Liquid distributor

A liquid dispensing head and liquid dispensing technology, applied in the field of parts and components, can solve the problems of high energy consumption, affecting the cooling effect of air conditioning, uneven liquid dispensing, etc., to reduce system noise, prevent insufficient liquid filling, and uniform liquid dispensing pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

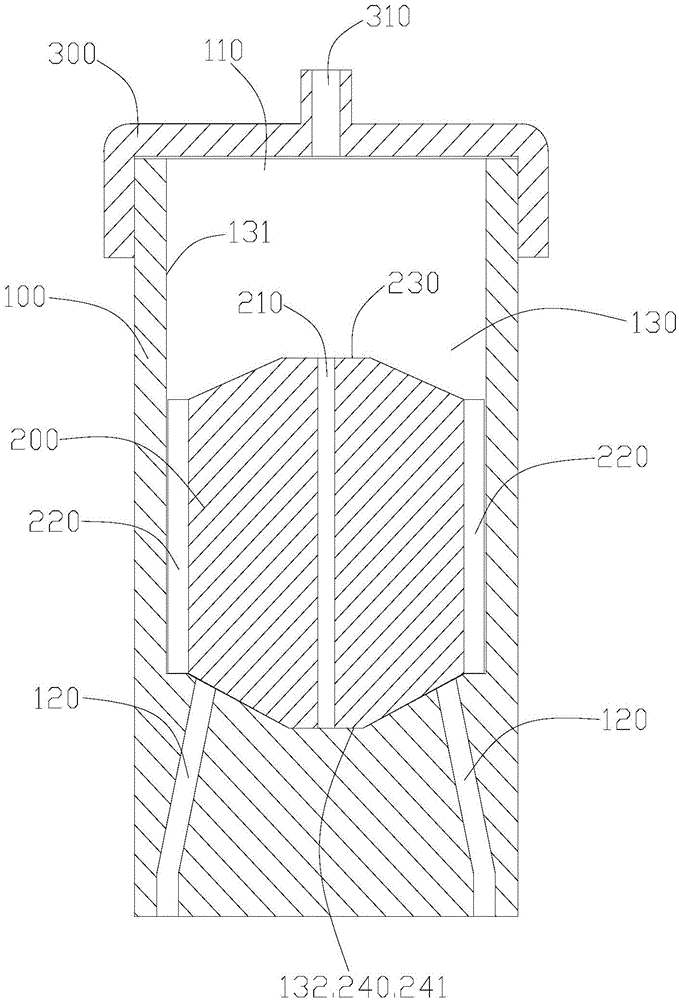

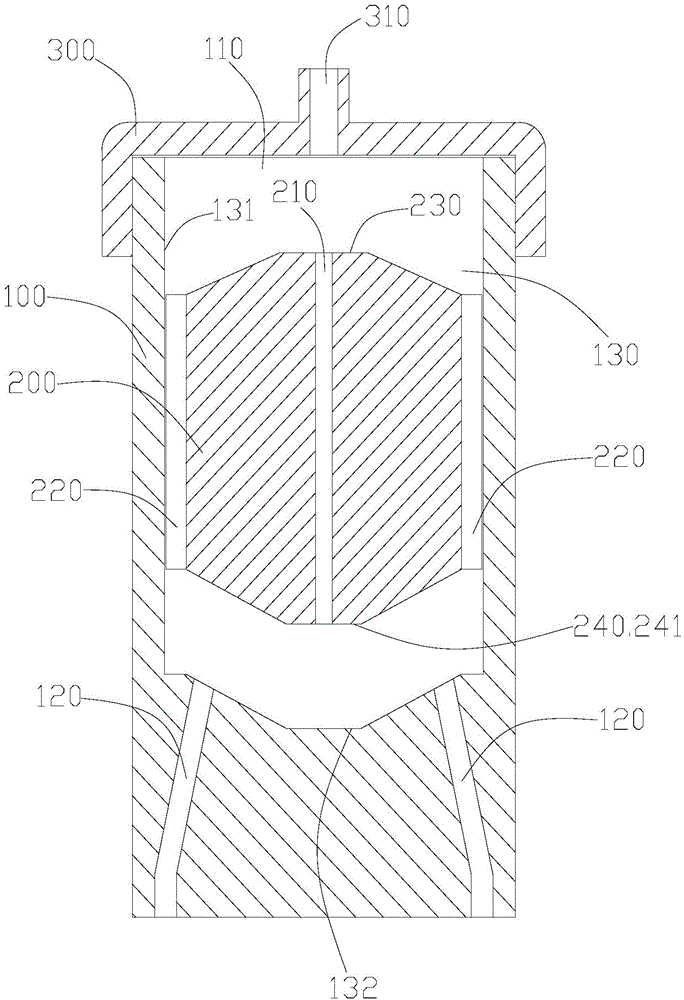

[0020] A dispensing head, comprising a dispensing head main body 100 , a mixed-flow suspension core 200 and a dispensing head gland 300 .

[0021] The upper end of the main body 100 of the liquid dispensing head has an opening 110, and the lower end has a plurality of liquid outlets 120, and each liquid outlet 120 is correspondingly connected with each liquid outlet branch pipe. The liquid separation lumen 130 communicates the opening 110 with the plurality of liquid outlets 120 . Of course, the number of liquid outlets 120 at the lower end of the liquid dispenser head body 100 is not limited to the number in this embodiment, and should be determined according to actual heat exchange conditions.

[0022] The mixed-flow suspension core 200 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com