pipeline; an outlet of the inner medium container is connected with an inlet of the circulating pump through a pipeline; an outlet of the circulating pump is connected with one end of a first heat exchange pipeline of the plate type heat exchanger through a pipeline; and the other end of the first heat exchange pipeline is connected with the inner medium inflow set part through a pipeline. In addition, two ends of a second heat exchange pipeline of the plate type heat exchanger are respectively an inlet and an outlet of an outer medium. The cooling device provided in the invention is suitable for cooling of a heating element in a power supply.

Owner:JIANGSU EASTONE TECH

Heat energy recovery and treatment system for baking seaweed products

ActiveCN111854353BEasy to collectSlow down the flowDomestic cooling apparatusClimate change adaptationWater storage tankMechanical engineering

The invention discloses a heat energy recovery and processing system for baking seaweed products. An outlet pipe is installed on the top of the oven, an output pipe is installed on the top of the outlet pipe, an exhaust pipe is installed on one side of the output pipe, and one end of the exhaust pipe is installed on a storage tank. On the top of the water tank, the exhaust pipe is connected to the heat exchange pipe through an adapter. The outer surface of the heat exchange pipe is covered with a number of heat conduction strips, and the inner side of the heat exchange pipe is installed with a deceleration ring. Water pipe, a booster pump is installed on one side of the water inlet pipe, through the exhaust pipe, the first restriction valve, the heat exchange pipe, the discharge pipe, the heat conduction strip, the deceleration ring, the air outlet fan and the temperature detector, the water vapor with heat Input into the heat exchange tube, reduce its flow speed, accelerate its heat exchange in the heat exchange tube, make the heat exchange effect more perfect, and circulate water supply through the water inlet pipe, booster pump and outlet pipe to ensure the temperature difference between inside and outside, and accelerate heat exchange.

Owner:苏迪(福建)生物科技有限公司

A water circulation evaporative heat exchange cooling condenser

The invention relates to the technical field of condensers, and discloses a water cycle evaporation heat exchange cooling condenser, which includes a condenser shell, a heat exchanger is arranged in the middle of the condenser shell, and a liquid inlet is arranged on the upper side of the heat exchanger. There is a liquid outlet pipe on the lower side of the heat exchanger, a water distribution pipe is located on the upper end of the heat exchanger in the condenser shell, a number of nozzles are evenly arranged on the lower side of the water distribution pipe, and an exhaust fan is installed on the top of the condenser shell The side of the lower end of the condenser shell is provided with an air intake grid, the bottom of the condenser shell is a sump, the side of the condenser shell is provided with a return pipe, the lower end of the return pipe is connected to the sump, and the upper end of the return pipe is connected to the water distribution pipe. A water pump is arranged on the return pipe, and a water eliminator is arranged on the upper side of the water distribution pipe. The invention has the beneficial effects of reducing the waste of cooling water and improving the utilization rate of cooling water.

Owner:浙江宝丰科技股份有限公司

Clothes processing device

InactiveCN102535129BWith cleaning functionEfficient removalDrying gas arrangementsOther washing machinesEngineeringWaste management

The invention relates to a clothes processing device, comprising a housing forming the appearance, an accommodating space which is disposed in the housing for accommodating clothes, an air supply device for supplying air in the accommodating space, a discharging channel for discharging air in the accommodating space, a filter assembly for removing exotic matter from air flowing in the discharging channel, a storing space which can be taken out and is disposed in the housing, and an exotic matter removing part for moving the exotic matter collected by the filter assembly to a moving device of the storing space. With the arrangement of the filter assembly, exotic matter can be effectively removed from air discharged from the accommodating space, ensuring the efficiency of heat exchange. With the arrangement of the exotic matter removing part, the function of cleaning filter assembly which is discharging exotic matter collected in the filter assembly outside of the filter assembly is provided.

Owner:NANJING LG PANDA APPLIANCES

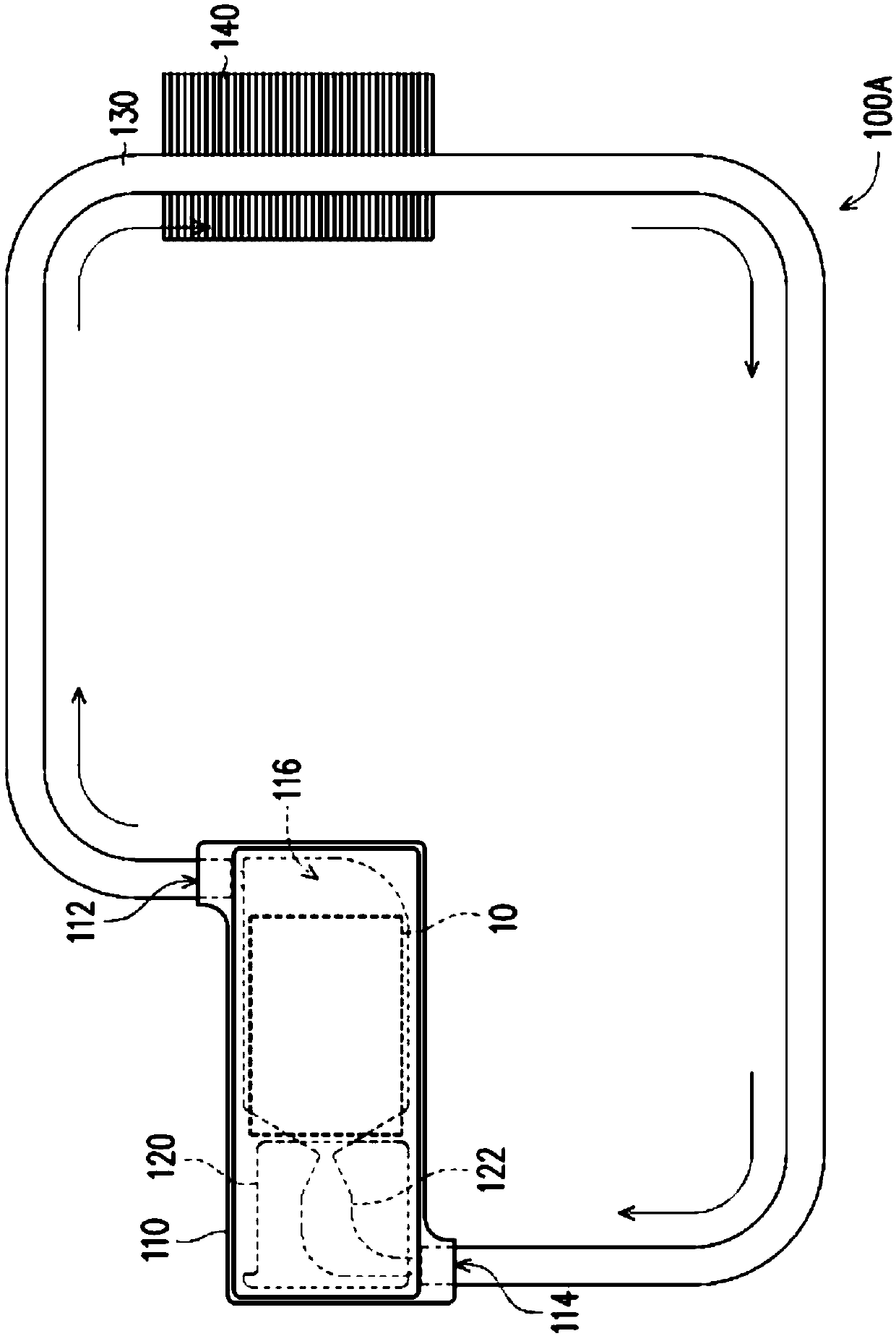

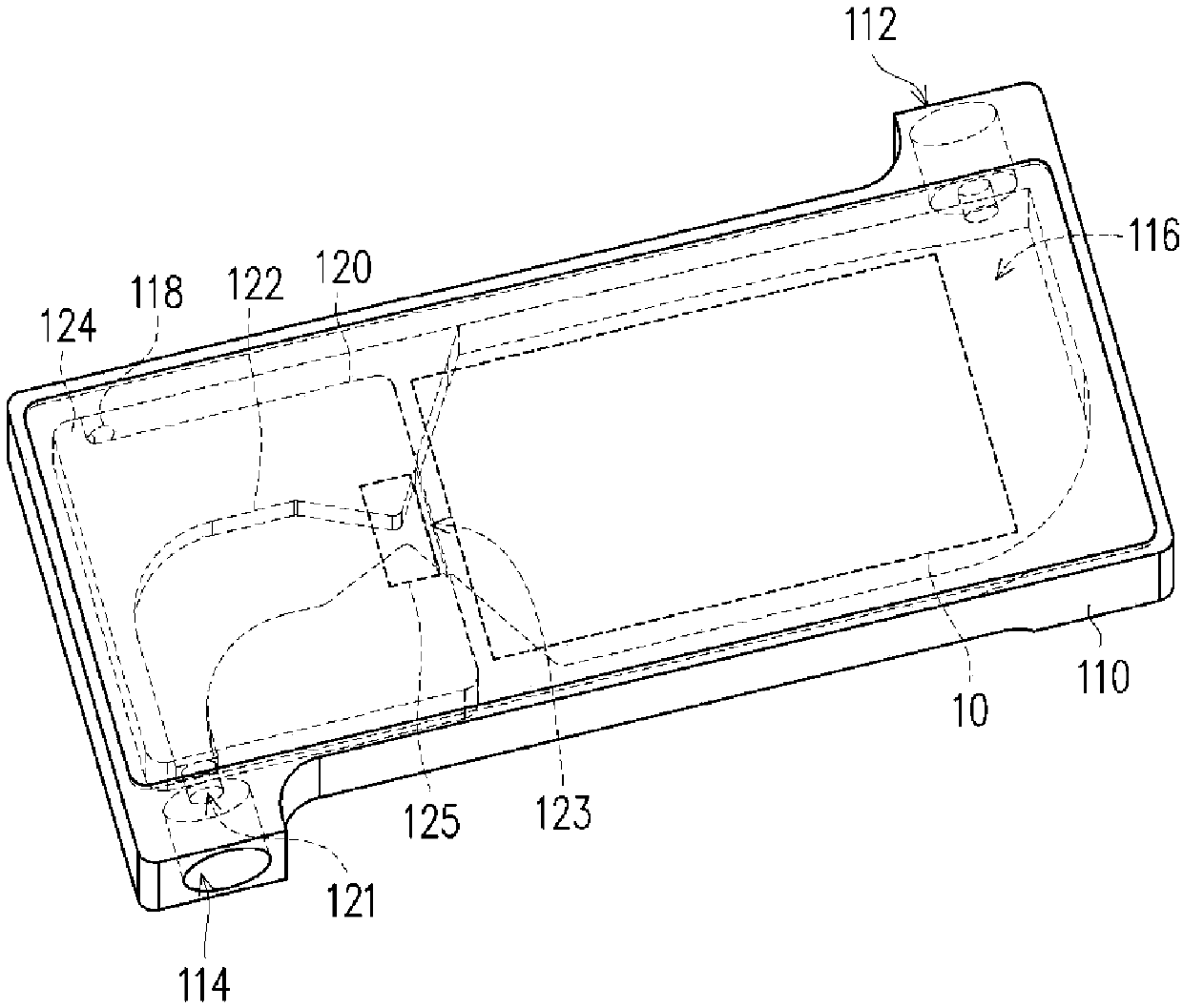

heat sink

ActiveCN107764111BImprove cooling effectAvoid thermal vaporizationIndirect heat exchangersWorking fluidNeck parts

The invention relates to a heat-dissipating device and aims to dissipate heat from a heat source. The heat-dissipating device comprises an accommodating tank, a heat-insulating unit and a pipe body, wherein the accommodating tank comprises an outlet end, an inlet end and an accommodating space, and is used for receiving the heat from the heat source from above; the heat-insulating unit is arrangedin the accommodating space of the accommodating tank and comprises a heat-insulating nozzle; the heat-insulating nozzle comprises a first opening, a second opening and a necking part; the first opening communicates with the inlet end; the second opening communicates with the accommodating space; the necking part is adjacent to the second opening; and the pipe body is connected with the outlet endand the inlet end, and then a closed circulation loop is formed by the pipe body and the accommodating tank. By adoption of the heat-dissipating device provided by the invention, a working fluid canbe effectively protected against vaporization caused by the heat generated from the heat source before entering the accommodating tank, and the enough working fluid in the accommodating tank can be ensured. Consequently, the heat-dissipating device can have the relatively high heat-dissipating efficiency, and is applicable to a high-wattage electronic product.

Owner:ACER INC

Battery hybrid heat exchange device and battery pack

PendingCN114614141AUniform temperatureGuaranteed heat exchange efficiencySecondary cellsThermodynamicsHeat management

The battery hybrid heat exchange device comprises a liquid cooling loop which is tightly attached to the bottom surface of a battery module; the heat conducting plate is tightly attached to the surface of the battery module, and at least one side surface of the heat conducting plate is in contact with the liquid cooling loop and exchanges heat with the liquid cooling loop; the heat conducting plate comprises a metal plate, the metal plate forms a closed loop on the heat conducting plate, and a refrigerant is arranged in the closed loop formed by the metal plate; wherein the heat conduction plate exchanges heat with the liquid cooling loop, so that refrigerants in the heat conduction plate are mutually converted and absorb and release heat in a gas state and a liquid state, and the heat conduction plate absorbs the heat of the battery module or transfers the released heat to the battery module. Through a mixed heat management technology combining a refrigerant direct cooling technology and a liquid cooling technology, the advantages of direct cooling phase change heat efficiency, uniform battery temperature, simple structure, relatively low cost and the like are realized, and the heat exchange efficiency of the battery module and a liquid cooling loop can be ensured, so that the temperature consistency of the battery pack is improved.

Owner:ZHIJI AUTOMOTIVE TECH CO LTD

Heating device for food processing

PendingCN111035237AMaintain heat exchange efficiencyReduce energy consumptionDomestic stoves or rangesLighting and heating apparatusVapor generatorProcess engineering

The invention relates to the technical field of food processing equipment, in particular to a heating device for food processing. At present, food cooking equipment generally has the problems of low heat efficiency and the like. According to the technical scheme, the device comprises a main water tank, a preheating water tank, a water supplementing pipe and at least one smoke exhaust pipe, whereinthe preheating water tank and the smoke exhaust pipe are designed in a split mode; the lower end of the smoke exhaust pipe penetrates the side wall of the main water tank and is communicated with a combustion part at the bottom of the main water tank; the preheating water tank is assembled with a smoke exhaust pipe outside the main water tank in a sleeving manner and is fixedly connected with theside part of the main water tank to form a barrel-shaped water jacket surrounding the smoke exhaust pipe; and the preheating water tank is communicated with the main water tank through the water supplementing pipe. The main water tank can be used for cooking food and can also be used as a steam generator to be matched with a steam box for use. Water supplementation has no influence on the cookingeffect in the processing process of the device, the utilization rate of heat energy is greatly increased, accumulated scale is conveniently removed, and the device is suitable for large-scale and continuous operation of food processing enterprises or restaurants and the like.

Owner:方绪龙

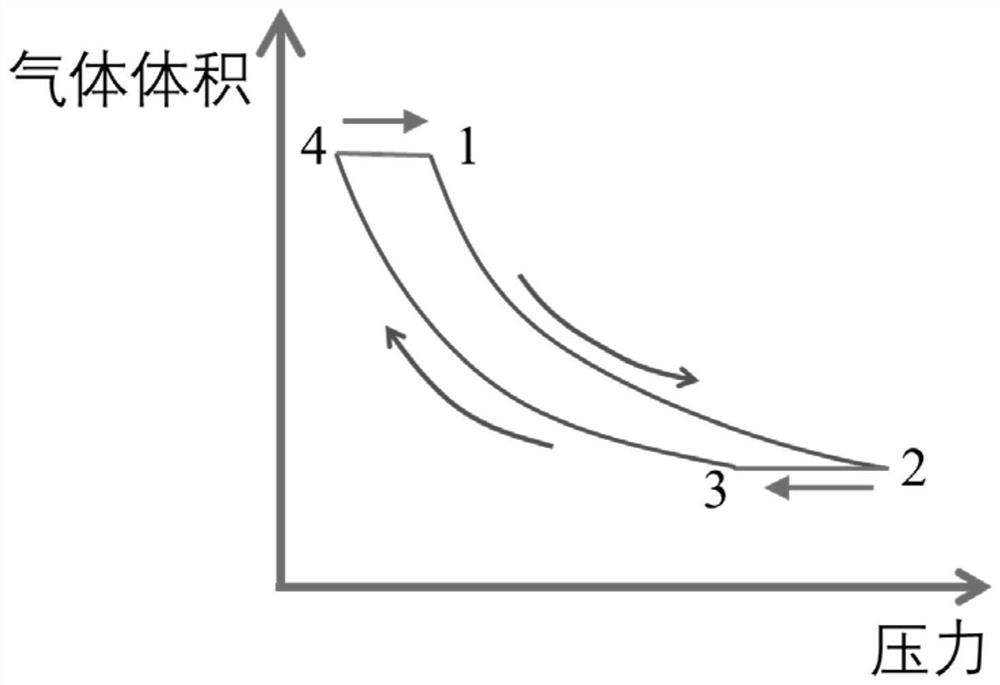

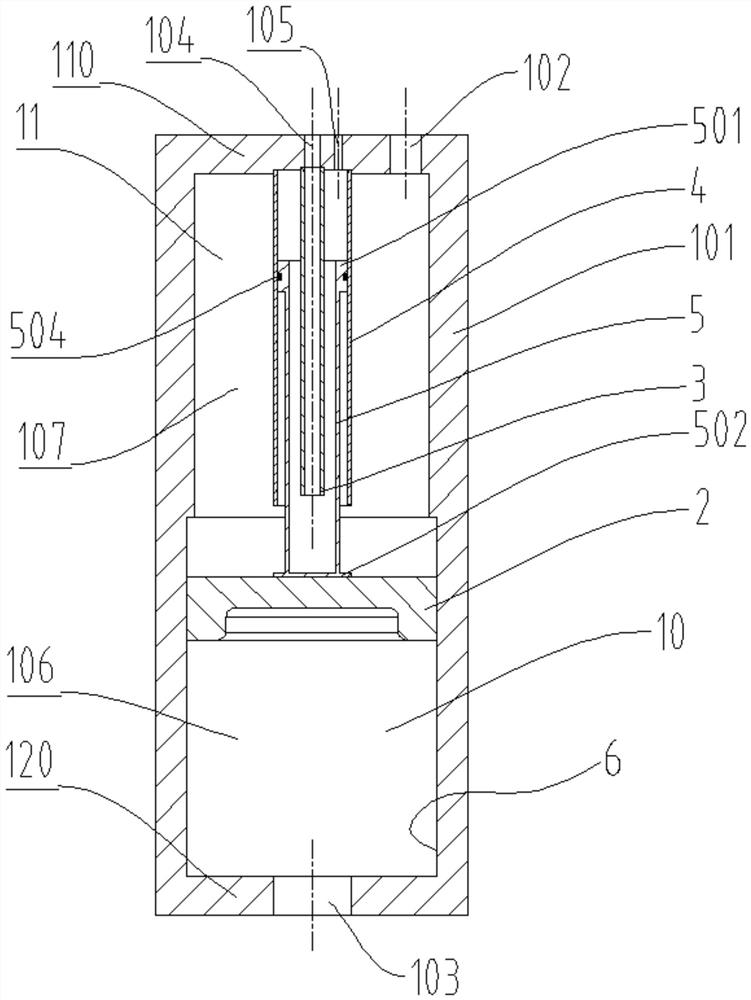

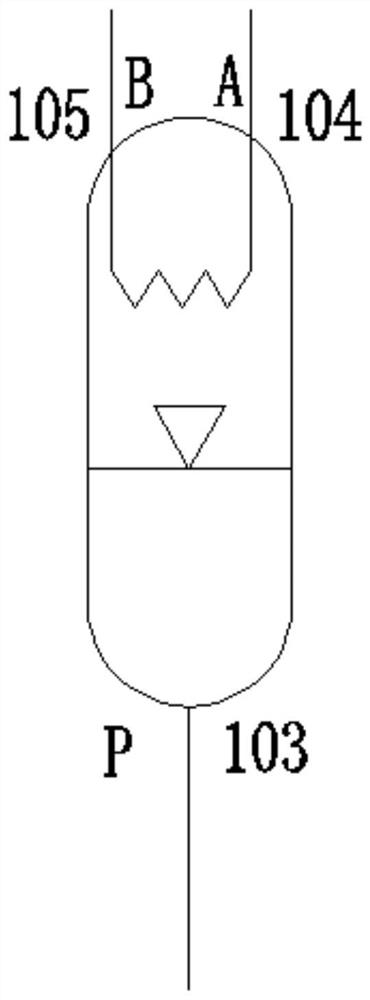

Energy accumulator and energy-saving system utilizing waste heat of engine tail gas

ActiveCN111963333AReduce heat lossImprove work efficiencyInternal combustion piston enginesEngine componentsEngineeringExhaust pipe

The invention provides an energy accumulator and energy-saving system utilizing waste heat of engine tail gas. A stepped cavity is arranged inside a cylinder barrel, and upper and lower end covers arefixedly connected to both ends of the cylinder barrel; the stepped cavity is composed of a small diameter section and a large diameter section; a piston assembly is assembled in the large diameter section, and divides the stepped cavity into a gas storage cavity and an oil storage cavity; a heat dissipation assembly is composed of a second pipeline, a third pipeline and a first pipeline with theinner diameters reduced in sequence and coaxially arranged from outside to inside in sequence, and the upper ends of the second pipeline and the first pipeline are both fixedly connected with the upper end cover; the lower end of the third pipeline is fixedly connected to the upper end of the piston assembly through a fixing plate, and a sealing ring sleeves the outer side of the upper end of thethird pipeline; an oil port is formed in the lower end cover; an air inlet is formed in the portion, corresponding to the first pipeline, of the upper end cover, an exhaust port is formed in the portion between the corresponding second pipeline and the first pipeline, and an air inflation port is formed in the portion corresponding to the periphery of the second pipeline. An energy accumulator body is connected with an exhaust pipeline through a reversing valve and a one-way valve. The energy accumulator can improve the working efficiency, and the system has good energy-saving and environmental protection effects.

Owner:XUZHOU COLLEGE OF INDAL TECH

A method for rapid cooling of high-temperature flue gas

InactiveCN108955299BDoes not increase stressAvoid mixingDirect contact heat exchangersFlue gasPhysical chemistry

The invention discloses a high-temperature flue gas quenching method. The high-temperature flue gas quenching method comprises the following steps that 1, flue gas is guided; 2, liquid metal is primarily dispersed; 3, secondary dispersion is carried out on the liquid metal, 4, the liquid metal is recycled; and 5, the flue gas is discharged. The high-temperature flue gas quenching method can guarantee the normal temperature of a high-temperature flue gas quenching experiment.

Owner:北京宏帆态金节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com