Heat exchanger with automatic cleaning device

A technology for automatic cleaning and heat exchangers, applied in the direction of cleaning heat transfer devices, types of heat exchangers, indirect heat exchangers, etc. In order to achieve the effect of maintaining heat exchange efficiency, ensuring normal operation, and avoiding manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be specifically described below in conjunction with the accompanying drawings.

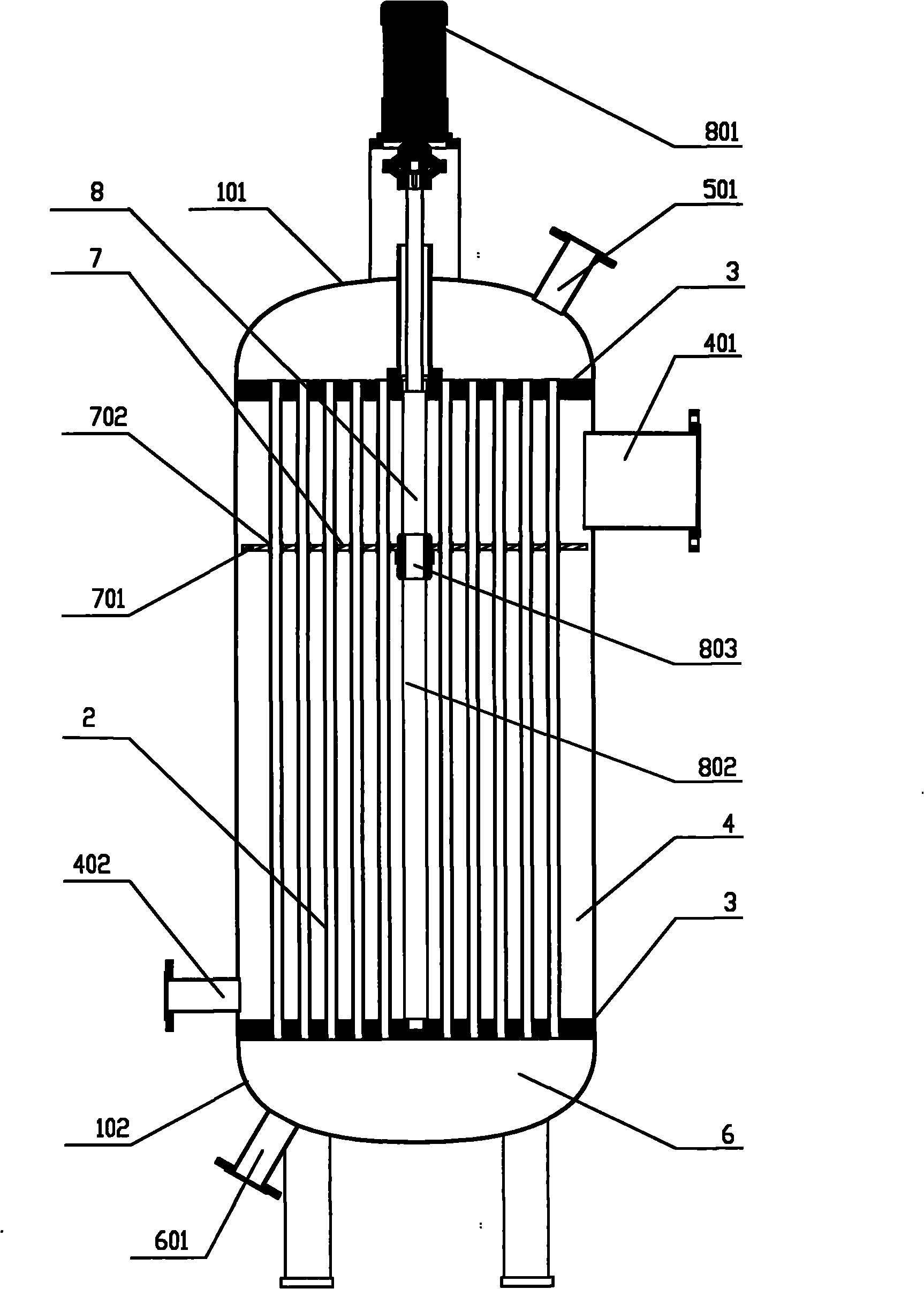

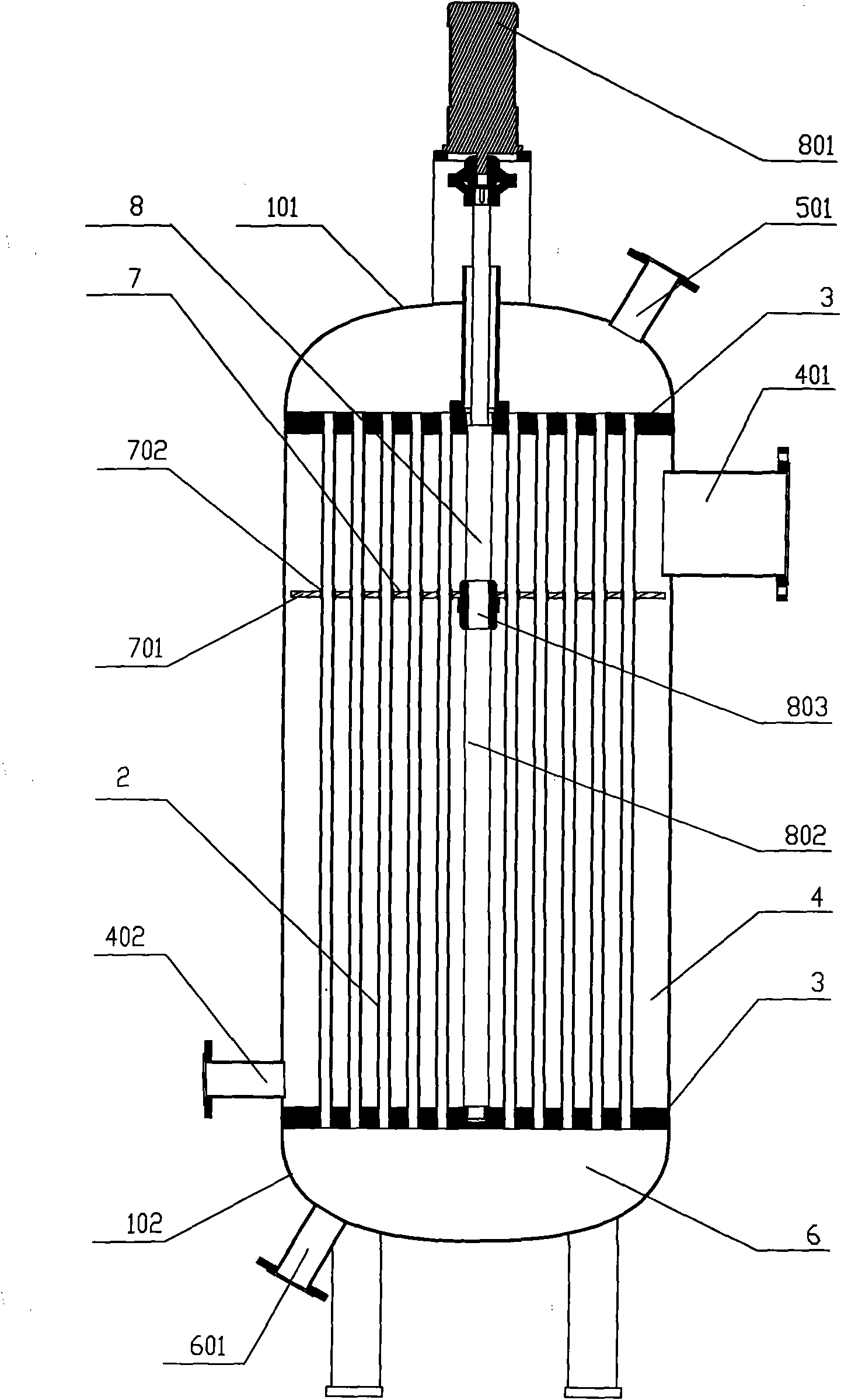

[0013] Such as figure 1 As shown in , the heat exchanger with automatic cleaning device provided by the present invention includes a cylinder body 1 with end caps at both ends and a group of heat transfer tubes 2 parallel to each other, and also includes an automatic cleaning device 7, the The inlet 401 and the outlet 402 of the medium A are respectively arranged on the two ends of the cylinder wall, the heat transfer tube 2 is a straight tube, and its two ends are respectively fixed on a mounting plate 3, and the two mounting plates 3 A heat exchange chamber 4 is formed between the wall of the cylinder; the two ends of the heat exchange chamber 4 are provided with a medium A inlet 401 and a medium A outlet 402; the two mounting plates are blind plates on which holes for heat transfer tubes are provided For installing the heat transfer tube 2, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com