Process for recovering aluminum ions and sulfuric acid from aluminum alloy anodic oxidation tank

An anodizing tank, aluminum ion technology, applied in the direction of anodizing, process efficiency improvement, cells, etc., can solve the problems of lye consumption, increase processing cost, waste aluminum resources, etc., to reduce tank liquid resistance and optimize oxide film. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Take anodizing solution: free sulfuric acid 281.8g / L, Al 3+ 21.54g / L, temperature 20°C, experiment according to Table 1, after 20 minutes of crystallization, detect aluminum ions in time.

[0057] Table 1

[0058] Oxidation solution (ml)

1000

1000

1000

1000

1000

1000

1000

1000

10

20

30

40

50

60

70

80

Al 3+ (g / L)

19.54

16.45

13.64

11.14

9.25

7.78

7.32

6.85

[0059] Take anodizing solution: free sulfuric acid 281.8g / L, Al 3+ 21.54g / L, temperature 20°C, experiment according to Table 2, after 24 hours of crystallization, detect aluminum ions in time.

[0060] Table 2

[0061] Oxidation solution (ml)

1000

1000

1000

1000

1000

1000

1000

1000

10

20

30

40

50

60

70

80

Al 3+ (g / L)

18.94

16.05

13.14

10.64

...

Embodiment 2

[0077] The present invention is designed according to the annual output of 100,000 tons of alumina profiles, and produces about 20,000 tons of oxidation waste liquid and about 400 tons of dissolved aluminum. In order to achieve the goal of treating 20,000 tons of oxidized waste liquid, a 40M 3 Oxidation waste liquid reaction tank, 40M 3 Oxidation solution collection tank and a belt filter press, as well as matching pipelines, pumps and valves.

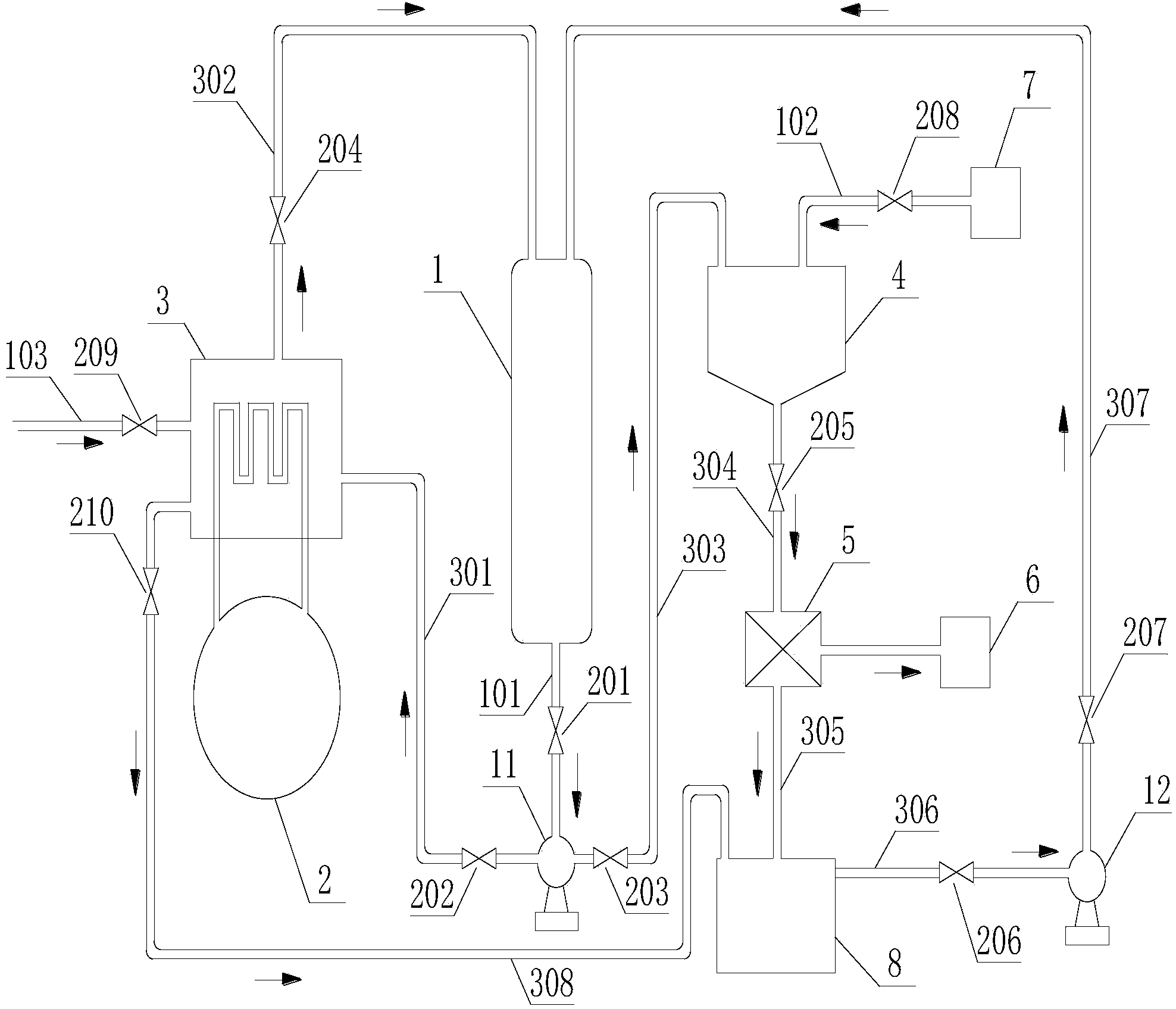

[0078] combined with figure 1 , the concrete operating procedure of process device of the present invention is as follows:

[0079] A. Close No. 3 valve 203, open No. 1 valve 201, No. 2 valve 202 and No. 4 valve 204, and start No. 1 pump 11 and refrigerator 2, the oxidation tank 1 starts to cool down, and the oxidation line starts production;

[0080] B. Open the No. 3 valve 203, close the No. 2 valve 202, the oxidizing liquid in the oxidation tank is introduced into the reaction tank 4, then close the No. 3 valve, open the No. 2 va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com